Hard Capsule Shell Manufacturing: A Complete FAQ Guide In 2025

Have you noticed a hard capsule shell on the outside while eating capsules? Have you ever wondered if hard capsule shells can be eaten? In fact, the hard capsule shell is made of edible medicinal gelatin, which has good solubility and can be quickly digested in the human body.

Capsule production cannot do without capsule shells. Do you know the production process of hard capsule shells? Next, let’s take a look at the complete FAQ guide for hard capsule shell.

1.What Is the Hard Capsule Shell?

Empty capsule shell- Sourced: Health Capsules

Empty capsule shell is a common form of drug packaging, whose main function is to provide protection for the drug and ensure its effective release in the human body. The production process of empty capsule shells includes multiple fine steps, each of which has a profound impact on the quality of the final product.

In the pharmaceutical industry, the production of empty capsule shells not only requires precision and consistency, but also must meet strict quality control standards to ensure the safety and effectiveness of the final product. After the hard capsule shell is completed, the capsule filling machine can be used for the next step of operation.

2.What Is the Specification and Volume of Hard Capsule Shell?

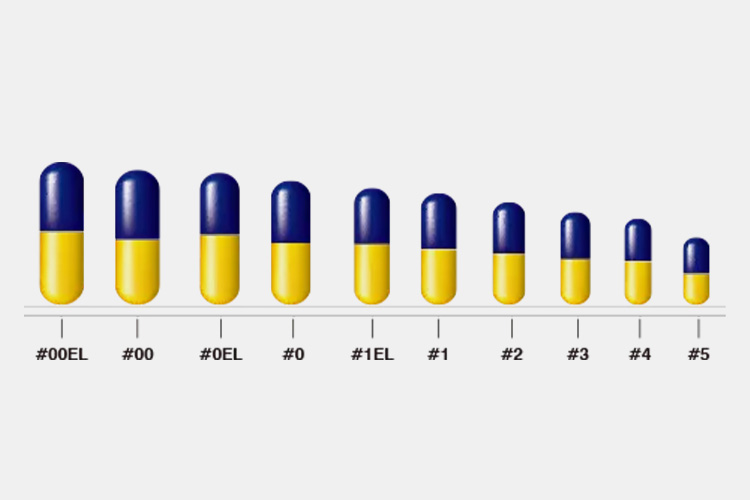

Specification and Volume of Hard Capsule Shell

The commonly used specifications for hard capsule shells include 000#, 00#, 0#, 1#, 2#, 3#, 4#, 5#, etc. Capsules can be selected according to the filling requirements of different sizes of hard capsule shells, and special size designs can be made according to some special filling requirements, such as extended, clinical double-blind, preclinical, etc.

Generally, 0# and 00# capsules are more commonly used in health foods, while 1#, 2#, and 3# capsules are more commonly used in pharmaceutical capsules.

The volume of hard capsule shells is generally determined by the volume of the capsule body. If the density of the contents is 1g/ml, the filling capacity of hard capsule shells is generally 0.91mg for 00#, 0.68mg for 0#, 0.50mg for 1#, and 0.37mg for 2#.

3.What Is the Function of Hard Capsule Shell?

Why is it necessary to use hard capsule shells including granular drugs? In fact, hard capsule shells have many functions.

Protect the drug itself

Protect the Drug Itself - Sourced: Yuyama USA

Our stomach not only has strong acidity to digest food, but also various enzymes to digest food - including drugs. Some drugs can withstand strong acids and enzymes in the stomach, but some drugs cannot withstand them.

The hard capsule shells specially designed for these fragile drugs will only dissolve in the intestine. Some drugs cannot even withstand the intestinal environment and can only be absorbed in the gentlest part of the colon, which requires capsule shells that dissolve only in the colon.

Avoiding the trouble of taking medication

In order for drugs to dissolve quickly and take effect, some drug powders are very small. When opening the capsule shell, accidentally lifting the powder means that the dosage is insufficient.

More importantly, when swallowing such small powders, they may choke into the trachea, which is particularly dangerous for children. Not only to ensure sufficient medication, but also to prevent choking from the powder, please be sure to swallow the capsule directly.

Covering up the odor of medication

Many drugs themselves have unpleasant odors or flavors. Through capsule encapsulation, the adverse odor of these drugs can be effectively masked, improving patient medication adherence. At the same time, the capsule shell can also protect the drug from external environmental damage, ensuring the stability and effectiveness of the drug before reaching the site of action.

Reducing irritation to the gastric mucosa

Reducing Irritation to the Gastric Mucosa - Sourced: Triborough GI

Capsule shells generally do not irritate the gastrointestinal mucosa and can reduce the stimulation of drugs on the stomach. Some drugs have strong irritation to the esophageal and gastric mucosa. Directly using these drugs may cause discomfort or even damage. The capsule shell can serve as a buffer layer, reducing direct contact between drugs and the digestive tract, thereby reducing irritation and discomfort.

Solidifying liquid drugs

As you can see, some liquid drugs also use hard capsule shells. Liquid drugs may have poor absorption in the intestine, so they can be encapsulated in a solid shell for easy administration.

4.How Many Types of Hard Capsule Shells?

There are actually various types of capsule shells, but it is difficult for us to distinguish them. The main reason is that the materials used are different, and the size and shape can be adjusted freely.

Gelatin capsule shell

Gelatin Capsule Shell - Soured: Empty Hard Gelatin Capsules

Gelatin has a wide range of uses in pharmaceuticals and is the preferred material for making capsules, mainly because it is relatively easy to manufacture. The gelatin capsule shell is mainly composed of gelatin, plasticizers, and light blocking agents.

Gelatin is obtained through collagen denaturation. As a amphoteric substance, gelatin can react with acids and bases. In addition, gelatin capsules also undergo cross-linking reactions, further reducing the solubility of the capsule shell and the dissolution rate of active drugs inside the capsule.

HPMC capsule shell

HPMC Capsule Shell - Sourced: SE Tylose

Hydroxypropyl methylcellulose (HPMC) capsule shells are made from plant-based raw material hydroxypropyl methylcellulose with appropriate excipients.

Pure plant-based sources can meet the medication requirements of vegetarians and people with special beliefs, fully embodying the concept of safe, non-toxic, environmentally friendly and healthy high-end drugs and health products. This kind capsule shell has low moisture and high toughness characteristics.

5.What Is the Manufacturing Process of Hard Capsule Shell?

Hard capsule shells are essential for capsule production, and the production process of hard capsule shells is quite complex. Let’s take a look together.

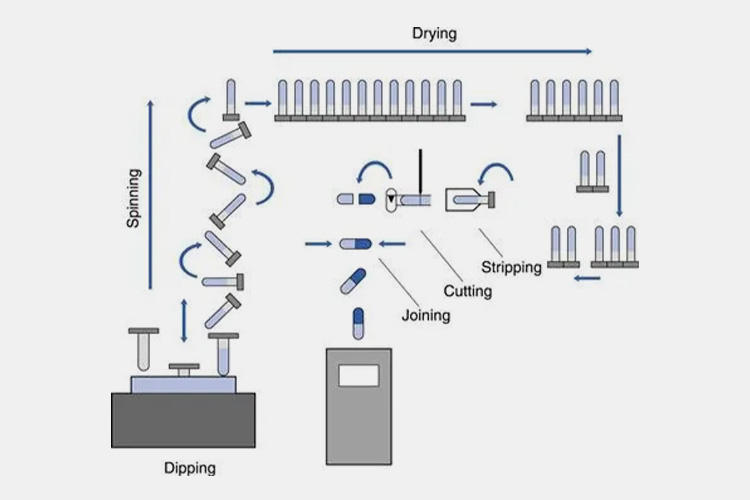

Production Process of Hard Capsule Shell

Preparing raw material

The capsule shell material is generally made of gelatin (such as animal bone glue or starch glue) and water-soluble polymers (such as hydroxypropyl methylcellulose). These raw materials need to undergo strict quality control to ensure they meet pharmacopoeia standards.

Melting

Raw materials such as gelatin are solid, and in order to achieve better molding, gelatin or hydroxypropyl methylcellulose needs to be fully melted in a sol tank.

Molding

After the sol is finished, immerse the mold rod into the sol and then soak it to form the preliminary capsule shell. The shape and size of the preliminary capsule shell are not yet the final product.

Drying

In order to further shape and maintain the stable shape of the capsule, it is necessary to dry it and place it in a drying oven for drying.

Cutting

The initially formed capsules still have some minor flaws. In order to maintain consistency in the size and dimensions of each capsule shell, it is necessary to trim and perfect each capsule shell.

Packaging and storage

If the capsule shell needs to be packaged after production, it also needs to be further packaged, such as packaged in bottles or stored in a suitable place, such as a dry and clean place, to prevent the capsule shell from getting damp.

6.What Machines Are Used in the Hard Capsule Manufacturing?

In the process of capsule production, there are some machines involved. Let’s take a look together.

Capsule inspection machine

Capsule Inspection Machine - Sourced: CapPlus Technologies

Adopting high-resolution industrial cameras and advanced visual image processing technology, the capsule inspection machine can comprehensively inspect the appearance of capsules.

This inspection machine can detect whether the size of the capsules meets the standards, whether there are defects on the surface (such as scratches, cracks, etc.), whether the color is uniform, and whether there are stains. It can quickly identify and remove capsules with unqualified appearance.

Capsule filling machine

AIPAK Capsule Filling Machine

After the production of the capsule shell is completed, it is necessary to fill the prepared medication. Capsule filling machine will not react with any medication. Equipped with an electronic automatic counter, and variable frequency speed control device, it can achieve automated capsule filling.

With the continuous improvement of technology, this machine is also constantly being upgraded. It has the function of automatically removing defective capsules, which can remove capsules that do not meet product requirements, achieve the recycling and reuse of defective products.

7.What Quality Standard Should the Hard Capsule Shell?

GMP - Sourced: ERIKS.com

The capsule production process should strictly comply with GMP (Good Manufacturing Practice) and other relevant regulations and standards to ensure the cleanliness of the production environment, the progressiveness of equipment and the professionalism of operators.

During the filling process, contamination and cross contamination should be avoided to ensure the hygiene quality of the product. After filling, the capsule should undergo quality inspection, including visual inspection, content determination, disintegration time limit, etc., to ensure its integrity, aesthetics, and functionality.

The packaging of capsules should comply with relevant regulations and standards to ensure the safety and stability of the product during transportation and storage.

8.Which Kind of Capsule Shells Can Not Be Opened to Take?

Have you ever seen people around you say they would break open a capsule and eat it? They think it's more effective this way. Actually, that’s not the case. Some capsule medicines may even have worse efficacy when broken open.

Enteric coated capsules

Enteric Coated Capsules - Sourced: CapsCanada

If the capsule shell of this medicine is removed, it will be prematurely destroyed by gastric juice, increasing irritation to the stomach and even causing gastric ulcers.

Slow and controlled release capsules

Slow and Controlled Release Capsules - Sourced: Capsuline

This kind of medicine must be swallowed completely in order to release the drug in a balanced dose. If the capsule is opened and the medication is poured out for taking, it will destroy the sustained-release properties of the capsule and fail to achieve the purpose of sustained release.

Controlled release capsules

Controlled Release Capsules - Sourced: Healing Pharma

Controlled release capsules act on specific tissues and organs in a controlled form, and eating them after removing the shell does not have a controlled release effect, and naturally cannot achieve the effect of treating diseases.

9.Why Can’t Some Capsule Shells Be Open And Taken?

The design of each capsule has a specific purpose, aimed at ensuring the rational release and absorption of drugs in the body to achieve optimal efficacy. Randomly breaking capsule shells may damage their dosage form structure, leading to the following adverse consequences:

Drug overdose release

Some drugs use a controlled release design, and if broken and taken, it can cause a large amount of drug release in a short period of time, increasing the risk of drug overdose.

Drug failure

If the shells of enteric coated capsules are opened, their outer protective layer may be damaged, and the drug may dissolve in the stomach in advance, losing its intended therapeutic effect.

Increased adverse reactions

Increased Adverse Reactions - Sourced: Verywell Health

Breaking the capsule shells may increase their irritation to the digestive tract, especially enteric coated tablets or capsules. After damaging their outer layer, the drugs may come into direct contact with the stomach or mouth, which may cause discomfort. These consequences indicate that when taking medication, the selection and use of drug dosage forms must strictly follow the advice of physicians and the guidelines in the instructions.

10.What Are the Common Problems And Solutions In the Hard Capsule Shell Manufacturing?

During the production process of capsule shells, there may be some problems, including the following:

| Question | Solution |

| Inconsistent color

|

If the color of the ingredients is improper during the production process, the color of the ingredients can be checked and the proportion of the ingredients can be changed.

Inconsistent colors may be due to the capsules being exposed to light, heat, and other environmental factors. Therefore, storing the capsules in the appropriate location. |

| Inconsistent length

|

Some capsule shells have inconsistent lengths, mainly due to problems during the cutting stage, causing some capsule shells to be too long and some capsule shells to be too short. Therefore, the cutting parts should be inspected. |

| Hole

|

Some capsule shells may have voids or scratches during the production process, which can affect the filling of the capsules. This may be mainly due to small fragments falling during the impregnation process of the mold, so it is necessary to inspect the mold for the presence of debris. |

| Printing is not clear

|

Insufficient ink viscosity and ink drying can cause unclear printing, which can affect product recognition. Therefore, replacing the printing ink. |

| Double cap

|

The capsule shell has a double-layer shell, mainly due to insufficient pre locking positions connecting the two hats, so it is necessary to detect the pre locking positions and leave appropriate space. |

Conclusion

With the continuous development and technological advancement of the pharmaceutical industry, the production process of hard capsule shells is also constantly being optimized and improved. Manufacturers must always pay attention to industry standards and regulatory requirements, continuously improve production efficiency and product quality, and ensure that patients can safely and effectively use drugs. If you want to know more information, you can contact AIPAK at your convenience.

Don't forget to share this post!

Empty Capsule Related Posts

Empty Capsule Related Products

Empty Capsule Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine