THE ONLY MANUFACTURER IN CHINA OF LIQUID CAPSULE FILLING AND SEALING LINE

PROFESSIONAL MANUFACTURER OF CAPSULE LIQUID FILLING MACHINE

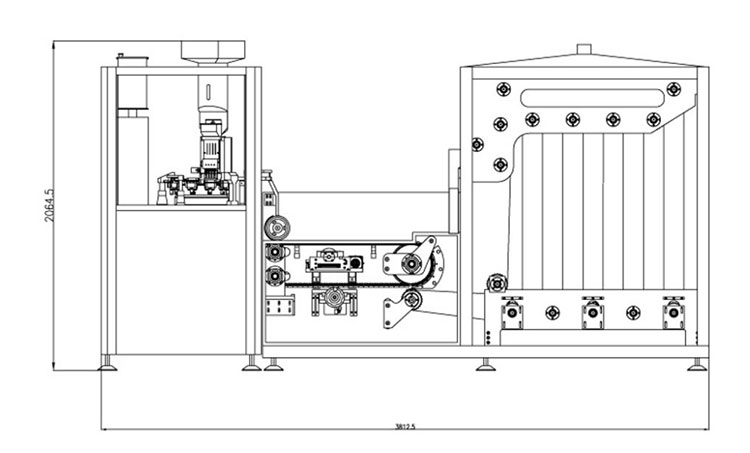

AIPAK Hard Capsule Liquid Filling Machine

AIPAK hard capsule liquid filling machine can be filled in a hard capsule (solution, suspension, microemulsion). The machine adopts the stepless frequency converter, which is convenient and intuitive to operate. As a new and convenient mode of administration and filling concept in the new century, this machine is the latest filling equipment for developing high-end products in the pharmaceutical, health care and other industries.

All AIPAK hard capsule liquid filling machine adopt man-machine interface control system, which automatically lacks capsules and lacks material alarm.And all its capsule feeding machine have a vacuum positioning and separating mechanism, so that the probability of the capsule is over 99%. The fiber is automatically detected, and the capsule is missing in the upper and lower mold holes. High-precision ceramic pump and servo motor dosing system are adopted to control the difference of the loading amount to about ±2%, and the dosage is accurate.

The Buyer's Guide

Complete Buying Guide for Capsule Liquid Filling Machine in 2025

You must find it difficult to fill liquid in capsules. An accurate filling will be very hard for you to achieve manually.

So, the Capsule Liquid Filling machine is very vital & plays a very important role in the pharmaceutical industry for filling liquid in capsules.

In the future, it will be very fruitful for you to have a proper working Capsule Liquid Filling production line for this reason you need to have some knowledge about the machine which I am going to tell you.

In this complete buying guide, I am going to tell you about the Capsule Liquid Capsule Filling Machines importance on your business, and I am going to explain you working of Capsule liquid filling machine, what advantages & disadvantages you can get & some quality standards you need to know whenever you are going to have one for your business.

1.What is Capsule Liquid Filling Machine?

AIPAK NJYF-300C capsule liquid filling machine

A capsule liquid filling machine is used to fill liquid in capsule and the main purpose of capsule liquid filling machine is to meet the need of machine from which a variety of capsule liquid can be derived.

It’s inspired by powder filling machine but as the functionality of powder filling machine was limited and you could only use it for filling powder in capsules.

But new liquid filling machine not just hold liquid but it can also paste it in a new empty capsule.

The machine distinct the two halves of capsule very accurately and then fill it with liquid. After the filling process then comes capsule sealing procedure.

A Soft Gelatin seal are used to seal this capsule so the inside liquid can be stay secure and effective.

2.What are the Benefits of Capsule Liquid Filling Machine?

It is not that easy for you to invest so much money on the capsule liquid filling machine there must be something important or key points that you need to achieve while investing on the machine.

So, in this section I am going to tell you about some important and major points that you can easily achieve with the help of capsule liquid filling machine.

Here are some key points that you can get while investing on the machine.

Accurate & Precise Filling

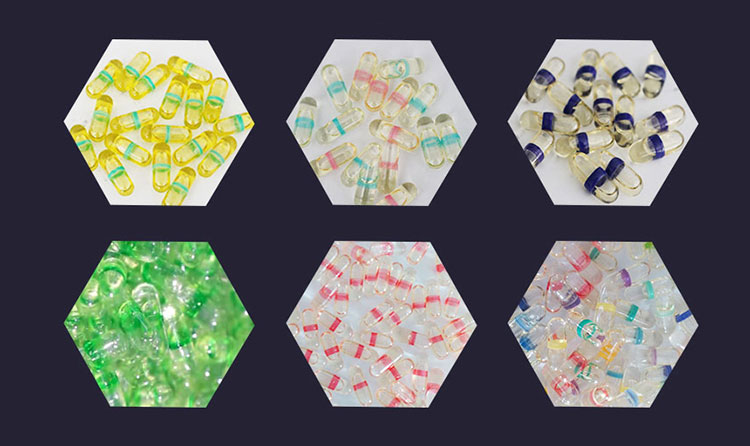

Liquid Filled Capsule

As the capsule liquid filling machine is designed according to the quality standards so, it is easy for you to accurate filling.

It is hard for you to get the accurate amount of filling level in the capsules because the photo-electric system present in the machine fills the capsules very precisely.

No material will be wasted during the filling as the machine is very flexible in filling different kinds of capsules.

The accuracy of liquid filling machine is very precise as you will get 99.9% accurate filled capsules with capsule liquid filling machine.

This is the major key point that you can get while investing on the capsule liquid filling machine.

User Friendly

As the machine is controlled with the help of digital touch screen so, it will be easy for you operate the machine easily & properly.

You can easily handle the working of the machine by reading the manual guide about it.

Some of the fillers have lots of operation buttons on them but capsule liquid filling machine is very specific with a single operation screen on it.

You can understand what to do and what is going on inside the machine.

Some of the buyers don’t buy the machine because of its complicated operation control but AIPAK capsule liquid filler is very easy to handle and operate.

Greater Production

Liquid & Powder filled capsules

Greater production can be achieved by working on capsule liquid filling machine. Thousands of capsules can be filled in the single cycle by using capsule liquid filling machine.

Manually it is hard for you to fill many capsules in less time but capsule liquid filling machine is very quick and specially developed for getting larger amount of filled capsules in less time.

According to the work and operation of a machine every machine has its own production speed but the average speed of a capsule liquid filling machine is 18k capsules/hr.

Quality Product

As we all know quality production is the main demand of every customer so, you need to deliver quality to your customer and this can be done with the assistance of capsule liquid filling machine in terms of filling capsules with accuracy & efficiency.

If your capsules are well maintained after the filling then you will reach more customers by giving them quality in capsule filling.

Capsule Size Variation

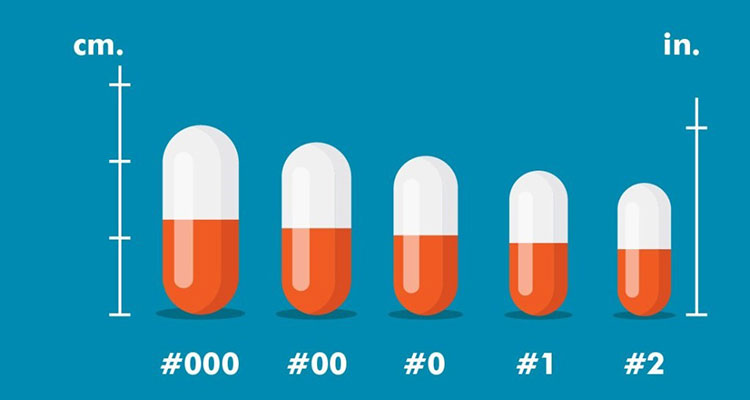

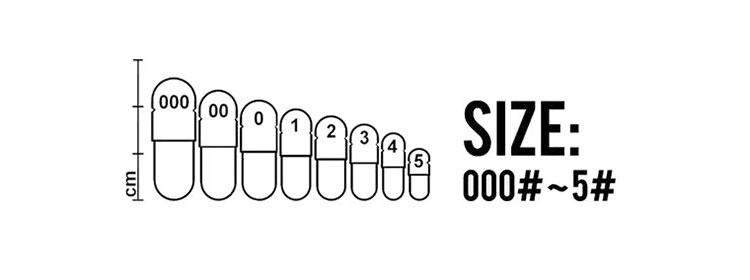

Different sizing of capsules-Photo Credits: CapsuleSize

If you are looking for a machine in which you can use almost every type of capsule for filling purpose then capsule liquid filling machine is the best solution.

Because of its flexible working principle it is easy to maintain & fill different size of capsules with the filling dosage by using capsule liquid filling machine.

Size variations like, 000, 00, 0, 1, 2, 3, 4, & 5 size capsules can be used for filling purpose in capsule liquid filling machine.

It is easy for you to adjust different parts of the machine so, that you can use the required size capsule for your filling purpose.

Contamination & Stain Free Product

As the capsule liquid filling machine works in a fully enclosed system so, there will be no chances of contamination on your product.

Enclosed system of the machine makes the dust free production.

Inner side of the machine is made with stainless steel so, that your product remain stain free and your machine remain safe while working.

Filling Material Variation

Different sorts of liquid substances can be filled in the capsules using the capsule liquid filling machine.

As I told you before there are many types of liquids that can be used in filling.

So, this is one of the main key features that you can get using the capsule liquid filling machine.

Water based liquid substances & oil based liquid substances all can be used in filling process.

Easy to Maintain

As the machine is made with a very good quality material it won’t get rusted quickly but if there is any kind of maintenance factor occur during the working it will be easy for you to maintain the machine.

A guiding manual about the machine will let you know about its maintenance level.

Less Noise Effect

AIPAK capsule liquid filling machine sealing connection diagram

Servo motor present in the machine makes it work in a very silent manner without disturbing the environment.

In terms of giving you quality output with less noise polution capsule liquid filling machine is very effective.

3.What are the Disadvantages of Capsule Liquid Filling Machine?

Main interface may not be that complicated or complex but you must hire a technician

to operate it else you might face some serious problems.

It is not that easy to buy capsule liquid filling machine because you have to invest lots of money but it will be very beneficial for you for longer run & greater production.

4.What are the main parts of Capsule Liquid Filling Machine?

Every machine consists on different working parts those parts help the machine to work more effectively with greater efficiency. In capsule liquid filling machine there are some following main & basic parts which assist the machine to perform different kinds of operations.

Capsule Loader

This part of the machine is used to load the empty gelatin capsules in to the main hopper called as the capsule hopper. This is the first basic part of the capsule liquid filling machine used for loading the capsules.

Hopper

Feeding hopper

In the capsule liquid filler there are two main hoppers. These two hoppers perform two different types of operations one is used to hold the material. The filling material or dosage that is going to be filled in the capsules. This hopper is called as the dosage hopper.

And the other hopper is used to hold empty gelatin capsules for filling process. All the empty capsules are present & halted in the capsule hopper. This is called the cap hopper as it holds the capsules inside of it.

Both of these two hoppers perform different kinds of operation according to their presence inside the machine. These two are the basic main parts of the machine where the working started.

Capsule Filling Station

This is the main working part of the machine where all the filling process takes place. It is based on different working stations of the machine.

Capsule Separation Unit

This is one of the first and basic parts of the liquid filler present in the filling station. In this unit when empty capsules enter the unit they are separated from their body.

In this way capsule head and body is separated for further processing.

Mold Separation Unit

In this part of the machine hot container hold the capsule and give it a proper shape for molding according to the filling material like for small capsule filling in big capsule or only liquid filling inside the big capsule.

Capsules are separated with the help of a molding container which provides heat for the separation of the capsules. Big size capsules are separated with the help of this unit.

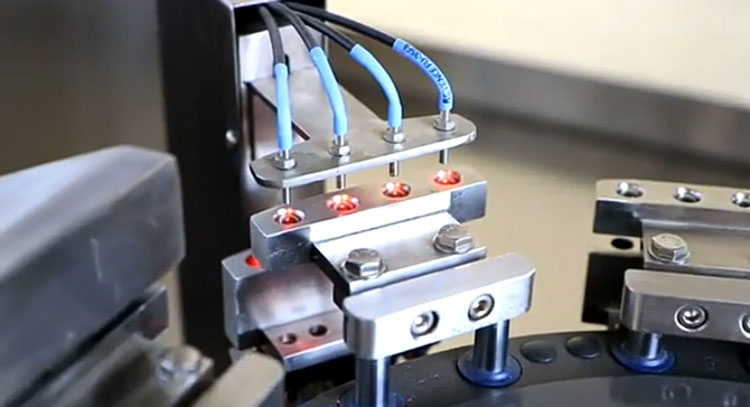

Detection Unit

In capsule liquid filling machine this part works very effectively in terms of telling you about the normal separation of capsule head and body. When the separation is done this unit works in such a way to make sure that the capsule body and head are in good shape after the separation.

It normally detects if there is any kind of fault happened on the capsule during the separation.

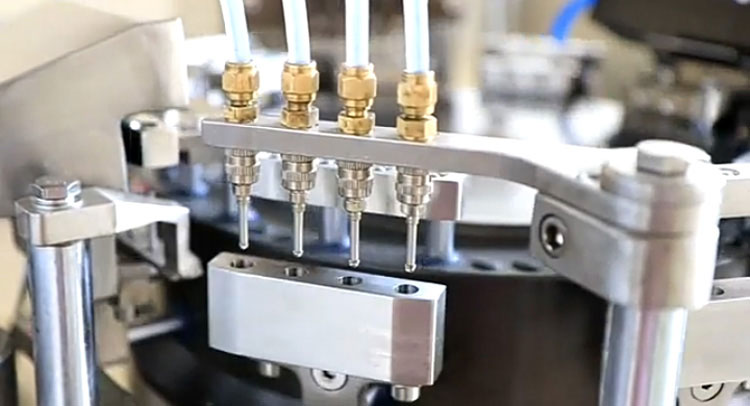

Filling Unit

AIPAK Filling unit of NJY-300C capsule liquid Filling Machine

This unit of the machine works to fill the liquid or any other type of dosage in to the capsules with right amount. When the small capsule is molded according to the requirements then filling is done inside of it.

Filling level is achieved perfectly & accurately as the machine does this work automatically with no need of human effort.

Every type of liquid or any other type of dosage flows through the feeding nozzle that is present in the filling unit and then goes in to the capsule and fill it with the right amount.

Addition of Capsules

AIPAK NJY-300C Liquid Filling Machine Part

If you are filling the small size capsules with the dosage then they will be added in to the large & big size capsule after the filling is done.

In this way small capsules are added in to the big ones.

Small capsules may hold pellets or granules inside them rather than the liquid so, that the addition is done for making them safe.

Rejection & Detection of Capsules

Capsule Ejection Station

When the capsules are filled or added then a sensor system checks the capsule in every possible way to know that the capsule is perfect after the filling and addition in one another.

This unit is based on a sensor system to check the damaged capsules and if there is one in the machine then eject it in to the bin & do not send it for further processing.

Vacancy Detector

The main working of this part of the liquid filling machine is to check the empty area or space is available for the other capsules to come so, that the filling can be done.

It checks the every disc area space and fill it with the capsule for filling process.

Locking of Capsule

Loacking of capsules

When each of the above mentioned tasks are done then you can say the capsule is ready for the last step of locking & this specific unit is used to do this work.

You can say when the filling of the small capsules or big capsules is done the capsule body & head are locked together again to make the filling secure.

This unit plays an important role for making sure the safety of the filling dosage inside the capsule.

Discharging Unit

Capsule drying ststem

When capsule are filled completely and every step is make sure then discharging unit discharge all the filled capsules for further processing.

These are the small basic units present in the capsule filling station and they work specifically according to their work rate and movement.

5.What is the Working Principle of Capsule Liquid Filling Machine?

Capsule liquid filling machine is very effective in terms of giving you accurate & efficient filling.

And this is not that simple to gain and achieve quality product for this purpose every part of the machine works in a manner to complete the cycle.

Every specific part of the machine works in its own specific way to give you the perfect product.

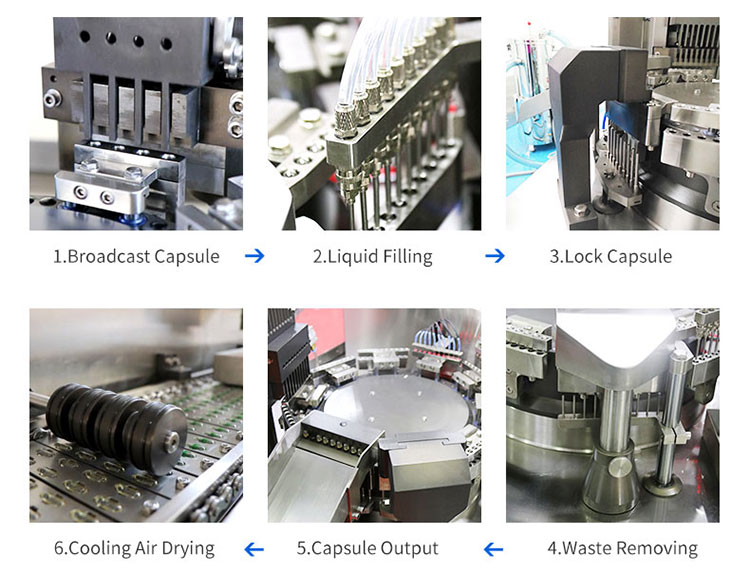

Here are some following steps that a capsule liquid filling machine took during the filling process.

1.Capsule Loading

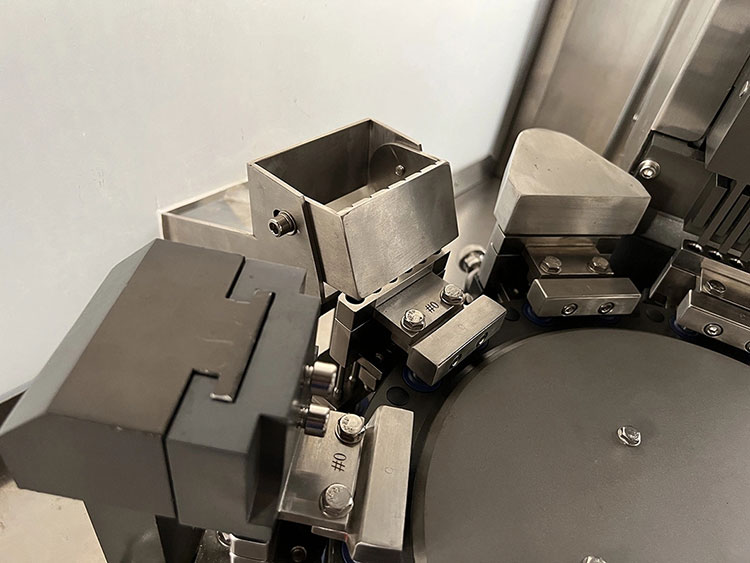

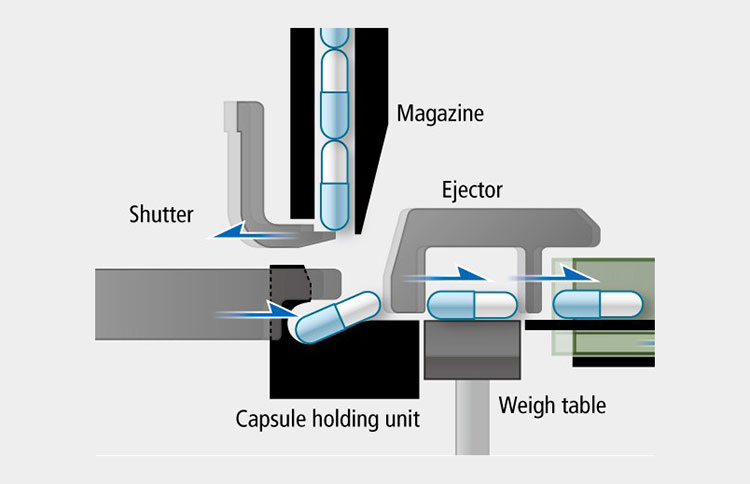

Capsule Filling Process-Photo Credits: Anritsu

First and for most this is the first working step in this step empty hard gelatin capsules are loaded in to the main hopper. This could be done automatically with the loader or you can do it by your own.

And this hopper holds the capsules for sending them to the further processing.

Different size of capsules can be used it depends on your production line & your product requirements.

It is very comfortable to hold every different kind & size of capsule.

2.Capsule Insertion

Empty gelatin capsules when loaded in the hopper then the positioning of the capsules is done in such a way that the cap head of the capsule remain in upper position & the body of the capsule remain in downward position.

Photo-Electric sensor system present in the machine make sure that all the empty gelatin capsules are positioned properly & placed on the desired location for filling purpose.

Positioning of capsules is done with the help of rotation & this step is performed in such a way to make sure that the capsules are filled easily without any problem.

3.Capsule Separation

When empty capsules are placed on the specific position then separation of the capsule head & body is done.

Separation of the capsule parts is done with the help of vacuum.

Vacuum pressure is applied on the capsule body & head and in this way separation is done.

After the separation capsule body goes downward with the help of vacuum and enters the lower area of the machine.

A bush that is used to split the body & head of capsule it holds the capsules head and the go along with the body of the capsule.

Then the split bush open the capsule for filling and keep the cap head remain in its hole.

Alignment of the capsule is done automatically with the help of photo-electric sensor system.

4.Precise Liquid Filling

As you know in this step liquid filling machine done the precise liquid filling in the capsules.

Filling of the capsules is done with the help of ceramic pump.

This highly precise ceramic based pump fill the capsules up to the right amount of liquid or any other dosage.

Empty gelatin capsules can also be filled accurately & precisely with the help of this pump.

It provides very high rate of precision in filling. Because you know the size of capsule is very small & it will be very hard for you to fill it precisely and accurately so, for gaining the perfect quality this pump is very important.

It can work with the precision average of ±1.5 in the filling process.

Servo motor is used in the machine because it contains the bearings that are oil free & make zero noise during the working.

A needle based nozzle goes inside the split bush and then enters the capsule & fill it with dosage material & comes out after the filling.

When the filling of the dosage inside the capsule is done then the cap head & body are aligned again.

In this way the filling of liquid dosage inside the capsules is done.

5.Locking of capsule liquid

In this step when the empty gelatin capsules are filled with the liquid or any other small dosage then they are locked again as they were locked before.

Locking on the capsule is done to make sure that the inside liquid of capsule can not comes out and remain inside without any problem.

Locking of the capsule is done with the split bush that holds the filled capsule body and head as well.

Upper and lower jaws of the bush come together and do the locking.

With the help of locking your capsule make contamination free & to make sure no liquid spills out from it.

6.Capsule Discharging

When the locking of the capsule liquids is done then they are sent for the further packing to make them safe and secure for travelling purpose.

Discharging unit help the filled capsules to move forward when the filling and locking is done.

It makes sure that your capsules are moving forward step by step in a manner so, that each specific step is performed perfectly.

7.Sealing of capsule liquid

This is one of the major process in which more packing of the capsule is done.

When the locking of the capsule is done it may not help you to control the flow of liquid inside the capsule & inside liquid of capsule may comes out.

Sealing is done by using some amount of gelatin based substance.

A layer of gelatin based substance is coated on the capsule at the centre point where capsule head & body meet so, that the liquid can not spills out from it & remain inside without any contamination.

In this process your capsule is made leakage proof.

A moderate amount of gelatin is used for coating the capsule. If you are using high amount of gelatin layer on the capsule for sealing then it will not be good and it will also take more drying time as compared to the thin layer.

If the layer is very thin then it may break down when any type of shock happens so, for this purpose moderate amount of gelatin is used to make moderate type of coating layer on the capsule.

8.Rejection of Capsule

Working process of capsule liquid filling machine

When you start the machine you set your requirements according to your production line to get the quality product but if some of your capsules are not filled properly and machine is failed to deliver you your desired product then in this step the rejection of that failed filling capsule will be done.

If some of the capsules remain empty or not filled properly because of some external or internal error then capsule liquid filling machine will eject those capsules out and reject them ffrom going further.

Sensing system present in capsule liquid filling machine works to check the capsules and reject them from further processing.

When every other working step is performed on the capsules then in this step capsules are measured and checked to move them forward if they are good enough.

And if capsules are not good in quality and shape then they will be removed & rejected for further processing.

This is the whole working of the capsule liquid filling machine that I just explained to you step by step.

6.How Many Types of Liquid can be Filled Using Capsule Liquid Filling Machine?

Capsule liquid filling machine is very flexible in filling different kind of liquid dosage in the capsules.

You can fill different type of liquids in different type of capsules by using capsule liquid filling machine to reach the market standards.

Some of the liquids are water soluble and some are based on oil or some other semi liquid substances but capsule liquid filling machine is very capable of filling almost every type of liquid substance.

Here is the list of some liquid substances than you can fill using the capsule liquid filling machine.

- Oil based solution

- Water based solutions

- Fat containing substances

- Liquid suspension

- Dense paste of liquid

- Liquid formulations

- Protein based solution

Here are some substances that can be filled inside the capsules with the help of capsule liquid filling machine.

7.How You Compare Capsule Liquid Filling Machine with other Capsule Filling Machines?

There are different sorts of capsule fillers that works according to their specification & requirements.

Here is some main difference points between capsule liquid filling machine & other capsule filling machine.

Capsule Liquid Filling Machine

This unique machine is basically designed and manufactured for filling the liquid substances in the capsules.

Different size of capsules can be filled with different type of liquid dosage.

In pharmaceutical industry capsule liquid filling machine is very important for filling liquid in capsules with accuracy and precision.

capsule liquid filling machine is not only capable of filling liquid in the capsules but it will also allow you to fill different small dosages in the capsules.

Some other dosages can also be filled by working on this unique filling machine like, liquid, semi liquid, liquid with pellets, liquid with small size capsule, and liquid with capsules.

Capsule liquid filling machine products

Capsule liquid filler is very effective to give you quality filling.

capsule liquid filling machine works on multi packing of the capsule because the liquid inside the capsule is very hard to control.

For controlling the liquid leakage locking and sealing on the capsule is also made in capsule liquid filling machine.

capsule liquid filling machine works on the basis of servo motor.

Some addition of operations make it different from other capsule fillers.

Other Capsule Fillers

In two piece empty hard capsule this filler can be used to fill powder, pellets, granules, Powder with pellets, granules with powder or pellets with granules but you can not use liquid for filling purpose.

Liquid filler is specifically designed for liquid and some other small products filling but other capsule fillers can fill only dry filling material in the capsule.

This is one of the main differences between the capsule liquid filler & other capsule liquid fillers.

Operation and working of this liquid filler is different as compared to the other capsule fillers.

When it comes to the powder filling it is very easy to maintain and control the powder inside the capsule as compared to the liquid.

Other capsule fillers can work with the hard and dry substances for filling but liquid can not be used in these machines for filling purpose.

Basic electric motors are used in other capsule fillers for giving them the required power to perform their operation.

Sealing system is not available in other capsule fillers.

8.What Size of Capsule can be Filled using Capsule Liquid Filling Machine?

Sizing of capsules-Photo Credits: CapsulCn

Capsule liquid filling machine is very reliable in filling different size of capsules. You can fill almost every type of hard or soft gelatin capsule with the help of capsule liquid filling machine.

Capsule that often came in smaller size and in larger size can all be filled with capsule liquid filling machine.

Your filling level or requirement will let you know about the size of capsule that you want to use or going to use for filling purpose.

As you pellets and other type of small substances can also be filled in the capsules with the help of capsule liquid filling machine so, it must be very flexible in terms of filling different kinds of capsules.

Here is the list of some empty gelatin capsules that can be filled with capsule liquid filling machine.

000 Size Capsule

Capsule size of 000 is divided into three different filling weight classes light, medium and heavy.

It is considered as the largest size capsule with more filling capacity.

In light weight class you can fill the capsule with 615 density of filling material.

In medium weight class you can fill the capsule with 960 density of filling material.

In heavy weight class you can fill the capsule with 1370 density of filling material.

00 Size Capsule

0, 00 & 00 Size Capsule-Photo Credits: PharmacyTech

This capsule size is the second larger in the capsule sizing it can be filled by using the capsule liquid filling machine.

Filling weight density in light division of this capsule is 430.

In medium weight density you can fill 665 filling material inside the capsule.

You can fill up to 950 density of filling weight in the capsule.

0 Size Capsule

This is the third big capsule that can be used for filling purpose.

All these big size capsules lies in the same family called as the big capsule category.

305 filling weight density can be gained in light division of the capsule.

In medium weight division you can fill the capsule up to 475 filling density.

In heavier density class you can fill it with 680 filling density.

1,2 & 3 Size Capsules

Different size capsules-Photo Credits: Harvard Apra

This is considered as the medium size category of the capsules. Capsule with size of 1, 2 and 3 can be used for filling purpose in the capsule liquid filling machine.

These size of capsules are often used for filling pellets along with liquid inside them.

Size 1 capsule is the bigger one in this category of capsule sizing and vice versa.

All of these three capsule sizes have different filling weight density according to their capacity and size.

4 & 5 Size Capsules

These are the two smallest size capsules that can be used for filling process.

Most of these capsules contain small amount of pellets and granules inside them along with liquid in the big capsule.

Filling density of these two capsules is very small as compared to the other capsules.

Because of their small size very small amount of dosage can be filled inside these capsules.

5 size capsules are considered as the smallest one but in the new market some other small size capsules are also available but they are not often used for filling purpose.

9.How Many Applications are there for Capsule Liquid Filling Machine?

Capsule liquid along with small size capsule-Photo Credits: Healthcare

There are some specific applications that a capsule liquid filling machine provides you for your business.

capsule liquid filling machine is specially designed for liquid and small dosage filling in the capsules.

Liquid Filling

One of the most used applications of capsule liquid filling machine in pharmaceutical industry is filling liquid in the capsules.

If you are struggling to fill the hard gelatin capsules with liquid manually then capsule liquid filling machine is the best solution and provides you variety of operations for filling purpose.

Ceramic pump is used to fill the capsules with accurate amount of liquid or other small dosage.

Pellets Filling in Small Capsules

Pellets & capsules-Photo Credits: vita Pharmed

Some small size can be filled with pellets and then added into the large capsules. This is also one of the applications of capsule liquid filling machine.

capsule liquid filling machine can easily control both of the products inside the capsule like pellets in the small capsules and liquid in the big capsule.

Granules Filling in Small Capsules

Granules and liquid filled capsules

Granules are the large size powder particles used for filling in the small and large capsules & capsule liquid filler can also fill granules in the small size capsules along with liquid on the other capsule.

It is very easy for capsule liquid filling machine to manage these different type of filling substances in a large size capsule.

Oil Based Liquid Filling

Different types of oil based liquid are also used for filling in the capsules & capsule liquid filling machine is applicable of this type of filling.

It is one of the main and basic applications of the capsule liquid filling machine in pharmaceutical industry.

Combined Filling

Combined Filling

Capsule liquid filling machine is based on different wide range of applications and multitasking. It can provide you every type of ease for filling different combined products in the same capsule.

You can fill variety of filling materials in the same capsule & capsule liquid filling machine will provide you ease in filling process.

You can fill the capsule with the mixture of oil based & water based liquid filling dosage in the capsule.

You can also fill pellets & liquid in the same capsule as well.

These are the wide range variety of applications that AIPAK capsule liquid filling machine can provide you.

10.Can you fill Hard Material Alongside Liquid in the Capsules using Capsule Liquid Filling Machine?

The basic and main purpose of liquid filling machine is to fill the liquid based substances in the capsules but you can also fill other hard dosage in the capsules with the help of capsule liquid filling machine.

For filling the other hard dosage you will require to use small size capsules and when filling is done inside the hard gelatin based small size capsules then you will add them into the liquid filled capsules of big size.

Most of the capsule liquid filling machines uses the already filled capsules for adding them into the big size capsules.

Only liquid based filling dosage can also be used for filling because this is the main parameter of capsule liquid filling machine.

capsule liquid filling machine can use tablets along with liquid for filling in the capsules.

You can also fill pellets with liquid based substance in the capsules by using capsule liquid filling machine.

It will also help you to fill or add small size capsules inside the big capsules for filling purpose.

So, capsule liquid filling machine is very formal in terms of filling different types of hard & liquid substances in the capsules.

11.What Quality Standards you Should Consider while Buying the Capsule Liquid Filling Machine?

Here is the list of some following standardizations that you should consider in the buying guide of capsule liquid filling machine.

GMP

This is the main and basic quality standard for every type of machinery that tells you about the raw material that is going to be used for the manufacturing of capsule liquid filling machine.

The raw material must be of good quality.

Reaction free material is used for manufacturing the machine.

In the first and for most step FDA provides you ease in selecting the quality based material for manufacturing your equipment according to your needs.

If the material that is used for manufacturing is of good quality then your machine will operate perfectly & will remain in its shape for long time.

CGMP

This is latest standardization developed by FDA for checking the quality of the material that is used in the design & development of the machine.

GMP standardization plays its own role for selecting the best quality machine in terms of its material but CGMP uses some latest technology to check the raw material of the machine.

ISO

Customers demand is the first priority in every firm wherever you go in the world. To fulfill customers demand this standardization was introduced in the market.

With the help of this standardization a firm will design you the capsule liquid filling machine according to your needs that you told them before the manufacturing process.

Always consider to tell your demands before the manufacturing work.

Use simple and latest based operating system in the machine.

Customer satisfaction will be make sure with this quality standardization so, that you can get your machine according to your specifications.

You can select the design and manufacturing purpose of your machine according to your production line that what it holds and what you are working on.

CE

Every type of working operation is performed on the machine to check its versatility and capacity of the work rate before handing it over to you.

All the working & operational practices are made on the capsule liquid filling machine are gained with this CE standardization.

In this process the work rate and production speed of the machine is checked properly.

ASTM

A general and basic quality standard that is important to consider while you buying the capsule liquid filling machine.

With this ASTM standard your product is make error free & must be operated at once to check every working part of the machine.

It tells about all the working parts as they are operating perfectly or not.

ROHS

Your machine must be designed without the use of any reactionary material that can make harm to your labor and to your product.

Some materials are restricted to use in the manufacturing of the machine so, that you can safely operate the machine in any type of environment.

ROHS standardization keeps in mind the security and safety of your labor as well as your product.

Raw material that is used inside and outside must be shock proof and if there is any danger occur during the production a safety button must be designed to stop the working of the machine.

EN

Your economical parameters are explained in the EN standardization that how much money you need to consider to invest on the capsule liquid filling machine.

European Union is the main firm behind the developing of this quality standardization to see the economy parameters.

Rough mapping about the investment can be generated with EN standardization and this can be done by checking the rates of working parts of the machine.

It will be easy for you to arrange the investment money according to your product easily in a simple manner.

So, these are the some quality standards that you need to consider while buying the capsule liquid filling machine to get the quality product according to your needs.

12.Should you need to Buy only Capsule Liquid Filling Machine only or you require Sealing Machine as well?

Yes, it is important for you have a sealing machine along with capsule liquid filling machine.

Let me explain it to you that why you need to have a sealing machine as well.

When the capsules are filled and sent for further processing then there is a sealing unit present that helps the capsules in sealing.

And this sealing make your inner material safe for travelling purpose and make capsules leakage proof.

When the capsules are locked then further more they are sealed in the center with a gelatin based substance because it is not easy to control the liquid that is filled inside the capsules.

For making the liquid safe and secure sealing must be done on the capsules.

That is the reason that a sealing machine is also required along with capsule liquid filling machine to make your product safe & secure.

Sealing on the capsules is not that easy because a well maintained gelatin layer is very hard to form on the capsule.

Sealing machine is very important to make your filled capsules safe for placing & travelling purpose.

When the capsules are filled accurately with the capsule liquid filling machine & sealing is not done on the capsules then all your accuracy in filling will be gone because capsule may get leaked during the replacing.

AIPAK provide you a single machine that can perform both filling and sealing operation at the same time.

So, you will not need to invest on the other machine for sealing purpose you can buy AIPAK capsule liquid filling & sealing machine in a single unit.

13.What are the different applications of Capsule Liquid filling machine?

There are some applications that some main industries use for capsule liquid filling for their production.

Here is the list of some industries that use the capsule liquid filling machine.

Medical/Pharmaceutical Industry

This is one of the main and major industries that use capsule liquid filling machine for filling different size of capsules.

All the liquid medicines that are filled inside the capsules are done with the help of capsule liquid filling machine.

You can fill variety of filling material inside the capsules with capsule liquid filling machine because of its flexible working principle.

Health Industry

So many health products are made with capsule liquid filling machine and then sold to the customers.

Most of the health products are present in the form of liquid & other form they can also be filled in the capsules with the help of capsule liquid filling machine.

Protein and vitamin capsules are filled with capsule liquid filling machine.

Food Industry

Most of the food items like sweet capsules & capsule shape sweet candies that we like to eat & enjoy eating them they are also made with the capsule liquid filling machine.

Food industry is one of the growing industries in the world and lots of food products can be made with capsule liquid filling machine.

14.How You can Maintain the Capsule Liquid Filling Machine?

There are some following points that you can use to maintain the capsule liquid filling machine to get the quality output.

If a machine is well maintained and good in shape then it can be operated for longer run easily.

By making some small effort you can easily maintain the machine.

Proper Cleaning

When you are done with your required production of the day then utilize some energy for cleaning purpose.

Clean all the working parts of the machine according to the manual.

Lubrication

Use lubricants & oil for all the moving components of the machine.

During the movement of different working parts of the capsule liquid filling machine the lubrication level may get lower so, always check the oil level in the machine.

Lubrication on the moving parts of the machine made the machine very smooth & increases the speed as well.

Replacing Damaged Parts

Always check all the working parts of the machine that they are in good shape or not.

Must check all the working parts are in good shape or not if some of the parts of the machine are torned or damaged during the filling try replace these damaged parts with the new ones.

In this way your machine will remain in quality shape & will provide you continuous production.

So, these are some following key points that you need to keep in mind for maintaining the machine.

Let’s get forward and read the last but not the least question about the capsule liquid filling machine.

Hard Capsule Liquid Filling Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586