Gummy Molds: The Complete FAQ Guide in 2025

Have you wondered how do you get infinite shapes of delicious gummies? Teeth gummies, watermelon gummies, bottle gummies, and so on. Gummy mold is a critical player that offering you innumerable shapes. Without this component, gummy making process is incomplete. While, on commercial scale gummy mold, installation, procurement, and integration might be bit complex instead home based.

You’re going to find some productive aspects of gummy mold that we discovered for you.

1.What Are Gummy Molds?

Gummy molds are a mandatory piece of equipment utilized by commercial, industrial, and household sectors for transforming liquid candies, chocolates, and gummies into assorted shapes and designs.

Various exciting shapes like gummy bears, fruit shapes, gumdrops, and many others are now made with the help of such molds.

Industrial gummy molds are comparatively designed on a large scale where bulk batches can easily be handled. For that, special confined area planning is done for evaporation, cooling, and drying procedures. Various equipment i.e depositing tank, melting tank, molds etc are involved in this procedure.

Similarly, for small production individual home based molds are available in the market that is used to pour gummies manually and can be used to rest in the refrigerator, to dry, or heat in a microwave oven for making variety of treats.

They aid manufacturers in the production of gummy candies into a solid state from a liquid like slurry state without turning them into a blob of candy.

2.What is The Significance Of Gummy Molds?

Although it might seem that it is not of enough importance, gummy molds play a significant role in impacting the commercial manufacturing of gummies and other sweet treats. Before filling the mold cavities with gummy, they exist in a hot molten liquid called slurry.

- Gummy molds are essential tool designed for repetitive use to give form and shape to the gummies’ slurry.

- It saves the gummy from changing shape or being irregular in consistency while resting to acquired shape.

- It also aids the gummies to stay in place and dry to form only as intended shapes are desired to be achieved.

- Customized gummy molds offer unique designs to establish your brand.

- Gummy molds are available in different shapes and designs ranging from traditional gummy bears to gummy worms, bottles, fruit, gum drops, geometrical shapes, animal shapes etc.

3.What Materials Are Gummy Molds Are Made Of?

Gummy molds are structured and made up of various types of materials, such as:

SILICONE MOLDS

Silicone composed molds provide excellent durability and flexibility to shape your gummies as you want. They can withstand a broad range of temperatures while manufacturing gummies.

Silicone molds offer commercial grade quality to ensure thickness and toughness for repetitive use. They have a manual system for depositing gummies into mold’s cavities.

TEFLON ALUMINIUM MOLDS

These molds are made up of aluminum and coated with teflon. They offer new standard of filling mold cavities automatically.

Old methodology employed creating cavities unaffordability which had many steps to follow. This new method of molding gummies eliminates excessive steps and provides easy cleaning, good productivity and cost-affordable equipment.

POLYCARBONATE MOLDS

Polycarbonate molds are made of strong durability and strength. It does not warp of flex. They are known to be refrigerator safe, microwave safe and maintain it’s shape as long as possible. Candy making experts often use them for making hard candies.

PLASTIC MOLDS

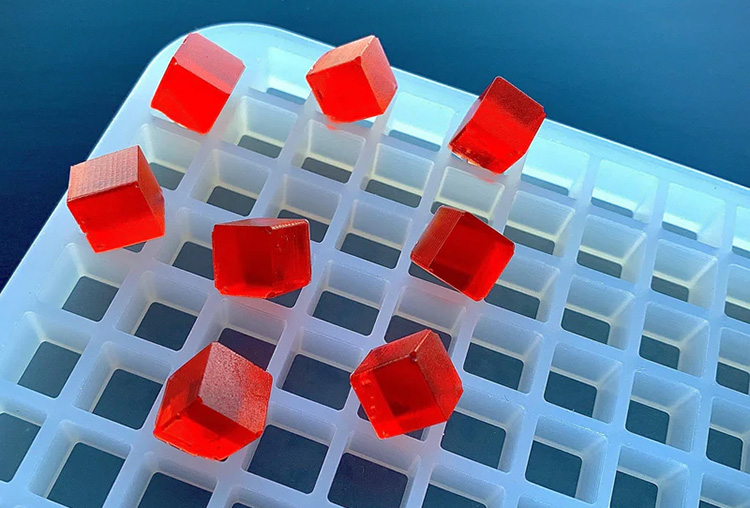

Plastic molds that are white colored allows you to look through the gummy’s consistency and thickness. Their flexibility allows you to make softer candies like gummies to evacuate them without deformity.

These molds offer great heat resistance and can bear up to 350°C of temperature. They set the mixture quickly and are very convenient for cleaning.

4.What Different Shapes Gummy Molds Offer?

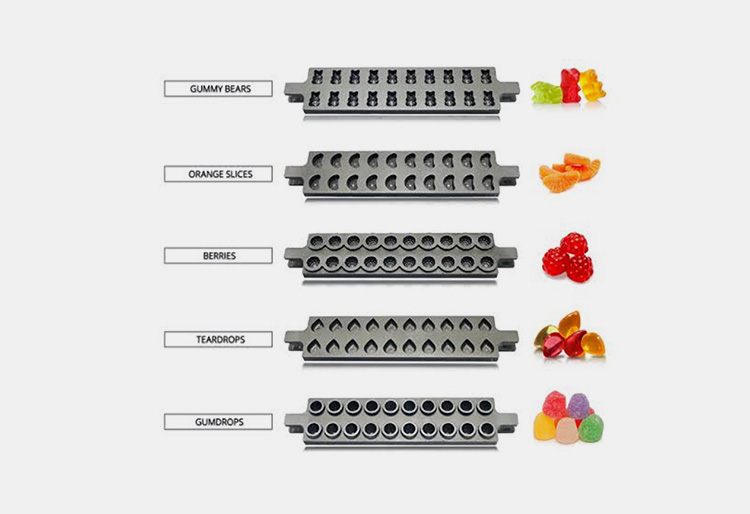

You might’ve been fascinated with the unique and eye-catching shapes that gummies arrive in the market. Ever wondered how do they form into such amazing designs? Gummy molds present an assortment of interesting shapes in cavities to fill your candy as per your customized choice.

Gummy molds offer different shapes as simple as

- gummy bears,

- worms,

- bottles,

- heart-shaped,

- geometrical patterns,

- gumdrops,

- fruit shapes,

- animal shapes,

- 3D modeled shapes etc.

Many more designs and patterns can be created as per your brand’s choice.

5.What Are Different Gummy Mold Sizes?

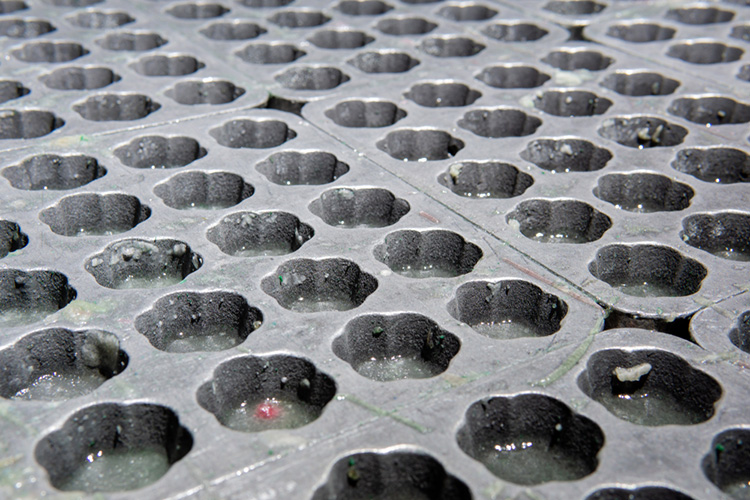

Gummy mold arrives in various sizes along with different shapes as well . It depends on your choice which one you’d like to buy. Often commercial brands that operate on industrial scales go for large dimensional trays having many number of cavities in them. While home based gummy makers usually prefer a small sized gummy mold.

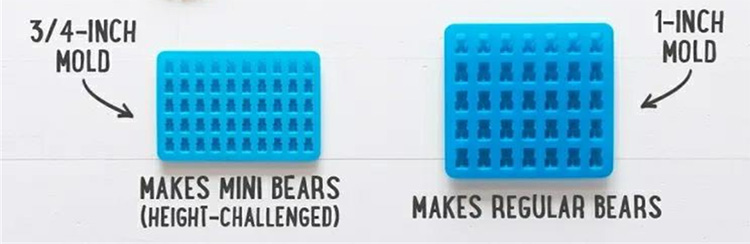

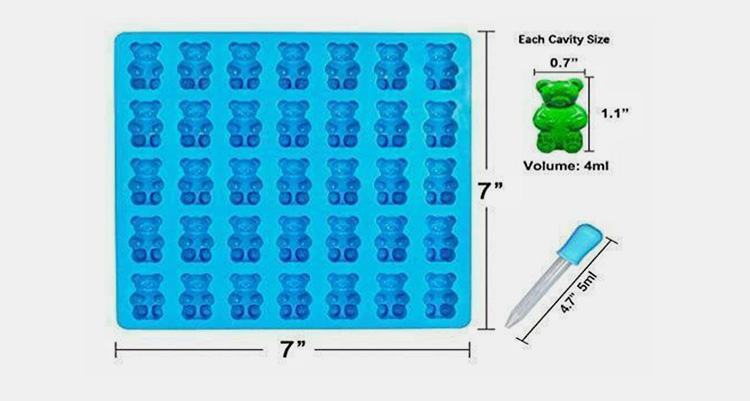

Gummies can be developed as small as sized less than 1” or can be customised to as per your demand .About more than 1-2 ” sizes are considered normal gummies. Each cavity size measures according to the size of gummy you will achieve. Brands manufacturing gummy molds offer variable sizes . We’ve presented few examples of gummy cavity sizes that are in the market.

A gummy cavity size which can hold upto 4ml of gummy mixture to form a gummy of size dimensions 1.1” and width 0.7” . They include 35 cavities per tray.

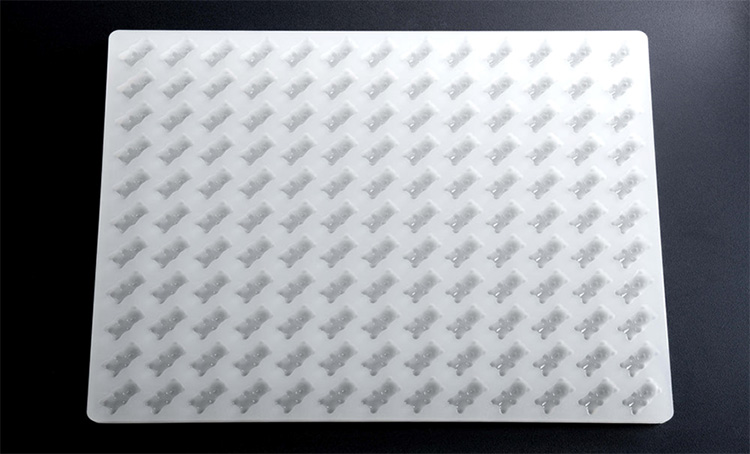

Some gummy molds offer cavities as much as upto 150- 200 cavities per tray. The fill capacity of each cavity for the gummy mixture is about 2.5 ml and the gummy dimensions would measure about 1.02” in height and 0.43” in width.

6.What are Different Types of Gummy Molds?

Although gummy mold are same whether using for industrial or homebased production. But we have categories them into two broad sections:

INDUSTRIAL GUMMY MOLDS

For industrial-scale manufacturing of gummies , there are huge depositors filled with hot gummy mixtures that are ready to fill large trays of gummy molds. Depositors like universal depositors and pour and scrape depositors are usually used.

Gummies are manufactured by incorporating them using depositors into massive starch sprinkled trays known as ‘Starch molding machine'. This machine prevents gummies from sticking to the mold. Once the gummy mixture is filled and cooled it is transferred to the sieve for the removal of excess starch.

HOME BASED GUMMY MOLDS

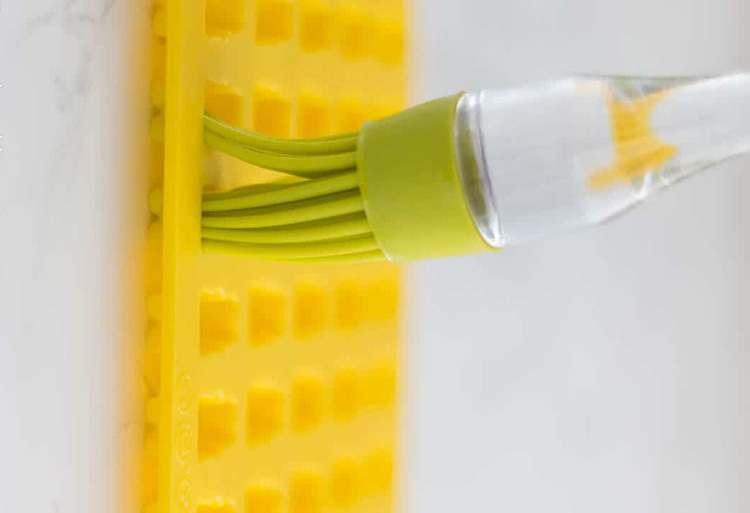

To use gummy molds, you must first prepare a gummy candy preparation according to your preferred recipe. Now, you’ll spray the mold with an anti-sticking agent or a cooking fuel to prevent the sticking of gummies into the mold after setting.

Pour the gummy slurry into mold cavities in sufficient quantity when it is warm with the help of a depositor, a confectionery funnel , measuring cup or a dropper. Allow the gummy candies to set in the mold at room temperature for few minutes and then refrigerate. Once set, you can demold the gummies from the mold cavities.

7.Which Section of Gummy Production Line is Required with Gummy Molds?

Gummy making process is for sure a laborious task. It requires quality manufacturing parameters to be followed. Apart from gummy molds, components that are required with it for gummies manufacturing constitute a gummy manufacturing machinery. We will see those components here one by one.

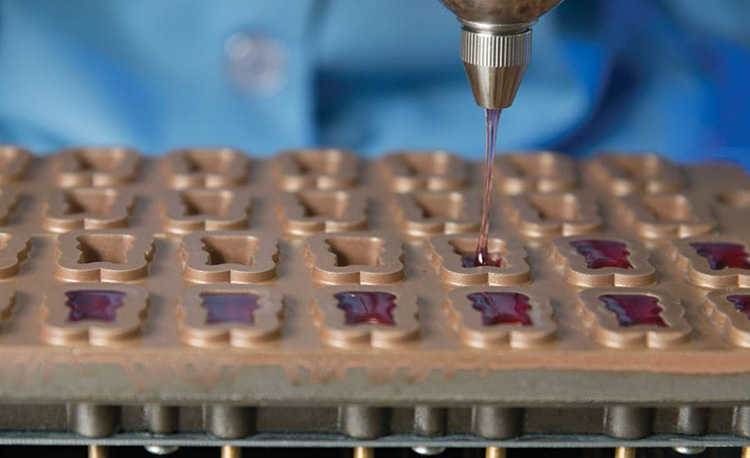

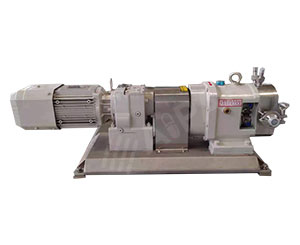

GUMMY DEPOSITOR

This allows convenient and high performance deposition of gummy mixture working at a greater speed to achieve maximum productivity. These depositors control how much fill each mold cavity is supposed to receive.

COOLING TUNNEL

This is the final section of gummies manufacturing process. In this unit, gummy mold is driven by chain; similarly, it is equipped with demoulder that ensures pushing gummies out of the mold.

8.How To Fill Gummy Molds? Industrial Vs Home

Once your formulation plan of the gummy bear is ready, ensure first that it is warm enough to be poured into the molds and doesn’t set prior to filling only. The filling of gummy molds is of course different for industrial setup and for home use. Let’s see the method of each.

| INDUSTRIAL GUMMY MOLD FILLING | HOME GUMMY MOLD FILLING |

| If your production is small scale, you can conveniently fill the mold manually using confectionery funnel. It allows user to have a control over the fill quantity.

|

Filling of gummy molds in home is much simpler and manual. Along with silicone molds , a polypropylene dropper tube is provided to aid filling of cavities easy.

|

| Another type is for small and medium scale industries called as ‘Pour and Scrape Depositing' . This method is also operated manually and allows the user to fill multiple cavities at a time.

Molds are laid on a straight surface like table ensuring that the edges are not touching each other and there is no gap in between. After pouring the slurry into molds , scrape it off using dough scraper quickly moving it across each cavity so that it doesn’t set. |

Once you’ve prepared your gummy treat, you can also set your gummies into mold by using measuring cup carefully to fill each cavity.

|

9.Are Gummy Molds Also Prone To Stickiness?

Due to the sticky and slimy nature of the gummy’s mixture , it is quite possible that it gets stuck to the mold itself before even setting. Although it also depends on which formula you’re following to constitute the gummies. Ingredients like gelatin are said to be more susceptible towards getting stickier due to their low temperature resistance.

Certainly there are molds which have non-stick properties that handles the hot gummy liquid very well, such as silicone. Even though if you want to avoid any chances of mess, you should apply Anti-sticking agents to the mold with the help of a brush. For this purpose corn syrup, starch, waxes and oils are used too.

10.How Long Do Gummies Take To Mold?

There are certain factors that have a say in how much time will a gummy take to form into a specific shape. Usually, it depends upon the ingredients added such as gelatin or pectin, the size of the mold chosen to fill the gummy mixture, and the time allowed for drying the hot and wet gummy slurry.

- Using Gelatin as an ingredient takes longer to set into the molds around two to twenty four hours, consuming time in between batches as well.

- Using Pectin as an ingredient takes much less time than gelatin to set. It usually forms shape around minimum 30 minutes.

- Incorporating a gummy mixture into a small sized mold takes a shorter duration to set.

- Incorporating a gummy mixture into a large sized mold takes a much greater duration to set.

- Refrigeration takes around 4-5 hours to perfectly set and dry your gummies.

- If you’re considering air drying at room temperature it would take from 2- 48 hours for getting into form once free from the mold.

11.How To Customize Gummy Molds?

Customized gummy molds can be manufactured by ideally presenting unique and eye-catching patterns and designs to offer your customer. Materials composing customized gummy molds are specially designed with excellent durability, resilience, strength and flexibility to allow gummies or any confectionery product to set into it.

Customers are asked for their preferred type of design in the form of an illustrated sample either digitally or graphically, hand drawn, or a gummy model to bring it into practical existence. The primary materials used are Silicone, Aluminium, Plastic , Polycarbonate or Metal.

12.How Can You Clean Gummy Molds?

Whenever you undergo any cooking procedures you need to clean the utensils, don’t you? Likewise, as we read above that gummy making process might get messy, cleaning is compulsory to ensure best results for repetitive use of the molds.

METHOD 1

To clean a gummy mold, you need hot water and some dishwashing detergent. Make sure you do not keep the gummy mold immersed in soapy water as some of the materials of gummy mold are porous.

This might absorb the soapy liquid rendering taste variation to your gummies and also affecting the material’s integrity. If you’re washing it in a dishwasher, check for the gentle settings and wash with hot water only.

METHOD 2

You can also use vinegar to soak the gummy molds in them to wipe away tough stains, The leftover time should not less than one hour, and then soaping and rinsing it with water.

METHOD 3

This is also an effective method where the application of baking soda over gummy mold can clear the gummy residue in no time. Here, you can mix baking soda with hot water for thorough rinsing.

13.How Gummy Mold supports the Generation of Multicolored Gummies?

Gummy molds can be utilized to create wonderful , multicolored gummies as well. For that you will need a plastic bristle paintbrush to customize various colors in your gummies. Using candy coatings on a gummy mold will be possible by employing such brush. Other types of brushes might leave behind traces of bristles which spoil your gummy.

Adding different colors in a gummy would require using a dabbing motion to create patterns of colors as per you want. Then allow the mold to set and air dry for a few minutes.

If you wish to formulate a multiple color layered gummy, you will need rainbow colors to be filled in disposable piping bags. After addition of each layer, it is required to tap the mold to let the color settle and remove any air bubbles.

14.What Factors Affect Gummy to Mold?

There are many factors that can affect gummies from getting into a perfectly molded shape. These include stickiness, inability to bloom, unsuccessful setting, pre-mature setting, non-uniformity in size. Let’s see them each stepwise.

STICKINESS

This problem causes your gummy to form wet and sticky appearance due to reasons like high amount of sweeteners added, humectant level being high, no proper drying carried out or due to degraded gelatin.

INABILITY TO BLOOM

This is due to water and gelatin ratios not being proportional to each other. For gelatin to thrive and set properly, make sure sufficient water is added to achieve desired level of bloom.

UNSUCCESSFUL SETTING

Gelatin may not be set properly if added fruit flavors like papaya , kiwi , pineapple, or mango is contained due to their protease enzyme. Other reasons might be not giving enough time for the gummy mixture to set or any mistakes while following recipe.

PRE-MATURE SETTING

As discussed in earlier point, not giving enough time at the required temperature for the gummies to set can result in their pre-mature setting. Both gelatin and pectin have certain preset requirements for temperature.

NON-UNIFORMITY GUMMY CONCENTRATION

The machine should be set for uniform quantity distribution by the depositor and the molds should be checked and maintained for any errors.

15.What Precautions Can You Take To Avoid Gummy Sticking to Your Mold?

There are a few precautions that you can adopt to avoid gummies sticking to your mold. They are as follows:

USE CLEARED GUMMY BEARS MOLDS

It is mandatory to clean up your gummy mold cavities and it’s surface before producing another batch of candies. We have already discussed cleaning techniques above so it’d be easy for you to understand how the cleaning is done. Once cleaned, you must allow it to air dry . This ensures the mold is free from any dust particles, left debris of gummy mixture or any other substances.

ADDING COATING

Coat your gummy mold cavities with oil such as corn oil or any other oil or use corn syrup. You can also use wax for this purpose. Anti-sticking agents also play a role in preventing stickiness. For this, you can apply powder coat of fruit or vegetable starch over outer surface of gummies that combat against potential exposure of unwanted humidity.

ESTIMATE MELTING AND BOILING POINT

Nevertheless, estimating freezing, melting, and boiling point can overall influence on final outcomes of gummies. If they are not properly addressed this could lead to way stickier gummies' texture and more chances of product damage.

If you do not know the melting or boiling point of ingredients then we would recommend asking your supplier to provide the mandatory properties of the product. Thus, this will increase more chances for a greater product with minimum risk of product loss.

STORAGE

Gummy mold must be kept in airy, temperature-controlled, and dry environments for cooling and evaporation jobs.

CONCLUSION

Yet, No one can deny the importance of gummy bears mold in the emergence of fun filled, unique, and enticing shaped gummies. Do you want to add customized gummy bear molds in the production line? Get in touch with our AIPAK Pharmaceutical Team and we Promise to Offer Amazing Equipment lists in an Economical Budget. Contact Us Now.

Don't forget to share this post!

Gummy Making Machine Related Posts

Gummy Making Machine Related Products

Gummy Making Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine