FULL SERVICE GUMMY MANUFACTURING

AIPAK will be your one-stop solution provider for your premier gummy formula development, scaled manufacturing, and packaging.

OPTIONS FOR YOUR GUMMY MANUFACTURING

Gummy Depositor

Do you want your gummy candies to be sugar free,organic, vegan, or allergen free ?Gelatin, Pectin, or Agar based? Whatever your specifications are,AIPAK gummy depositor could help you manufacture various kinds of sugar,honey or sugar free gummies.It is a machine that will help you deposit gummy candy accurately,efficiently pour the gummy ingredients when forming gummy candy products.The machine has high precision which results in high reliability.

Small Scale Gummy Manufacturing

Whether you just want start a business of gummy manufacturing or want a lower risk point-of-entry to gummy candies production,small scale gummy making machine will be your premier choice.A scale of gummy making machine could be easier to maintain and you could spend more time on quality control or optimize the manufacturing resources.It will be easy to operate by using the touch screen to control the production.

Medium Scale gummy manufacturing

After the entry level,if you still want to produce more professional-grade,great-tasting,and consumer-safe gummy vitamins or supplements,AIPAK medium scale gummy manufacturing may suitable for you.It can produce up to 15,000 gummies per hour for either pectin or gelatin gummy formulas.With PLC control system,your operator will be easy to control the whole production,making various types of candy.

Large scale gummy manufacturing

Want a continuous production line for large scale gummy manufacturing?A large scale gummy making machine will be your good option,it is a great machine for your huge production.With which you can do one or two colors gummes,with modular designed gummy molds,you can produce different shapes and sizes of gummies by changing molds,AIPAK will also provide other auxiliary equipment such as sugar coating/sanding machine,drying trays,etc.

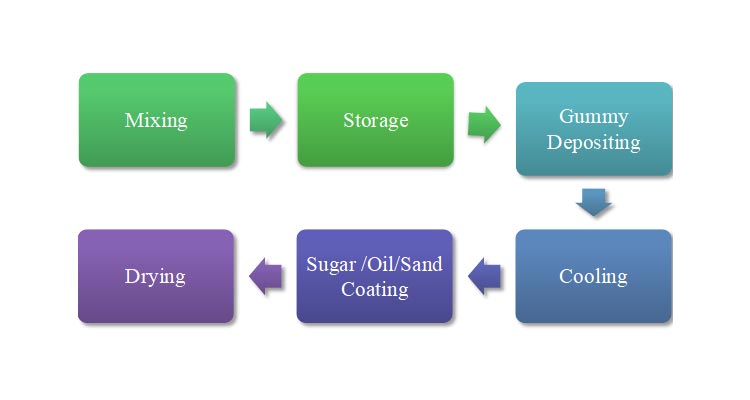

VITAMIN GUMMY MANUFACTURING PROCESS

Gummy vitamins are the most popular supplement among whatever adults or children.AIPAK expert team will recommend the most suitable formulations to meet any of your nutritional need,making you professional at any kinds of gummy vitamins manufacturing.

Ingredients Preparation&Mixing

AIPAK will help you choose the most suitable ingredients to meet your customer taste.Once the formula has been finalized,you will need to mixing and cooking these raw material,such as syrup,gelatin ,pigments,colors,etc.making them uniform mixed or flow smoothly to be stored in the storage tank for the next step depositing purpose.

Depositing

AIPAK will recommend the suitable model of gummy depositing machine as your actual capacity requirement.The mixed ingredients will be poured into the hopper for depositing into mold,here through various gummy mold,you will get various shape or size of gummy candies.The depositing process is also a very hygienic manufacturing process and meet with GMP standards.

Cooling&Coating

After the formation of the gummy candies,cooling is the most crucial part of the gummy candies.Here through the cooling tunnel your gummy candy will be more chewable.Then after the cooling process,your produced gummy candies will be sugar/sand/oil coated ,which depends on your taste requirement,and that will enhance your customer experience .

Filling&Packaging

Once sugar/oil/sand coated,your gummies will be evaluated for quality to ensure specifications are met with your requirement.Then with our gummy counting machine or premade pouch filling machine,you will get your gummy candies well packed into bottles or pouches and with good labeling,you will get your brand perfect displaying to your customer.

THE BENEFITS OF GUMMY SUPPLEMENTS

In the ever fast growing society,convenient and easy-taking are the worship of most people.While gummy manufacturing for all kinds of supplements such as vitamins,minerals,medication and botanicals have become more and more popular among most young adults.

Gummy Manufacturing: A Complete FAQ in 2025

Gummies are popular nowadays both as a snack and for medicinal purposes. Gummies are delicate product that requires special care, conditions and equipment for its manufacturing. Since its initiation, the manufacturing process has come a long way and manufacturers are using their own patented processes for gummy manufacturing to increase yield of gummy production and decrease product recalls.

If you are wondering about customizing your gummy manufacturer process then this “Gummy Manufacturing: A Complete FAQ in 2023” will facilitate you in this endeavor.

Let’s begin.

1.What Is Gummy Manufacturing?

Gummy manufacturing is the process in which different ingredients are mixed together to create viscous liquid and then this liquid is poured into trays or molds for forming gummies. These trays are stored in freezer or cooling systems for overnight and then resultant product is taken out of the molding trays.

For gummy manufacturing on industrial scale, innovative devices with high efficiency are employed to increase production capacity and speed.

2.Who Created The First Gummy Manufacturing Procedure?

Although gummies gain popularity worldwide in the 1980s, they are created way before this time. Gummy manufacturing process was first created by Johannes “Hans” Riegel Sr. in 1922 in Bonn, Germany using his kitchen tools like copper pot, rolling pin and stove.

He is the founder of pioneer gummy bear company called Haribo. Original gummies created by Riegel are made up of gum Arabic instead of gelatin hence named gummy.

3.What Are The Raw Materials Used In Gummy Manufacturing?

Flavor, texture, smell, and appearance of gummies depend upon the ingredients used for manufacturing gummies. Some of the ingredients used in gummy manufacturing are:

Gelatin

It is the main ingredient in gelatin gummies. Gelatin is derived from animal bone marrow and it is chief material that impart gummies their chewy texture. It forms gel like substance in water which give gelatin melt in mouth characteristic.

Pectin

It is the ideal substitute of gelatin and are formed from plant-based ingredients such as apple and citrus fruits. It is used as the thickening agent in gummy base. It is mostly used in vegan gummies and are consumed by people on vegan or plant-based diet.

Sucrose

As gelatin is flavorless hence common sugar or sucrose is added to gelatin for sweet flavor. It is usually manufactured by sugar cane juice or sugar beer. Sometimes, fructose is included in gummy recipe for boosting sweetness of gummies.

Corn Syrup

For preventing crystallization of sugars, corn syrup is used in gummy manufacturing. It preserves moisture content of gummies and decreases stickiness of gummies.

Sweetener

Gummy typically have about 65-75% sweeteners. Some common sweeteners include sugar, glucose syrup and tapioca syrups. Polypols or sugar alcohols such as sorbitol and mannitol are substitute of natural sugars that are added for flavor and prevents the microbial growth in gummies.

Natural and Artificial Flavors

Natural flavors are created from honey, maple syrup, fruit juices such as apple, berries, or oranges, lime, etc. Artificial flavors derived from chemicals like methyl anthranilate and ethyl caproate that are used in gummy preparation to enhance flavor of natural ingredients.

Dyes

These are coloring agents which are incorporated in gummy manufacturing for giving them desired color.

4.What Are Types Gummy Manufacturing Machines?

There are many makes and models of gummy manufacturing machine present in market. The use of these different gummy manufacturing machines is usually depended upon production needs. Some types of gummy manufacturing machines are detailed below:

Desktop Gummy Manufacturing Machine

These are small, manual, and portable equipments that are often utilized in small home-based productions and laboratory-based settings. The syrup is prepared and loaded in machine hopper manually. These machines perform the functions of depositing and molding themselves.

The molding units in these devices are made of silicon and are easier to clean. There are about 10 filling nozzles in these machine that are used for precise, uniform and high-quality gummies.

Semi-automatic Gummy Manufacturing Machine

These are small batch gummy manufacturing machines that are suitable for use in small and medium type business. These are equipped with 20-30 liters electric hopper, molding system, and PLC systems.

Depositor of these machines are equipped with servo motors and filling nozzles of accurate and precise control dosing of syrups. Depositing and molding of gummy products is carried out by these machines. Cooking, cooling and drying of gummies is performed manually in these systems.

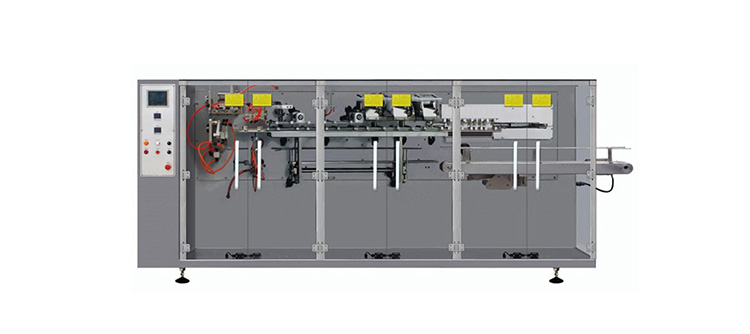

Automatic Gummy Manufacturing Machine

These machines are capable of performing every task involved in gummy manufacturing autonomously. These are automated machines with large footprint and consist of cooker, high capacity hoppers, depositor, filling nozzles, aluminum molding units, and cooling tunnels.

These systems have large output capacity thus are the need of mass scale gummy manufacturing plants.

5.How Is Gummy Manufacturing Done?

It is vital to know about different stages of gummy manufacturing to troubleshoot this process and optimize your production capacity. Following are the stages of this process:

Mixing

In first step, raw materials used during preparation of gummies are prepared and measured as per formulation before starting gummy manufacturing machine. Sugar, water, or in mixed in dissolving cooker machine and heat for 15-20 minutes for obtaining gummy syrup.

Pectin is directly incorporated into sugar-water mixture as it can withstand high temperature while gelatin is degraded at 50°C so syrup is cooled before adding gelatin. The cooking temperature is usually around 108-110°C

Storage

This mixture is then moved to buffer tank for storage. The purpose of storage tank is to decrease the temperature about 65-70°C for gummy deposition. Buffers tanks are equipped with heating hoppers that re-warm the syrup if temperature is further reduced than desired temperature.

Gummy Depositing

The syrup is placed in the molds via depositor. The depositor has filling nozzles which is used to gradually and precisely fill exact quantity of gummy syrup into the molding trays. Molds are used for giving gummies their desired shape.

Cooling

The hot gummies molds are then transferred to cooling tunnel where gummies are chilled for proper setting and for acquiring required shape. In cooling tunnel chilled air having temperature of -10°-20°C is circulated for rapid cooling.

Sugar/Oil/Sand Coating

After cooling, gummies are then moved to coating machines where they are coated with sugars, Sand, and oils for improving texture, stability, flavors, and colors of gummies. This step also minimizing gummy stickiness.

Drying

Gummies after demolding and coating, are moved to drying system for reducing the moisture content in gummies. The water in gummies is vaporized using compressed air that has temperature higher than 70°C. Drying of gummies typically take around 8-10 hours.

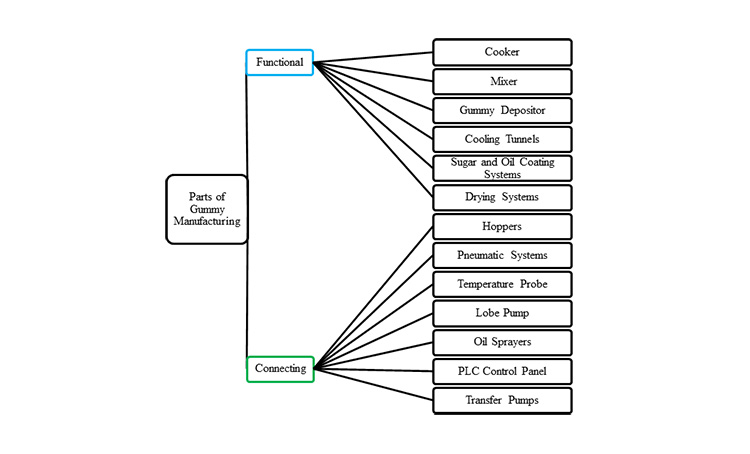

6.What are Parts of Gummy Manufacturing Line?

Gummy manufacturing machines are part of production lines that are utilized in large scale industries for mass output of gummies. These are enclosed systems that lower chance of gummy contamination.

Some parts used with gummy manufacturing machine are:

Functional Parts of Gummy Manufacturing Line: It involves all those components that include manufacturing of gummy making line.

Connecting Parts of Gummy Manufacturing Line: It involves all those components that helps in transferring or movement operations of gummy manufacturing process.

FUNCTIONAL PARTS OF GUMMY MANUFACTURING LINE

Mixer

This is categorized into two sections:

Mixing Tank for Raw Ingredients

This double jacket equipment is used for preparing the syrup by dissolving sugar and gelatin or pectin. These ingredients are heated at high temperature for mixing. The double jacket covering of cooker assists in temperature resistance and this equipment is equipped with its own specialized PLC system that is used for monitoring cooking temperature.

This mechanical device has a high shearing capability for efficient liquefication and mixing of ingredients.

Mixer for CFA ( Colorant Flavor and Additives)

Next machine in gummy manufacturing line is the CFA mixer (color/flavor addition system). This is also known as vertical dynamic mixing. The function of this device is to mix flavoring agents, dyes, acids, and other additives in the gummy base.

These ingredients are measured by load cell and are dosed into mixers via pumps. Precise metering systems in these mixers ascertain the quality of product and cut down operational cost by minimizing the superfluous addition of ingredients.

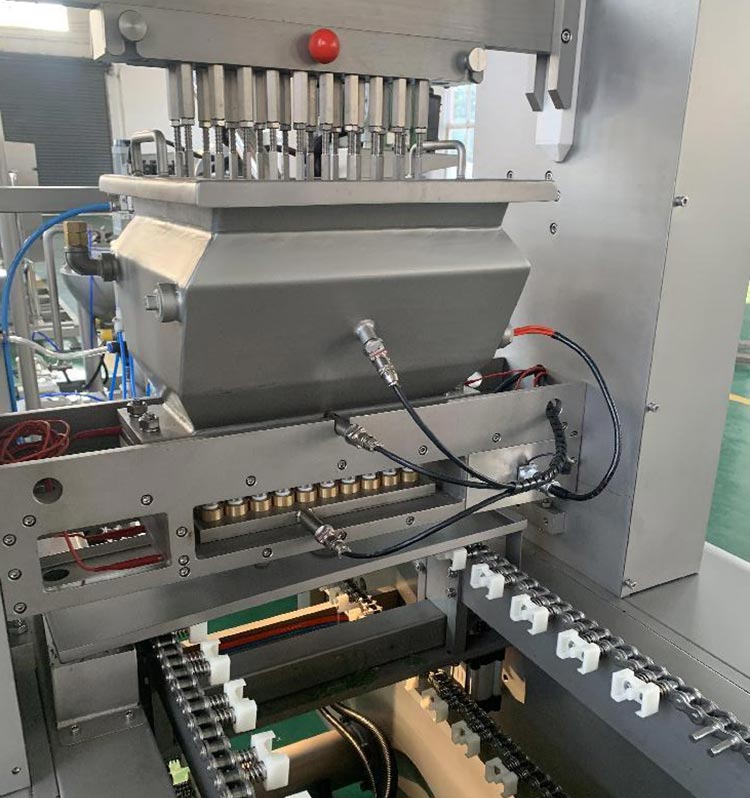

Gummy Depositor

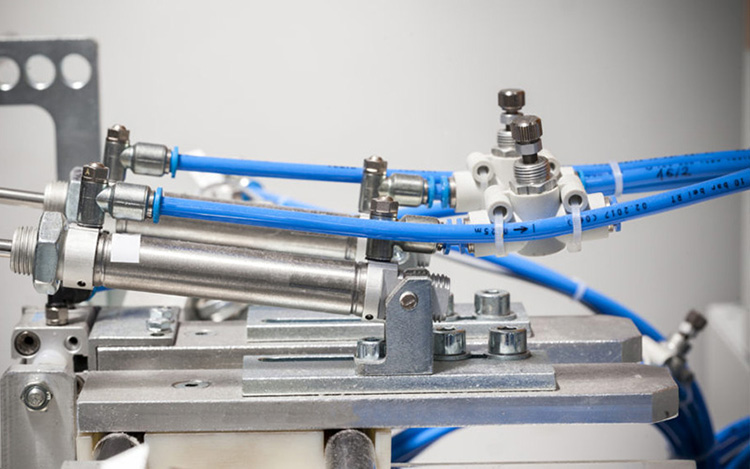

This part is made up of conveyor belt, cutting device, hopper, pneumatic systems and filling nozzles. The pumps are made from stainless steel and are used for loading syrup into the molding unit.

The filling nozzles deposit gummy syrup on molding device while cutting system is used for cutting and trimming these products into required shape.

They can have one or two hoppers depending upon the number of dyes used for coloring gummies. These equipments have high level accuracy and control which is handy in creating of high-quality gummies.

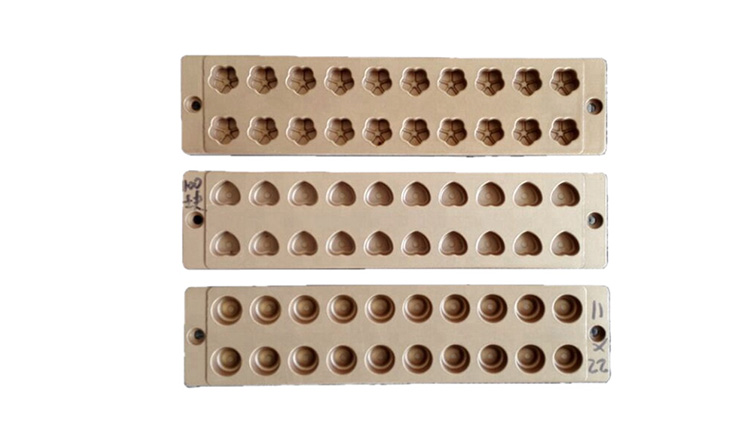

Molding Systems

Gummy depositors load liquid gummy syrup in molds. These are made from alloys like Locknut alloys coated with Teflon, plastic, or silicon mold (rubber mold). Their function is to impart required shape to gummies.

These molding devices are temperature resistant thus can easily withstand high temperature of gummy syrups. Molding systems have typically shaped like bear, star, circle, square, fruits, worms, etc.

Cooling Tunnels

These equipments are employed in downstream processing of gummies to reduce the temperature of gummies and also to stabilize their shape. There is no need of utilizing separate curing agents by using these machines.

They are 3 to 5 tiers depending upon the production and are made of stainless steel. They have centrifugal fans with top and bottom air conditioning for efficient cooling. Cooling tunnels also have air filtration unit with chilling and defrosting heating coils and discharge pipes.

Cooling tunnels also have demolding plate or devices for removal of gummies from molds.

Sugar and Oil Coating Systems

For polishing and coating purposes, sugar and oil coating machines are employed. These coat gummies with sugar, beeswax, mineral oil, or powders. These machines are hollow drums or rotatory cylinders that have nozzles for a continuous spray of oils or sugar solutions over gummies.

These are used for improving the slickness of gummies and helps to achieve uniform consistency of gummies. These are automated systems that are often employed at high temperatures for increasing fluidity of coating solutions.

Drying Systems

Gummy manufacturing machines are supported by auxiliary equipments such as drying trays. These are stackable devices with slot vented construction are optimum for providing highest drying rate. These vented slots assist in maximum air flow that reducing curing time by 40%.

It is made from food grade plastic polyethene and has perfect design that allows fast vaporization of water vapors and also assists in prevent gummy stickiness.

CONNECTING PARTS OF GUMMY MANUFACTURING LINE

Gummy manufacturing machines are furbished with various cutting-edge parts each having their own specific function in the running of material involved in gummy manufacturing. Some of these parts are discussed below:

Hoppers

Gummy manufacturing machines are equipped with one or two hoppers for storage of ingredients and syrup before processing. These are polished using food grade chemicals. Moreover, these hoppers are provided with a stirrer for efficient mixing and heating.

Pneumatic Systems

These systems consist of cylinder and piston. To and fro movement of piston in cylinder creates pressure that is used for drawing syrup in filling nozzles.

Temperature Probe

Gummy manufacturing machines are customized with temperature probe that shows the temperature of syrup anytime during processing.

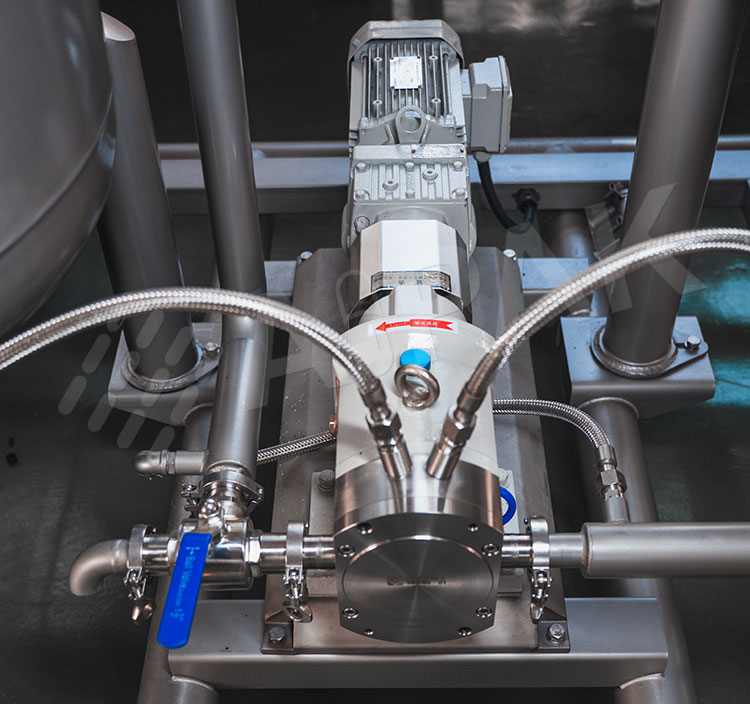

Lobe Pump

For transferring syrup from cooker to storage tank, advance lobe pumps are used. They not only maintain the temperature of syrup but also remove impurities from gummy syrup.

Oil Sprayers

It is the double injection device which ascertains precise control of oil spray inside molding device without any interpretation.

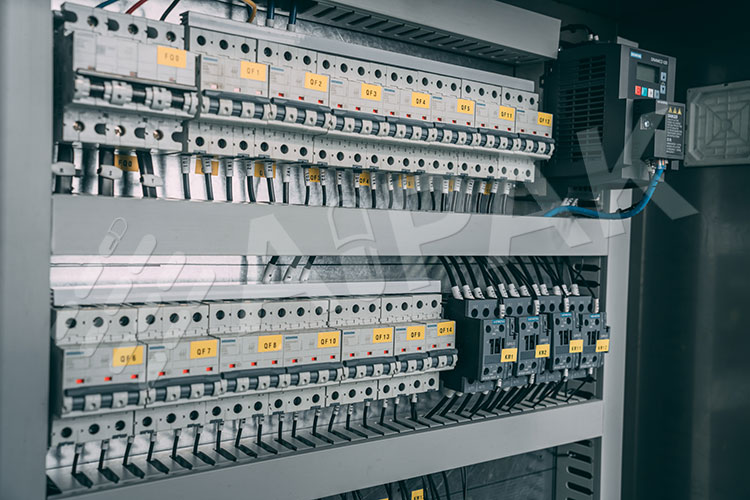

PLC Control Panel

It is the brain of gummy manufacturing machines that consists of electronic wiring, relays, and switches. It supplies power to motors, pumps, and other moving parts of machine. These are also used for monitoring the progress of gummy manufacturing.

Transfer Pumps

These are employed for moving syrup and gummy base to different parts of the machine. Double layered pumps are equipped with hot water circulation for lowering solidification of syrup, keeping syrup warm, and maintaining the flow of syrup.

7.What Auxiliary Equipment are used in Gummy Manufacturing?

Gummy manufacturing line only include the process machineries but a set of integrated machines are also involved once they are produced. Such as :

Gummy Counting Machine

This is another essential component required once gummies are formed. A gummy counter helps in accurate counting as per serving sizes.

This machine also has the ability to accept corrected products while rejecting faulty ones. This means the final packaging delivers a presentable product. Moreover, this machine is not just a cost economical solution but reliable instead of manual counting.

Sachet Packaging Machine

This machine forms four-sided sealed sachet from a plane sheet of plastic film. The machine has ability to transfer gummies into each sachet once it produces. Moreover, it gives efficient, accurate, and safe packaging automatically without chances of leakage or product contamination.

Machine forms a sachet from a filmstock roll, it is created by sealing from three sides with the help of heat sealer bars. Once gummies are introduced; the top edge of the sachet is sealed and cut with cutting knives.

Jar or Bottle Packaging Machines

Gummies are commonly dispensed in bottles, jars or containers. This job is perfectly performed by jars or bottle packaging machine. These machines are equipped with dispensing nozzles that ensures an accurate dose delivery without chances of stickiness or product’s cross-contamination.

They’re automatic and fast machine where digital programming and a pneumatic filling system promises you error free packaging.

Once bottles/jars/containers are filled; they’re transferred to capping section.

Premade Pouch Packaging Machine

Already made pouches for gummies are a flexible way of packaging that is exclusively done by a premade pouch packaging machine.

The machine efficiently works by suction of individual premade pouches. Using an air inflator can opens the bag and material filling and sealing is done using hopper, nozzle and sealers of the machine.

8.What Is the Difference Between Starch Molding Process Of Gummy Manufacturing And Starchless Molding?

Although, starch molding and starchless molding of gummy manufacturing have same functions of shaping gummies, however there are quite a number of differences between both these systems. These differences are discussed below:

| Starch Molding Gummy Manufacturing | Starchless Molding Gummy Manufacturing |

| Starch molding has the advantage of flexibility and can create gummies varying in texture and bites. It can produce gummies of different shaped and sizes. | This type of molding creates limited gummy types with small texture option. |

| In this type of gummy manufacturing molding, de-starching, and drying are performed consecutively. | Molding, cooling, and drying are performed one after other in starch molding of gummy manufacturing. |

| It results in starch wastage and requires deep cleaning for starch removal. | It does not process starch thus there is no need of deep cleaning in this type of gummy manufacturing. |

| Starch molding of gummy manufacturing has longer cutting time. | This has shorter curing time. |

| There is high risk of dust explosion and ignition in this gummy manufacturing. | There is no chance of dust release in this gummy manufacturing since there is no likelihood of starch discharge. |

9.What Are The Storage Conditions After Gummy Manufacturing?

After gummy manufacturing, the gummies are stored in cool, dry, and dark place. Shortly after their manufacturing, these gummies candies should be packaged in airtight containers to decrease their environmental exposure.

If gummies are stored at high temperature, the gelatin and sugar in gummies will melt resulting in sticky mess. Moreover, if these are stored at high humid conditions, gummies will absorb moisture from surrounding leading to weeping or sticking of gummies. This decreases chewy mouth feel of gummies and reduce their shelf life.

If gummies are stored in dry place at temperature below 25°C, they will remain fresh for 6-12 months.

10.How Will You Troubleshoot Gummy Manufacturing Process?

Some technical problems arise during normal gummy manufacturing process that can decrease production speed and increase downtime of gummy manufacturing. However, these problems are easily resolved by following below mentioned guidelines.

| Problem | Analysis | Remedy |

| Ripped Gummies | Inadequate oiling of mold before gummy deposition.

Defect or irregularity in molding device. Insufficient chilling of gummies. |

Properly oil molding device before deposition.

Replace molding device. Increase chilling time of gummies. |

| Weeping Or Sticky Gummies | High levels of reducing sugars

Insufficient coating or polishing Inadequate drying of gummies |

Cut down amount of reducing sugar in gummy formula

Use adequate amount of carnauba wax or cornstarch for coating Increase the drying time of gummies. |

| Low Blooming Of Gummies | Decrease quantity of water in gummies | Add proper amount of water during gummy preparation |

| Incorrect Setting Of Gelatin | Presence of protease enzyme in gummy formulation cause degradation of gelatin | Do not include fresh fruit juice in gummy formulation. |

| Non-Uniformity In Gummy Sizes | Incorrect setting of gummy manufacturing machine

Deformity in the molding unit |

Properly set the gummy manufacturing machine before start

Replace the molding unit |

| Premature Setting Of Gelatin | Low processing temperature | Increase processing temperature to 150°F. |

| Cloudy Appearance Of Pectin Gummies | Improper straining of juice

High quantity of green fruits Rapid pouring rate of mixture in molds |

Properly strain juice and pulp

Decrease the amount of green fruits Gradually pour mixture into molding unit |

| Chewy Texture Of Pectin Gummies | Inadequate pH during gel setting

Lower temperature of pectin-sugar-water mixture |

Maintain proper pH of 3.5

during gel processing Heat the mixture to 220-240° F |

Conclusion

Gummy manufacturing is a complicated process having numerous steps such as cooking, mixing, depositing, molding, cooling, coating, and drying. Each step requires specific and precise control otherwise failure in equipment and product wastage occur. Gummy manufacturing is executed by specialized high-tech equipments. If you want to upgrade your existing gummy manufacturing line you are more than welcome to browse our advance gummy manufacturing machines.

Gummy Making Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

LET US MANUFACTURE A HIGH-QUALITY SUPPLEMENT PRODUCT FOR YOU!

Whether you’re entering the industry for the first time or looking for a new supplement manufacturer, Alliance Nutra is poised to be your partner. Contact us to learn how we can assist you!