Gummy Filling Machine: The Complete FAQ Guide In 2025

Gummies are perennial favorite of children, adults, and older people, whether they are candy, vitamin, or dietary supplements. Similarly, the increasing demand has revolutionized the gummy manufacturing industries; eventually grow importance of gummy processing equipment-the most notable of which is the gummy filling machine.

Having been a key equipment gummy filling machine performs the responsible function of filling accurate volume of gummy into molds. However, the minor inaccuracy may ruin overall quality and outlook of gummies which might upset you. Are you thinking to avoid such situation by acquiring a cutting-edge gummy filling machine? Or caught in a dilemma how to select effective equipment and what criteria you should consider? The answers to all of these and other questions are provided below for your convenience. Just be there, and make sure to not miss any of them!

1.What Is A Gummy Filling Machine?

A gummy filling machine is an electronic tool used to carry out the function of accurately filling number of empty molds with liquid gummy solution. It extracts the predetermined amount of the gummy formula from the hopper and feeds it through tiny filling tubes into various molds for forming unique gummies with lovely colors. Thus, you can use it for filling soft gummy candy, chewy gummy candy and jellies with a single, dual and multiple flavors.

Even though there are various types of gummy filling machines, and they can operate independently, it can be directly integrated with other machines for gaining exceptional results. Similarly, the growing importance of a gummy filling machine can be seen in numerous sectors, including food, pharmaceutical, nutraceutical and cosmetic industries.

2.Highlight The Essential Features Of A Gummy Filling Machine?

When it comes to increasing your gummy production output, a gummy filling machine can provide many advantages characterized by its features including:

Ensure Accuracy

Using a gummy filling machine will ensure filling accuracy as the entire mechanism is executed by machine itself. Every mould of gummy is filled with the exact dosage of gummy without any wastage. It eventually leads to the formation of smooth and perfect gummies without any edge broken or left unfilled.

Customization

Every enterprise wants to introduce their own production with new ways which is only possible with customization. Here you can better modify the machine setting as per your desire by changing the gummy molds and amount of each dosage etc.

Flexible

It is most reliable, adaptable and has vast application in a way that you can use it for filling gummies and jellies with different colors, flavors and shapes.

Durable

It is highly compact and precise with robust construction that you can easily control it during operation. The movable casters make it more convenient and portable for mobilization.

3.What Are The Working Principles Of A Gummy Filling Machine?

Understanding the gummy filling process requires knowledge of the basic operating concepts of a gummy filling machine. It is based on the following basic steps:

Material Preparation

The process of gummy filling starts with the preparation of material which has to be filled in the gummy molds. It is prepared in a separate machine by mixing different ingredients including gelatin, sugar, water, colorants and flavors.

Material Loading

The prepared gummy recipe is transported to the hopper of gummy filling machine either manually or automatically through heated tubes. Here, plunges located inside hopper continuously moves up and down to keep the solution free flowing and avoid any sort of air bubbles.

Mould Filling

When mould arrives under the filling station, detector detects the presence of moulds and delivers message to machine. This leads to the final stage of filling moulds with precise dosage of gummy solution. The process of gummy will be followed by gummy cooling, coating and drying phase.

4.Describe The Main Components Of A Gummy Filling Machine?

There are various components in a gummy filling machine, and each one has a specific function. Below is a detailed explanation of these parts:

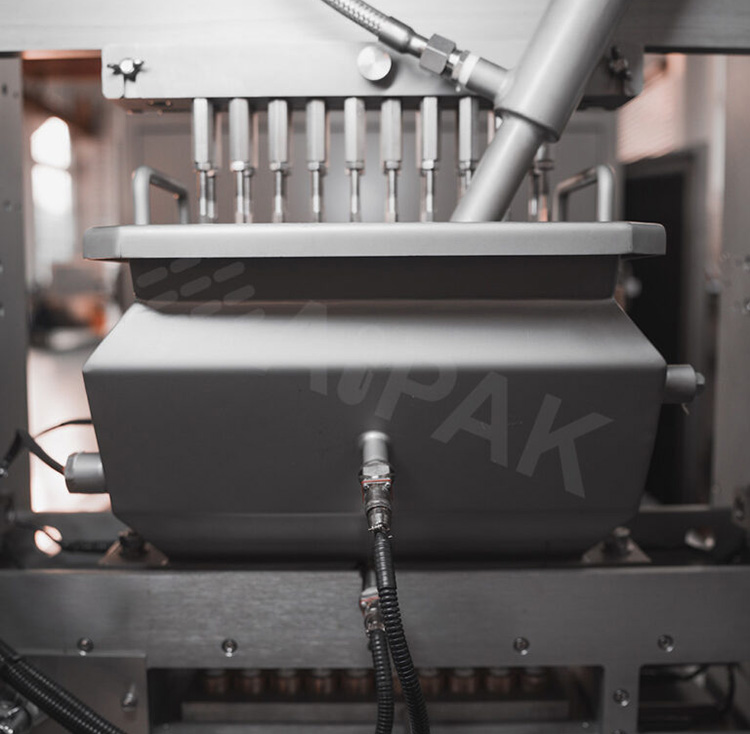

Hopper

Hopper is located on the top of gummy filling machine which functions as the collection tank for holding gummy recipe. It consists of inlet tube through which gummy mixture is entered inside, plunges and the outlet valves.

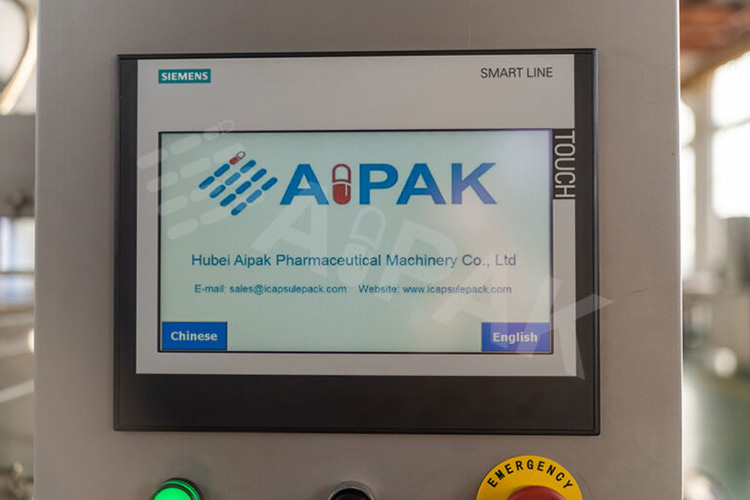

PLC Control System

The gummy filling machine has touch screen control panel through which the entire system of machine can be easily controlled and executed. For instance, the amount of filling gummy, speed of conveyor belt and the temperature of gummy in hopper can be fixed while using user-friendly touch screen display.

Plunges

Plunges are long stainless steel rods that continuously travel up and down inside the hopper to prevent the clotting of liquid gummy solution.

Filling Nozzles

Every gummy filling machine has the number of filling nozzles which are used to deposit the exact amount of gummy solution into empty moulds.

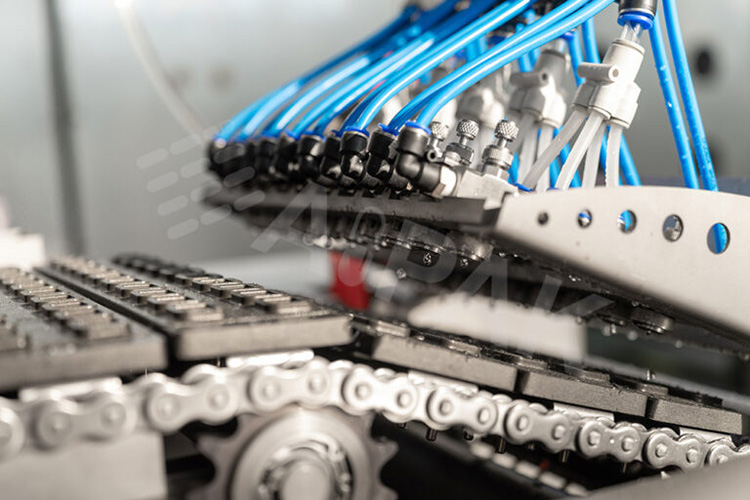

Lubrication System

The lubrication system involves spraying device which performs the function of spraying the gummy molds with oil to prevent gummy from sticking to the mold.

Heating System

As the recipe of gummy quickly get thicker when exposed to air. Thus, a safe operation is adopted to deal with this matter. For this purpose, the gummy mixture is kept in the heated hopper which constantly gets required temperature to release the solution uniformly.

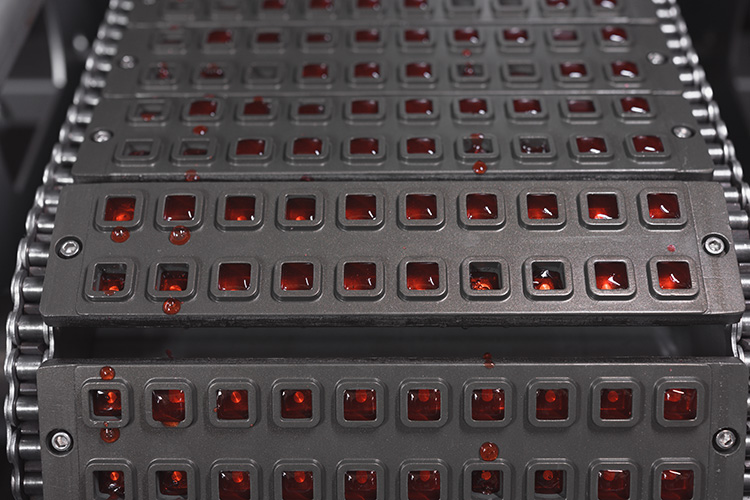

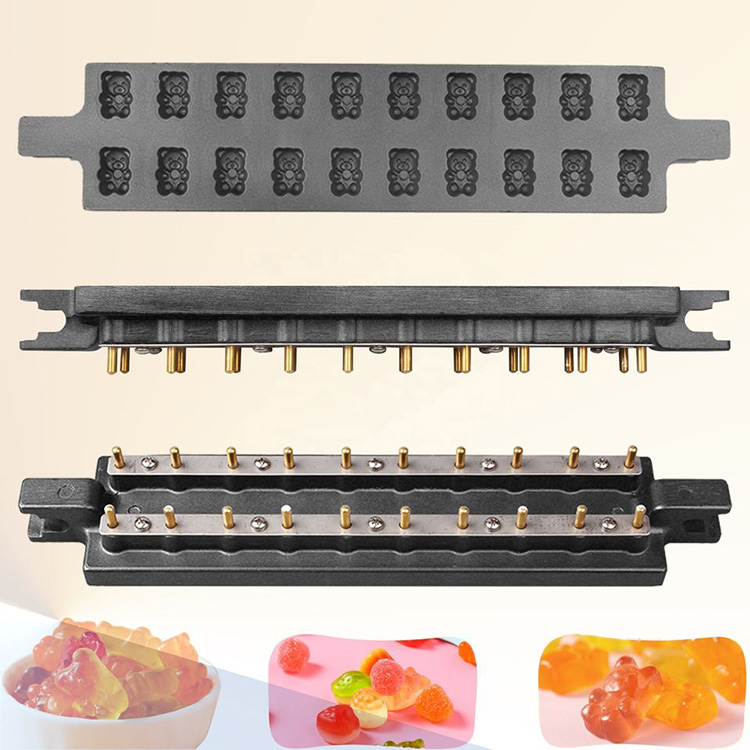

Gummy Moulds

It is an important part which cannot be overlooked while talking about the components of a gummy filling machine. Gummy molds are made from different materials like plastic, silicone or non-stick. They come in small to large size of molds with various shapes and give your gummies the actual shape.

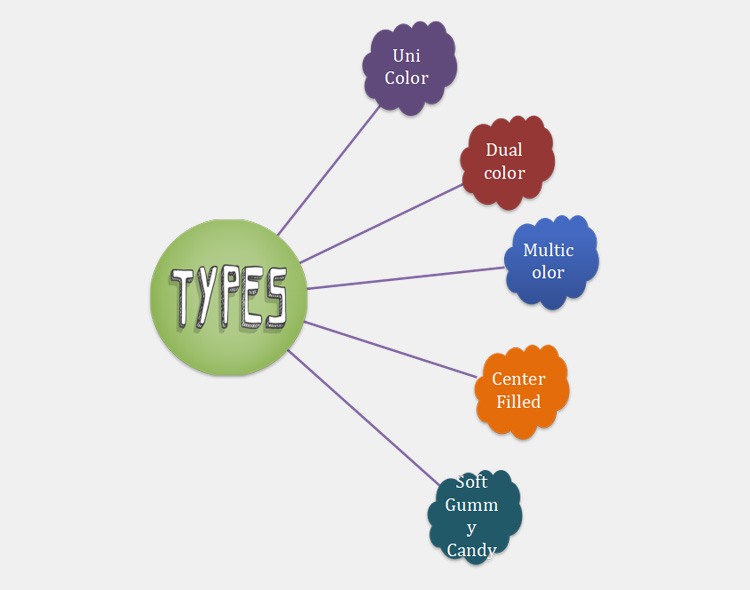

5.Which Type Of Gummies Can Be Filled By A Gummy Filling Machine?

One of the most prominent reasons for the popularity of gummies among children and adults is the alluring and energetic colors they depict. Similarly, every enterprise is in struggle to take these demands when producing gummies. In this way, following details about the colors and types of gummies which a gummy filling machine can fill, would be of great importance for you:

Uni Color

Uni color gummies are those which contain only one color and one flavor. Here an example of fruits likes apple, mango, strawberry and orange flavored gummies can be taken which often come in a single color. Such types of gummies can be easily filled by using a gummy filling machine.

Dual Color

Another type of gummies includes those which contain two colors at same time. You may have enjoyed the sour and sweet taste of tamarind gummy in a single bite or the fruity flavors of egg gummies among others. All these gummies are perfectly filled by a gummy filling machine.

Multicolor

Multicolor gummies are good source of enjoying various flavors at same time. These flavors may be sour, sweet or fruity. Gummy worms, body parts gummies and gummy alligators are the common examples of multicolor gummies which are mostly filled by this machine.

Center Filled

Do you ever have an experience of enjoying center filled gummies? What a delightful sensation it leaves behind when the sudden release of inside content occurs in mouth! No doubt, this pleasant experience is the result of innovative gummy filling machines which can perfectly do this task.

Soft Gummy Candy

Another type of gummies is soft gummy candy which is jelly like having bouncy structure which can be easily broken down through teeth. Most of the soft gummies are prepared for kids and children, due to ease of eating.

Chewy Gummy Candy

Chewy gummy candy is gelatin based gummy having strong texture which can be swallowed after longer chewing. Mostly, such type of gummies are coated with wax and used for adults in form of gummy supplements, as they have strong teeth.

6.Enlist The Machines Who Works Alongside A Gummy Filling Machine?

There are many other machines which might be helpful for you when using a gummy filling machine. These machines include:

Gummy Making Machine

Gummy making machine is an inevitable machine you would definitely need when producing and filling gummies. It is also known as gummy melting tank or jacket cooker in which all the ingredients required for gummy making are poured and cooked on specific temperature until they are turned into final recipe. The recipe is further mixed with colorants, and flavors to give the gummies actual beauty, and thus it can be transferred to the gummy filling machine either automatically or manually.

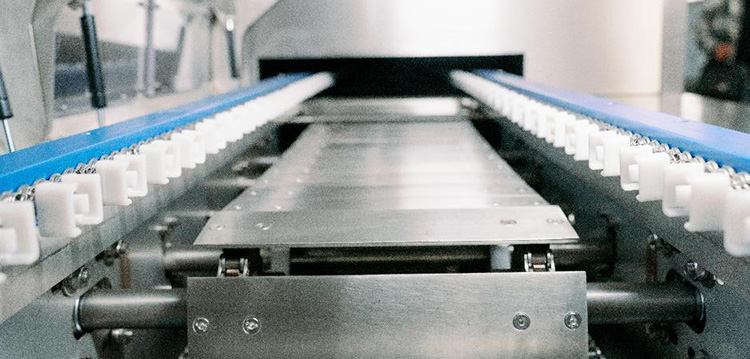

Gummy Cooling Tunnel

Gummy cooling tunnel comes with the function of cooling down gummies, so their texture and integrity could be well retained which may get damage if hot gummies are directly discharged. Thus, gummy cooling tunnel works along with gummy filling machine and is connected through conveyor belt. It provides cold air to gummies and push them off the molds via demolder.

Gummy Coating Machine

Gummy coating machine is another significant instrument used for the protection and beautification of gummies. You can use it for coating your gummies with sugar, starch or wax to keep the gummies away from each other especially during packaging.

Gummy Drying Machine

The process of drying gummies is most crucial as it can fully eliminate the presence of moisture from them. For this purpose perforated plastic trays are used for putting the gummies in drying machine where the moisture is removed through compressed air.

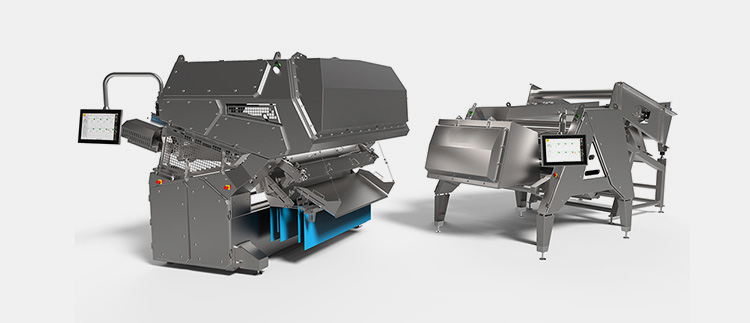

Gummy Sorting Machine

There may be change in size and weight of gummies after their production. Here, to make your production and packaging are perfect, a gummy sorting machine can be

used for the removal of defective gummies and separating the gummies of same size and weight.

Gummy Counting Machine

Gummy counting machine is an innovative technology which can intelligently count your gummies, candies and chocolate balls in a rapid run. It is very helpful in meeting the targeted production rate and especially for packaging purpose.

Gummy Packaging Machine

The gummies you produced needs to be attractively packed to catch the consumer's attention. For this purpose, you should never ignore the essential instrument of gummy packaging machine for your production line. It can perfectly pack your gummies into different shapes bags, bottles and containers.

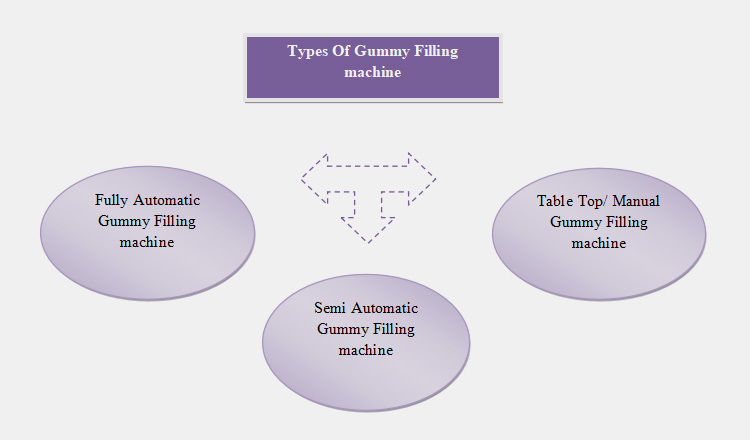

7.Explain The Types Of Gummy Filling Machine?

There are various types of gummy filling machine which are distinguished from one type of machine to another. These machines can be divided into two categories as shown below:

Automatic Gummy Filling Machine

Automatic gummy filling machine is effective equipment made with advance technology that carries out the entire mechanism of gummy filling and making automatically. It can be directly integrated with other machines for extremely perfect and high output. This fully automatic gummy filling machine is the best ever solution for large scale industries.

Components

It consists of stainless steel body, electric cabinet, hopper, filling nozzles, plunges, guide rail, heating system; touch screen display, mold chiller and air cylinder.

Working Principles

The machine works through specified process after the parameters are fixed by operator. The gummy recipe is delivered to the hopper of gummy filling machine by gummy cooking tank through heated tube. Now, the plunges in hopper constantly move up and down to avoid clotting. On the other side, molds are passed through oil spray and filled with the accurate dose of gummy solution dispensed via filling nozzles. These filled molds further go through the cooling tunnel and get discharged by conveyor belt.

Semi-Automatic Gummy Filling Machine

A semi-automatic gummy filling machine requires human input in order to complete the task of filling gummies. It is highly portable and an excellent option for carrying modest volume manufacturing with reasonable price.

Components

The main parts of machine include precise body, clutch, control board, hopper, dosing tubes, transportation system, lubricating unit, casters and air regulator.

Working Principles

The hopper must be manually fed with the gummy formula by the operator. The gummy solution is thoroughly blended and precisely poured into the empty gummy molds. After that, the operator takes the loaded gummy molds for further processing.

Table Top/ Manual Gummy Filling Machine

A table-top gummy filling machine is a piece of precise machinery that does an excellent job of filling gummy into moulds. It is best utilized in laboratories for sample purposes, for small-scale production, or for home-based businesses.

Components

The machine is composed of a gummy tank, handle, and conveyor belt, filling hoses, pistons, gummy transporting tube, oil / water heating system, control system and servo motor.

Working Principles

Gummy formula is simply poured into the material tank to begin the process. Hot oil or water is kept into the wall around the hopper to keep the material flowing freely. After that, the preset dosage of gummy is released into the molds by piston filling nozzles when the power switch is turned on. These molds are then moved forward via conveyor belt where operator takes them out.

8.Name The Kinds Of Molds A Gummy Filling Machine Can Fill?

If you are new to the gummy production, you may not be familiar with the different kinds of molds available for gummies. In this question you will get to know these various types of gummy molds:

Silicone Gummy Molds

Another type of molds used for gummies is made up of silicone. Such molds can tolerate high temperature and easily get cleaned. They are light weighted and flexible that you can pop up your gummies through your hands.

Teflon Gummy Mold

Teflon gummy molds are popularly used in large scale industries to fully assure the safe filling and remolding of gummies. Such molds do not require the oil or grease for lubricating purpose as they have natural nonstick surface which allow quick release of gummies.

9.What Are The Applications Of A Gummy Filling Machine?

Due to gummies' widespread use across all industries, gummy filling machine can be employed in a variety of settings. Its application can be found everywhere, whether in domestic level or commercial level, the medical or cosmetic industries. Here, the few examples among them are taken below:

Food Industry

The food industry is consistently at the top of the list for having a strong demand for a gummy filling machine. This machine is ideal for producing confectionaries including soft gummy candy, chewy gummy candy and jellies.

Pharmaceutical Industry

People throughout the world are increasingly sick of taking large, bitter-tasting medicines. As a result, the pharmaceutical sector is attempting to introduce novel substitutes, among which gummies are the most popular. For this purpose, pharmaceutical industry is providing medication in the shape of gummies with the help of gummy filling machine.

Nutraceutical Industry

Gummy supplements are the good source of taking essential vitamins and nutrients required for daily life. It contributes to the overall beauty, strengthening immunity and reducing the risk of chronic diseases like cancer. Pharmaceutical industry thus aims at providing consumers with best flavored gummy vitamins to make them enjoy while promoting a healthy lifestyle.

Cosmetic Industry

Like other sectors, cosmetic industry is also involved in producing gummies for enhancing the natural beauty from within. You can find the wide variety of gummies with different flavors which can be used for strong nails, removing dark circles and for promoting long shiny hairs. Thus, a gummy filling machine has significant role in cosmetic industry.

10.What Are The Maintenance Requirements For A Gummy Filling Machine?

Do you know that a gummy filling machine require proper maintenance for running smoothly? Its negligence can lead to the inefficiency and occurrence of various other problems. Thus, to keep your equipment on right track, you should know and follow the maintenance necessary for it:

- When installing your gummy filling machine, make sure the surrounding environment is clean and free of pollution to avoid the risk of contamination.

- Try to follow the safety instructions mentioned on manual guide like wearing gloves, mask and avoid touching electric parts with wet hands.

- Clean your gummy filling machine on regular basis including nozzles, hopper and inlet/ outlet valves.

- Lubricate the moving parts to ensure consistent flow of machine.

- Keep the process under observation and make use of emergency button in case of unexpected mishap.

11.Factors To Consider Before Purchasing A Gummy Filling Machine?

Purchasing a right gummy filling machine for your business is a responsible task which should not be done without its clear understanding. There are certain factors which may be essential for you in this regard:

Depositing Parameters

It is the most crucial aspect to know about your gummy filling machine. The depositing parameters include the filling speed, air pressure and temperature used for heating hopper. These elements greatly influence the quality of your gummies. Thus, you should keep the information about filling specifications of the machine you want to buy.

Filling Capacity

What is the filling capacity of a gummy filling machine you are intending to purchase? How many moulds can it fill in a minute? Is there any space for adding more filling nozzles? These questions are necessary to be answered by your vendor.

Support Equipment

Every machine need support equipment for the fulfillment of desired task. Similarly, a gummy filling machine require gummy cooking machine, gummy cooling tunnel and coating machine as obligatory tools. So, you must have an idea about these machines and their usage.

Conclusion

Gummy filling machine is the core part of gummy production. Its ability to be utilised alone has pushed many industrialists to recognize importance. However, the insufficient knowledge sometimes might lead you to go for the machine which may not be compatible to your current manufacturing. Therefore, we recommend you to consider AIPAK Pharma for purchasing a single or whole production line for your gummy manufacturing and filling needs. You can also visit our website and watch upcoming guidelines regarding gummy to stay completely informed.

Don't forget to share this post!

Gummy Making Machine Related Posts

Gummy Making Machine Related Products

Gummy Making Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine