Gummy Depositor:A Complete Buying Guide in 2025

Grown-ups might have remembered sweet gummy candies as a wonderful treat that originated in the early 1980s. But these gummy eatable’s date is much farther than that.

Hans Riegel a German entrepreneur was the first person who originated the gummy sweets early in the 1920s for his candy company ‘Haribo’. Today, this company is considered a top-class maker of gummy candies across the globe.

Have you wondered-

- How gummy candies are molded so perfectly?

- How does a gummy depositor facilitate the accurate and beautiful design of gummy candies?

- What is the production line of gummy depositors?

A Gummy Depositor

If you’re planning to invest money in gummy depositor for your business. Then, this blog is for you. we’ll assist you to provide basic and advanced knowledge about gummy depositors, for instance, features, specification, installation, and much more.

1.What is gummy candy?

Gummy candy is a unique form of sweets that are made up of three important bases. For instance, Gelatin, Pectin and Carrageenan with artificial sweeteners, purified water, colors, plant extracts, citric acid, flavoring agent, etc. Due to it jell-like texture,gummy candies can easily be molded into thousands of shapes that come to be one of the highly versatile confectionary products ever. The prime ingredient responsible for unique gummy characteristics is ‘gelatin’, ‘Pectin’ and Carrageenan.

Additionally, blending other raw materials can enhance other characteristics such as texture, sweet taste, and attractive appearance.

Gummy Candies

2.What are popular shapes of gummy candies?

When you start eating gummy candies, it is hard to stop until a packet of gummy candies gets to finish. Because these bites are so addictive with perfect flavors, shapes, and colors. But there are certain popular shapes of candies that are well-known to us since childhood. Such as:

- Gummy bears

- Jelly bottles

- Jellybeans

- Fruit Jelly

- Lego gummy

- Worm gummies

- Gummy sharks

- Jelly rings

3.What are the advantages of gummy candies?

Gummy candies are enjoyed across the globe due to the following reasons:

- It has a nice, delicate, and soft texture.

- Due to the sweet taste, flavor, color, and chewy properties, gummy candies bring a nice feeling when you eat.

- You can easily design, add flavors and colors according to manufacturer preference. per

- You can add multi-vitamins into their ingredients hence it can bring health benefits also.

- These are better to eat when you feel hypoglycemia or low blood sugar.

- Eating gummy candies gives a wonderful feeling hence it overcome depression or stress during workload.

- Gummy candies are free from fat, comprised of proteins and carbohydrates, hence it is safe to eat.

4.How gummy candy can mold easily?

Gummy candy is a unique flexible candy that can be molded so easily. This unique property of gummy candy is due to the incorporation of gelatin, pectin and carrageenan.

Gelatin is mainly extracted from animal tissues that creates a gel formation when added to water. Physically a gel is a thermo-reversible compound that melts or gets thinner when you heat them. That’s why gummy candies also melt in the mouth as well.

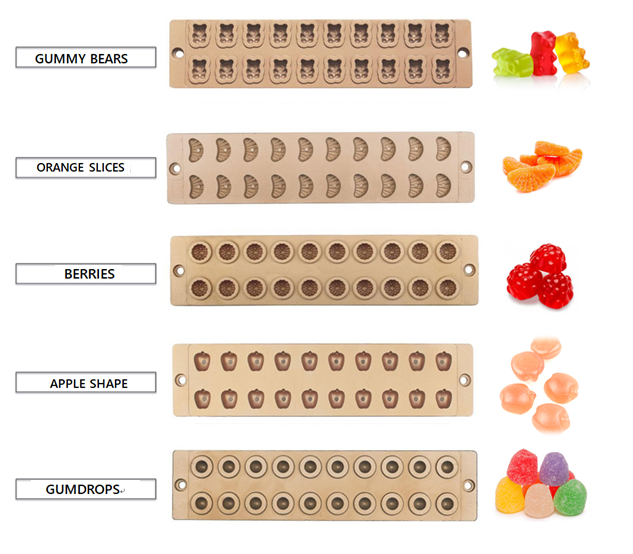

Various gummy candy molds

The texture and dissolution time of gummy candies is regulated by the concentration of gelatin, pectin, and carrageenan used in the manufacturing process. Additionally, cornstarch is added into mixing material to facilitate the stability.

Without cornstarch, gummy candies would be prone to stick into molds that can ultimately affect the process of manufacturing and results uneven texture and fineness.

A suitable slurry of gummy candies when pouring into molds can be cooled at 65º F and settle for 24 hours. This will allow slurry to transform into elastic and chewy form. If candies are too hard, you can soften them by rehydrating them.

5.What is a gummy depositor?

AIPAK gummy depositor

A gummy depositor for gummy candies is constructed to ease the fillingor pouring a slurry of gummy candies into each cavity with accuracy, uniformity, and elegance. A gummy depositor works for low heat confectionery items (jelly, chocolates) as well as high heat ingredients (caramel, hard candies, and gummies). A gummy depositor allows you to manufacture gummy candies or jellies of various sizes and shapes.

The production line of the gummy depositor is regulated by PLC. A typical gummy depositor is comprised of a cooking unit, depositor, mold, cooling unit, and inter-connected pumps and pipes. Hence a gummy depositor machine is an artistic technique that yields an eye-catching gummy candy with a delicious taste. A gummy depositor is a piece of ideal equipment that gives high- productivity to confectionary items.

6.What is the working principle of a gummy depositor?

The working principle of the gummy depositor is discussed below:

Gummy depositor machine- Picture courtesy- GCMM

- Preparation of Raw Material

The preparation of raw material before initiation gummy depositor machine is of prime importance. Because, for successful batch production, the entire list of ingredients should be properly measured and available. For instance, glucose, gelatin, water, etc.

- Cooking

A slurry is prepared from mixing and cooking sugar, gelatin, pectin, carrageenan, glucose, water, and another required ingredient for 15-20 minutes. The prepared syrup is transferred into the storage tank.

- Addition of mixing ingredients

After preparation of syrup, flavoring agent, coloring, acids are added to it. - Gummy Depositor

A slurry is introduced into the gummy depositor via a hopper. The gummy depositor will allow the formation of different shapes in gummy candies.

- Cooling

The mold will be transferred to the cooling tunnels. After achieving desirable cooling, they are transferred to the drying room with the help of a conveyor belt. The drying of gummy candies is mandatory to attain optimum moisture content.

7.What are the features of a gummy depositor?

A gummy depositor machine is a well-constructed machine that creates accurate pieces of gummy candies in an excellent shape, size, and texture. The use of gummy depositor allows creating gummy candies with no air-bubble with a beautiful smooth surface. Discussed below are the following features of the gummy depositor.

Gummy Depositor Machine

- A gummy depositor machine yields high production output with minimal labor requirements. A consistency in size, shape, and weight allows easy wrapping efficiency.

- Gummy depositor machine has high hygiene features that lower the cleaning and maintenance expenditure.

- Hopper, depositing molds, depositing head covers, frames, cooling fans, are made up of stainless steel.

- A gummy depositor machine is robust, validated equipment suitable for production where constant validation and repeatability of the process is required.

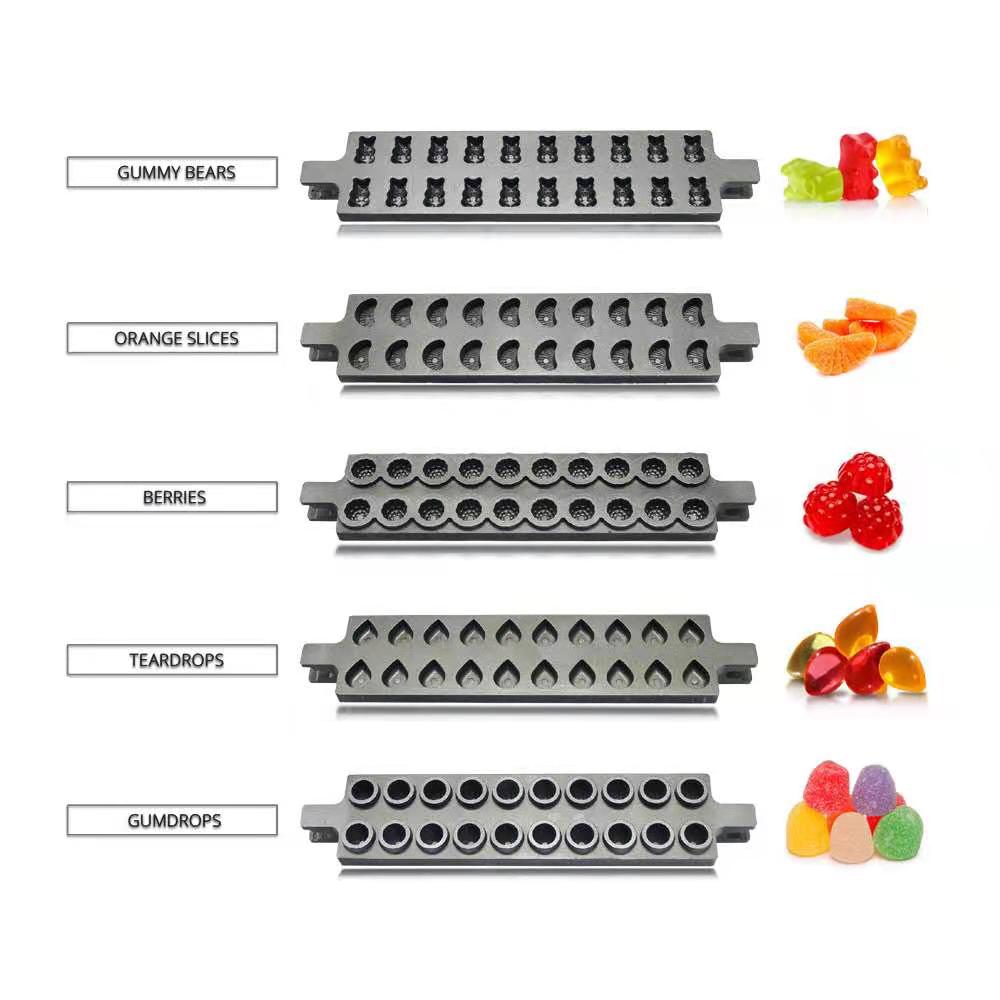

- Mold for soft confectionery products is made up of silicon rubber or aluminum.

- Gummy depositor machine provides high speed, accurate and consistent control over product manufacturing with negligible scrap rate. Thus, this machine allows the simultaneous manufacturing of gummy candies of various shapes, sizes, and colors.

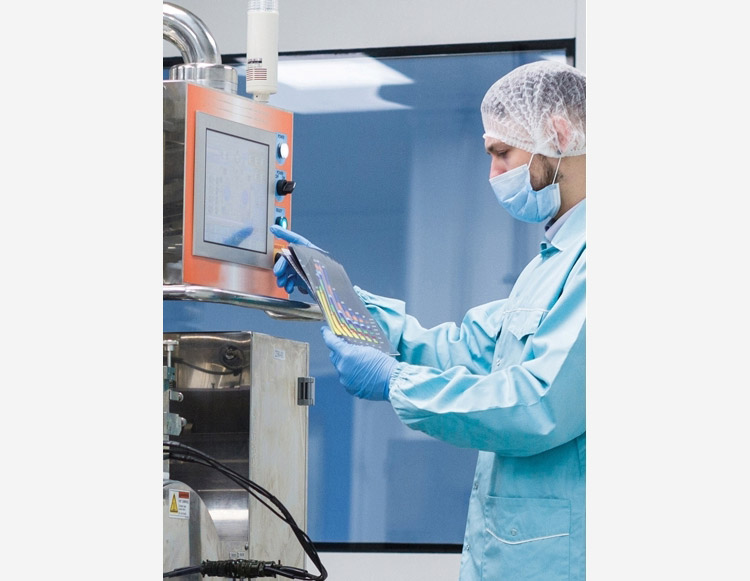

- A gummy depositor machine allows complete visualization of the running process, management of formulation, and alarm handling.

Visualization of the process- Gummy Depositor Machine

8.What raw materials are used in the manufacturing of gummy candies?

Gummy candies are generally manufactured by trained chemists and food technologists. By mixing of various ingredients involved in the manufacturing of gummy candies gives high characteristics to gummy candies such as taste, shape, and texture. Initially, gum Arabic was used as a base ingredient. Today, gum Arabic is replaced by edible gelatin, pectin, and carrageenan. The use of edible gelatin, pectin and carrageenan give gummy, chew consistency to candies with expanded shelf life.

- Gelatin

The unique characteristic of gummy candies is due to gelatin. Gelatin is a natural protein which is originated from raw collagen. Gelatin is safe to consume that s comprised of essential amino acids with several health benefits. This is a prime ingredient that requires proper mixing to form a gel-like thick solution. For this, you need to mix the right amount of gelatin into the optimized volume of water. Under assigned conditions, the mixing of gelatin will lead to form a chewy, elastic, and gummy texture of jelly.

Gelatin

- Pectin

Pectin is a dietary soluble fiber present in fruits in the form of polysaccharide (a long chain of indigestible carbohydrate). Pectin is utilized as a thicker in many eatable formulations such as gummy candies, jam, and jellies.

When you heat, pectin in the presence of water you’ll observe the transformation of pectin into gel form because it expands in the presence of water molecules and acts as a great thickener. It is also used in making of medicines also, syrups.

Additionally, there are several health benefits of pectin for instance, improving blood sugar, reduces the risk of developing cancer, improve weight, prevents stomach problems etc. Therefore, addition of pectin in your diet may helps to improve your health.

Pectin

Always remember, pectin requires approximately 60- 80% of sugar content under acidic environment. A pH below 3.5 is suitable for gel formation, as under alkaline environment pectin won’t be chewy and elastic. Furthermore, making of pectin gel require controlled temperature, moisture, and sugar.

As gummy candies become undesirable sticky due to high heat (can stick to your teeth), and nobody prefers that.

- Carrageenan

Carrageenan is naturally occurring marine polysaccharide which is extracted from seaweed. Carrageenan is water soluble dietary fiber which is a best alternative to animal-based thickeners for e.g., gelatin.

Carrageenan

Carrageenan is preferably used as a base material for the manufacturing of gummy candies. It enhances the gelling properties as well as alkalinity, solubility, emulsifying, thickening etc. Gummy candies with carrageenan as a based material has certain benefits such as a good taste, transparency, bright color and cost-effective. Furthermore, they are also used in making of frozen dough, ice-creams, milk, and baking goods.

Carrageenan

- Sweeteners

Gelatin, pectin, and carrageenan are tasteless, odorless, lipid-free compounds. Thus, you can enhance the sweet taste into gelling base by incorporation of sweeteners.

- For this purpose, many sugar substances are used such as sucrose, fructose, or corn syrup.

- Corn syrup is preferable in manufacturing as it helps to prevent the crystallization of sugar that can destroy the gummy texture. Additionally, corn syrup also helps in the maintaining of moisture content.

- Sorbitol is also added to maintain the sweetness as well as moisture content.

The addition of sugars not only gives some sweet taste but also benefits in the preservation of gummy candies from microbial contamination.

- Flavor

Whenever you eat gummy candies, it will give you a unique flavor with sweetness. Flavor in gummies can be enhanced by mixing artificial and natural flavoring agents.

The natural flavoring agents are extracted from fruits such as orange, maple, berries, etc. This impact of flavor is further improved by the addition of aromatic chemicals such as methyl anthranilate, citric acid, lactic acid, or ethyl caproate. The use of citric acid in gummies manufacturing also acts as a preservative that ensures the safe healthy production of gummies with no microbial growth.

- Sodium Citrate

Sodium citrate is used in the manufacturing of gummy candies to assure the high accuracy, consistency, and purity of the product.

- Purified Water

Water is a universal solvent, that acts as a vehicle in the manufacturing of gummy candies. The addition of water in the raw material also led to form softness in gummy candies. Therefore, to achieve the perfect mixture you will always require purified water.

- Citric Acid

Citric acid is an important ingredient used in gummy candies to enhance the sour flavor. Furthermore, citric acid also has antioxidant properties that is preferably utilized as an excipient in pharmaceutical preparations. It is originated from citrus fruits that extends shelf life of the product and serves as preservative.

9.What are the industrial applications of gummy depositor machine?

Gummy depositor machine is extensively used in following areas:

- Food & Food Décor Industry

A gummy depositor is mainly utilized in food industries in the making of chocolates, hard candies, soft candies, jellies, gummy candies, chewing gums, and much more.

Applications of Gummy Depositor in Food Industry

Furthermore, food décor items are mainly composed of gummy candies used as topping over cakes, milkshakes, and desserts.

- Nutraceuticals

Today, the gummy depositor machine is widely used in nutraceutical companies for the manufacturing of innovative nutritional supplements in form of soft gummy candies. The purpose of soft gummy nutraceutical products is to develop taste, boost the health and fitness of an individual pleasantly.

Applications of Gummy Depositor in Nutraceutical Industry

- Stationery Industry

A gummy depositor is ideally used in the manufacturing of stationery items such as making gummy scented erasers in various customized forms as well as key chains, pencil toppers, and other decorative items.

Thus, this new advancement is preferably adopted by many stationery manufacturing units.

Gummy Depositor Machine- Gummy Scented Erasers

Gummy Depositor Machine- Gummy Pencil Toppers

- Soap Industry

Ancient soap art is developing day by day. Today, everyone prefers gummy soaps with beautiful fragrances, shapes, and colors. Gummy depositor machine plays a vital role in molding and creating this art. Sugar-scented soapy bars can use as gift boxes or nourishing your skin. It encourages everyone to practice hygiene beautifully.

Sugar Scented Gummy Soap Bars- Gummy Depositor

10.What are the advantages of gummy depositors?

The gummy depositor is beneficial equipment for making sweet confectionery products. Discussed below are the following advantages of the gummy depositor.

- Hygienic Production

A gummy depositor is an advanced machine that can manufacture multiple types of gummy candies under a controlled environment to yield hygienic products.

- Easy to operate

The entire production line of the gummy depositor machine is adopted by an electrical integration system and steam controller that allows easy operation and significant utilization of equipment.

- Consistency Cooking System

A consistent cooking unit allows gentle and vacuums heating that high-quality sugar masses.

- Allows Making of Extensive Gummy Candies

A gummy depositor can allow the manufacturing of gummy candies of various shapes, sizes, and colors with variable molds.

- Accuracy, Repeatability, and Robustness

Gummy depositor machines allow the manufacturing of jellies and gummy candies with a precise, accurate quantity, that highly shows consistency and uniformity in batch-to-batch production. A gummy depositor machine is an idea for that product where consistent inspection of validation, repeatability, and robustness is required.

- High-Quality Production, Low-Cost Method

Gummy depositor machine is ideal for a reputable manufacturer and new entrants to the business as it significantly produces high-quality products with low energy cost compared to traditional molding machines. Thus, it can create high-value products that appeal to health and fitness-conscious people with diverse ranges of fruity ingredients.

- Minimum Wastage of Raw Material

Gummy depositor machine provides running of accurate and sustains controlled products with negligible scrap rate. This allows maximum production of gummy candies with minimum wastage of raw material with reduced cleaning maintenance requirements.

11.What are the disadvantages of gummy depositor machines?

With so many benefits, every piece of equipment has some drawbacks. Similarly, the gummy depositor machine also has some disadvantages such as:

- High Cost

Gummy depositor machine is highly effective but expensive equipment that costs higher when you plan to spend on it. Furthermore, the manufacturer does not allow free transportation and installation of machines hence you are required to pay additionally for these processes.

- Continuously Drying Process

During the manufacturing of gummy candies, you are required to provide consistent drying using two-way centrifugal fans. The drying procedure varies from types of gummy candies such as soft or hard until you achieved an optimized moisture content.

Hence, their production requires high-energy electrical consumption than other processes of confectionary manufacturing.

Drying Process- Gummy Depositor

- High Work Area

A gummy depositor machine is a large piece of equipment that requires maximum working capacity for the installation of this equipment.

You cannot install a large production plant of gummy depositor machines in a limited area.

- Electrical Heating

The first step of preparing slurry from raw material requires cooking substances. This can be achieved by either steam heating or electrical heating. Electrical heating requires high power consumption and may cost higher.

12.What is the production line of gummy depositors?

Gummy candy, also known as soft-gel gummy candy or soft candy is gelatinous sweet composed of gelatin as the main ingredient.

The production line of the gummy depositor is as followed:

Gummy Depositor

#1- Cooking Unit

Cooking slurry is the first step of making gummies. This step is achieved by boiling syrup either by steam heating or electric heating. The manufacturer has the right to choose the method of heating as per economical need. For the larger production of gummy candies, steam heating is a preferable option due to its cost-effectiveness to electric heating.

In the case of high-pectin ingredients, homogenization during the heat is required. Additionally, heating the ingredients is a controlled process.

At the bottom of the storage pot, there is a pneumatic plug that stops syrup from leakage.

Cooking Unit- Gummy Depositor Machine

#2- Storage Tank

When all the ingredients of the slurry are heated properly, to get rid of excessive heat material is held for two to three hours. This process is intended before the depositing step where all the ingredients are homogenized and cooled as required. To maintain proper fluidity of syrup a continual mixing is also required.

A Complete View of Gummy Depositor Machine

Storage Tank- Gummy Depositor Machine

#3- Coloring, Flavouring, Dosing, and Mixer

This unit is comprised of three to six pieces of holding tanks, dosing pumps, and dynamic mixers. The in-line injector is employed for the appropriate proportion of colors, flavors, and other ingredients. The entire system is made up of food standard stainless steel.

The advantage of a mixer is to supply stable, accurate mixing to gummy mass for depositor units that can also reduce manpower with improved quality. There are two types of mixing involved for gummy mass, dynamic mixing (small capacity production) and static mixing (for large capacity gummy mass with evenly mixing of syrup and colors).

(A)- Mixer- Gummy Depositor Machine

(B)- Mixer- Gummy Depositor Machine

(C)- Mixer- Gummy Depositor Machine

#4- Gummy Depositor Unit

The gummy-depositor machine is a new technology that is comprised of main six parts. A mixer, syrup hopper, a cylinder with piston, mold, nozzle, and a conveyor. The depositor is capable to generate soft as well as hard candies and variable molds that can be changed according to manufacturing requirements. The syrup is introduced into the depositing machine via hoppers. The temperature of the hopper is also controllable as per requirement. The presence motor facilitates the running of syrup over channels of the mold. In this way, the syrup is quantitively deposited on the mold. The speed of running syrup over-mold is basically controlled by a PLC touchscreen.

(A)

(B)

(A, B and C)- Gummy Depositing Machine

#5- Gummy Cooling Unit

When gummy candies are set into their assigned mold, these molds are taken into the cooling unit. This cooling unit is equipped with an air conditioning environment through high-speed centrifugal fans. The advantage of using a high-speed air fan is to lower the temperature and maintaining better cooling. The size of air-cooler or cooling fans is preferred according to the production capacity of gummy candies.

Cooling Unit- Gummy Depositor

#6- De-Molding of Gummy Candies

The mold chain helps in transferring molds into the cooling unit for five to ten minutes. Then de-mold of gummy candies is attained for further stabilizing the product and increase their shelf life. For de-molding, the molding plate is pressed with thimbles inside the mold. The brushes constantly move to clean excessive fragments to give a cleared finished product. The gummy candies will release from the mold into the conveyor belt. The conveyor is associated with a gummy cooling tunnel and a coating drum. This outlet transporting conveyor belt is an optional step for the gummy depositor.

De-Molding of Gummy Candies- Gummy Depositor

De-Molding of Gummy Candies- Gummy Depositor

Conveyor belt- Gummy Depositor

#7- Drying

A drying process is mandatory for all gummy candies. The water content in newly formed gummy candies was observed to be 18%. While the recommended water content for gummy candies should be less than 13%. For this purpose, a drying process is required. Drying gummy candies is necessary to increase the shelf life of gummy candies. For the drying process, various gummy candies have different required parameters of temperature and humidity. Most often, pectin gummy candies require low temperature and high- drying time about right to twelve hours.

Furthermore, Carrageenan requires a drying time of more than 24hours under high temperatures.

Drying Tray- Gummy Depositor Machine

Drying Unit- Gummy Depositor Machine

#8- Control Panel

The main controlling system of the gummy depositor machine is regulated by a PLC panel. The entire processing flowchart is displayed on the monitor that allows easy operation.

A Control Panel- Gummy Depositor Machine

13.How many types of gummy depositor machines are there?

Gummy depositor machines are available in three basic types. Such as:

- Manual Gummy Depositor

- Semi-Automatic Gummy Depositor

- Automatic Gummy Depositor

- Manual Gummy Depositor

A manual gummy depositor machine is a small-scale depositor machine. Most often the design and construction of a manual gummy depositor machine is suitable for depositing a small batch production of chocolates, jellies, gummy candies. This machine is a nicely adjusted tabletop confectionary depositor made up of stainless steel.

The entire working procedure is carried out manually to deal with precise products.

Manual Gummy Depositor Machine- Picture Courtesy Truffly

- Semi-Automatic Gummy Depositor

A semi-automatic gummy depositor machine is especially intended, an advanced form of machine used for making gummy candies, soft and hard toffees, etc. This machine is widely used in the nutraceutical, healthcare, and food industries for the making of functional products.

This is a piece of ideal equipment that yields high production of gummies with reduced manpower and occupying space. You can place a semi-automatic gummy depositor machine in a limited area or lab for research purposes as well. This machine is integrated with a Touch screen control panel and PLC for easy operation. Additionally, a semi-automatic gummy depositor is constructed according to pharmaceutical standards with a high level of sanitization that prevents chances of microbial growth.

Gummy Depositor

- Automatic Gummy Depositor

An automatic gummy depositor machine is a highly advanced machine, extensively works on the large production capacity of gummy candies, chocolates, jellies, etc. The production line of automatic gummy depositor consists of jacketed cooking unit, storage units, depositing units, drying unit, with extensive pumps and connecting pipes, control panels, cabinet, etc. From mixing till end product entire function is performed automatically as per the feeding command on the control panel. Automatic gummy depositor machine has a high degree of automation that assures a stable accurate, and uniform production of goods with less manpower.

Automatic Gummy Depositor

14.How to install a gummy depositor?

- Before installation of gummy depositor machine, you must assign and clean the area for placing the machine.

- Transportation of gummy depositor machine should be done using fork lifter.

- Lay down the machine as per the designed layout.

- Integrate all devices and adjust them in a horizontal position.

- Connect cooking unit, storage unit, depositor unit, etc according to assigned pattern mentioned in the catalogue.

- Fix the heat-insulating water inlet and outlet.

- Fix the compressed air into cylinders tubes.

- Set mechanical and electrical connections properly.

- All electrical connections must be grounded that ensure safety and prevention against damaging wires.

Grounded Wires

15.How to clean and maintain a gummy depositor?

Regular cleaning and maintenance of any equipment ultimately result in high productivity, high efficiency, and extended shelf life. Therefore, maintenance and cleaning of the gummy depositor are of prime importance to get maximum and better outcomes with reduced chances of any mechanical issues. Discussed below are the following important cleaning and maintenance parameters of the gummy depositor machine.

- Focus on Main Key Components of the Machine

A gummy depositor is an extensive machine that is comprised of a huge list of units such as, cooking unit, gummy depositing unit, drying unit, connecting pumps and pipes, etc. Each of the components requires high maintenance and cleaning before and after the running of the procedure. Furthermore, having proper knowledge about every key component will also allow you to understand the working knowledge and exact cause of fault if occur. Thus, you can easily identify and solve the problem.

For cleaning and maintenance procedures, personnel training and utilizing protective equipment are extremely mandatory.

Components of gummy depositor Machine

- Daily

After performing the procedure, flushing of key units, cooker, pipes, pumps, and connecting line with hot water (80°C) will allow removal of sticky residues present in the streamline. Proper flushing will reduce downtime and efficient workflow.

Also, run the hot water into depositor hopper. After cleaning, allow hot water in molds and center of hopper.

This protocol is strictly followed if you’re using multiple production batches to get the precise, accurate, and uniform product.

Electrical earthing should be checked regularly.

- Weekly

Maintenance of vacuum pump, steam jackets, and checking lubrication of conveyor, drive chain, tunnels, and the external connection is required on weekly basis. Always inspect the level of noise and unusual sound during the running of the machine. Examine electric wires and connections and replace them in case of inadequate or damaged out wires.

- Monthly

Pump connection and belt tension of conveyor should be examined every month. Furthermore, rubber tubing, molding, drying unit, and efficiency of centrifugal fans should be checking every month.

- Bi-Annually

Oil filters, electrical connections, and molding trays should be replaced bi-annually to minimize downtime of the machine.

- Keeping Maintenance Record

The scheduled maintenance of the machine should carry out based on the utilization of equipment. To keep a maintenance record as well as having spare parts of equipment such as valves, lubricant, nuts and bolts will allow you quick repair if required.

After using the machine, place all integrated or extra tools out of the machine instead of placing them on the machine. During maintenance of gummy depositor always follow safety instruction and make sure entire process of performed safely, e.g., no water content reach to electric panel or an electrical motor.

16.What safety measures are required during operating a gummy depositor?

Gummy depositor machine continuously required input and output of materials during and after the process. Therefore, it is necessary to follow safety measures while treating gummy depositor machines to avoid unwanted operational hazards.

- The operator should well- trained when operating gummy depositors, especially when handling steam or electric heaters.

- During the procedure, protective equipment such as heat-resistant gloves, goggles, and safety shoes are required.

- Do not try to remove the part from the machine during the process or the machine is connected to an electric supply.

- In case of error during the process, remove and disconnect the main electric supply, maintain the normal temperature prior to attempt for maintenance.

17.What are the expected faults and troubleshooting of the gummy depositor?

Sometimes when operating a gummy depositor machine, you may experience some unwanted problems. Discussed below are the following problems and their solution.

- Connecting Pumps does not work

Connecting pumps help to provide syrup from the cooking unit to the hopper. When transferring of slurry is not achieved properly, it might be due to phase missing or due to pump jamming. Additionally, after completing the process, if the machine is not completely washed, particles of syrups also may stick and dried that lead to cause interruption and induce overloading.

- Solution

To encounter this problem, check the wiring of the machine and clear the connecting pipes with proper washout.

Check whether sticky particles are stuck inside the connecting pipes and clear the debris and excessive particles by washing them using hot water that may dissolve excessive unwanted particles. Check the flow of electric current as well.

Electrical Unit- Gummy Depositor Machine

- Over- Heating of Motor

During the manufacturing process using a gummy depositor machine, you may experience overheating of the motor. This problem may interrupt the smooth running of reaction and productivity. The reason behind this problem may be due to phase missing, overload, or breakage of the motor bearing.

- Solution

To solve this problem you should examine proper wiring and current flow of electric current. You can repair the electric connectivity problems by replacing the old connection with a newer one.

- Cooking Unit cannot Induce Heating

To melt and mix all raw ingredients uniformly, a cooking unit is required that works either by steam heating or electric heating. Sometimes you may experience irregular heating or failure in achieving desirable temperature. That’s due to interruption of heat conduction in steam jackets, In-let valves, or trap valves.

- Solution

To encounter, this problem allows generous draining of water and properly check the valves.

- Inaccuracy in Mixing of Ingredients

Sometimes, you may experience inaccuracy in ingredients mixing and flow. This problem might be occurred due to the slow speed of the gummy depositor machine. Furthermore, this problem might be due to obstruction of ingredients as gelatin may clog the passage.

- Solution

To solve this problem, unclogging of passage is required to facilitate free-flowing movements of raw ingredients.

- Depositor Unit cannot respond

The depositor unit is of prime importance as it helps in the deposition of molding material and allows the proper shape of gummy candies. Sometimes this unit cannot respond. The reason behind this problem is due to failure of motor function or no power supply.

- Solution

To solve this problem check motor wiring, main power supply, and proper functionality of electric motor.

18.Why invest in a gummy depositor?

To invest in gummy depositor may benefit you in certain ways:

- It can improve productivity, innovation, and diversity in the manufacturing of gummy candies.

- Gummy depositors can yield an outstanding quality product in no time.

- A gummy depositor machine can assure precise, robust, accurate, uniform, and smooth gummy candies with reduced downtime.

- It can yield a unique form of eatables with attractive shapes, scents, colors, and flavor.

- On a commercial scale, the gummy depositor can boost high productivity, automation with high revenue.

- This machine is a cost-effective tool for manufacturing gummy candies that allow minimum product wastage.

19.Does gummy depositor comply with international quality standards?

Every piece of equipment from pharmaceutical, nutraceutical, food, and beverage etc., industries require globally assigned quality standards for manufacturing goods.

Hence, gummy depositor machine that is primarily belong to above mentioned sectors of manufacturing unit also complies with the following quality standard such as:

- UL Certification

Gummy depositor machine is well-documented, identified, tested by UL safety and sustainability standards. Moreover, gummy depositor machine is evidently conceivable free from risk of fire, electric malfunctioning or electric shock categorized in a division II environment. Thus, combining a broad safety research, extensive scientific expertise, and excellent focus on the entire quality of gummy depositor machine helps to create a safe production environment.

- cGMP Compliance

Gummy depositor machines, high-quality equipment demonstrated compatibility with assigned requirement of cGMP. Thus, it ultimately renders as a trusted and the most demandable manufacturing equipment.

The entire construction of gummy depositors is made up of stainless steel. therefore, it offers a high-level sanitation and hygiene.

- CE Certified

CE certification is the product manufacturer's claim regarding their product that meets all relevant requirements assigned by European directives and regulations. The assigned regulation outline is related to product safety and performance before they can sell in European Union or EU.

- ISO Certified Machine

A gummy depositor is labeled in EN ISO 140-6 standard, deemed as an assigned manufacturing machine that certifies quality- assurance and standardization.

- FDA Compliant

Gummy depositor machines is an FDA-compliant equipment certifies the following equipment as a highly robust, safe, effective, and properly manufactured with no false parameters.

20.What are the important consideration factors that you should follow before purchasing a gummy depositor?

Before purchasing a gummy depositor machine you should consider certain important factors to get the right choice of machine that can meet your requirements.

- Dimensions of Installation Area

Before purchasing a gummy depositor, the dimension of the working area should be measured properly. This will allow you to select a suitable category of gummy depositor machines. If the working area is confined and limited, then you cannot go for a larger set-up. Similarly, if you have a large surface area for the installation of a machine then you can select a larger manufacturing plant.

- Production Capacity

Before buying a gummy depositor machine, you must assess your production capacity for gummies manufacturing. For instance, small-scale production must be carried out on manual or semi-automatic gummy depositor machines. For high automation and high production batches, the manufacturer must look for a larger gummy depositor plant.

- Budget of Production

To run a business, the manufacturer must know their production cost estimation. If you have a low budget and small-scale production, then always opt for cost-effective tools, such as tablet-top gummy depositor or semi-automatic gummy depositor. Furthermore, the availability of a second-hand gummy depositor machine is also a suitable option for purchasing and initiate your work.

- Power Consumption

Different machines have various power requirements that are entirely depending upon the mode of production. You can assess the power consumption according to a type of machine such as automatic gummy depositor machine has high electric power consumption instead manual or semi-automatic gummy depositor.

Gummy Depositor Machine

Since the development of new products is the lifeline of any manufacturing company, this new addition in the gummy business is constantly rising day by day, for instance, the emergence of marshmallows with gummy candies.

- Conclusion

Consequently, by reading this blog you will be able to assess the importance of gummy depositor machine in food, nutraceuticals, décor and much more.

In this blog, we have discussed the production line, applications, components involved, and all basic mandatory factors related to the gummy depositor. Thus, the above-mentioned details would be helpful and understandable.

Hence it is proved a gummy depositor is mandatory to skyrocket your business and attaining high consumer trust.

Don't forget to share this post!

Gummy Making Machine Related Products

Gummy Making Machine Related Posts

Gummy Making Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine