How to Make Gummy Bears:the Complete Buying Guide for New Beginners

Searching online,you may find there are numerous ways as to how to make gummy bears,but take a careful look,they are just home-made .

If you or your kids are loyal lovers for gummy bears,you may have a try as that.

If you want to do large scale gummy bear manufacturing,there should be delicate equipment combined with clear guidelines.

So,today’s guide is right for you.

Reading through,you will get some of the useful information as to how to make gummy bears,then skyrocket your gummy bear business.

1.What are Gummy Bears?

Gummy Bears-Photo Credit:drhealthbenefits

Gummy bears are fruity gum candies that are very small in size. It has the shape of the bear and its length is about 0.8 inches or 2 cm. However, it is one of the types of gummies (gelatin-based fruity candies present in different shapes, colors, and sizes). They are named “Gummy” because of their origin. They were manufactured in 1922 inspired by the bears which were trained to perform in different festivals.

They were made by using the thickener (Gum Arabic). Riegel, the manufacturer of a gummy bear, named it as Gummibären. This name is used ever since. Gummy bears are available in different varieties and shapes. Gummy bears are prepared in different sizes ranging from the standard size of candies to the bigger bears that may weigh several kilograms.

Haribo gummy bears are available in the US in five different flavors. These are strawberry, raspberry, pineapple, orange, and lemon. Their colors are green, red, colorless, orange, and yellow respectively.

After the success of gummy bears, different companies have started making candies of the shape of different animals. Like sharks, frogs, penguins, lobsters, worms, and snakes, etc. They are made in the shapes of fruits as well like apples, oranges, and peaches, etc.

Sugar-Free Gummy Bears

Sugar-Free Gummy Bears

For some people, the sugar containing gummy bears are health hazards. For example, the diabetic patients cannot take that much sugar, so gummy bears are also available in sugar-free form. The sugar alcohols are used as the alternatives for the sugar as sweeteners. Sugar alcohols are present naturally in different fruits and vegetables but they can also be synthesized artificially. They are used in place of ordinary sugar because unlike sugar, they do not have the affinity to react with the blood glucose levels and they have lower calories content.

2.How will you Benefit from Gummy Bears?

Gummy bears are one of the most favorite snacks in the current era. They are liked by adults and children alike. Whenever you hear the word “Gummy Bears”, the first word that pops up in your mind is “Yummy”. But is it beneficial for you to eat gummy bears? So here is the good news for the gummy bear`s lovers. Gummy bears have some qualities that make them way better than other candies and jellies.

Before talking about its health benefits, we should know about its nutrient content. Gummy bears contain proteins, calories, sugar, carbohydrates, and sodium. Some of the benefits you take from the nutrients of gummy bears are

Helps in Dieting

Unlike other candies and jellies which do not have proteins, the gummy bears have proteins but the quantity is still very small (15 pieces of gummy bears contain about 3g of proteins). Proteins have the property to hold the food in the stomach and thus gives the person a feeling of stomach fullness. In this way, the gummy bears can help you in dieting.

Replenishes the Energy after Workout

The gummy bears have sugar content present in them. When you work out or do any hard physical exercise, the glycogen (stored form of glucose in muscles and liver) level decreases and you need to replenish the level of glycogen. The gummy bears are a great source of carbohydrates and thus can help you replenish your glycogen level.

An important point here is that the gummy bears provide you the sugars in the form of dextrose which, unlike fructose, does not need any breaking down. Thus, the gummy bears provide a faster way to replenish the glucose levels.

Increases the Amount of Insulin

The gummy bears increase the levels of insulin in the blood. This is because the gummy bears increase the blood glucose level and thus leading to a greater level of insulin in the blood.

Source of Minerals and Vitamins

Some gummy bears contain vitamins and minerals and thus they provide your body with these two. Therefore, gummy bears can help reduce the vitamins or mineral deficiency of your body to some extent.

Fat-Free

Most of the time, the gummy bears are free of any fat and thus can be taken without worrying much. As they are fat-free, patients with high cholesterol can also take them.

Gummy Bears -Photo Credit:sugargeekshow

3.Are there any Disadvantages of Taking Gummy Bears?

Although gummy bears have some health benefits everything that is taken in excess is bad for your health. Gummy bears also have some disadvantages on your health. Some of these are described below.

High Sugar Content is a Health Risk

Gummy bears have a very high sugar content and increased levels of sugar are always dangerous for your health. The increased blood glucose levels can lead to diabetes and other serious health issues.

Tooth Damage

Gummy bears or other sticky candies or jellies can stick to your teeth for a long time and thus cause decay of your teeth. High sugar content also damages the teeth. Therefore, it is best for you to properly brush your teeth twice a day or after taking any sugary snack like chocolates, jellies, and gummy bears.

Weight Gain

Although gummy bears do not have fats, they are still a rich source of calories. High-calorie content can cause obesity. If you consume too many gummy bears, there are high chances of you becoming overweight. An overweight person is at a greater risk of getting health issues including cardiac diseases, diabetes, and high blood pressure, etc.

Choking Hazard

Gummy bears are small in size and so they are a choking hazard especially for children. The children may choke them while eating them or playing with them. You should supervise your children and make sure they are sitting instead of playing or running while eating gummy bears. This will greatly reduce the chances of choking and save you from any trouble.

Gummy bears are made from gelatin and sometimes the gelatin may have prions that are very dangerous for the health of cattle and humans. Some prions may cause Creutzfeldt–Jakob disease in humans. CJD is a degenerative disorder of the brain that is fatal most of the time.

These are the disadvantages of taking the gummy bears but they can be avoided if you intake them in a limited amount.

Gummy Bears -Photo Credit:candykitchen

4.What are the Ingredients for Manufacturing Gummy Bears?

For making gummy bears, you need to have the following ingredients.

- Sugar

- Sorbitol

- Glucose

- Flavored gelatin (3 ounces)

- Unflavoured gelatin (1/4 ounce)

- Water(Room temperature) (1/3 cup)

- Corn syrup (1/4 cup)

- Citric acid (1/4 tablespoon) (optional)

Role of the Ingredients

Gelatin

It is used to give your gummy bears a nicer chew. It can be replaced by agar for making gummy bears for vegetarians.

Sugar

You need sugar as it is the main sweetener in gummy bears.

Sorbitol

It gives your gummy bears a better texture. If you do not use sorbitol, your gummy bears will be a bit softer.

Glucose

It gives your gummy bears a chewy texture that makes them look yummy.

Citric Acid

Citric acid is used if you want to make sour gummy bears.

5.How to Make Gummy Bears?

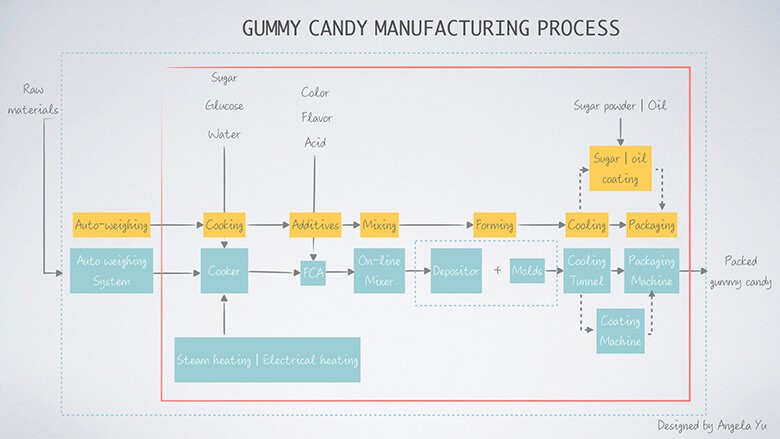

Gummy Bears Making Process(-Photo Credit: isweetech.com

Gummy bears are produced in different steps in the gummy bear-making machine, they are discussed below.

- Collection of Ingredients

For making gummy bears, first of all, you have to gather all of the ingredients mentioned earlier.

- Compounding

During the process of compounding, you need to pour down the ingredients you collected into the mixing tanks of the gummy bear-making machine. These tanks are very large and can mix, heat, and then cool the ingredients.

The time required for the compounding process depends upon the number of gummy bears you want to produce. The ingredients are tested for quality after compounding to ensure that they meet the quality standards. The ingredients are then transferred to the starch mogul machine.

- Trays Stacking

The trays are stacked by the gummy bears formed in the compounding process. These trays then move one by one for further processing.

- Starch Scrubbing

The gummy bears move to the starch buck. Gummy bears are then inverted onto the vibrating sieve. A sieve is a metallic screen that vibrates and scrubs the extra starch off the surface of the gummy bears. The gummy bears are then transferred to the next segment through the conveyor belt for further operation.

- Deposition

After the extra starch has been scrubbed, the gummy bears are then deposited into the mods with the help of the depositor of the gummy bear-making machine. This part has a nozzle so that it easily deposits the gummy bears into the molds. In the advanced depositors, flavors and colors can be added easily.

- Cooling

The cooling process takes place in the cooling room. The gummy bear ingredients are sent to the cooling room of the gummy bear-making machine after they have been deposited into the molds. The cooling process can take up to 24 hours. Starch plays an important role here by absorbing excessive moisture.

- Removing the Bears

After the cooling is done, the gummy bears are removed from the molds. The starch can be reused by the gummy bear-making machine.

Your yummy and delicious gummy bears are ready.

6.What are AIPAK Gummy Bear Making Machines?

AIPAK Gummy Making Machine

Gummy bear-making machines are machines that are specially designed for making gummy bears. It slightly differs structurally and functionally from the candy-making machine. The candy-making machine is slightly smaller than the gummy bear-making machine and is used to make candies that are hard and melts in your mouth. On the other hand, gummy bears making machines make gummy bears that are jelly-like and are softer as compared to candy making machines.

There are different types of gummy bears-making machines. Based on your requirements, you can use the one that suits your business. They are semi-automatic or automatic. They are also available in different sizes and have different production capacities.

Semi-Automatic Gummy Bear Making Machine

It is a partially automatic type of gummy bear-making machine. It does some of the functions by itself but for the rest of the function, it depends on an operator. So, you have to hire some staff for operating this type of gummy bear-making machine.

In case you want to reduce the power consumption, this machine is better than the fully automatic one.

Fully Automatic Gummy Bear Making Machine

AIPAK Fully Automatic Gummy Bear Making Machine

This type of gummy bear making is fully automatic and does all of the tasks by itself and so you do not need to hire more employees for operating this machine. It does almost everything by itself and requires very little human support for its function.

Small Scale Gummy Bear Making Machine

AIPAK Small Scale Gummy Bear Making Machine

It is a small-sized gummy bear-making machine that is very useful if your production requirement is less. This machine is way cheaper than other types of gummy bear-making machines and is the best option if you want to manufacture gummy bears on a small scale.

Medium Scale Gummy Bear Making Machine

AIPAK Medium Scale Gummy Bear Making Machine

This type of gummy bear-making machine is medium-sized and is the best choice if your production requirement is greater than the small-scale production.

Large Scale Gummy Bear Making Machine

AIPAK Large Scale Gummy Bear Making Machine

If you are running a big industry and you have to produce a large number of gummy bears at a faster rate, this machine is the best for you. It is greater in size than the other two types. Although it costs greater than the small and medium-scale gummy bear-making machines, it is best suited for bigger industries.

7.What Other Equipment is Required for the Gummy Bear Making Process?

For making a complete line for the production of gummy bears, you need to have some support equipment besides the gummy bear-making machine to aid in the gummy bear-making process. Some of that equipment along with its function is described below.

1.The Holding Tank

The holding tank is used for storing the ingredients that are used for the production of syrup which is used for making the gummy bears. These tanks are available in a variety of sizes, shapes, and capacities and you can select the one which fulfills your requirements.

2.The Cooling Tunnel

In the jacketed cooker, the ingredients are heated to high temperatures and now you need to cool them down. This task is done by the cooling tunnel. You can cool the ingredients by passing them through it.

3.The Candy Cleaner

Since gummy bears are ready to eat the product, cleanliness is the prime requirement. The candy cleaner will do this job for you. It removes any dust or contaminants from the gummy bears. In this way, you can make them clean enough to become consumable.

4.The Depositor

You need a gummy depositor for delivering and depositing the gummy bears after they have been manufactured. The gummy depositor is so designed that it deposits the gummy bears at the right time and the right place.

5.The Packaging Machine

Once you are done with manufacturing, cleaning, and depositing, you have to pack the gummy bears. The gummy bears packaging machine will do this job for you. This machine packs the gummy bears perfectly.

6.The Coil Cooker Type of Gummy Bear Making Machine

The coil cooker gummy bear making machine is a type of gummy bear making machine that uses a coil cooker for the process of boiling and mixing those ingredients that will later be used for making the gummy bears.

7.The Weigher Gummy Bear Machine

This is a type of gummy-making machine which requires a proper weighing system to weigh the ingredients accurately and then it makes the gummy bears according to the weight.

8.The Cooker (Jacketed)

You need to have a jacketed cooker so that you can melt and heat the ingredients faster. You can melt and heat maltose and sugars by using the jacketed cooker.

9.The Cooker (Jet)

By using the jet cooker, you can heat, melt and mix the ingredients for making the gummy bears.

10.The T Gel Conditioning of Starch

In the process of making the gummy bears, you need proper conditioning of the starch. The T gel conditioning of starch will help you in that.

11.The T Gel Moulding of Starch

For the proper making of the gummy bears, you need proper molding of the jellies and the masses of gums. You can get help from the T gel starch molding for this purpose.

12.The Sander

You can use the sander for coating the gummy bears. Another interesting feature of the sander is that you can use it for starch molding.

13.The Oiler

For the process of lubrication of the gummy bears, you can use the oiler. The oiler will assist you in putting a layer of oil for making it is surface slippery and thus increasing its mobility and lubrication.

14.The Counting Machine

The counting machine will count the number of gummy bears produced. This machine is very accurate and gives you the exact number of gummy bears produced. Thus, you can keep a check on your production rate.

15.The Polishing Machine

The polishing machine will help you clean and polish the gummy bears. Its sieves and brushes vibrate and in this way, it removes the debris from the gummy bears.

16.The Ingredients Mixing Tank

The ingredient mixing tank mixes the ingredients of the gummy bears. They are available in a variety of sizes and you can choose the one that best suits your business.

8.How to Prepare Gummy Bear Ingredients?

The ingredients of the gummy bears can be divided according to their function. These divisions are discussed below.

Active Ingredients

The active ingredient is the most important ingredient in any formulation be it pharmaceutical preparation or anything else. You have to be very careful while preparing the active ingredients of the gummy bears. They are the ingredients that account for the taste and smell of the gummy bears. The amount of the active ingredient required depends on the nature of the active ingredient.

For instance, you can allow more than 15% of the proteins or fibers but cannot allow even more than 0.1% of the substance that may have adverse effects on the health. Active ingredients are also important when it comes to taste masking of those ingredients that have a bad taste.

Gelling Agents

The main role of the gelling agents is to provide stability to the gummy bears. Pectin and gelatin are the most commonly used gelling agents. However, the older and more commonly used ingredient is gelatin. But gelatin is extracted from the porcine and so the vegetarians can not eat gummy bears that have gelatin as a gelling agent.

For this problem, the solution is very simple, you can use pectin instead of gelatin as a gelling agent. Pectin is extracted purely from plant sources and so can be eaten by vegetarians without any hesitation. Blended with carrageenan or gums, agar can also be used as a gelling agent. Agar is also extracted from plant sources.

Sugar-Free Ingredients

Sugar free gummy bears

Although most of the gummy bears have corn syrup and beet sugar, some sugar-free ingredients can be used to replace them with sugar-free ingredients. Nowadays, the most demanded sugar-free ingredient is inulin. The inulin is extracted from the roots of the chinchory plant. By using sugar-free ingredients, you can make your gummy bears easily edible for diabetic people as well.

9.How to Mix Gummy Bears Ingredients?

For making the perfect gummy bears, you have to mix the ingredients perfectly. Here is a guide for mixing the ingredients of the gummy bears. First of all, you have to mix the gelatin with water or juice and stir it well to make a mixture. Then leave the mixture for about five minutes so that gelatin absorbs the maximum amount of the liquid. Your gelatin mixture is ready.

Now take a saucepan and mix sugar and sorbitol (and corn syrup too if you are using it). After that, you need to add your gelatin mixture and heat both the mixtures until both of them melt. Leave this mixture for about ten minutes. You will see foam rising to the surface of the saucepan.

Then leave this mixture for a few minutes and then add your flavoring to it. After the addition of food flavoring, the last step is the addition of the coloring. You can add any color of your choice.

However, working with a gummy bear-making machine makes it much easier. The mixing tank has mixers that help in mixing the ingredients. You just simply put the ingredients in the compounding chamber of the gummy bear-making machine and it does everything itself including mixing, heating, and cooling.

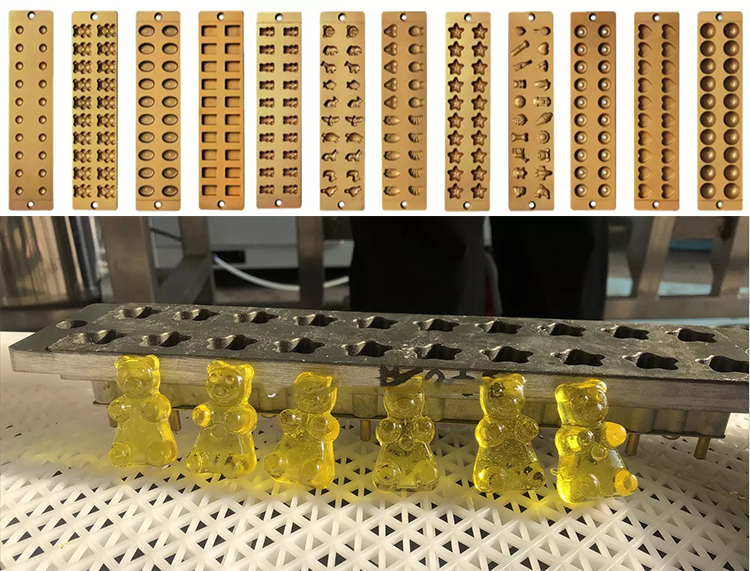

10.What should you do to Make Different Shapes of Gummy Bears?

Different Shapes of Gummy Bears

You may think of making your gummy bears in different shapes. A question may arise in your mind: Is it possible? So here is a piece of good news for you that yes it is possible. Gummy bears are made by making the mixture and pouring that into the mold and the mixture takes the shape of the mold and making gummy bears of the shape of the mold. You can use molds with increased flexibility to make gummy bears of different shapes. The enhanced starch molding will allow you to make gummy bears of different shapes and sizes. So you can make gummy bears of any required shape.

11.How to Cool Gummy Bear?

Cooling of the gummy bears is as important as any other step involved in the making of the gummy bears. After putting your mixture of ingredients in the molds, you have to cool them so that your gummy bears become perfect for serving. Perfect cooling is necessary because it ensures that your gummy bears attain the right shape and they are ready to serve or pack. You can use a refrigerator or a cooling room for cooling the gummy bears.

Normally they are cooled in six hours and can be used after that but the cooling of 24 hours is recommended for perfect cooling of the gummy bears.

12.How to Unmold Gummy Bears?

After you have finished making and cooling your gummy bears, you have to remove them from the molds, the process known as unmolding. The molds of gummy bears are usually made up of silicone and are thus flexible. The flexibility of the molds makes the process of unmolding easier.

For removing the gummy bears from the molds, you need to gently push the sides of the molds and then apply the force towards the center of the mold and then you have to pull the gummy bears upward, removing them out of their molds. For unmolding the gummy bears, you have to be very careful as any mistake can affect the shape of your gummy bears and thus making them unpresentable.

It must be noted that you must use a silicone mold because it provides flexibility and eases the unmolding process. On the other hand, if you use a plastic mold, it will mess up the whole process and you would not be able to unmold the gummy bears perfectly. Therefore, for better unmolding of the gummy bears, you need to take care of both things; the type of mold and the unmolding process.

13.How to Dry Gummy Bears?

The drying process for the gummy bears is very important as it makes your gummy bears chewy and hard. However, you have to be very careful because if you dry out gummy bears more than the required amount, they will become too hard and if you fail to dry them out properly, they will be much softer than standard.

You need to dry the gummy bears after they have been unmolded because at that time they are too soft to enjoy. For drying the gummy bears precisely, you have to place them standing on a table or any other surface at which they are exposed to the air to the maximum extent. You have to leave them in that position for a couple of days. After that, you have to leave it lying upright on the same surface for one day. Now your gummy bears must be chewy enough to be eaten and enjoyed. Gelatin plays an important part in drying the gummy bears by absorbing their moisture content.

The more you dry the gummy bears, the chewer they become. Once you feel the gummy bears are chewer enough to be eaten joyfully, you should pack them in an air-tight container. In the gummy bear-making machine, all this is done by the conditioning system. The conditioning system pumps hot air onto the gummy bears and thus drying them out.

14.How should you Clean Gummy Bears?

Hygiene is the basic requirement for any edible product. Gummy bears are also ready to eat the product and so they need to be clean and germ-free. For this purpose, you have to clean your gummy bears after they have been manufactured. This important task is done for you by the candy cleaner. The candy cleaner removes any dust or contaminant that the gummy bears may have contacted during the whole process of making, heating, and cooling.

The polishing equipment also plays its part in cleaning the gummy bears. It removes any dust present on the gummy bears and also polishes the surface of gummy bears. Despite the presence of candy cleaner and the polishing equipment, which will clean gummy bears, you should make sure that you manufacture the gummy bears in a sterile environment.

15.How to Coat Gummy Bears?

AIPAK Gummy Bears Sugar Coat Machine

Gummy bears usually have a coating of solid dry sugar. There can be different purposes for coating the gummy bears. In order to give your gummy bears a wet look, you can coat them with a 1:3 ratio of citric acid to sugar. If your gummy bears are sticky, you can coat them with a layer of cornstarch which makes them less sticky. The coating process is done by the gummy bear-making machine itself. You can adjust the coating process according to your needs and the coating is done accordingly in the starch mogul.

16.How to Sort Gummy Bears?

Sorting the gummy bears is an important and crucial process. You need to separate the gummy bears of different sizes, colors, and shapes from each other. This task is done by the digital sorter of the gummy bear-making machine. The digital sorter is mind-blowing innovation that can sort the gummy bears even by the coating material. If this thing is done by a human being, it will never be this quick and accurate. Digital sorter has made this tough task very easy.

17.How to Quality Control Gummy Bears Manufacturing?

During the process of manufacturing the gummy bears, you wish to have better quality control. For quality control, you need to check the quality of the raw materials used. The ingredients or raw materials are tested in the lab. Their color, appearance, smell, particle size, pH, and flavor are the things that are tested in the quality control lab. You also need to test the quality of the end material i.e. the manufactured gummy bears.

The common and traditional method of quality testing is a comparison of the required sample to the standard. A standard is set and you can check the quality of your sample by comparing it with that sample. For example, for testing the flavor of the gummy bear, you have to compare it to the standard. However, the more accurate method is the use of sensory panels. The sensory panels have a group of parts that have the ability to detect small details of the ingredients or products so that you can better analyze any difference present.

18.How to Package Gummy Bears?

The packing of the gummy bears is also a very crucial process. This job is done efficiently by the packaging system of the gummy bear-making machine. After you are done making your gummy bears, the packaging machine comes into action and packs the gummy bears. This is an advanced system that is fully automated and does all the packaging without requiring any human assistance. It can open the seal of the packing, fill the accurate number of gummy bears in it and then seal the packing. In this way, you can easily pack your gummy bears.

19.How to Preserve Gummy Bears?

Preservation of anything is important as it increases its shelf life. For preserving the gummy bears, you need to focus on their packaging material and storage conditions.

Packaging Material

During the packaging of gummy bears, you need to check that whether a certain substance is good enough for preserving your gummy bears for a longer time. You should prefer using polypropylene plastic bags as they are impermeable to oxygen and thus can preserve your gummy bears for a longer period and thus increasing their shelf-life.

Storage Conditions

You should prefer storing your gummy bears in a cool and dry place. The reason behind this is the fact that at a higher temperature, gummy bears will melt and in the presence of moisture, they are more viable to the microbial attack.

20.What are the Common Problems During the Gummy Bears Making Process? How to Solve Them?

Like any other machine, the gummy bear-making machine also does some problems sometimes which may be due to different reasons. Some of these problems, along with their solutions, are discussed below.

1 Improper Ingredients Flow

You may experience a lack of proper flow of the ingredients of gummy bears through the gummy bears-making machine. This problem may occur due to two reasons;

The first reason can be the blockage of the passageway of the ingredients. The passage may be most probably blocked by the ingredients themselves or maybe because of some other substance. You can easily solve this problem by unblocking the passageway. By doing this, the ingredients will not face any hindrance anymore and so they will be able to move or flow throughout the gummy bear-making machine without any lag.

The second reason can be the speed of the machine. If the machine is set at a lower speed, the ingredients will not be able to reach the right place at the right time, and in this way, it disturbs the whole process of gummy bear production. This problem can be easily sorted out very easily by adjusting the speed of the machine to an ideal point. This will help you optimize the whole process.

2 Jelly-Like Final Product

You can also face the problem of insufficient quality of the gummy bears. Your gummy bears might be jelly-like if you are unable to mix the ingredients precisely or if any problem occurs during the process of manufacturing the gummy bears. This problem can be solved by accessing the origin of the problem. You have to find out where the machine is not working properly and by adjusting all the parameters of the machine accurately, you shall get rid of this problem as well.

For getting the perfect results from the gummy bears making machine, you have to take great care of the machine. It requires proper and regular cleaning and maintenance of the machine. For the purpose of maintaining. You have to keep a check on every part of the machine and make sure that every part is doing its work perfectly.

For cleaning the machine, you have to disconnect it first so that it gets cool. Then you have to get the parts of the machine removed. Then you have to thoroughly clean each and every part and then you have to assemble all the parts again. The parts must be assembled precisely and the machine must be tested (after cleaning) before doing any further operation.

21.How do you Optimize the Gummy Bears Making Process?

Optimizing the process of gummy bear production means increasing productivity and attain maximum efficiency so that you can have maximum production.

For this purpose, you have to do the following things.

Increase the Flexibility of Starch Moulding

The increased flexibility of starch molding will enable you to manufacture the gummy bearshttps://www.icapsulepack.com/gummy-making-machines/ in different varieties. It allows you to make gummy bears of different shapes and sizes. You can also make multi-colored gummy bears. Therefore, the enhanced flexibility of starch molding will help you satisfy all your customer requirements. Another benefit of increased flexibility is that you can make a variety of confectionery items like marshmallows.

Advanced Technology for Coating

The recent technology is so developed that it can coat the gummy bears all by itself. In the traditional method of coating, there were greater chances of drenching the gummy bears. Advanced technology does not allow this thing to happen. It coats the gummy bears through a special technique and so the chances of drenching become negligible. This advanced system is also very fast and thus saves your time, increasing the overall output and productivity of the gummy bear making process.

Efficient System for Packaging

You should look for an efficient system for the packaging of your gummy bears. An efficient system is that which will provide you a precise and accurate packing at maximum speed. Packing should be of good quality as this plays a very important role in the preservation of the gummy bears.

Preparation for Growth

For retaining your name in the ever-evolving market, you should always be ready and prepared for growing and adapting to the new things that emerge in the market.

Digital Sorter for Gummy Bears

Digital sorter is a new addition to the technology of gummy bears making machines. This system automatically sorts and then removes any foreign substance that got entry into the gummy bears during the production. In this way, it helps you improve the quality of your gummy bears. This machine is so efficient that it can sort the gummy bears based on their coating. It can also differentiate the gummy bears according to their sizes, shapes, and colors, etc.

Gummy Making Machine Related Products

Gummy Making Machine Related Posts

Gummy Making Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours