Gummy Bear Machine:the Complete FAQ Guide in 2025

Gummies are the most popular item among the confectioners, mostly they are small candies weights around 2.5g to 3.5g, but can be the bigger one. They are chewable products with no gum inside.

Have you ever wonder how such gummies are made in different shapes and colors. There is a proper machine that makes these gums according to your requirements.

You will be amazed to know that it is one of the most demanded machines, and you can increase your sales by both hands through the use of this machine.

Let’s embark on the journey of buying a perfect Gummy Bear Machine to fulfill your all requirements. By the end of this blog, you will be aware of all the aspects of a Gummy Bear Machine and will make your decision of buying.

Q1.What is a Gummy Bear Machine?

AIPAK Gummy Bear Machine

Gummy Bear Machine is an automatic machine that uses a PLC control system to make gummies of different shapes, textures, sizes, and colors from a number of different ingredients mixed in definite proportion. The machine has the specialty of producing high quality products. Because of increasing demands of gummy bear products, the machine has become an important equipment in industries including pharmaceutical, confectionary, food industry, nutraceuticals and other relevant industries.

Q2.What are the advantages of using a Gummy Bear Machine?

The development in science and technology has led to great inventions and gummy bear machine is also one of such inventions. It has a number of useful aspects, I am going to describe you few of them.

Gummy Bears

- Being a competitive manufacturer quality is your priority. You will never going to compromise over your quality. So this machine is one such equipment that will going to give you high quality products.

- High number of production of good quality products is the need of market, to stay in the market you must meet the production demands of the consumer and overall market. So this machine will going to benefit you in terms of high production rate.

- Time is money, the manufacturers are always in hunt of high quality production in minimum time period. This machine is capable enough to produce thousands of candies in a very less time.

- This machine is capable of performing work of high human labor, so it benefits you by saving your labor cost.

- Variety of products is another important feature of this machine. You can produce different gummy candies, multivitamins, supplements, honey gummies, medicated and functional gummies, THC and CBD gummies. This huge variety of products will surely increase your profit share of the market.

- The biggest advantage of this machine is that it doesn’t cause trouble of cleaning and high maintenance. All parts of the machine are removable so you can easily clean them individually.

- Greasing of all the parts is the only maintenance that this machine requires.

- The machine has been manufactured by the high quality stain less steel so you don’t need to worry about the damage of the machine. It is also resistant to corrosion.

All these useful aspects makes this machine a must have equipment for you to grow and excel in the industry.

Q3.Are there any disadvantages of using a Gummy Bear Machine?

Like any other equipment this machine too has some drawbacks, so before purchasing the machine you should be fully aware of these drawbacks to avoid any issue later on. These drawbacks include:

- The machine works on a touch screen PLC control system, so you must have a fully trained personal to operate the machine. Any kind of mishandling can result in great loss in terms of time, money, and production.

- This machine costs you a little more than the usual, it will be a lifetime investment for your industry. So at first you have to pay a big amount of money.

- The installation of this machine is also a little tiresome process so you also need to invest on its installation.

Irrespective of these drawbacks, the machine is a great value for money. Your growth in the gummy industry will surely be impacted by this machine.

Q4.What ingredients are used for making a gummy bear candy?

The process of making gummy bear candies is very interesting. These products are made through the careful mixing of different ingredients in definite quantities. They are usually made by food scientists and chemists. It is very important to observe the different characteristics like shapes, sizes, taste, colors, odor, texture and consistency of the product. All these characteristics are important in the quality determination of the product.

The list of ingredients include:

- Sugar:

It is used as a major sweetener in gummy candies. But besides sweetness, it will also give texture to your product. It is also used as a preservative as well as a coloring agent for candies.

- Water:

It is a solvent in which all other ingredients are mixed. It will also provide lubrication to your product.

- Glucose Syrup:

It is used to increase the flavor of candies, and it also prevents the sugar from crystallization. It will make the candies soft and gives them a volume.

- Gelatin:

Gelatin

It is a chemical that is obtained from boiling different parts especially the skin, horns, and bones of animals for a longer period. This itself is an odorless, colorless material, and is elastic thus gives the perfect elasticity to the product.

- Flavor:

These are used to give an edible and pleasant taste to the candies. Commonly used flavors include strawberry, lemon, orange, and raspberry.

- Starch:

It gives the bulk to the gummy candy and also ensures the health safety benefits of the product.

- Food Color:

These are used to give appealing colors to the gummy candies depending upon the flavor of the candy.

- Citric Acid:

It has antimicrobial properties, it protects the candies from bacteria by lowering the PH of the gummy candy. It is also used as a preservative.

Q5.What are the major components of a Gummy Bear Machine?

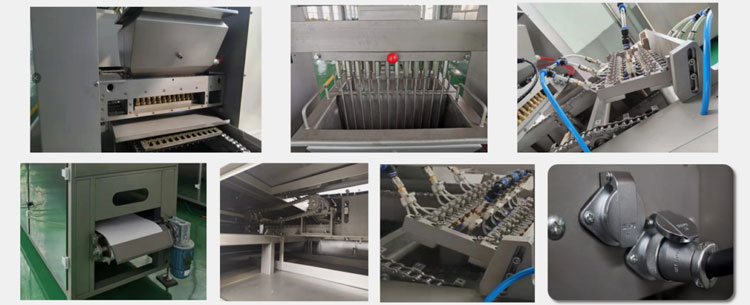

Parts of AIPAK Gummy Bear Machine

The machine is made up of combination of different parts, all these parts are arranged in such a way to perform their specific function. The machine is multitasking thus it has many different units. Each unit has its own specifications, and the collective action of all these units make the perfect gummy bear product. Here I will describe you the important parts of a gummy bear machine. These includes:

- Cooking Compartment

- Mixing Unit

- Deposing Unit

- Cooling Compartment

- Conveyer Belt

- Electric Box

- Molds

- Lubrication units

- Pressure Control system

- Sensor System

- Dumping System

- Cooking Compartment:

Gummy Making Machine Cooling tunnel

This is a huge compartment consists of different small parts like tanks for dissolving sugar, pectin, gelatin and other ingredients. This part has an attached PLC control system to allow you to check the temperature of mixture while the machine is working. A container for mixing of different ingredients is also present in this part. There is a double layer tube and an ejecting pump that pipes the prepared mixture in the hopper.

- Mixing Unit:

Gummy Making Machine storgae mixng tank

This unit has small tanks that helps in the uniform mixing of ingredients. It saves you from the labor of mixing and an accurate quantity of uniform mixture is supplied to dumping unit.

- Deposing Unit:

Gummy bear machine Depositing machine

The mixture is molded in different shapes and sizes in this unit.

- Cooling Compartment:

The product formed has a quite high temperature that needed to cool down for further action. In this part of the machine cool air is puffed on to the candies. It helps the gummies to retain their shape and it make them chewable.

- Conveyer Belt:

Conveyor belt

The formed candies are transported to other units through conveyer belts.

- Electric Box:

Part Marking-Electric components

This unit is responsible for the main energy supply to the machine. It also has a PLC control system that runs the machine. This unit is very important in operating the machine.

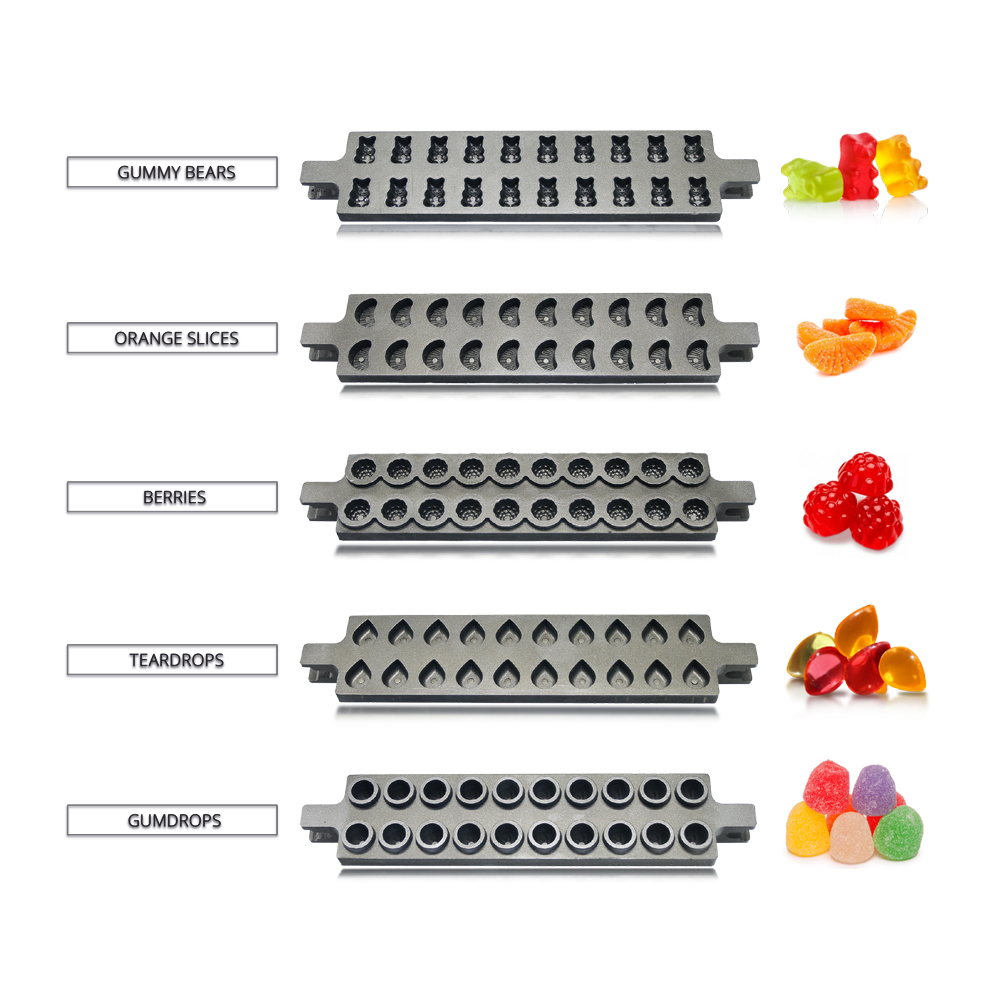

- Molds:

Different molds

Different kind of molds are used to give different shape to the gummy candies. These molds are made up of temperature resistant materials like alloy and silicon, and they have a high thickness to allow the candies to attain the required shape.

- Lubrication Units:

This part is involved in the oiling of different parts of the machine to protect them from the damage of friction. Also lubrication is necessary for maintenance of parts of machine from being worn out.

- Pressure Control System:

There is a special pneumatic system to control the air pressure of the machine. This system adjusts the air pressure as required by the machine for its proper working.

- Sensor System:

The machine has special sensors attached with it to check for any abnormalities. Whenever there is something out of the way happens, the machine immediately stops working. It checked the quantity of the coming mixture and warns in case of excessive quantity. Also it keeps an eye on the quality of the final product.

- Dumping System:

Any extra starch, sugar or coating is removed from the candies through the action of oscillating brushes. And all this extra material is collected the dumping section of the machine, from where the excessive starch is checked for further use.

Q6.What is the working principle of the Gummy Bear Machine?

The working process of the Gummy Bear Machine is somewhat technical and needs your proper attention when the machine is in its working stage. I am going to give to step understanding of how the machine works. The different working stages of a Gummy Bear Machine are:

- Preparatory Phase:

The first and the foremost important step in the preparation of the machine as well as the preparation of the ingredients needed for the production of gummy candies. Check if the machine is in its proper working condition, all the parts of the machine are intact.

Next, you will carefully measure the ingredients and will properly mix them. You will set all the parameters using a touch screen control panel.

- Mixing Phase:

This is also called as compounding phase. The ingredients will move from the hopper to the mixing and melting tank of the machine. These tanks have properties of heating, melting mixing, and stirring of the ingredients. The machine will take up to three or more hours to carry out this action depending upon the quantity of the ingredients.

- Testing Phase:

In this stage, you will test the mixed ingredients in the laboratory to check if it meets your requirements. It is very important for the health safety of consumers.

- Gummy Candy Formation:

After testing the material will be pumped from the mixing tank into the molding tank, here the starch will mix with the ingredients. This will improve the texture of your product, and prevents it from sticking to the walls of the machine. It also holds the product intact during the molding, drying, setting, and cooling phase. At this stage, the product will take the shape of different animals like bears, fish, or different fruits.

Then the candies will move along the conveyor belts of the machine to reach the next destination.

- Finalization of Products:

The candies that fall in the sieves when they reach the starch buck will be decorated according to the requirements. Also, all the extra starch will be clean through the movement of oscillating brushes.

Then the product will be moved to the inspection machine to check for the damaged candies, and then it will send to the sorting section and will be sort according to their shape and sizes. And finally, it will move to the packaging machine.

Q7.What are the different types of Gummy Bear Machines available in the market?

There are different types of the gummy bear machines available in the market. Each type has its own specifications, advantages, disadvantages. So, before purchasing a gummy bear machine you must account the type of the machine you need depending upon the requirements of your industry.

The two main types of the gummy bear machine are:

- Semi-Automatic Gummy Bear Machine

- Fully Automatic Gummy Bear Machine

I am going to give you a brief overview of both of the types so that you can have knowledge of the both of the types.

- Semi-Automatic Gummy Bear Machine

This machine is not a complete automatic one. You will need little help from the human labor to complete the process of the production. Although the machine is designed to perform a lot of functions on its own, but some processes require your assistance. This machine will be helpful in small scale industry where there is low production demand.

- Fully Automated Gummy Bear Machine

Fully Automated Gummy Bear Machine

This is the product of modern age, it is completely automatic machine with a PLC controlled system to manage the operations of the machine. Only a single trained technician is enough to operate the machine. After giving the instructions at the PLC system you just need to monitor the process of production.

The fully automatic system saves your cost of human labor and also has high production rate in minimum time. Thus, it is very useful in large scale industries.

Q8.What are the industrial applications of a Gummy Bear Machine?

Gummy Bear Machine finds its uses in the pharmaceutical industry, nutraceuticals, as well as in the Food industry.

- Nutraceuticals:

Nutraceuticals are the substances that play an important role in the control, prevention and treatment of different ailments. All these substances come in the form of supplements and vitamins that are chewable candies that are made with the assistance of the gummy bear machine.

- Food Industry:

Food industry is a huge industry and everyday food scientists come up with new and different products to compete in the market. And gummy bear products contributes high revenue to this industry. Thus, this machine has a huge role in food industry. Food technologists are making very interesting products using this machine and thus increasing their sales.

The use of this machine is very evident in the food processing industry, you can make different candies from this machine that may be used for different purposes.

Q9.What quality standards are necessary for a Gummy Bear Machine?

There are few quality assurance standards that are necessary to check before buying a Gummy Bear Machine. These standards are important for your safety and for the permanency of the machine.

You can always check for the following quality standards.

- Food and Drug Administration:

This is an important organization that will give the certificate of safety to the machine. Thus, it guarantees that the machine is safe for the production of the gummy bear products.

- CE Standards:

It regulates the electric supply standards and gives the certification for electric safety of the machine. This is very important standard for life and health safety of the machine buyer and operator.

- cGMP Standards:

It is another standard that guarantees about the manufacturing standards of the machine, its certification is important to prove that manufacturing of the machine is according to current quality standards.

- ISO Certification:

International Standards Organization Certification confirms that the machine fulfill are required international laws and qualities.

These quality standards may vary according to the region of manufacturing the machine. As some countries have their specific quality regulation authorities. Despite everything, you should always check the specifications of the machine by performing a quality control test to ensure the size, flavor, color, texture, shape, and consistency of the production material.

Q10.What kind of problems may arise in a Gummy Bear Machine?

The productivity of the machine can be greatly affected by any kind of the problem that may arise due to mishandling of the machine. These problems needs to be checked as early as possible so that to avoid the loss in productivity.

Here I will brief you about some of the common problems of a gummy bear machine along with their solutions.

- Improper Gummy Bear Candies:

There will be production of damaged gummy bear candies and the sole reason for this is the improper arrangement of the different parts of the machine. All the parts of the machine are separated from each other and they require proper alignment before the operation.

So, the simple solution to this problem is checking the arrangement of all the parts of the machine and fix the misplaced part if any. In this way, you can avoid the production of the damaged candies. One thing is important here that is to seek the guidance from the guide book for the arrangement of different parts.

- Hindrance during the Flow of Ingredients:

The flow of substances through the machine is very smooth and any disturbance in the flow accounts for the problem. The reason for the improper flow rate may be the slow speed of the machine or there may be some kind of material deposition at the outlets of the machine.

So, using a PLC control system you can easily adjust the speed of machine according to the required rate of the production to avoid any problem during the process. And if there is blockage of substances then you must have to clear it first.

- Jelly like Consistency of Gummy Bear Candy:

The gummy bear products have their required consistency that is not too hard nor too soft. But if there is some kind of problem in the mixing of the substances or the quantities of ingredients aren’t rightly measured then it will give more jelly like soft products.

This problem can easily be solved by taking the right proportions of ingredients and then efficiently mixing them.

Q11.How you can maintain a Gummy Bear Machine?

With the passage of the time the machine requires cleaning and maintaining of its parts to improve efficiency and life of machine. It is advisable to do regular cleaning of the machine as,

Regular cleaning of the machine is essential for high efficiency and error-free results. It also prolongs the life of different parts of the machine and protects them from any kind of damage.

The cleaning of a Gummy Bear Machine can be carried out in the following ways.

- First, you will need to cool down the machine once the main power supply is disconnected.

- You will carefully disassemble the different parts of the machine for cleaning purposes. For the disassembling of different parts always use the right tool, you may seek help from the manual guide provided with the machine.

- With the help of detergents, chemicals, water, and cloth you will clean the different parts of the machine. Always use the chemicals and detergents in the right proportion. The stubborn stains can be removed by soaking in water and detergent mixture for some time and then cleaning with the cloth. In the end, you dry clean each part of the machine with a dry towel.

- If any part of the machine is damaged then you must need to fix it or replace it with a new part.

- You should grease the moving parts of the machine to avoid damage from friction during the operating process of the machine.

- When you are done with the cleaning and are satisfied with the cleaning process, then carefully assemble the parts of the machine at their right place.

Always remember to seek expert advice in case of any technical issue.

Q12.What is the future of the Gummy Bear Machine?

The increasing demand for gummy bear products needs to be fulfilled by a better and high-performance machine.

- At present there is a problem of explosion hazards during the process of drying the starch, hence experts are trying to fix this problem by using spark-proof switches and blast walls.

- The technicians are also trying to add new flavors and formulas in the gummy bear machine to increase the quality of products as well as to introduce new products at the same time.

- Also, the experts are working on the control of microbial activity of products of the gummy machine to ensure safety standards.

- All these major and some minor improvements in the system of the machine will make it a better choice for industries.

- Experts are also working on the development of a machine that will provide products in the combination of gummy candy and marshmallow candy.

Some Technical advancements are also under consideration to enhance the uses of the Gummy Bear Machine. These include:

Introduction of smart sensors that will help the machine to sense and reject any foreign material during the production. It will surely increase the accuracy and efficiency of the machine.

To increase the speed of the gummy production a device called SiMoGel is introduced in the machine that will replace the starch moguls with silicones and blisters thus improving the speed of the machine five to ten times.

Q13.Why you should invest in a Gummy Bear Machine?

gummy bears

Gummy bear is one of the most demanding items of the confectionery industry, it is equally popular among children and adults. Its industry is the fastest growing industry of the future because of the high demand for gummy candies, gummy vitamins, honey gummies, CBD gummy bears medicated gummies, THC gummy bears, and functional gummies. So it will be a wise decision for you to invest in the Gummy Bear Machine because of the following reasons.

- It gives you high production in a shorter period.

- It doesn’t compromise the quality of the product.

- You can create many interesting products of different shapes, sizes and, colors from this machine and can increase your sales.

- It saves you from the wastage of raw material.

- For a high scale industry, this machine is very useful in earning profits.

- This machine is completely hygienic thus ensures health safety of consumers

- It is quite inexpensive equipment that benefits you a lot.

- The up-gradation of the machine also costs less.

Conclusion:

Now that you have fully understand the basics of the Gummy Bear Machine, you can make your decision.

Gummy Making Machine Related Products

Gummy Making Machine Related Posts

Gummy Making Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours