AIPAK Granulation Line For Solid Dosage Form

AIPAK granulation line for solid dosage form is a single-frame solution that integrated drying and granulation for all pharmaceutical solid dosage forms production, is a common technique in the production of pharmaceutical solid dosage forms to improve the flow properties, homogeneity, and compressibility of the powder mix.It also can be called oral solid dosage granulation line,solid dosage granulation line,solid dosage granulation of tablets.

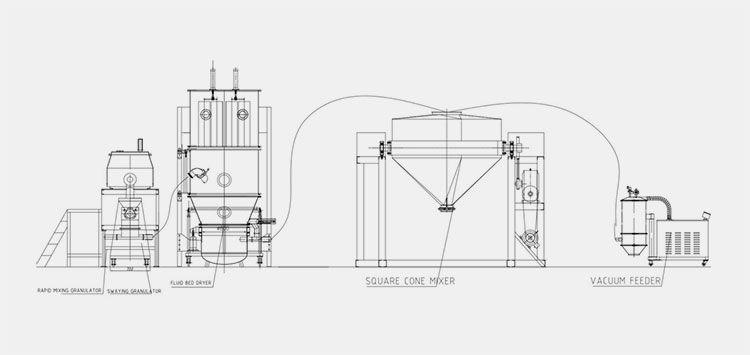

The granulation line for solid dosage form is made of conical mill/wet granulator,fluid bed dryer/granulator,lifting column/hopper elevator,dry conical mill,vacuum conveying system.With the granulation line for solid dosage form,it will help you reducing your space requirement in your cleanroom and minimizing the risks of cross-contamination while ensure you a fine-powder heterogeneous mixture that will turn into a uniform granulation with increased particle size and higher density.

The high shear mixer granulator and dry conical mill often installed together as the high shear mixer granulator will directly transfer the wet granules into the fluid bed dryer.The fluid bed dryer is the granulation line for solid dosage form will not only perform the function of drying,but also do the function of a liquid spray granulator.It inetgrates the fnction of granulation machine,granules coating machine and drying machine.

Due to the high-quality requirements of the formed granules in terms of content uniformity and physicochemical properties,AIPAK granulation line for solid dosage form will be your best choice,it is available in capacities ranging from 45L to 1500L that also can carry two different processes.

The Buyer's Guide

Granulation Line for Solid Dosage Form: The Complete Buying Guide In 2025

Granulation is a must for solid dosage formulation. It is essential in transforming raw particle materials into spherical granules. For granulation, pharmaceutical and other manufacturing industries adopt granulation line for solid dosage form. It is a comprehensive setup that is pivotal in altering fine powders into granules.

The granulation line for solid dosage form boosts the compressibility and homogeneousness of powders. This line also improves the packaging of granules and prepares coating materials. It caters to the demands of both small- and large-scale industries.

First, read this all-inclusive guide “Granulation Line for Solid Dosage Form: The Complete Buying Guide In 2024” before setting up your plant. This guide will offer a detailed answer to your queries regarding the subject.

1.What is the Granulation Line for Solid Dosage Form?

Granulation Line for Solid Dosage Form- Picture Courtesy: World Pharma Today

A granulation line for solid dosage form is an integrated line of machines that perform the related tasks associated with generating optimized and pharmaceutically based granules. You must know that granulation is not a one step process though it is connected with series of methods. For that, a number of machines are integrated to bring the following task readily efficient for pharmaceutical preparation.

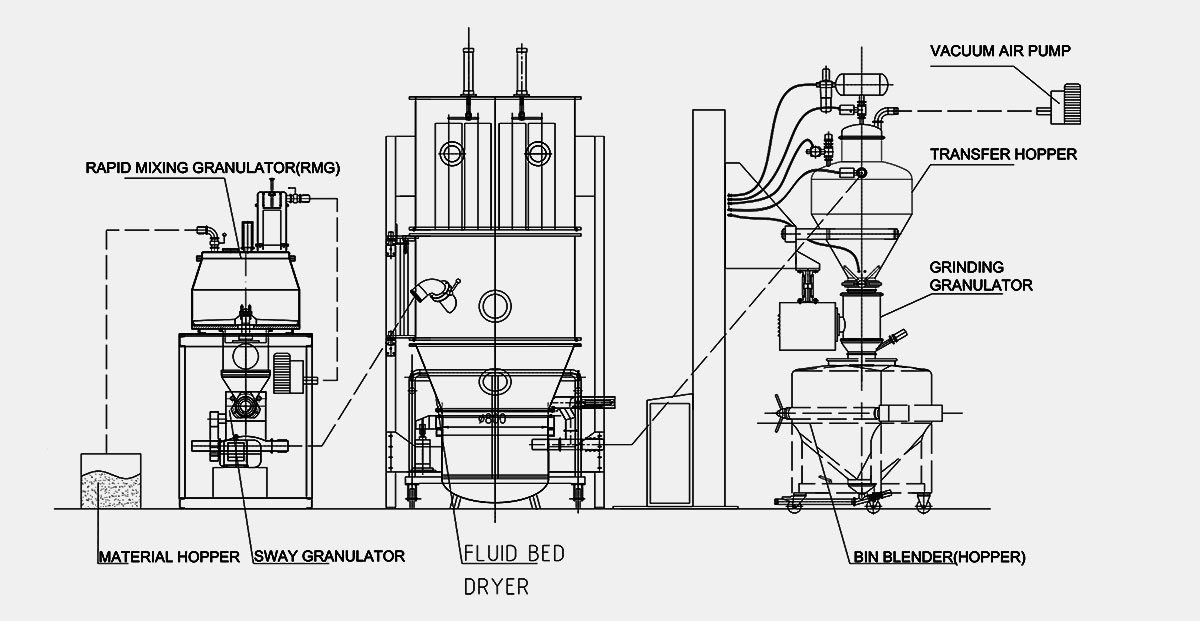

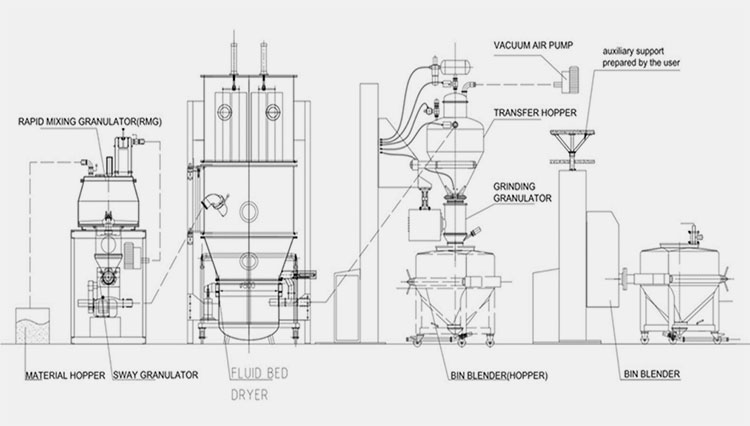

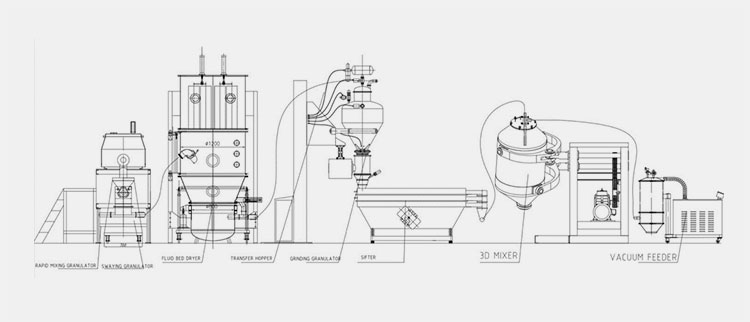

A flow chart of granulation line for solid dosage form

The advanced system which begins with material hopper for the charging of raw material and composed of broad series equipment such as granulator, dryers, sifter, high shear mixers, blender, and vacuum feeder. This production line is involved in agglomeration and particle enlargement. It transforms raw materials into dust-free and easy-to-compress spherical granules.

2.What are the Benefits of Granulation Line for Solid Dosage Form?

Manufacturers opt for different machines because of their various advantages and the granulation line for solid dosage form is no different in this perspective. It is found in different industrial sectors because granulation leads to efficient manufacturing. It is adaptable and essential in producing high-quality ingredients. Let’s explore some advantages of a granulation line for solid dosage form.

Better Flowability

Better Flowability- Picture Courtesy: Healthline

The granulation line for solid dosage form is vital in improving the flow of powdered materials by transforming them into granules. The powders tend to clump together, causing bridging and rat-holing. But this production line increases the particle size, while reducing the surface area of powders for clumping, therefore enhancing product flowability. This is essential for tablet compression.

Accuracy in Dosage

Accuracy in Dosage

Uniform mixing of active ingredients has a pivotal role in the accurate dose. This is linked with better drug response and safety. For homogenous mixing, a granulation line for solid dosage is routinely employed in the industries. Also, it has a noteworthy part in reduced segregation, which is essential in upholding the consistency of the mixture.

Minimized Dust Production

Minimized Dust Production

Processing of fine powders generates huge quantities of dust but with the application of a granulation line for solid dosage form, dust production is significantly decreased. This improves the safety of the production line and reduces the dust inhalation risk. Moreover, cross-contamination between batches is also minimized because of less powder dust generation.

Enhanced Solubility

Enhanced Solubility- Picture Courtesy: Pharmaceutical Technology

By changing powders to granules, the granulation line for solid dosage form also contributes to better solubility of poorly soluble active ingredients. This leads to better bioavailability of drug materials.

Better Stability

Better Stability- Picture Courtesy: New Scientist

This production line is also significant in stabilizing the active ingredients. Exposure of drugs and excipient materials to environmental agents like moisture, air, and light is reduced by the granulation process. This lengthens the shelf-life of the granule products.

Short Production Time

Short Production Time- Picture Courtesy: Epodex

The granulation line for solid dosage is highly efficient, processing high-volume batches in short duration. This production line is much faster than other mixing equipment. This is highly beneficial in boosting product quality, swift production time, and less energy consumption.

3.In What Industries Granulation Line for Solid Dosage Form is Applicable?

The granulation line for solid dosage form has a specialized role in different industries because it forms homogenous granules. Some of its industrial applications are stated below:

Pharmaceutical Industry

Pharmaceutical Granulation- Picture Courtesy: saidsupport

It is the primary industry, where granulation line for solid dosage is applied. Granulation assists in smooth tablet compression and encapsulation. This production line produces consistent-sized granules that have better fluidity and bonding. Furthermore, it minimizes the risk of powder separation, resulting in more homogeneously dispersed ingredients.

Nutraceutical Industry

Nutraceutical Granulation- Picture Courtesy: Mother Earth Living

This industry also employs granulation line for solid dosage form because of its inherent advantages like improved stability and better ingredient distribution. This production line processes raw materials for the formulation of vitamins, minerals, and other dietary supplements. It also enhances the flow attributes of protein powders and sport supplements.

Food Industry

Food Granulation

Besides the pharmaceutical and nutraceutical industry, granulation line for solid dosage form is also found in the food industry. It mixes different kinds of powders for the formation of instant foods and drinks like soups, drinks, and dessert mixtures. It also increases the uniform blending of spice, seasoning, and herbal mixes.

Chemical Industry

Chemical Granulation

The granulation line for solid dosage form creates free-flowing and non-clumped spherical granules of catalysts and additives. Moreover, it also mixes and produces different kinds of detergent and cleaning agent granules for better cleaning action.

Animal Feed Industry

Feed Granulation

Often animal feed has a homogenous composition and stability. This superior-quality animal feed is produced by the granulation line for solid dosage. It ascertains the homogenous distribution of medicinal substances in the animal feed, thus, manufacturing uniformly dose medicated animal feed.

Agriculture Industry

Fertilizer Granulation

In the agriculture industry, a granulation line for solid dosage form produces different kinds of fertilizers, pesticides, herbicides, and pathogen control formulations. It minimizes powder drift and boosts agriculture product handling.

Cosmetic Industry

Cosmetic Granules

Different cosmetic powders and pigments are consistently blended by the granulation line for solid dosage form. It is involved in the creation of foundation, blushes, effervescent cosmetic tablets, and bath bombs. It enhances the ease of use of these cosmetic products.

4.What Units are Integrated into the Granulation Line for Solid Dosage Form?

There are different types of machines integrated into the granulation line for solid dosage form production. The entire granulation line is composed of enclosed set of machine bringing a promising processing of powders without risk for contamination or dust. These devices have their specific part in the mixing and granulation of drug and excipient powders. Let’s discuss these units one by one.

A flow chart of granulation line for solid dosage form

Unit 1: Material Hopper

| Material subjected for granulation is stored in the hopper, it is mainly available in various sizes. The charging of materials into other units are taken place by the high-speed pipes that are provided with high suction pressure from vacuum feeder. The raw materials are sent to next machine in a sophisticated manner under compact and enclosed circulatory system. |

Material Hopper |

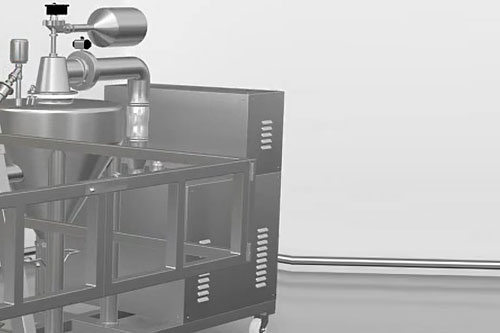

Unit 2: Rapid Mixing Granulator

| RMG is required for dry as well as wet granulation to make raw ingredients or powder prepare for the compression and preventing segregation of material with better flow characteristics by making spherical granules.

In this type of granulator, binders, and powders are mixed in the mixing bowl using impellers. It aids in the clumping and granulation of different particle residues by combining different solvents and fluids. Granulation occurs in a short time due to the creation of high-shear forces. It is widely used in industries because of its efficient design, production of excellent quality uniform granules, and low rejection of tablets. |

Rapid Mixing Granulator |

Unit 3: Swaying Granulator

| The swaying granulator is suitable for handling moist or wet particle processing; the machine is designed with multiple agitative motor arms with sharp endings to break down clumps in powders. The working is based on continuous oscillation from side to side to minimize the particle sizes to be granulated.

The repeated action of blades with prominent mechanical driving force leads to produce a pellet from the sieve which is equipped in the machine. |

Swaying Granulator |

Unit 4: Fluid Bed Dryer

| Granules from granulator are moved to fluid bed dryers for removal of moisture content from it by application hot fluidized air in order to get greater contact with particles.

Fluid beds, spouted beds, and Wurster coaters are a few kinds of fluidized granulators. This machine has many advantages like boosting the characteristics of feed and its solubility. It is employed for both thermos-sensitive and non-thermo-sensitive powders. In this machine, first raw powders are loaded in the fluidizing chamber, then hot air after heating and filtration is introduced in this chamber via inlet. It causes the suspension of powders, creating fluidization of particles. Now binders are sprayed over fluidized powders. These wet particles hit each other to produce granules. After the formation of desired-sized granules, hot air is introduced inside the bed for drying of granules. |

Fluidize bed dryer |

Unit 5: Transfer Hopper & Vacuum Air Pump

| Optimized granulated materials from fluidized bed dryer is pumped to grinding granulator by help of transfer hopper and vacuum air pump. The entire circulatory system is based on enclosed loop transfer designs to keep your product entirely safe. |

Transfer Hopper & Vacuum Air Pump |

Unit 6: Grinding Granulator

| Grinding granulator, with a high speed of mixing impellers leads to further chopping or grinding of the particles inside the bowl of the machine. The uniform and high shear leads to form a consistent and smooth granule with de-lumping properties.

Various batches of dry granules are further subjected to grinder to form uniform and smaller particles required for solid dosage formulation. |

Allpack Grinding Granulator |

Unit 7: Sifter

| To strain unwanted particles, a sifter is integrated in granulation line which helps you in the grading of materials from solid-solid, solid-liquid. This is required to be connected as it will eliminate the chances of lump formation and separates the materials based on required sizes. |

Sifter |

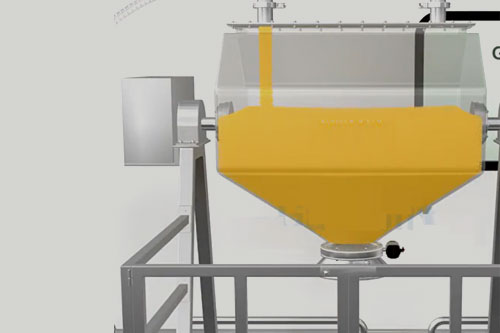

Unit 8: 3-D Mixer/Square Cone Mixer/Bin Blender

A plot illustrating the granulation line for solid dosage form

| To add excipients and mixing, a suitable mixer is used in pharmaceutical solid dosage formulation preparation, where a quick and better powder mixing are processed in a machine tank by gentle multi-direction mixing to avoid segregation. For example, lubricant or glidants, fillers, binders, etc.

It ensures the homogeneity of blends after granulation and decreases the size of granules, resulting in uniformity of the final product. You can use various blenders or mixers such as: 3- mixer, V-blender, double-cone mixer, ribbon, bin, and octagonal blender. The working of the blender/mixer starts by loading granules and excipients in the mixing vessel. The mixing vessel rotates for lifting, cascading, and folding of materials, causing the collision of granules and the formation of a consistent mixture. Some blenders like ribbon blenders have helical ribbons, or agitators to promote the mixing of granules and other excipients. |

Mixer/blender |

Unit 9: Vacuum Feeder

| A vacuum feeder is significant equipment which utilizes compressed air and forms vacuum for conveying of materials from material hopper till various integrated machines such as granulator, sifter, fluidized bed dryer etc. It is a closed system to transfer loose powder via flexible pipes that overall protect the production line and lightens operator workload by handling overall machines process with GMP compliance. |

Vacuum Feeder |

5.What Type of Solid Dosage Are Made from Granulation Line for Solid Dosage Form?

There are different types of solid dosage forms made from granulation line for solid dosage form. A few of them are penned below:

Tablets

Tablets

It is a unit dose medication unit in which active ingredients and excipients are compressed in solid form. It forms different forms of tablets like effervescent, chewable, sublingual, buccal, oral-disintegrating, and standard-shaped tablets. It manufactures tablets varying in shape, dimension, dissolution rate, and, other characteristics.

Capsules

Capsule- Picture Courtesy: Pharma Trends

Filling materials for both hard and soft gel capsules are produced by this line. It processes different oily and watery blends for soft gel capsules and granules, pellets, and tablets for hard gel capsules.

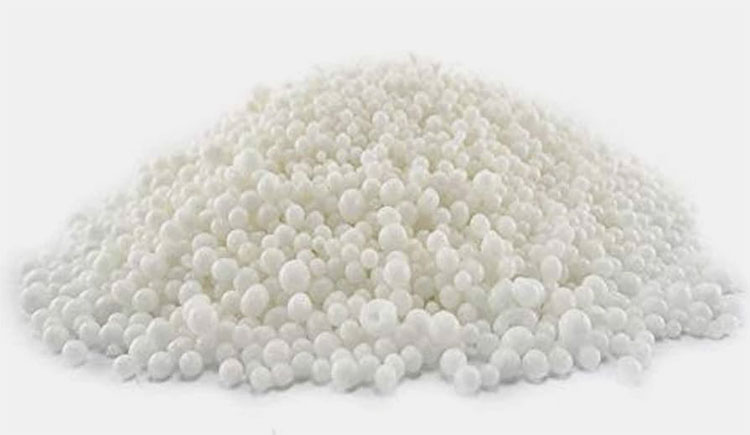

Granules

Granules

The main purpose of the granulation line for solid dosage form is the formation of granules. This line is involved in size enlargement and agglomeration of powders. The granule increases the ease of handling of powders.

Pellets

Pellets in Capsules

They are tiny spherical balls manufactured by the accumulation of powdery and granular substances. Pellets have both immediate-release and extended-release drug components.

6.What Problems Arise in the Granulation Line for Solid Dosage Form? How to Troubleshoot Them?

Problems usually arise in the granulation line for solid dosage form that cause unexpected loss of productivity and operativity. However, there are many ways to troubleshoot these problems, for instance,

Inconsistency in the Size of Granules

Inconsistency in the Size of Granules

Cause

This is because of inadequate binder concentration.

It is also due to poor mixing time.

Inadequate speed of granulator also results in non-uniform sized granules

Moisture content also affects the size of granules

Troubleshooting

This problem is solved by:

Adjusting the concentration of binder in the mixture.

Increasing the mixing time.

Changing the speed of the granulator.

Increasing or decreasing the moisture content.

Variation in Batch Quality

Variation in Batch Quality

Cause

There is variability in the quality of raw materials, resulting in variations in batches.

Poor calibration of equipment also leads to inconsistencies.

Variation in the process parameters, for instance, mixing time, binder concentration, and drying time.

Troubleshooting

It is recommended to

Use consistent quality materials.

Fix the calibration issues in the equipment.

Ensure the standardization of process parameters.

Segregation of Granules

Segregation of Granules- Picture Courtesy: Bell Africa

Unsuitable blending techniques lead to the separation of granules.

Non-uniformity of particle size also causes segregation.

Decrease blending time also produces the splitting up of granules.

Troubleshooting

Using suitable blending methods like double-cone or bin blenders solves this problem.

It is also resolved by using sieving techniques to maintain uniformity in particle size.

For complete mixing and minimal granular segregation, it is best to optimize blending time.

Lumps in Mixture

Lumps in Mixture- Picture Courtesy: yourbutlerspantry

Causes

The main reasons for this problem are:

Increased liquid amount in the mixture.

Stickiness of the powdery material.

High binder amount.

Troubleshooting

Some suggestions to solve this issue are:

Reduce the speed of liquid sprinkling.

The airflow rate should be increased to prevent stickiness.

Use an appropriate amount of binder.

High Rate of Granular Fine

High Rate of Granular Fine- Picture Courtesy: Anthony The Spice Maker

Cause

This issue is due to:

Decreased quantity of binder in the mixture.

Airflow speed or fluidizing velocity is very large.

The pressure of atomization is exceedingly high.

Addition of weak potency binder.

Troubleshooting

Some suggestions for troubleshooting these problems are:

Increase the quantity of binder in the mixture.

Decrease airflow speed or fluidizing velocity.

Lower the atomization pressure.

Optimize the strength of the binder.

7.What are the Consideration Factors for Procuring Granulation Line for Solid Dosage Form?

Procuring a granulation line for solid dosage form is a hefty task, involving consideration of many buying factors. You should not go in blind but make a selection decision after weighing the pros and cons of several machines. Here are a few consideration factors that must be taken into account before the selection of a granulation line for solid dosage form.

Production Capacity

Production Capacity- Picture Courtesy: Silverson Machines

You should not only consider your present production capacity needs but also keep in mind future production needs when selecting a granulation line for solid dosage form. Your potential production line must be capable of processing your desired batch size but can be scaled up if needed.

Material Compatibility

Material Compatibility- Picture Courtesy: Caleva

It is a pivotal factor when it comes to procuring granulation line for solid dosage form. Your desired production line must be capable of processing your potential raw materials and binders. Moreover, for heat-sensitive materials, the production line should be able to operate at appropriate temperatures.

Kind of Production Line

Wet vs Dry Granulation Line for Solid Dosage Form- Picture Courtesy: Romaco

It is a major factor that holds a key place when going out to purchase granulation line for solid dosage form. You should decide between the kind of production line (wet or dry granulation line) depending upon final granular product needs. Moreover, this granulation line must be able to output granules of required density, shape, and size.

Performance

Performance of Granulators- Picture Courtesy: L.B. BOHLE

To get quality results, you must evaluate the performance and efficiency of different equipment in the granulation line for solid dosage form and determine if they are up to par. Granulators, dryers, and mixers must be proficient in delivering remarkable and consistent granulating, drying, and mixing results, respectively.

Cost and Budget

Cost and Budget- Picture Courtesy: Contract Pharma

Last but not least, establish the cost-effectiveness of the granulating line in terms of investment, running cost, and long-term value. It is crucial to weigh the purchase price of a granulating line for solid dosage form against its quality, operation, and lifetime expectance.

Conclusion

The granulation line for solid dosage form is the all-purpose production line involved in the mixing, blending, sizing, granulation, layering, and, drying of raw powdery substances. Its main function is the agglomeration of powders into granules. Various benefits like improved granular characteristics, compressibility, flowability, and, homogeneity go hand in hand with the granulation line for solid dosage form. Its importance and popularity have been on the rise since its start because of its efficiency, shorter processing time, and accuracy. So, choose wisely by going for Allpack to avail excellent series of reliable equipment with trustworthy customer services. Please message us now!

Granulation Line For Solid Dosage Form Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586