Fluid Bed Dryer Vs Spray Dryer:The Complete Buying Guide In 2025

Do you wonder how granular particles are formed for use in different formulations? How each granule is so similar in size and shape? Drying is critical step in many industries like pharmaceutical, food and chemical industries to improve product shelf life, quality, appearance and efficiency.

This can be easily achieved by fluid bed dryer or either spray dryer. If you are planning to purchase drying equipment of commercial grade. Fluid bed dryer or spray dryer which one is suitable for use at large scale? What are difference of method used in these dryer, their working and uses?

In this “Fluid bed dryer vs Spray dryer: The complete buying guide in 2025” article your all question are answer through expert opinion. Let’s begin this article without any further delay.

1.What Do You Know About Fluid Bed Dryer Vs Spray Dryer?

Fluid bed dryer

Fluid bed dryer

Fluid bed dryer is the equipment widely used in industries like food processing industry, pharmaceutical industry and chemical industry for drying different materials. It is the drying process used to maintain moisture content at desired level in powder and granules.

This machine works on fluidization principle by drying material using hot air under high pressure. This equipment is highly adaptable to different material and can operate at different speed which makes it best choice for various industries.

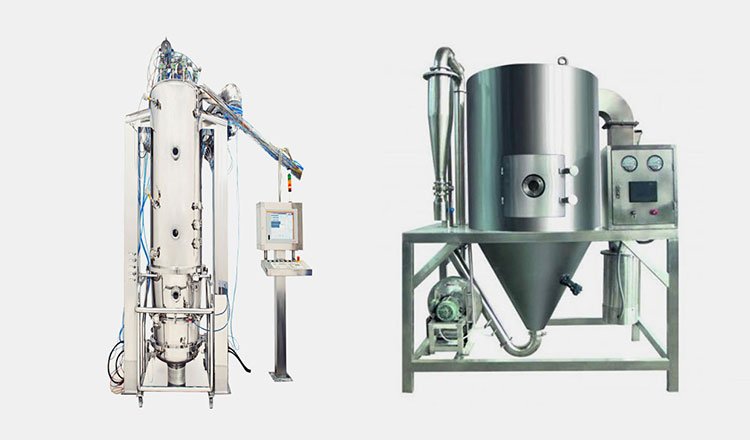

Spray dryer

Spray Dryer- Picture Courtesy: AntiTeck

Spray dryer is an advanced equipment which is used to transform paste or liquid material into dry powder. This equipment involved spraying of material in hot gases which as result evaporated liquid and powdered material is left.

This dryer is also used in food industry like for production of powdered milk. Other than that, this equipment is used in various industries like pharmaceutical and chemical industry.

2.What Are the Benefits of Fluid Bed Dryer Vs Spray Dryer?

Both drying equipment are widely used in various industries due to providing fast drying process, quality product and many more. In this topic, you will learn few beneficial impact of fluid bed dryer vs spray dryer.

Benefits of fluid bed dryer

Efficient drying

Efficient Drying- Picture Courtesy: LFA Tablet Presses

Traditional drying process take longer time but advancement of fluid bed dryer it greatly saves processing time resulting in high efficiency with quality product. Due to efficient performance, it is preferred in many industries.

Improving granules quality

Improving Granules Quality

Fluid bed dryer efficiently dry granules enhances flow properties and compaction quality of granules. It means if you are using great quality granules it will enhance quality of product.

Easily integrated

Easily Integrated

Fluid bed drying cannot work alone. It can be integrated with other equipment in many industries to ensure smooth function of production line. It can efficiently work with other equipment enhancing production quality.

If you integrated a fluid bed dryer in your production line, it will enhance the quality of product as well as increase productivity by saving time.

Low maintenance cost

Low Maintenance Cost Picture Courtesy: Vector Solution

If you are worried fluid bed dryer, a highly efficient equipment required high maintenance which affect your budget. You are surprised to know that it’s maintenance is quite cheap due to it stainless steel body which cannot easily damage.

Benefits of spray dryer

Adaptability for different material

Adaptability for Different Material

Spray dryer are advance equipment manufacture in a way it can reduce moisture content of variety of product like milk powder, instant drink powder, coffee powder etc. It is designed in a way that it can handle different variety of materials.

Producing different particle sizes

Producing Different Particle Size- Picture Courtesy: Nature

Spray dryer is configured in this way that you can easily control particle size by using different models. This machine can efficiently produce particle size sizes 300-500µm.

Drying efficiently

Drying Efficiently- Picture Courtesy: Spray Dry Nozzles

Spray dryer work by atomization which helps in even and fast drying of particles. Due to atomization, surface area increases which aid in rapid evaporation and fast drying.

Ease of handling

Ease of Handling- Picture Courtesy: Lab Bulletin

Spray dryer is easy to handle as most of drying process is done in single step without need of crushing and sieving. It also reduces need of manual labor.

3.What is The Application in Different Industries of Fluid Bed Dryer Vs Spray Dryer?

These are most commonly use drying equipment in various industries. Let’s discuss application of fluid bed dryer vs spray dryer in other industries.

Application of fluid bed dryer

Food industry

Food Industry- Picture Courtesy: Refresh

Fluid bed dryer is widely used in food industry or processing of various materials like chocolate powder, chicken powder, tea, protein powder, corn starch and many more. Fluid bed dryer can process salt and sugar.

Agriculture industry

Agriculture Industry

Fluid bed dryer is also applicable for producing high quality granules fertilizer and powdered pesticides. It is used to make powder, granular and tablet which then used in agriculture industry.

Pharmaceutical industry

Pharmaceutical Industry- Picture Courtesy: Hudi Pharma

Fluid bed dryer is widely used in pharmaceutical industry for its efficient drying process. It can dry drug granule, powder, tablet, herb powder and list goes on. This process also ensure quality of product is not compromised.

Chemical industry

Chemical Industry

Fluid bed dryer is widely used in chemical industry like dyes, detergents and pigments are remove extra moisture content dried using it. On the other hand, desiccant which is granular is form is subjected to fluid bed dryer to remove extra moisture.

Metal industry

Metal Industry- Picture Courtesy: Powderclad.com

It is another application of fluid bed dryer. It applied to metal industry to dry metal powder, metal granules and other metal product to high quality metal powder which is used in further processes.

Application spray dryer

Plastic industry

Plastic Industry- Picture Courtesy: Vismec

Spray dryer is widely use to dry plastic polymer and pellet. This process is done by evaporating moisture of plastic suspension like PVC, PP etc.

Nutraceutical industry

Nutraceutical Industry

It is widely used to dry vitamin, protein and probiotic to make supplement powder. Spray dryer is preferred in this process because it will dry product without compromising on quality of product.

Pharmaceutical industry

Pharmaceutical Industry- Picture Courtesy: Ebbecke

Spray dryer is used to dry heat sensitive material and also enhance bioavailability of product. Due new innovation it is also used in encapsulation of drug to extend shelf life.

Biotechnology industry

Biotechnology industry- Picture Courtesy: The University of Chicago

It is used to preserve bioactive ingredient like enzymes and probiotics are dried to use in supplements. It also employed in yeast fermentation process to make dry yeast.

Food processing industry

Food Processing Industry- Picture Courtesy: POS Biosciences

Due to demand of instant meal and powders, spray dryer use is greatly increases in food industry. It is widely employed to dry food product like powder milk, spices, tea, coffee and dried vegetables.

4.What Is the Basic Working Principle of Fluid Bed Dryer Vs Spray Dryer?

Spray dryer and fluid bed dryer both are used in drying process in various industries. But both of them work on different principle and uses different mechanism for drying process.

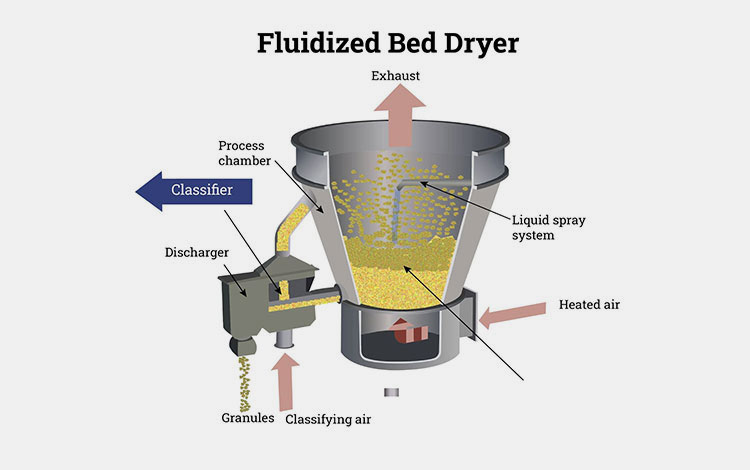

Fluid bed dryer

Fluid bed dryer is used to convert free-flowing loose powder into strong, dry and even granules.

Working principle

Working Principle of Fluid Bed Dryer- Picture Courtesy: IQS Directory

Fluid bed dryer works on principle of fluidization which means particles are subjected to passing air that makes particle to behave as fluid. The process involves few steps discuss below.

Fluidization

It is first step in fluid bed drying, in which particles are placed in drying chamber. Then hot air is passes through punctured plate from the bottom. By passing air, particles are fluidized and act as a liquid.

Drying

It is the second step in which moisture is evaporated by passing hot air through punctured plate. Fluidized layer allows for better heat and mass removal which results in efficient and fast drying.

Collection

When the particles are completely dried, collected with help of cyclone or filter and sent for further process or packaging.

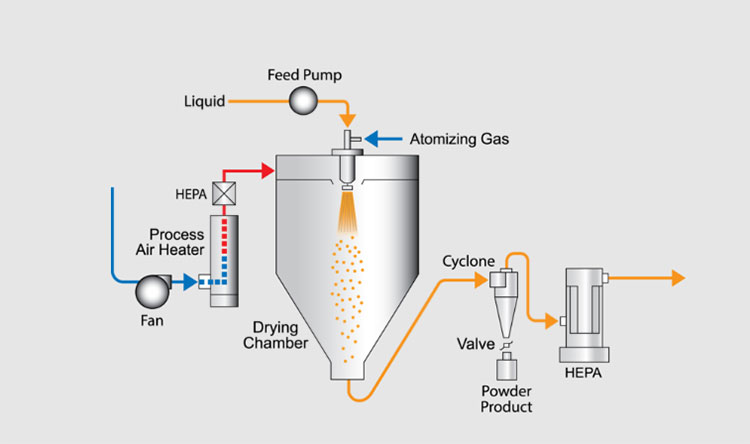

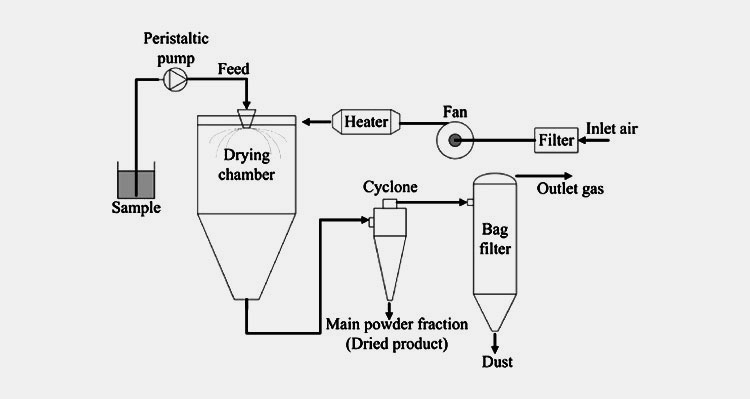

Spray dryer

Spray dryer is commonly used for uniform particle production. It is used to convert fluid material into dried particle with the help of moving hot air.

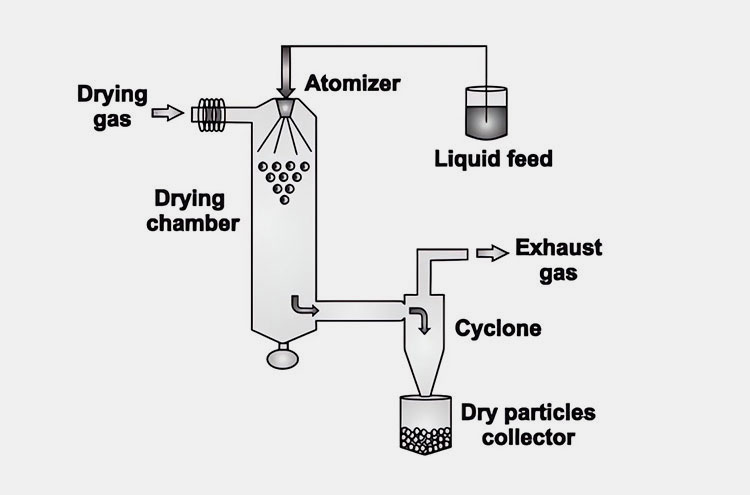

Working principle

Working Principle of Spray Dryer- Picture Courtesy: Pharmanotes

The basic working principle of fluid bed dryer depend on atomization of liquid material into small droplet which is then treated with hot air. There few key steps which is discuss below for you.

Atomization

This is the first step, liquid feed which is in the form solution, suspension or emulsion is introduced by spray nozzle. Spray nozzle atomized the liquid in tiny droplet leading to increase surface area. The size of tiny droplet may vary from 10-2000 µm.

Drying

After atomization fine droplets are introduce in drying chamber with hot air. This circulating hot air, when contacted with droplet causing immediate evaporation of moisture and leaving dry particle behind.

Collection

Once the particles are dried, it is collected by cyclone or specialized filter for next processing step.

5.What Are the Different types of Fluid Bed Dryer Vs Spray Dryer?

There are different types of fluid bed dryer and spray dryer depending on type of material used, desired particle size and structure or shape of material. In this article, each type in describe for your better understanding.

Types of fluid bed dryer

There are three main category of fluid bed dryer which are widely used in manufacturing unit depending on the requirement of manufacturer.

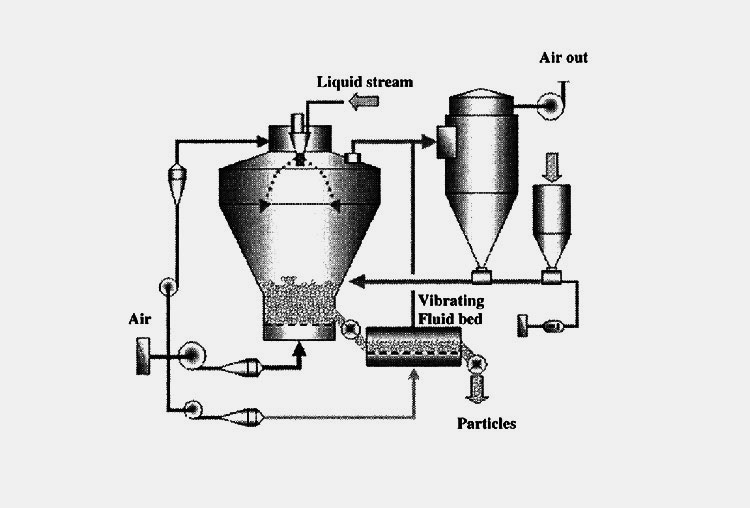

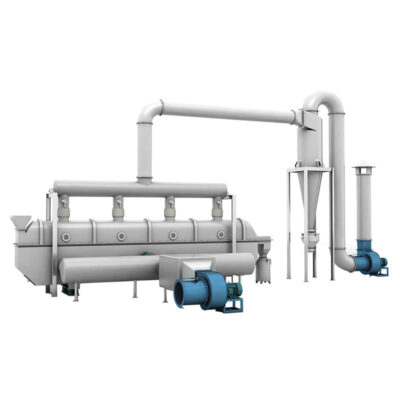

Horizontal or continuous fluid bed dryer

Horizontal or Continuous Fluid Bed Dryer

Continuous fluid bed dryer is ideal for drying crystals and granular powders. It also aids in cooling process food product, fertilizer and other organic product like coffee, tea and many other products.

Working principle

In this dryer, process is continuously in progress. The wet feed is introduced from feeder on fluidizes bed which is connected with vibration system on both side. Vibration motion prevent clumping of wet feed.

Fluidized bed moves horizontally in the in or out direction. Hot air passed from the bottom of perforated plate of fluidized bed which enables fast drying. After drying, Dried particles are collected with help of cyclone separator or bag filter.

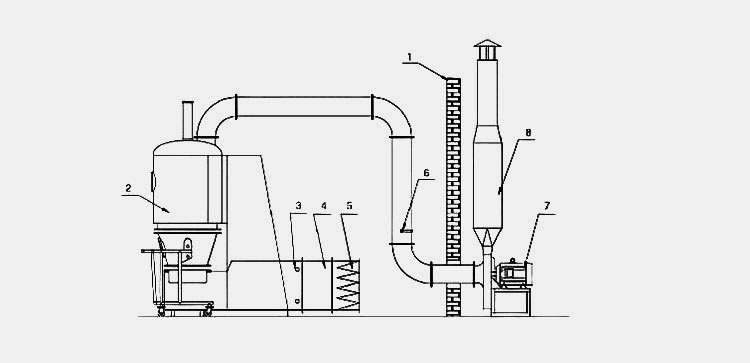

Vertical or batch fluid bed dryer

Working Principle of Vertical or Batch Fluid Bed Dryer- Picture Courtesy: Senieer

In this dryer, a complete batch of product is dried at once. It is widely implemented in food and pharmaceutical industry. This dryer is suitable small scale manufacturing unit where small batches with more complex process.

Working principle

The drying fan which is located at upper part of dryer, introduces air stream that passes through heating chamber. The heated air is then passed through the material in drying chamber. The material is place on a wired mesh and hot air is passes from bottom. Then dry particles are collected in the collector.

Types of spray dryer

On the basis of stage of drying

Single stage spray dryer

Single Stage Spray Dryer- Picture Courtesy: Research Gate

As the name indicate, this type dry liquid and slurries in just one pass. Both feed and heat enter from the top in drying chamber. When both come in contact instant moisture evaporation resulted in dried particles.

Two stage spray dryer

Two Stage Spray Dryer- Picture Courtesy: Research Gate

In this type, drying process occur in two stages. The feed exit after first step have higher moisture content which is removed in second stage. These dryer type work on low temperature and ideal for heat-sensitive feed material

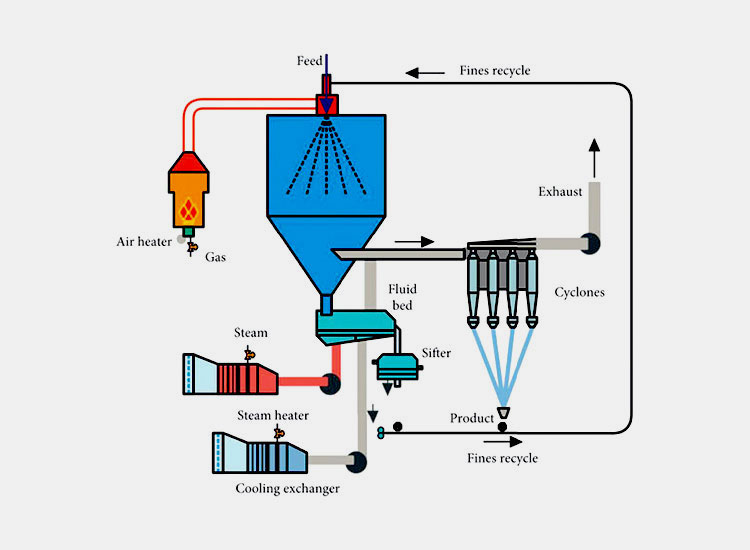

Multi stage spray dryer

Multi Stage Spray Dryer- Picture Courtesy: Research Gate

The multi stage dryer involves series of step for drying slurries and liquid. At first, material is pre-dried to reduce excess moisture. Afterward pre-dried feed material is introduced in drying chamber of spray dryer where it comes in contact with hot air and dried into powder and granules. In the last step, dried powder or granules are dried to desired moisture content and cooled by using fluid bed dryer.

Types of Spray Dryer on the Basis of Flow Type- Picture Courtesy: ScienceDirect.com

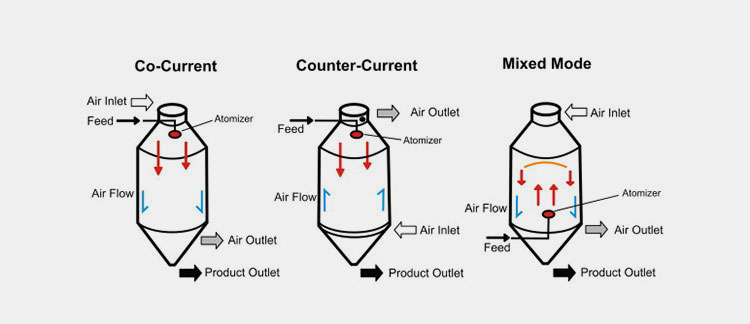

Co-current spray dryer

In co-current spray dryer, flow of material feed and hot air works simultaneously which means both are moving in same direction. This flow is generally from top to bottom resulting dried powder and granules which is afterward collected by cyclone separator.

Counter current spray dryer

Counter current spray dryer, in this type material feed and hot air counter each other which means both move in opposite direction. The feed material is introduced in drying chamber from spray nozzle which atomizes feed into small droplet and counter hot air which is entering from bottom quickly dried particle due this opposite movement. Afterward, dried powder is separated by cyclone separator and collected.

Mixed spray dryer

Mixed spray dryer is specialized dryer because it works on both co-current and counter current principle which hot air moved in both direction and feed material is added in drying chamber from bottom through atomizer nozzle. This dual movement of hot air ensure efficient and fast drying. These dried powder is collated by filters.

6.What are the Main Components of Fluid Bed Dryer Vs Spray Dryer?

Main component of fluid bed dryer

Here are some key components of fluid bed dryer.

Main Components of Fluid Bed Dryer- Picture Courtesy Yatherm scientific.

- Drying Chamber

- Air Distributor

- Fan

- Exhaust system

- Control system

- Heater

Drying Chamber

The drying chamber is used for drying the material. It has sufficient space for both fluidization and drying.

Air Distributor

The usage of this part is to disburse the hot air uniformly all across the fluid bed particles. It ensures even fluidization of liquid.

Fan

This part provides the air flow into the drying chamber as the airflow passes through the air distributor and liquefied the particles and provide maximum airflow to suspend particles.

Exhaust system

This exhaust system is located on top side of the system and is used to clear moisture from drying chamber. It also supports the system to work properly without any worst event this system has other components which include filter and scrub.

Control system

The control system helps to monitor, operate and maintain the system. It includes some other components like, sensor to control pressure and temperature, and also a control panel through which system work smoothly.

Heater

The heater controls the air temperature constantly. It heats the air to maintain the temperature. The heater has other types include steam heating, electric heating and gas heating.

Main components of spray dryer

Main Components of Spray Dryer- Picture Courtesy: ScienceDirect.com

Here are the key components of spray dryer system and it include heating system, atomizing, drying tower, and recovery system.

Heating system

This system design in two method include direct method or indirect method as in direct method air directly in contact with flame and indirect method air is indirectly heated by heat exchanger

Atomizer

Atomizer is used to control evaporation process. It will convert material in tiny droplet and also play crucial role in producing particle of desired specification. In atomizer, different type of nozzle is used depending on type of pressure used.

Drying tower

Spray drying process is carried out in drying chamber. In these chambers, moisture is removed by a feed material by spraying tiny droplet into hot air. When hot air circulated the droplet, moisture is evaporated.

The dimension of drying chamber depends upon type of feed material, atomizer type and distribution type.

Cyclone or separator

After hot air is exited from chamber along with tiny dried particle, it is necessary to separate these dried particles. To perfume this, cyclonic separation is used which work on centrifugal force.

7.What is The Difference Between of Fluid Bed Dryer Vs Spray Dryer?

In industries, the two majorly used drying equipment are fluid bed dryer and spray dryer. The both process operate differently for different purpose. Now let discuss about differences between both.

Difference Between Fluid Dryer Vs Spray Dryer-Picture Courtesy: Nicomac & SeFluid

| Key feature | Spray dryer | Fluid bed dryer |

| Definition | In this process, conversion of liquid into powder form. In spray dryer, liquid is refine into fine drop form and water evaporate and finally collect the powder or dry particles. | In this process conversion of powder form in granules .In this technique hot air passes through bed of powder and solution is spray onto the particles the moisture evaporates and particles convert into granules form |

| Purpose | The main purpose of this technique is to convert liquid feed into powder form. | The purpose of this technique is to convert powder form into larger granules |

| Equipment | The equipment include like drying chamber , and point for collection, atomizer. | The equipment include fluid chamber ,Spray part for particle binder ,drying component |

| Particle Formation | It consist of a fine powder form and it has a specific size | It consist of larger particle in the form of large granules |

| Implementation | It work on producing powder formation of food ingredients and also in pharmaceutical industries for vaccine y | Its majorly work on tablet formation |

8.What Main Factors You Need to Consider Before Buying Fluid Bed Dryer Vs Spray Dryer?

Factors Need to Consider Before Buying Fluid Bed Dryer Vs Spray Dryer

| Considering factor | Spray dryer | Fluid bed dryer |

| Material properties | If you are using heat sensitive and less viscous material, spray dryer is more suitable | Fluid bed dryer is best choice for heat resistant and high viscosity material |

| Desired product characteristic | If you are looking for uniform particle size and immediate solubility is required then spray dryer is best fit for it. | If more larger particle size is required which is stronger and even, fluid bed dryer is preferred. |

| Drying Efficiency | Spray dryer are more efficient and rapidly dry. It can remove more than 50% moisture content. | For removal of low moisture content fluid bed dryer is suitable. It can remove 10-15% moisture content. |

| Production unit | Spray dryer is considered for small and specialized complex batches. | If you are look for large scale unit, Fluid bed dry is best fit due to its production capacity |

| Cost reduction | If you initially starting, then spray dryer is more expensive due to complex structure. | On the other hand, fluid bed dryer is more cost effective choice due to its simple operating system. |

9.What are the Problems and Their Trouble Shooting in Fluid Bed Dryer Vs Spray Dryer?

Due to continuous operating, dryer may cause some problem which may decrease production. For that you need to do trouble shooting. How you do that? In this part you will learn some common trouble shooting step to avoid downtime od dryers.

Trouble shooting in fluid bed dryer

| Problem | Reason | Solution |

| Prolong drying time

|

Sometime dryer take longer time to dry feed than usual, may be due to increase moisture content or you added more quantity of feed than it space. | To overcome your you need to add in small batches and try to do dry processing before hand |

| Increase Temperature

|

Sometime product over dried due to increase temperature or denatured. | To overcome this problem, you need to check heater, if they working fine. If still problem persist check your temperature sensor |

| Product contain impurities

|

I you see your final product is not desired quality. Either final product after filtration carry impurities. | For this problem, you need to check filters and other than that there might be grid of filter is larger than your required particle size, replace it with proper one. |

Trouble shooting in spray dryer

| Problem | Reason | Solution |

| Defect in cyclone separator

|

The main is problem is that cyclone separator may damage or separator discharge outlet is block by material accumulation. | To overcome this, first replace defective separator either clean the separator discharge outlet properly. |

| Decrease fluidization

Picture Courtesy: ScienceDirect.com |

The fluidization is effected due blockage of atomizer orifice or the feed material is too viscous. | For proper atomizer working you need to clean orifices thoroughly. Used correct viscosity material for machine. |

| Particles inadequate drying

Picture Courtesy: ProPhos Chemical |

You may notice that feed material is not completely dried after drying process. |

There is simple method to overcome is reduce quantity of feed or increase temperature. |

Conclusion

In this article, you learn about fluid bed dryer and spray dryer. If you are planning for large scale production unit then fluid bed dryer is best fit due to its easy handling and cost effectiveness. On the other hand, if you are doing more complex or specialized product drying for this purpose spray dryer is more appropriate. We also learn about common problem while using dryers and how you can overcome this problem. Now your all questions are answered. If you are planning to buy or still have some confusion, you can reach out to our AIPAK service team for more information.

Don't forget to share this post!

Drier Machine Related Products

Drier Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine