Fluid Bed Dryer Granulator: The Complete Buying Guide In 2025

From coffee to milk powder, tablets, fertilizers, and detergent powder there is a presence of granules making their use easier in our daily life. But do you have any idea about their manufacturing process, or the technologies used behind? If not! Let us introduce you with a Fluid Bed Dryer Granulator which is actually carrying out this granulation process in a very perfect way.

This machine has been designed to fulfill the industrial requirement of granulation in areas such as pharmaceutical, food, chemical, and agriculture etc. The machine's commendable automation level, precise structure, and simple performance further enhance its charm. To unveil these aspects, you just need to give this buying guide a quick read. So, let's get started!

1.What Is A Fluid Bed Dryer Granulator?

AIPAK FL series fluid bed granulator

Fluid bed dryer granulator is an advanced and sophisticated machine designed to facilitate the drying and granulation process. It is dual function equipment that can perfectly turn loose powder into granules and dry the wet granules by reducing their moisture content.

It is made with automatic technology fitted into robust construction with no dead corners. The structure of machine helps in the gentle processing of particles in a way that hot air suspend the particles inside fluidized bed where drying and granulation occurs. Its use is quite simple and at the same time necessary in fields like pharmaceutical, foodstuff, and agriculture etc.

2.Explain The Benefits And Features Of A Fluid Bed Dryer Granulator?

Fluid bed dryer granulator features precise structure with convenient working principles and high quality performance. Together these attributes helps you in getting more benefits on part of your business and production growth. These advantages are enlisted below:

Compact Design

KDY-FBD Fluid-bed Spray Granulator /Dryer- Picture Courtesy: kwangdah.com

The design of a fluid bed dryer granulator is unique with vertical structure that has small footprint. Similarly, it offers ease in handling, operating as well as cleaning. Moreover, the machine is suitable for all kinds of facilities especially for those with limited space.

Efficient Processing

The machine is a product of various systems such as hot air circulation, spraying, filtration, and stirring etc. All these systems are regulated automatically once the machine is set and powered on. Resultantly, each step is carried out quickly and simultaneously leading to efficiency in production.

Hygienic Environment

Hygienic environment of fluid bed dryer granulator- Picture Courtesy: SAMETO

Another significant advantage of a fluid bed dryer granulator is its enclosed environment which is fully safe against harmful environmental elements. The air used is clean and particles are dispersed in sealed area thereby restricting their exposure to contamination.

Multifunctional

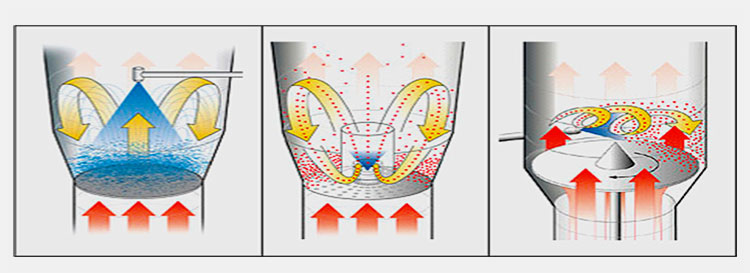

Working principles of a fluid bed dryer granulator- Picture Courtesy: vjinstruments.com

The machine is well known for its utmost versatility in terms of performing multiple tasks such as drying of wet particles, granulation of dry substances, stirring, and mixing of different particles etc., by utilizing same energy and techniques.

High Consistency

Multiple granules with high consistency- Picture Courtesy: metso.com

By undergoing the particles through various stages, fluid bed dryer granulator produces uniform granules where solvent is evenly distributed. Thus, the finished granules are highly consistent in their shape, density, and porosity.

3.Highlight The Role Of A Fluid Bed Dryer Granulator In Pharmaceutical Industry?

Pharmacist operating a fluid bed dryer granulator- Picture Courtesy: gea.com

Fluid bed dryer granulator play a remarkable role in pharmaceutical industry due to the field's working necessities which usually involves the drying and granulation especially for solid dosage formulation. The machine's controlled temperature helps pharmacists to reduce the moisture content of heat sensitive particles without compromising their quality.

Similarly, precision is another important aspect that must be practiced in pharmaceutical manufacturing which is easily possible with a fluid bed dryer granulator where entire processing is carried out inside the sealed bed. Moreover, it is also required for modifying the flow properties and structural integrity of powders and granules to prepare them for further processing like compaction.

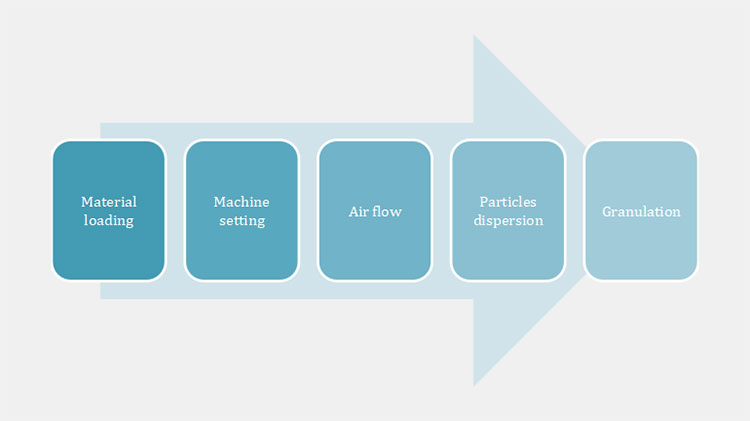

4.Explain The Working Process Of A Fluid Bed Dryer Granulator?

A fluid bed dryer granulator works on the principal of fluidization. This process can be easily understood after reading the underlying mentioned working principles. So, let's start exploring these steps one by one!

Material Loading

Material loading- Picture Courtesy: Ramashary Pharma Machinery

The process begins with solid material feeding into machine. Material is loaded into the large bowl or chamber located at the bottom side of fluid bed dryer. Once loaded, the chamber will be attached to the machine against shaking.

Machine Setting

Now, the setting of machine is carried out which involves structural adjustment and parameters setting. For former, the parts of machine are set to their adjacent place, so, it can function properly. Similarly, the parameters setting will include fixing cycle timing, temperature level, and spray amount etc.

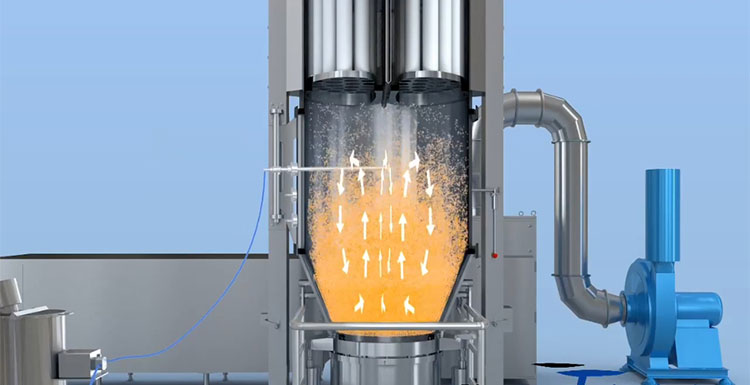

Air Flow

Air flow of the fluid bed dryer granulator- Picture Courtesy: Ramashary Pharma Machinery

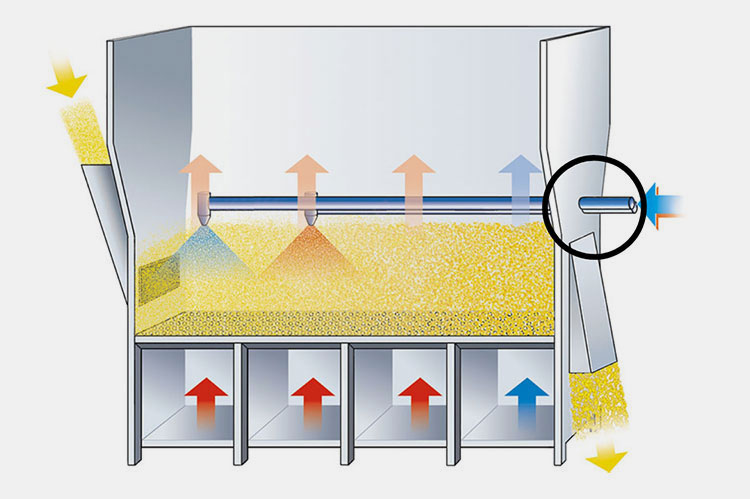

After material loading and necessary setting, the machine will be started. The first thing which is supposed to take place is the hot air flow from inlet into the material chamber and towards the bed.

Particles Dispersion

Particles dispersion into bed- Picture Courtesy: Pharmec Technologies

The constant flow of hot air through the solid particles causes their instant movement towards upward. The particles start dispersing into the bed and this phenomenon is called fluidization were solid particles flow as fluid.

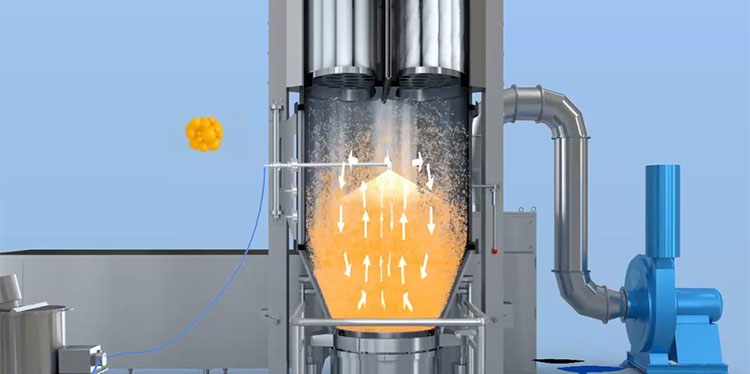

Granulation

Granulation- Picture Courtesy: Pharmec Technologies

During particles dispersion, the constant air flow evaporates their excess humidity level, and the drying occurs. At the same time, spraying of adhesive from the top down onto the fluidized bed make the particles wet. These tacky particles then form granules after colliding with other particles. Hence, the granulation is achieved.

Particles Discharge

At the end, formed granules are ready to be discharged out of the machine either manually or automatically.

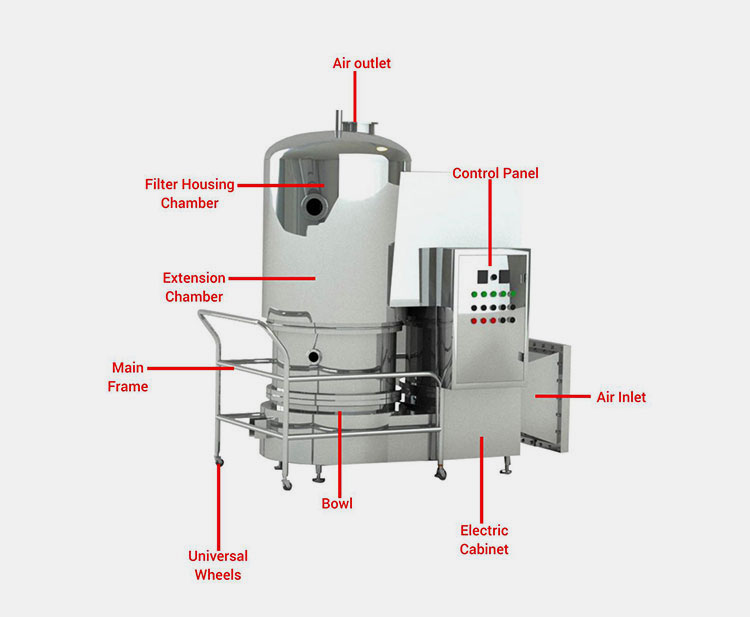

5.Describe The Various Parts Of A Fluid Bed Dryer Granulator?

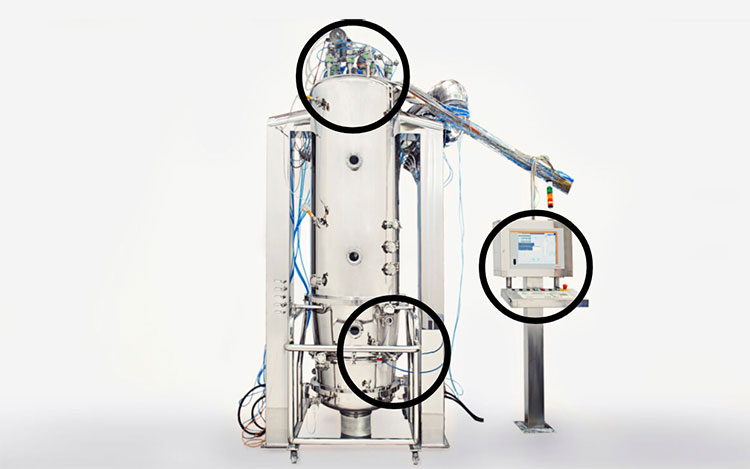

Fluid bed dryer granulator is composed of several components each performing particular task. These parts along with their functions are described below:

Components of Allpack's GF Series High Efficiency Fluidized Bed Dryer

Air Inlet

It refers to the important part of a fluid bed dryer granulator through which air source is provided to the drying chamber. With the help of blower and air distributor, the air is supplied to the machine via air inlet. The amount of air to be flowed inside is also fixed here.

Filter Housing Chamber

Filter housing chamber is situated on the top side of the machine. It is mainly used to pass the moisture and gases from extension chamber to exhaust system and restrict particles blowing from chamber.

Extension Chamber

It is the main fluidized bed where drying, and granulation of particulates occur. This extension chamber has no dead corner which support smooth flow of particles throughout the process.

Main Frame

The main frame of a fluid bed dryer granulator is also made up of durable stainless steel which help the machine by supporting its stability on ground.

Universal Wheels

The machine has universal wheels which rotate at 360° degree making it easier to move the machine from one place to another.

Bowl

It is a large size chamber with shape of a bowl where solid material is loaded before operation. This chamber is essential in providing adequate room for the air to pass through particles.

Electric Cabinet

As the machine is run by power behind which full fledged electric system is fixed into its body which energize it. This section is known as electric cabinet or electric enclosure which encases the various parts like wires, fuses, and circuits etc.

Control Panel

The machine has another important part which is control panel. It has several buttons and a small screen through which its working can be regulated and controlled.

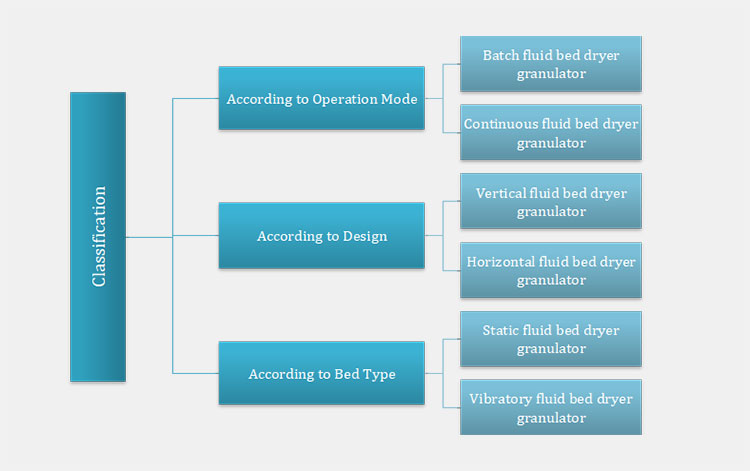

6.What Is The Classification Of A Fluid Bed Dryer Granulator?

Fluid bed dryer granulator can be classified into various types. This classification is well explained in the following paragraphs:

According to Operation Mode

Batch Fluid Bed Dryer Granulator

Batch fluid bed dryer granulator- Picture Courtesy: sedmachinery.com

Batch fluid bed dryer granulator is small size machine which is designed to process limited amount of material for single time. The machine has small footprint with easy operating procedure. It is cost-effective solution and best for small to medium scale industries which are new in the production field.

Continuous Fluid Bed Dryer Granulator

continuous fluidized bed dryer- Picture Courtesy: Ibbohle.com

In contrast to batch fluid bed dryer granulator, continuous fluid bed dryer granulator is more powerful with high capacity of production and dealing with large amount of material. Hence, it is ideal for large scale industries in medical, food, and chemical sectors.

According to Design

Vertical Fluid Bed Dryer Granulator

AIPAK high efficiency vertical fluidized bed dryer

Vertical fluid bed dryer granulator is another important type which is characterized by its vertical shape structure. It has longitudinal body making it easier to locate and operate while covering less space. The material is loaded from below and processed in a vertical manner inside the bed. The machine can also be integrated with auxiliary equipment to facilitate the production process.

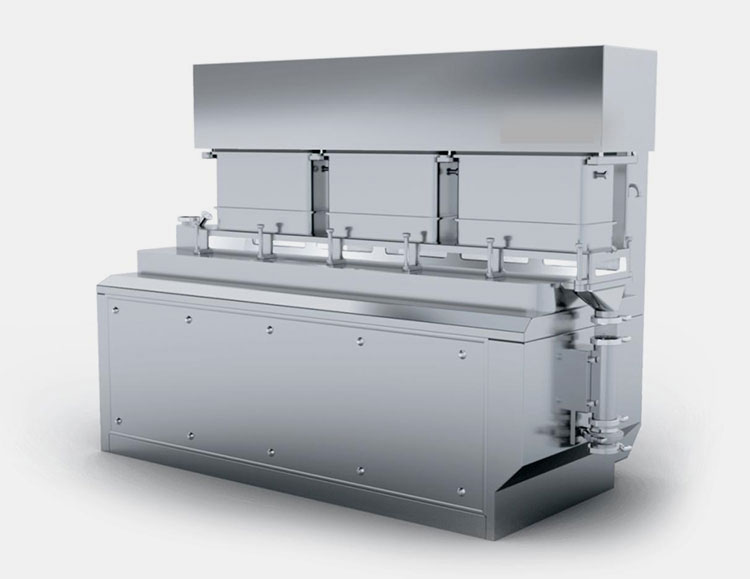

Horizontal Fluid Bed Dryer Granulator

AIPAK XF series horizontal fluid bed dryer

As the name indicates, this type of fluid bed dryer granulator has horizontal shape body which distinguishes it from vertical machine. Although its structure is bit complex, but this equipment can process material in an unstoppable manner. It can be operated by feeding material inside bed through horizontal direction. Similarly, the solid particles are processed and discharged out of it from other side. It is best suitable for large scale industries.

According to Bed Type

Static Fluid Bed Dryer Granulator

Static fluid bed dryer granulator- Picture Courtesy: gea.com

Static fluid bed dryer granulator is heavy-duty machine utilized for multiple functions such as drying, granulation, and cooling of powder and granules. It remains static throughout working and is able to handle different materials and produce uniform particles. Hence, it is best for chemical, pharmaceutical, and agriculture industry.

Vibration Fluid Bed Dryer Granulator

AIPAK FL-120 vibrating fluid bed dryer

Vibration fluid bed dryer granulator is another type of fluidized bed dryer granulator which works on the principal of vibration. The equipment has long standing vertical body. Inside the bed, the material is loaded and processed through vibration towards upward. It is best suitable for heavy weight particles like those in food industry and agriculture industry etc.

7.Enlist The Applications Of A Fluid Bed Dryer Granulator

A fluid bed dryer granulator is applicable to different industries where there is any kind of production or processing of powders and granules. These are highlighted as under:

Medical Industry

Capsules solid formulation presentation idea- Picture Courtesy: tainstruments.com

Medical industry especially the field which is involved in producing pharmaceutical, nutraceutical, herbal, and veterinary deugs is on the top of the list to use a fluid bed dryer granulator for manufacturing. The common examples include granulation of API's and excipients.

Food Industry

Coffee powder & beans- Picture Courtesy: istockphoto.com

The use of a fluid bed dryer granulator is also prevalent in food industry for the drying and granulation of products such as spices, coffee, milk powder, solid beverages, and pet food etc.

Cosmetic Industry

Various cosmetics products- Picture Courtesy: bloglovin.com

Drying and granulation is considered one of the essential steps during cosmetics manufacturing as they are made for face which is a sensitive part of the skin. Thus, the safe and hygienic fluid bed dryer granulator is used here in cosmetic industry.

Agriculture Industry

Fertilizer granules in a hand- Picture Courtesy: eos.com

Fluid bed dryer granulator is an ideal solution to process all kinds of free flowing and non free flowing powders both as dry or wet. Therefore, it is best suitable to be utilized in agriculture industry for the production of agrochemicals, fertilizers, pesticides, and mineral granules etc.

Chemical Industry

Detergent powder in scoops- Picture Courtesy: iStock

Chemical industry is another beneficiary of a fluid bed dryer granulator where the manufacturing of ceramics, dyes, and daily chemical powders like detergent powder is not possible without its help. Apart from this, the enclosed design of the machine make it more desirable in this field to avoid the flow of hazardous substances into air.

8.What Is The Cleaning And Maintenance Requirements Of A Fluid Bed Dryer Granulator?

If you want to keep your fluid bed dryer granulator at good working condition for longer period then make sure to regularly conduct its thorough cleaning and maintenance. Here are few tips for your help:

Operator maintaining a fluid bed dryer granulator- Picture Courtesy: gea.com

Cleaning

Cleaning decontaminate the machine against bacteria, dust, and residues that may otherwise deteriorate your production. For this, it is necessary to:

Disassemble the parts of machine like the bowl, filter bags, and stirrer etc.

Wash down these parts by using non acidic and clean water along with recommended detergent.

For electrical components and sensors, use a damp cloth to remove the pollution.

Once you have cleaned the parts, just locate them on their exact place.

Maintenance

Maintenance is a broad category under which multiple aspects of machine can be dealt such as structural adjustment, parts changeover, and lubrication etc. Let's know these all sequentially!

Before starting operation, it is necessary to carry out structural adjustment of the machine by fixing all the parts in concerned areas.

Similarly, it is significant to modify the parameters of machine for new batch.

During processing, keep observing the machine for its performance and noise if any.

On finding any part being damage or worn out, instantly replace it with new functioning one.

Add lubrication to the mechanical parts to avoid friction and jamming.

9.What Quality Standards Should A Fluid Bed Dryer Granulator Meet With?

FDA & GMP logo- Picture Courtesy: shipwizard.net

Fluid bed dryer granulator is an advanced yet conventional machine being used in pharmaceutical and other sectors. Its quality is always a major concern to conduct safe manufacturing. Therefore, we have certain quality standards working on national and international level to ensure the quality of machine. These are explained below:

ISO:International Organization for Standardization is the most comprehensive and important quality standard which a fluid bed dryer granulator must comply.

FDA:FDA is USA based agency formed to check the quality of drugs and associated machines. In this way, all the equipment which are supposed to be used to exported to USA should adhere to FDA principles.

GMP:Good Manufacturing Practices is a flexible framework that often deals with the different aspects of a fluid bed dryer granulator such as its structure which must be made up of a stainless steel.

CE:Conformate European is similar to FDA, however, it represents European Union countries for their concerns regarding safety of goods and products. Thus, the mark of CE is obligatory for machines which are used there.

10.Troubleshooting Of The Common Pitfalls Caused By A Fluid Bed Dryer Granulator?

While operating a fluid bed dryer granulator, you find some common errors which are easy to tackle provided that you have enough information about it. For this, we have explained the troubleshooting of common pitfalls which will be helpful:

Inadequate drying

Poor air flow- Picture Courtesy: Pharmec Technologies

Cause:

The flow of air inside the bed is not sufficient.

The temperature is low causing poor performance in evaporation.

Solution:

Check and modify the air flow rate within fixed range.

Adjust the temperature profile in accordance with the material condition.

Material clumping during drying

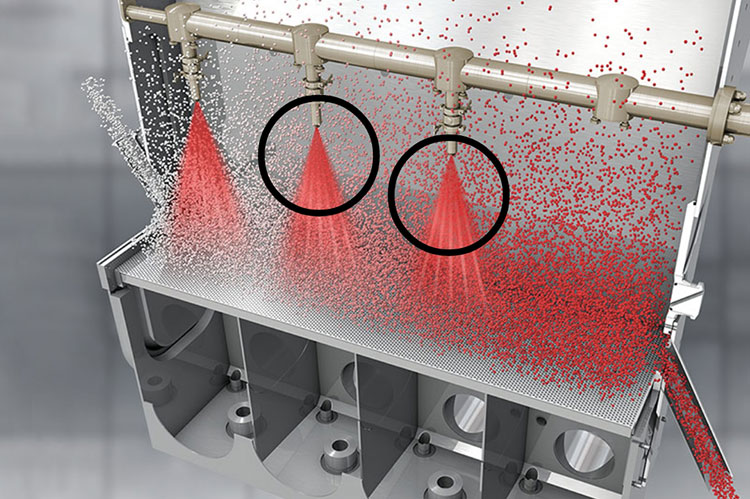

Excessive spray over material- Picture Courtesy: foodfeedfinechemicals.glatt.com

Cause:

The solvent or liquid sprayed during granulation is excessive.

Poor agitation and mixing often lead to stickiness of particles.

Solution:

Reduce the spray amount to avoid lumps.

Adjust the machine stirring performance to ensure proper mixing of substances.

Too much moisture buildup in bed

Clogged exhaust system- Picture Courtesy: foodfeedfinechemicals.glatt.com

Cause:

The major reason behind is the poor functioning of exhaust system due to which moisture is trapped inside the bed.

Temperature inconsistencies may also accelerate the moisture buildup.

Solution:

Check and correct the exhaust system to keep the bed humidity level at good condition.

Alter the temperature by keeping in view bed size and material state.

Structural Issues

Highlighting structural issues of a fluid bed dryer granulator- Picture Courtesy: nicomac.com

Cause:

The blower is broken.

Heating system is damaged.

Fuses and breakers are blown due to overload.

Solution:

Change the blower.

Check and repair heating system.

Try to not overload the machine and in case of serious issues consult with expert and timely replace the worn out parts.

11.What Should Be Considered For Purchasing Top-notch Fluid Bed Dryer Granulator?

When planning to purchase a fluid bed dryer granulator, never overlook considering some essential factors which we have enumerated below:

Production Capacity

Production capacity indicator- Picture Courtesy: cdmo-expertise.com

First, you should look at the production capacity specific machine is offering. Now, keep in mind that it greatly depends upon the bed size. Normally, a fluid bed can accommodate 30kg to 250kg. However, there are machines which have production capacity of 500kg.

Specifications

Another significant factor is to know the exact specifications of a fluid bed dryer granulator including the volume of air flow, and specifications of blower, electric motor, and heating system etc.

Overall Cost

Estimating cost- Picture Courtesy: freshbooks.com

Estimate the overall cost of buying a new fluid bed dryer by calculating the sales price and working expenditure such as power consumption and labour cost. By doing so, you will be able to opt for the machine which is light on your pocket.

Supplier Reputation

5 star rating- Picture Courtesy: ecsourcinggroup.com

Indeed, the most important thing to ever look for is the supplier itself. You should check the experience of vendor in relevant field, the customer support they offer, necessary certifications and warranty policy etc. Together, these assessment helps you to choose a supplier who can prove the best partner in solving your future issues related to machine.

Conclusion

Finally, after reading this comprehensive guide about a Fluid Bed Dryer Granulator, we have come towards conclusion that this equipment is becoming inevitable in pharmaceutical, food, and chemical industry. Its compact structure, simple operation, and high automation has made not only its use handy but also the cleaning and maintenance. The machine is highly versatile to carry out multiple functions and with easy troubleshooting, the spontaneous errors can be tackled. So, if you are interested in purchasing a fluid bed dryer granulator from reputable supplier, we recommend you consider AIPAK where quality matters along with customer convenience. For further information contact us!

Don't forget to share this post!

Granulator Machine Related Posts

Granulator Machine Related Products

Granulator Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine