Flexible Packaging:The Market Trend Of Future

According to Market data forecast market report analysis, the European flexible packaging market is worth US$28.22 billion in 2021 and will grow to US$41 billion by the end of 2026, at a CAGR of 7.76%. In addition, CEFLEX statistics show that more than 40% of food products in Europe use flexible packaging, accounting for 10% of all consumer packaging materials.

Flexible packaging is the mainstay of the packaging industry. Compared to traditional packaging, a single material does not need to be stripped of different plastics when recycling, which greatly reduces the complexity of the process and facilitates recycling.

At the same time, the necessary functions such as packaging barrier and printability can still be guaranteed.

Besides,depending on the recycling nature of the single material, it is possible to achieve a 100% recycling rate, making it a "powerful tool" for the sustainable development of the packaging industry.

At the same time, the market value of single materials is expanding, and they have now become the undisputed "windfall" of the industry.

1.P&G's 'air capsule' express packaging

In 2021, P&G developed its own lighter, more convenient and reliable green innovative e-commerce packaging - the Air Capsule.

It is made of 100% single recyclable material (PE polyethylene), with an integrated closure and tear line structure design, no need for filling, no need for carton, no need for tape, using air as the core resource to meet the cushioning protection needs of express transport, replacing the traditional combination of carton plus filling protection, cushioning performance is enhanced while 40% lighter, while effectively preventing rain and wet damage to the package.

When opening the courier, it only needs to be torn along the tear line, no tools are needed, and the air inside the package is automatically released and can be rolled up for recycling, which is convenient and space saving.

The Air Capsule is the first courier packaging in China to be certified under the Double Easy Standard, with an excellent rating. The "Double Easy Standard" stands for plastic products that are easy to recycle and easy to reclaim.

The Air Capsule is an innovative leader in replacing traditional composite materials with a single material in the courier industry, further promoting the greening, lightweighting and 100% recyclability of courier packaging.

2.Brookfarm Toasted Muesli

Recyclable, high-barrier upright bag

The Diamond winner of the Dow 2021 Packaging Innovation Award - O F Packaging (O F Pack) and its recyclable, high-barrier stand-up pouch for Brookfarm Toasted Muesli - provides a creative approach to sustainable flexible packaging and design.

The award-winning packaging, called Roll 'n' Recycle, is a 100% polyethylene (PE) bag that is rolled up after the consumer has finished using the product. A specially designed sticker is attached to the bag to secure the rolled up packaging.

The language on the sticker lets consumers know that they can put the bag in their household recycling bin after rolling. In addition to being recyclable, the bag also has the property of protecting the cereal from spoilage.

Rolling the bag into a semi-rigid 3D shape allows it to move through the existing recycling process without contaminating the paper stream as other soft plastics do, and without affecting the rotating mechanical parts within the material recovery facility.

3.Huhtamaki's 'world first' single-material PET blister cover

Huhtamaki Push Tab blister caps are made from a single material, PET (polyethylene terephthalate), and contain no aluminium, which significantly improves the recyclability of the packaging while maintaining compatibility with existing high-performance blister packaging lines, requiring no modifications or additional investment, and operating on existing blister packaging lines without compromising speed.

Huhtamaki and its cooperated partner:Kl ckner Pentaplast - are bringing this market innovation to help the global healthcare and pharmaceutical industries achieve their sustainability goals while meeting the growing needs of the market.

4.AmPrima recyclable pouch

The AmPrima recyclable pouch replaces the previous complex packaging system of tray, lid and outer box with a single, portable, high-barrier packaging format.

After consumption, consumers can drop them off directly at the designated drop-off point in the shop or in the nearest recycling bin for easy recycling.

AmPrima recyclable pouches meet both the growing consumer demand for recyclable packaging and Tyson's stated goal of incorporating more sustainable materials into its branded packaging.

With the AmPrima recyclable pouch, Tyson's ready-to-eat food packaging weighs 75% less and reduces its overall carbon footprint by 80%. The packaging also uses 84% less water for production and completely eliminates chlorine-based PVC materials.

5.Single PE back-seal bag solution developed by the Amcor team

The Amcor team has developed a single PE back-seal solution which is not only recyclable but also maintains the long shelf life, functionality and high safety standards required for hard cheese products.

Compared to traditional OPA/PE packaging, Amcor's new single PE structure reduces non-renewable energy use by 25%, carbon footprint by 41% and water use by 11% (calculated using Amcor's full life cycle assessment tool ASSET, certified by the Carbon Trust).

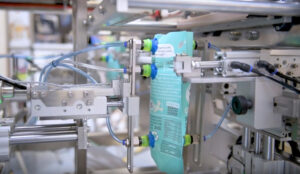

6.Pantene Stand-Up Pouch

Pantene stand-up pouches, described by Zacros as "Japan's first ever single material filled pouch", are laminated using a PE/PE adhesive that provides a barrier but does not interfere with the PE recycling stream.

The idea here, of course, is for the consumer to pour the contents into a reusable rigid container and then dispose of the bag in the PE recycling stream.

The challenge for Zacros in developing this single-material bag was to select the right materials, using only less than 5% by weight of the adhesive, ink and barrier materials that still provide durability for the liquid.

7.Mondi: replacing aluminium foil with an innovative high-barrier film

Mondi, a global manufacturer in the advanced packaging sector, has launched RetortPouch recyclable single-material retort packaging for a range of food and wet pet food applications.

Mondi has developed an innovative high-barrier film alternative to aluminium foil that maintains high temperatures during the retort process and enables shorter handling times. The new single material retort packaging is fully recyclable, providing exceptional shelf life for single material packaging solutions and reducing potential food waste.

In early 2021, Mondi is creating three sustainable packages for food manufacturer Orkla's new range of vegetarian products. Primarily used for Orkla's tortilla, tortilla chips and taco spice products.

The tortilla is the first food packaging from Mondi to use its "BarrierPack Recyclable" solution. The packaging is made of a single material with high barrier properties and is lightweight. The sealed tape maintains the freshness of the food and extends the shelf life.

To maintain the crispness and freshness of the corn chips, Mondi has used a metal-free high barrier laminate, which makes the new packaging solution completely recyclable. This packaging also prevents the leakage of oils and fats inside.

8.LINHARDT introduces the suPErtube tube

The suPErtube hose from LINHARDT is not only easy to recycle but also achieves a weight reduction of 25% thanks to the single HDPE material used for both the body and the cap. It is worth noting that the body is made of almost 100% PCR, i.e. the HDPE used in the body is recycled material.

9.Then what should you consider when using single-material flexible packaging in printing?

Whether pure PE or pure PP single material packaging, its printing and lamination are no problem, can adapt to all the inks and glues, but the single material will be lower tensile strength, elongation will be larger.

PE/PE is still mainly a tension control problem, because PE material is relatively soft, easy to stretch, its biggest problem is the bag-making process is difficult to control.

PP/PP, better barrier than PE, the Water barrier, oxygen barrier, light barrier, oil barrier are better than PE, less sensitive to tension, good flatness of the bag, but pure PP bags lack of softness, drop resistance is not good.

10.While what is the control point for the single material process?

If the face layer of PE is MDOPE, i.e. single-pull PE, basically you can assume that there is no printing problem. Because the PE after stretching, rigidity, flatness greatly improved, has been close to BOPET, at present in practice, basically can achieve accurate overprinting.

If the face layer of PE is HDPE, i.e. the main component is HDPE, then special attention should be paid to flatness.

Generally speaking, HDPE film has a good stiffness and as long as the flatness is relatively good, it will be able to meet the overprinting requirements. In practice, HDPE films have shown good value for money.

In terms of printing, it is important to choose printing equipment with high tension control accuracy. Attention needs to be paid to overprinting, ink adhesion and drying effects (residual and counter-stick).

Material flatness, tension control, drying temperature control at 55 degrees below, plate making attention to the stacked colour bit slightly larger; ensure the drying effect, the choice of suitable ink; try to use fast-drying solvents, drying air volume as large as possible, do not namely print that laminate.

Offset printing film, EB drying is one of the important ways to solve the problem of VOCs and carbon emissions at the same time. Drying with EB plus surface printing is a direction that can be considered for a single material.

11.The current situation and outlook of single-material flexible packaging

As people's awareness of environmental protection continues to rise, a consensus is gradually being reached within the industry to upgrade packaging materials, of which single material has become the dominant direction in the flexible packaging industry.

In January 2020, the United Nations Environment plan report mentioned:

1.Commitment to a plan to achieve 100% reusable, recyclable or compostable plastic packaging by 2025.

2.Government signatories working with industry and other stakeholders to achieve a 70% recycling rate for plastic packaging by 2025.

3.Unilever (50%), Mars Inc (25%) and PepsiCo (20%) set a 2025 target to reduce the amount of pure plastic used in packaging. Packaged goods brand companies and retailers have committed to increasing the recyclable content of their packaging by an average of 22% by 2025.

The environmental trends at home and abroad show that governments and large end-use brand owners are determined to promote a circular economy using single-material recyclable packaging, which is the general trend.

In flexible packaging production, biodegradable materials and paper alternatives to plastic packaging are receiving increasing attention, but the main trend in the sustainable development of flexible packaging is still to follow the 3R principle in the production of plastic film, namely: reduce (reduce), recycle (recycle) and reuse (reuse).

Amongst these, reduce means scientifically reducing the overall thickness and number of layers of the packaging, which requires both film and equipment performance improvements.

To make flexible packaging recyclable, it is important to avoid laminating films of different materials, such as the traditional PET/PE structure, which is known to be almost impossible to recycle. Single-material packaging is growing into the new industry standard, which can be achieved by coating a single layer of film with a functional fluid or by multi-layer laminated structures such as MDOPE / PE.

The main challenge in the production of single-material packaging is to maintain some functional requirements such as optical properties, barrier properties, mechanical properties, sealability, etc.

Our future development of single materials is also focused towards how to solve the barrier and heat resistance direction.

At present, domestic colour printing companies in single-material recyclable packaging attitude is very positive, generally believe that this is a major trend in the flexible packaging industry.

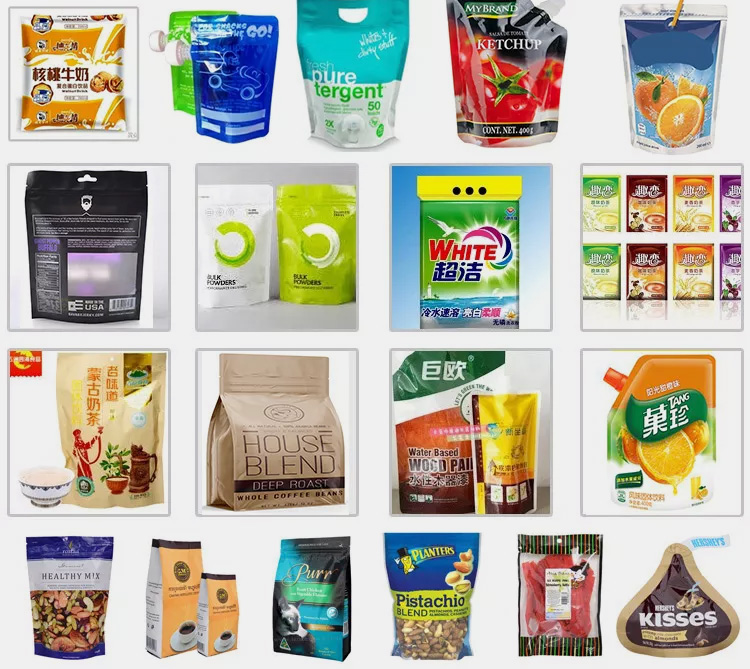

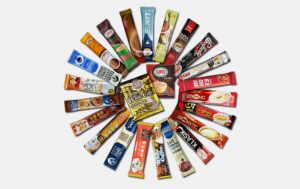

In terms of applications, focus on replacing the traditional BOPET/PE structure packaging, bag type to zip bags, stand-up pouches, the contents of coffee, pasta, cat food and dog food, snacks, dried fruit, daily chemical, etc., sales to export to foreign brand owners.

Yili has launched a paper-plastic structure of aseptic packaging, Nestle milk powder also uses a single polyolefin material milk powder bags, can be inferred that the process of domestic single material may soon, and is the emergence of explosive.

Although, the road to single-material packaging research and development will encounter many challenges and technical difficulties, but the single-material composite recyclability has the feasibility.

Single material composite makes flexible packaging recycling valuable and gives flexible packaging a second life. Overall, the future of single-material composite flexible packaging market prospects are promising.

Don't forget to share this post!

Stick Packing Machine Related Posts

Stick Packing Machine Related Products

Stick Packing Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine