Fish Oil Manufacturing: The Complete FAQ Guide In 2025

Do you know what fish oil is? Have you used fish oil related products in your life? Do you know that fish oil is one of the soft capsule products? Do you think fish oil is a medicine or a health product? Is the high quality of fish oil due to its production process? What is the difference between the production process of fish oil and ordinary soft capsule products?

By reading the whole post about fish oil manufacturing, you may learn about the production process of fish oil and its equipment. Unlike ordinary soft capsules, the production process of fish oil is more complicated and has more stringent requirements. It can improve your health to a greater extent.

1.What Is Fish Oil?

What Is Fish Oil-sourced: utsouthwestern

Fish oil is a healthy dietary supplement. It can supplement various nutrients that you lack. The nutrients in various precious fish are extracted and concentrated in the form of oil, and finally encapsulated into soft capsules for easy use by patients. Common fish used to make fish oil are whale, salmon, tuna and cod.

2.Why Do People Take Fish Oil?

You can get health benefits by consuming fish oil. These benefits mainly come from the valuable ingredients in fish oil, including Omega-3, DHA and EPA.

Support Heart

Support Heart-sourced: nytimes

It can help heart health, eliminate heart inflammation and improve your heart function.

Promote Joint Health

Promote Joint Health-sourced: kerry

For people who lack fitness and exercise, consuming fish oil can greatly improve joint health and thus promote exercise ability.

Maintain Healthy Blood Pressure

Maintain Healthy Blood Pressure-sourced: health

Fish oil can help maintain blood pressure balance in the human body, mobilize your positive emotions and promote physical health, improve your memory and motor skills, etc.

Vitamin Supplement

Fish oil contains other valuable ingredients and can also provide you with other types of vitamin supplements.

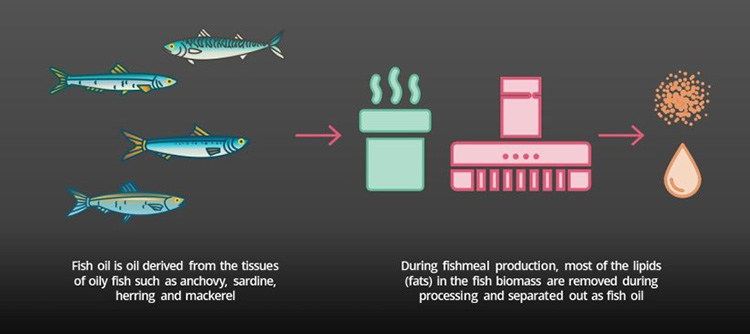

3.How Is Fish Oil Manufactured?

How Is Fish Oil Manufactured-sourced: iffo

The production process of fish oil is very complicated. It includes the early extraction and concentration of fish oil, the soft capsule packaging of fish oil, and the later quality inspection and monitoring of fish oil. The extraction of fish oil includes:

Extraction

AIPAK Fish Oil Extraction Machine

The fresh fish is heated and ground in the initial stage. So that the protein in the fish body condenses and releases the oil. The whole process requires the fish to be heated to about 95 degrees.

Separation

When the fish oil components in the fish body are extracted, the oil in the fish body is separated from other components through special processing technology. So as to obtain the essence of fish oil.

Purification

After the essence of fish oil is separated, further processing and purification are required. By removing impurities and toxins in the fish oil, the quality and safety of the fish oil can be guaranteed.

Drying

The separated and purified fish oil needs to further evaporate the water of its components. The water content in the fish oil needs to be reduced to below 0.05%, so as to maintain the high quality of the fish oil and the later storage.

The soft capsule packaging of fish oil for the mid-term includes:

Filling of fish oil soft capsules

Filling of fish oil soft capsules-sourced: iwilife

The essence of fish oil is sealed in the soft capsule by filling the soft capsule, so as to facilitate the storage and transportation of fish oil and the absorption of patients later.

4.What Is The Capsule Mainly Applied For Fish Oil Packaging?

Capsule Mainly Applied For Fish Oil Packaging-sourced: vantage-nutrition

Generally speaking, most fish oils on the market are packaged in soft capsules. This method can extend the freshness and shelf life of fish oil to a greater extent, and facilitate the patient's absorption in the body when used later. It is rarely packaged in the form of hard capsules, because hard capsules are more suitable for the encapsulation of powdered and granular drugs. Soft capsules are an affinity material for fish oil.

5.What Are The Benefits of Softgel Packaging For Fish Oil?

Why are soft capsules used for fish oil packaging? Because soft capsules have natural advantages for fish oil packaging. These include:

Attractiveness

Attractiveness-sourced: nutri-rich

Soft capsules are generally made of transparent materials. It allows users to clearly see the quality and color of the fish oil inside, which can attract users to buy and use it to a greater extent.

Uniform dosage

Uniform dosage-sourced: lifevisionhealthcare

Soft capsules can encapsulate different doses of fish oil ingredients to a greater extent. It not only protects the essence and drug ingredients in the fish oil, but also avoids waste by users.

High bioavailability

The airtight composition of the soft capsule can encapsulate the essence of fish oil to a greater extent, thereby preventing the loss of nutrients in the fish oil. And over time, the nutrients in the fish oil will not be lost.

Rapid disintegration

Rapid disintegration-sourced: mdpi

Soft capsules are made of gelatin. In addition to having good bioavailability, it can also disintegrate quickly after use and is more easily absorbed by the human body.

6.What Are The Types of Fish Oil?

There are many types of fish oil or fish oil capsules. It is mainly distinguished by the components of fish oil.

Natural fish oil

Natural fish oil-sourced: janathafishmeal

Natural fish oil is rich in DHA and EPA, as well as Omega-3. Different dosages can be controlled for your needs. In addition, it can provide you with necessary vitamins A and D.

Processed fish oil

Processed fish oil-sourced: jeffersonhealth

Compared with natural fish oil, processed fish oil is mainly made by concentrating and purifying natural fish oil, or by adding other fish additives. It can also remove mercury and other PCB pollutants in natural fish oil. This makes processed fish oil healthier and relatively cheaper.

Krill oil

Krill oil-sourced: riteflexhealth

Krill oil is also a type of fish oil. It is mainly produced by extracting ingredients from marine krill, refining and concentrating oil. It has strong antioxidant properties. Astaxanthin in the body can greatly improve human health.

Green-lipped mussel oil

Green-lipped mussel oil-sourced: hakalife

Green-lipped mussel oil is native to New Zealand. It contains rich EPA and DHA, as well as trace amounts of ETA. This ingredient can greatly reduce inflammation in the human body and is very environmentally friendly.

Flaxseed oil

Flaxseed oil-sourced: naturemade

Flaxseed oil is a healthy vegetable oil. It extracts nutrients from plants to obtain a nutrient called ALA. This ingredient can be directly converted into EPA and DHA after being absorbed by the human body, but the efficiency is relatively low.

Algae oil

Algae oil-sourced: everydayhealth

Algae oil is a kind of Y oil obtained by refining nutrients from marine algae. At the same time, its nutrients are also EPA and DHA. It is a good vegetarian alternative to fish oil, very environmentally friendly, and does not contain any metal pollutants.

7.Are There Side Effects to Take Fish Oil?

Fish oil is very healthy and has almost no side effects. Its special nutrients can greatly improve the body's functions. At the same time, it also has some minor side effects, including:

Fishy smell

Fishy smell-sourced: iwilife

Fish oil may have a fishy smell. If you don't like to eat fish or are a vegetarian, then they will refuse to take fish oil. This will make them feel uncomfortable or nauseous.

Indigestion

Indigestion-sourced: verywellhealth

The special nutrients in fish oil can cause indigestion side effects in some people with sensitive gastrointestinal tract or weak digestion and absorption ability. At this time, you need to use other oils with lower content or lower nutritional content as a substitute.

Prone to allergies

Prone to allergies-sourced: drfullerallergy

Fish oil is mainly made from nutrients extracted from marine organisms and fish organisms. It is very unfriendly to patients with seafood allergies or fish allergies.

8.What Are The Main Equipment For Fish Oil Manufacturing?

This part mainly introduces the fish oil softgel encapsulation machine, drying machine and counting machine.

Fish Oil Extraction Machine

AIPAK Fish Oil Extraction Machine

Fish oil extraction machine is a device that is specially used to extract essence from various biological or plant species. It is widely used in pharmaceutical, health care, cleaning, daily chemicals, food and other industries. By using supercritical CO2 as a solvent, it can extract and separate various solid substances under appropriate high pressure and high temperature.

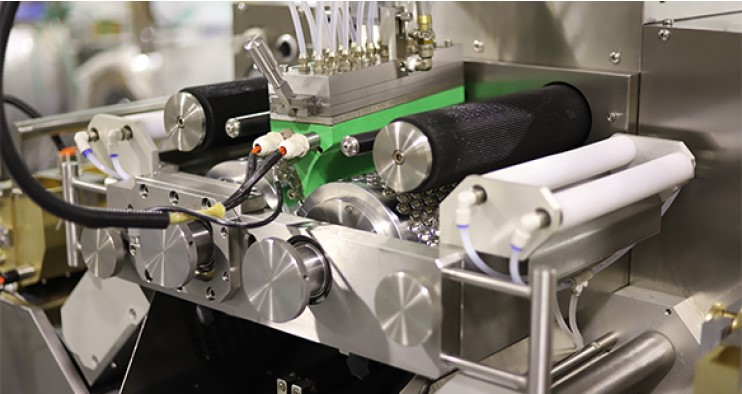

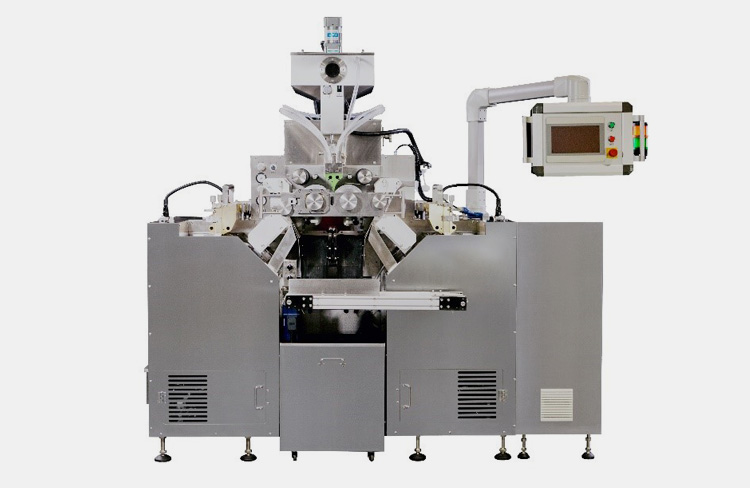

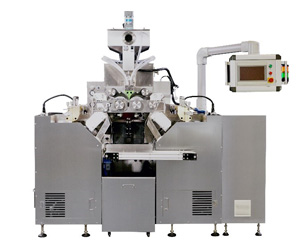

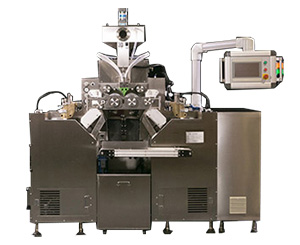

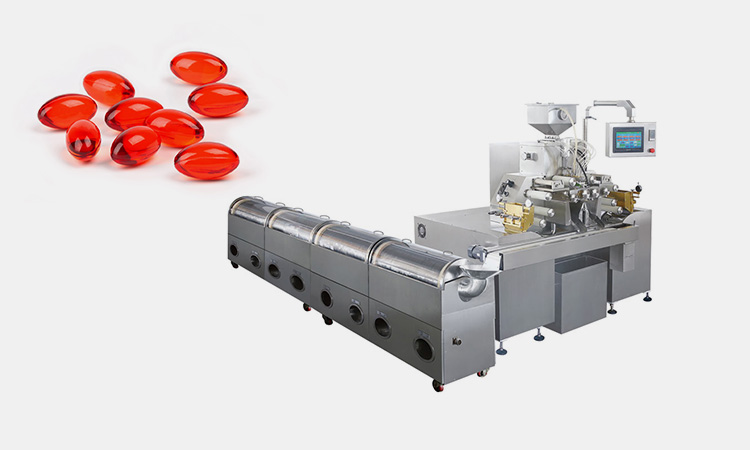

Softgel encapsulation machine

AIPAK softgel encapsulation machine

Softgel encapsulation machine is a softgel encapsulation machine specially used for oil, liquid, semi-liquid or suspension. It is widely used in various pharmaceutical, health care and cosmetic industries. This equipment can produce various types of high-precision softgel products for you. The softgel products produced contain precise drug dosage.

Softgel drying tunnel

Softgel drying tunnel-sourced: cvctechnologies

The softgel drying tunnel is used for drying and moisture removal after the softgel is made. It can maintain the moisture content in the softgel shell just produced to a stable level, thereby changing the hardness of the softgel and reducing the viscosity of the softgel.

Softgel counting machine

AIPAK softgel counting machine

The softgel counting machine can be used for counting softgels of different sizes, sizes and shapes, and filling the softgels into different containers. It mainly adopts a unique optical detection system to ensure a high level of counting accuracy and filling speed for various softgels.

9.What Can The Fish Oil Manufacturing Equipment Bring You?

Some fish oil soft capsule packaging machines on the market are novel in design and fully functional, which are very suitable for human functions. They can allow you to produce fish oil soft capsule products with moderate hardness, soft taste, and easy to swallow while using the equipment. Its advantages mainly include:

Reasonable design

Reasonable design of AIPAK softgel encapsulation machine

The appearance of the fish oil soft capsule packaging machine is mainly made of stainless steel. It has a glossy and simple appearance design, easy to operate, and can allow soft capsule manufacturers or workers to produce high-quality fish oil soft capsules with simple operations.

Compact structure

Compact structure of AIPAK softgel encapsulation machine

Most fish oil soft capsule packaging machines can not only be used on various production lines, but also facilitate your later cleaning and connection of various drying auxiliary equipment, with a compact structure.

High production capacity

High production capacity-sourced: vecteezy

The fish oil soft capsule packaging machine has a very strong packaging capacity, which can meet your production needs of different types of fish oil soft capsules. At the same time, it has low dependence on labor, and only manual training can achieve high-yield fish oil soft capsule production results in a short time.

Easy maintenance

Easy maintenance-sourced: vecteezy

You can perform simple maintenance, cleaning and lubrication on the machine by disassembly. It has no complex parts, which is convenient for your later maintenance and online use.

Solid structure

The fish oil soft capsule production machine uses solid stainless steel and aluminum alloy materials as the frame. It ensures mechanical durability, and can also handle some corrosive materials to maintain the long-term stability of the machine.

10.What Are The Main Parts of Fish Oil Manufacturing Equipment?

The main parts of fish oil manufacturing equipment are:

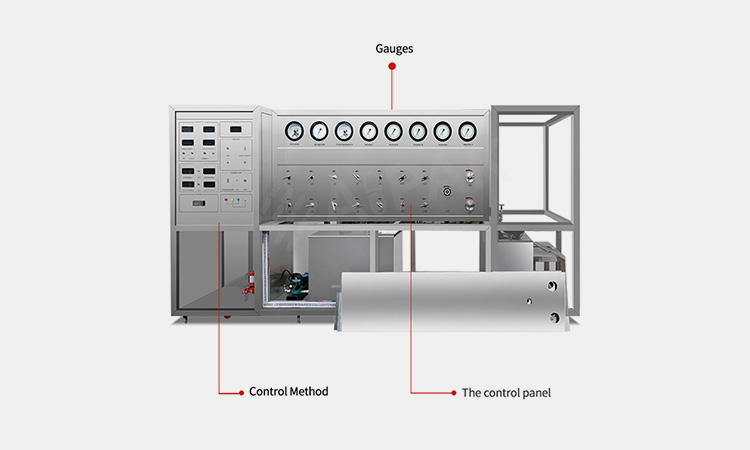

Main parts of the fish oil extraction machine:

Main parts of AIPAK fish oil extraction machine |

|

| Gauges | Used to display and control the critical pressure and critical temperature of the equipment during operation. It can also display the state of fluids and gases. |

| Control method | The control method is mainly divided into semi-automatic and fully automatic modes. Semi-automatic requires manual control and monitoring, and fully automatic mainly involves PLC program settings and automatic equipment monitoring. |

| The control panel | There are various dials on it, which can help you control each link of the refining process and make corresponding controls. |

Main parts of the softgel encapsulation machine:

Main parts of AIPAK fish oil manufacturing equipment |

|

| PARTS | DESCRIPTION |

| Hopper | It is located at the top of the equipment and is mainly used to store fish oil and fish oil mixtures. In addition, it can also store various liquids, semi-solids, suspensions, and various powders and granular materials. |

| Mold Roller | The mold stick is suitable for the formulation of the shape and size of soft capsules. It is a cylindrical metal part. There are cavities inside the mold stick. These cavities mainly determine the shape, size, etc. of the fish oil soft capsules you produce. |

| Cooling Drum | Also known as gelatin belt, it is a key component of the soft capsule encapsulation machine. When the gelatin mixture is poured on the cylinder and then cooled, a gelatin belt can be formed. |

| Conveyor Belt | When the fish oil soft capsule is successfully made, it will be de-molded and then fall onto the conveyor belt. The conveyor belt will transport the fish oil soft capsules to the dryer or drying machine for the next step of processing and operation. |

| Lubricating roller

|

During the formation of gelatin strips and the encapsulation of fish oil, it can minimize the friction between gelatin and the machine, thereby ensuring the quality of fish oil soft capsules. |

| Drum dryer

|

After the fish oil soft capsules are successfully made, the drum dryer will further dry and dehumidify these fish oil soft capsules. Prevent the soft capsules from sticking. |

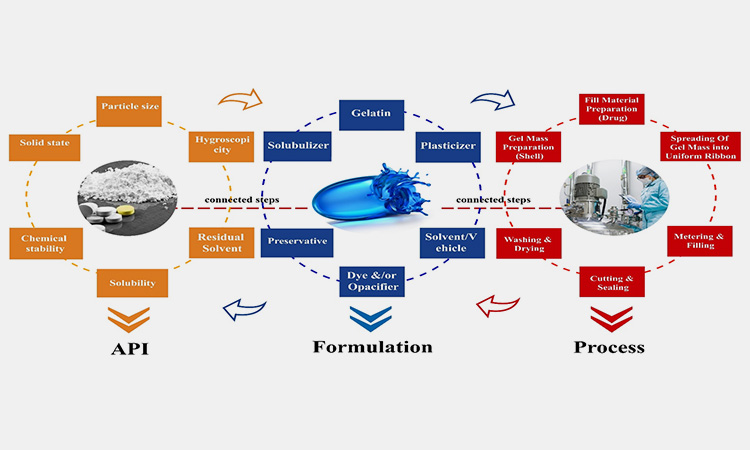

11.What Is The Fish Oil Encapsulation Process For Fish Oil Manufacturing?

The encapsulation process of fish oil is a very core part. It includes:

Soft capsule material selection

Soft capsule material selection-sourced: pharmaexcipients

- First, you need to prepare the materials for soft capsules, including:

- Gelatin: You can use animal gelatin or plant gelatin. They are both elastic and strong.

- Plasticizer: You can use glycerol. It can increase the flexibility of soft capsules.

- Water: It can ensure that the gel remains operable during the encapsulation process and will not break easily.

- Additives: You can choose the corresponding sunscreen according to the formula to enhance the stability of the appearance of the soft capsule and prevent the quality of the fish oil from being affected by direct sunlight.

Fish oil material selection

When choosing fish oil, you can add other hydrophilic materials to adjust the solubility of the API to meet the viscosity, stability and uniformity of the oil, etc.

Fish Oil Encapsulation Process For Fish Oil Manufacturing-sourced: AIPAK

Preparation of gelatin

- Add and mix the soft capsule materials you have selected;

- Cook by heating;

- During the cooking process, pay attention to the addition of water and the treatment of viscosity;

Production of soft capsule shell

- Pour the heated and mixed gelatin mixture into the casting cylinder;

- The casting cylinder and the round drum will rotate continuously;

- Through heating, the gelatin mixture gradually becomes a gel band with uniform thickness;

- When the gelatin band is formed, it will be sent to the cold fan area for drying and cooling;

Filling of fish oil and sealing of soft capsules

- Use the injection pump and wedge block to inject the quantitative fish oil into the cavity of the air-dried gel band;

- When the cavity is filled, the drum will automatically heat and seal the soft capsule;

- The soft capsules filled with fish oil are seamlessly connected;

De-molding

- The seamlessly connected soft capsules will be cut and de-molded;

- So that they automatically fall on the conveyor belt;

Drying

The de-molded soft capsules will be sent to the drying drum by the conveyor belt for drying;

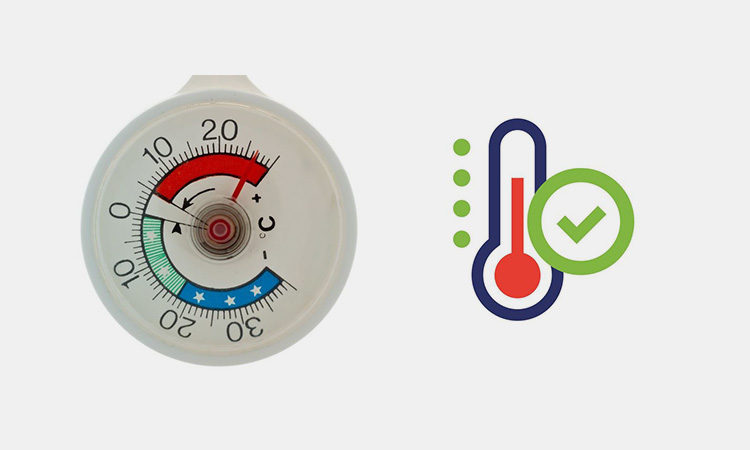

12.What Is The Temperature and Humidity Control During Fish Oil Manufacturing?

The temperature and humidity of the fish oil soft capsule production environment need to be controlled at about:

Temperature control

Temperature control-sourced: bakerpedia

It needs to be kept at about 21℃. This can not only maintain the flexibility of gelatin, but also ensure the quality and freshness of fish oil.

Humidity control

Humidity control-sourced: sylvane

The humidity in the fish oil soft capsule production area usually needs to be maintained at 25~30%RH. The humidity in the dry area needs to be maintained at about 20%~25%RH. This can achieve the requirements of soft capsule shell hardness at different stages.

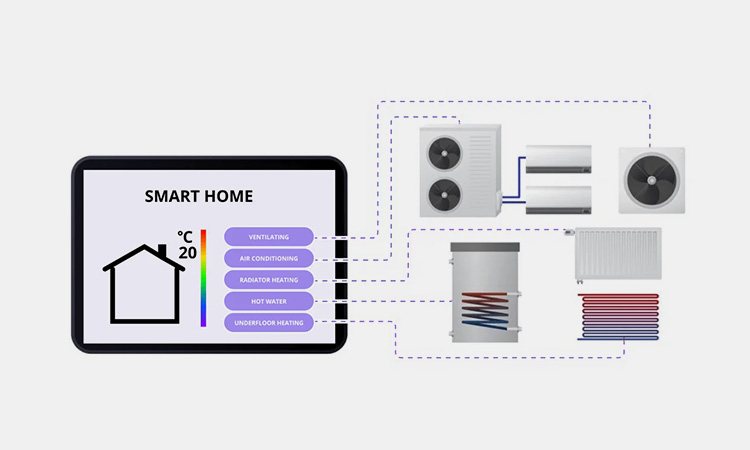

HVAC system

HVAC system-sourced: euristiq

The HVAC system needs to provide air filtration and appropriate pressure difference. This can not only maintain the air cleanliness during the fish oil soft capsule production process, but also prevent cross-contamination of pollutants.

13.What Are The Softgel Defects You may Encounter During Fish Oil Manufacturing?

Defects that are easy to occur in the production process of fish oil soft capsules include:

| Softgel defects | Images | Description | Cause |

| Bubbles in the filler |

Bubbles in the filler-sourced: sensum |

Fish oil soft capsules have small gaps or bubbles. This will cause the fish oil to deteriorate during storage or transportation. | It is caused by the fact that the soft capsules do not use degassing technology during the production process, that is, the air in the capsules is not additionally extracted during the mixture filling process. |

| Sedimentation |

Sedimentation-sourced: sensum |

It usually refers to the sedimentation of suspended particles in the fish oil soft capsules, resulting in uneven distribution of the mixture in the fish oil capsules. | This is usually because the fish oil is not properly homogenized during the refining and purification process, resulting in its unstable viscosity. |

| Opaque gelatin |

Opaque gelatin-sourced: sensum |

That is the appearance of the soft capsule shell is opaque and has impurities. | This is mainly because not enough water is added to the gelatin during the production process, resulting in a turbid appearance. |

| Uneven surface |

Uneven surface-sourced: sensum |

It is mainly reflected in the uneven thickness of the gelatin and the uneven color of the ingredients. | During the production of gelatin tape, there are contaminants in the mold or dosage problems. |

| Color change |

Color change-sourced: sensum |

It refers to the change in the color of the fish oil soft capsule shell during the production and packaging of gelatin. | This is mainly because the colorant is not evenly dispersed during the production of gelatin. |

| Capsule shell leakage |

Capsule shell leakage-sourced: sensum |

Capsule shell leakage refers to the leakage of oily components and other drug components in the shell of fish oil soft capsules after production, which affects the quality of the product. | The syringe pump and wedge are not calibrated. |

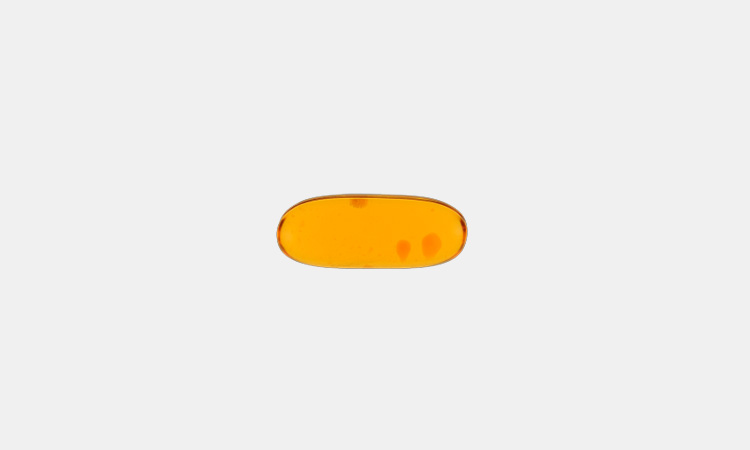

| Spots |

Spots-sourced: sensum |

This mainly refers to foreign matter or contamination in the oily components in the soft capsule. | Exogenous contaminants enter the soft capsule due to improper equipment cleaning. |

| Burrs |

Burrs-sourced: sensum |

The surface of the soft capsule is uneven or the seam boundary is not smooth. | This is mainly because the soft capsule is not cut or polished correctly after encapsulation. |

| Size inconsistency |

Size inconsistency-sourced: sensum |

This is caused by uneven thickness of the gelatin tape of the equipment or inaccurate dosage of the can. | Correctly control the dosage of gelatin tape and the dosage of filling materials during the formation process. |

| Wrinkling or shrinkage |

Wrinkling or shrinkage-sourced: sensum |

After drying, the soft capsule wrinkles or shrinks, resulting in the soft capsule not reaching the predetermined shape or size. | There is a problem with the soft capsule shell formula. |

| Cracks |

Cracks-sourced: sensum |

Cracks appear on the surface of the capsule shell. | During the preparation process of the gelatin mixture, insufficient water is added, resulting in cracks in the gelatin tape during the soft capsule encapsulation process. |

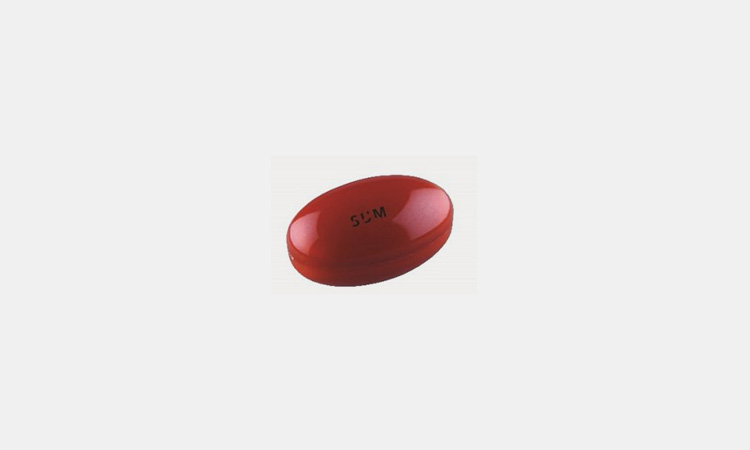

| Incomplete printing or printing errors |

Incomplete printing or printing errors-sourced: sensum |

The printing of fish oil soft capsules is incomplete, and the printed date and content cannot be clearly seen. | During the later encapsulation and packaging process of fish oil soft capsules, due to insufficient ink supply or failure of the printing equipment, the ink adhesion is weak or poor. |

14.What Are The Common Problems And Solutions You May Have During Fish Oil Manufacturing?

The above explains the defects that are easy to occur in the shell of fish oil soft capsules. Now let's introduce the challenges and solutions encountered in the production process of fish oil soft capsules. Mainly include:

Uneven thickness of gelatin tape

Uneven thickness of gelatin tape-sourced: farmako

It will cause improper sealing of fish oil soft capsules or defects in capsules.

Solutions

Periodically calibrate the casting cylinder or gelatin cylinder;

Set the temperature and speed of the gelatin tape during mixing and production;

Test in advance before formal production to see if the thickness of the produced gelatin tape is uniform and consistent;

Weak or leaking seams in soft capsules

Weak or leaking seams in soft capsules-sourced: sensum

If the seams of fish oil soft capsules are too thin, they are prone to leakage, which may cause the subsequent fish oil products to deteriorate and contaminate.

Solutions

You can solve this problem by adjusting the wedge temperature, which will cause the rotary mold to align correctly;

At the same time, during the filling process of fish oil soft capsules, the thickness of the seams should be monitored in real time to ensure that the thickness can reach about 20%.

Inconsistent weight of soft capsules

Inconsistent weight of soft capsules-sourced: sensum

The weight of the filler in the fish oil soft capsule is inconsistent, which may affect the final efficacy and safety of the product. Changes in weight will lead to changes in dosage.

Solutions

Regularly check the injection pump of the fish oil material, adjust and calibrate its dosage;

Ensure that the fish oil material is accurately metered during the filling process;

Adjust the servo control. To maintain the accuracy of the dosage and the speed of injection;

Regularly check and replace the injection pump or filler components to maintain the efficient operation of the parts;

Adhesion of capsule shell

If the capsule shell adheres after production, it will affect the normal operation of the equipment and reduce the efficiency of subsequent large-dose production.

Solutions

Regularly lubricate the injection pump and wedge to prevent the equipment from being too dry, which will affect its filling efficiency;

15.What Is The Quality Assurance and Inspection For Fish Oil Manufacturing?

The production quality monitoring of fish oil is very strict.

Quality assurance

Quality assurance-sourced: healthline

In 1994, FDA has included the production and sale of dietary supplements in the scope of supervision. Various regulatory measures are taken to ensure the quality inspection and monitoring of fish oil soft capsule products, thereby ensuring the quality and safety of the products.

Quality inspection

Quality inspection-sourced: eskimo3

By random inspection, batch inspection of the soft capsule products that have been completed is carried out. This includes the consistency of the size, dimensions and shape of the soft capsules. There is also the accuracy of the quality, composition and dosage of the fish oil products in the soft capsules.

Conclusion:

The production and packaging of fish oil involves high-quality process technology and equipment support. Through this complete FAQ guide of fish oil manufacturing, you can learn about the professional steps that fish oil undergoes from extraction to packaging. Whether you are a fish oil production supplier or an industry enthusiast, you can feel the charm of fish oil production through this post. If there are more about fish oil and softgel manufacturing, come to AIPAK now!

Don't forget to share this post!

Softgel Encapsulation Machine Related Posts

Softgel Encapsulation Machine Related Products

Softgel Encapsulation Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine