Factors Affecting The pulverizing Effect Of Airflow Pulverizer Machine

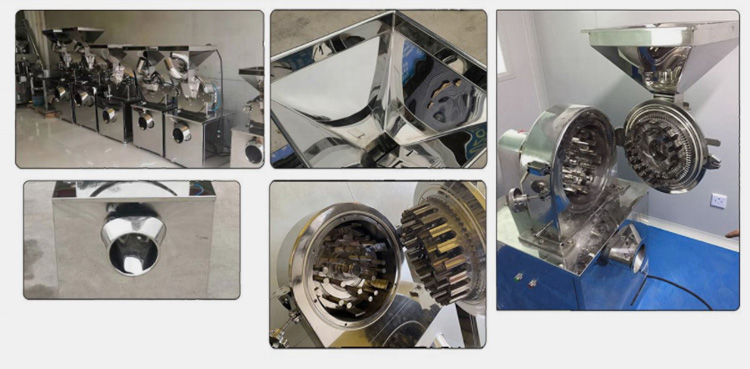

In the traditional Chinese medicine area, the airflow pulverizer machine plays an important role. It can micro-pulverize the cell level, so that the effective ingredients are fully released, and the bioavailability is greatly improved.

Otherwise, under the premise of ensuring the curative effect, it can the dosage of medicine and the and the quality of finished products is stable and controllable.

With the continuous promotion of favorable policies for traditional Chinese medicine, as well as

people's renewed understanding and recognition of traditional Chinese medicine, the scale of the traditional Chinese medicine market will continue to expand.

It is understood that the airflow pulverizer machine is also known as airflow grind, jet grind or flow grind. It is a kind of mechanical equipment that uses the energy of high-speed airflow (300-500m/s) or superheated steam (300-400℃) to pulverize the solid materials.

As one of the commonly used ultrafine pulverizing equipment, airflow pulverizer machine is widely used in ultrafine pulverizing and beating forming of superhard materials such as chemical materials, medicine, food and metal powders.

Some customers express that an airflow pulverizer machine has a wide range of particle size, simple and convenient operation, but in the process of pulverizing, often the pulverizing effect is not the same.

What does this happen? The technical staff of a powder equipment company said that the pulverizing effect of the airflow pulverizer machine is mainly affected by the following factors: gas-solid ratio, feed particle size, temperature of the working medium, pressure of the working medium and pulverizing additives.

Gas-solid ratio

It is reported that the gas-solid ratio is an important technical parameter and also an important index. If the gas-solid ratio is too small, the kinetic energy of the airflow will be insufficient, and then affect the fineness of the product.

So, some technicians suggest that when customers take superheated steam as the working medium, the hard material after pulverizing calcination, the gas-solid ratio is generally controlled in 2-4:1, and the material after pulverizing surface treatment is generally controlled in 1-2:1.

Feed particle size

When smashing hard materials, there is a strict request of the feed particle size. As far as titanium powder is concerned, it needs to be controlled in 100-200 mesh when pulverizing calcined material; the material after grinding surface treatment is generally 40-70 mesh, not more than 2-5 mesh.

Temperature of the working medium

The technical personnel says that when the temperature of the working medium is too high, the flow of gas will speed up.

Taking the air as an example, the critical speed at room temperature is 320m/s. When the temperature rises to 480℃, the critical speed can be increased to 500m/s, that is, the kinetic energy increases by 150%. Therefore, increasing the temperature of the working medium is conducive to improving the pulverizing effect.

Pressure of the working medium

It is known that the pressure of the working medium is the main parameter to produce the jet flow velocity, and also the main parameter to affect the pulverizing fineness. In general, the higher the working fluid pressure, the faster the speed and the greater the kinetic energy. So what’s the right pressure for pulverizing?

Some technicians said that this mainly depends on the pulverization degree and fineness requirements of the material. For example, when pulverizing titanium powder with superheated steam, the steam pressure is generally 0.8-1.7 MPa. Generally, the general pulverizing calcined material is higher, and the material after pulverizing surface treatment can be lower.

Pulverizing additives

Technical personnel said that the airflow pulverizer machine in the pulverizing process, if the appropriate pulverizing additives are added, not only can improve the efficiency of pulverizing, but also improve the dispersion performance of products in the medium. So how to choose pulverizing auxiliaries?

It is understood that titanium dioxide surface treatment, the addition of organic surfactants in most have the function of pulverizing additives, and inorganic grinding additives generally use sodium hexametaphosphate and sodium pyrophosphate (potassium).

At present, the airflow pulverizer machine on the market can basically meet the needs of traditional Chinese medicine pulverizing.

However, according to many customers, the airflow pulverizer machine is prone to the phenomenon of pouring when the pulverizing system is blocked, and a large amount of dust is ejected, worsening the operating environment. How to solve these problems in these situations?

In terms of this situation, some technical personnel from the airflow pulverizer machine manufacturers said that the use of ultrafine airflow pulverizer in the process of pulverizing, the production of dust is unavailable, but if a large mount of dust is taken in by the human body, it will cause harm to the body.

Therefore, it is suggested that customers can take the following measures to reduce dust in the process of operating the ultramicro airflow pulverizer machine.

First, install filter and dust removal equipment. For the dust produced by the airflow pulverizer, you can use foam dust removal, add wetting agent dust removal, ultrasonic atomization technology dust removal, composite filter bag dust removal, folding dust removal cloth bag, wide spacing electrostatic dust removal, these dust removal methods are good.

Second, if there is a slight leakage of dust in the manufacturing process, the dust will come out and cause pollution in the work area. Therefore, the customer needs to ensure the tightness of the joint of the airflow pulverizer machine.

Third, increasing the humidity in the operation area of the airflow pulverizing machine, strengthening ventilation, and preserving fire extinguishing equipment can effectively avoid the damage caused by dust inhalation into the human body.

Fourth, the manufacturer should configure corresponding protective equipment for the airflow pulverizer machine’s operators according to the regulations. At the same time, operators should also wear protective equipment correctly according to regulations.

Fifth, it is necessary to maintain and manage the existing dust-proof equipment to ensure that it can operate normally and play a role of dust-proof. The maintenance and management of equipment seems to be simple, but in fact there are many places that need to be dealt with and paid attention to.

The measures mentioned above are preventive measures. The industry professionals said that in order to prevent the harm caused by the dust produced by the airflow pulverizer machine, the manufacturing companies of the airflow pulverizer machine should also invest more money in technological transformation to improve the dust-proof efficiency and operation automation level of dust-proof equipment, and reduce the problems caused by dust.

Don't forget to share this post!

Granulator Machine Related Posts

Granulator Machine Related Products

Granulator Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine