Facial Cleanser Packaging: The Complete FAQ Guide In 2025

Whether you're a cosmetics manufacturer, packaging engineer, or simply interested in the field, you have to understand the intricacies of the facial cleanser packaging process. From understanding the key components of a machine to the best practices for ensuring consistency and accuracy in packaging, we've got it all covered.

Join us on this journey as we delve into the exciting world of facial cleanser packaging machines and discover the future of this industry. Get ready to take your packaging process to the next level and stay ahead of the curve with our expert insights and analysis.

1.What Is Facial Cleanser Packaging?

Facial cleanser packaging refers careful preparation of filling material that can hold your product. It is typically stored in jars, tubes, sachet, bottles, etc., and may include instructions for use, ingredient lists, and expiration dates. Better yet, they are manufactured in a modern way to present the product look more glamorous. The packaging offers long-lasting and durable outcomes and assures you that your product will remain safe and protected.

2.What Are Facial Cleanser Packaging Applications?

Facial cleanser packaging is a highly programmed process in term of manufacturing and transportation. With different types of containers and packaging materials, it provides flexibility in packaging trends. That is why, it is implemented in other industrial sectors also, such as:

Pharmaceutical

In the healthcare sector, facial cleansing packaging is implemented for packaging ointment, lotions, anesthetics, eye creams, sun- creams, dermatitis, bandage, or burnt goods.

Food and Beverages

Facial cleanser packaging is utilized in the food sector for storing viscous products like ketchup, mayonnaise sauces, mustard paste, jams, dressing, etc.,

Cosmetic and Toiletries

Products such as skin foundation, eye creams, facial kits, massage lotions, hair waxing creams, toothpaste, etc., are also filled in facial cleanser packaging.

Automotive

In the automotive industry, this method of packaging is utilized for packaging varnishes, paints, leather care., etc.

Pet Products

Veterinary products like pet shampoo, conditioners, ticks creams, stain remover, anesthetics, disinfectants, etc., are packed using facial cleanser packaging.

Chemicals

Various chemicals, such as bonds or glues, sealants, coating agents, paints, degreasers, etc., are dispensed in this packaging.

3.What are the 7 Best Facial Cleanser Packaging Design Ideas?

Pump Bottle

A facial cleanser in a pump bottle. Pump bottles are a popular packaging option for facial cleansers as they allow for easy and controlled dispensing of the product, which can help to prevent waste.

Squeeze Tube

A facial cleanser in a squeeze tube for travel-friendly packaging. Squeeze tubes are a great option for facial cleansers as they are effortless to use and can be easily packed for travel.

Biodegradable Container

A facial cleanser in a biodegradable container for eco-friendly packaging. Biodegradable packaging can be a great option for facial cleansers as it can help to reduce the impact of the product on the environment.

Airless Pump

A facial cleanser in a container with an airless pump for preservation of product's integrity. Airless pumps are commonly used in facial cleanser packaging as they help in keeping the product fresh and preserve its integrity.

Dropper

A facial cleanser in a container with a dropper for seamless and accurate dispensing

Spray Nozzle

A facial cleanser in a container with a spray nozzle for simple and refreshing application. A spray nozzle can be a great option for facial cleansers as it can provide a rejuvenating and invigorating experience.

Flip-Top Cap

A facial cleanser in a container with a flip-top cap for trouble-free opening and closing. A flip-top cap can be a great option for facial cleanser packaging as it can make the product easy to open and close, which can be especially useful for people with limited dexterity.

4.What are Facial Cleanser Packaging Types?

There are several types of packaging that are commonly used for facial products, including:

| Jars

Jars are a popular choice for packaging facial products such as creams, lotions, and balms. They can be made of a variety of materials such as glass, plastic, and aluminum, and can be sealed with a variety of different types of closures such as screw-on lids, snap-On lids, and flip-top caps. |

|

| Bottles

Bottles are used for packaging facial products such as toners, cleansers, and serums. They can be made of a variety of materials such as plastic, glass, and aluminum, and can be sealed with a variety of different types of closures such as screw-on lids, pump dispensers, and dropper caps. |

|

| Tubes

Tubes can be used for packaging facial products such as creams, gels, and lotions. They can be made of a variety of materials such as plastic and aluminum, and can be sealed with a variety of different types of closures such as screw-on caps, flip-top caps, and nozzle caps. |

|

| Sachets

Sachets are a popular choice for packaging small amounts of facial products such as masks, exfoliants, and peels. They can be made of a variety of materials such as plastic, paper, and aluminum, and can be sealed with a variety of different types of closures such as heat seals, cold seals, and ultrasonic seals. |

|

| Pouches

Pouches are used for packaging facial products such as powders, liquids, and gels. They can be made of a variety of materials such as plastic, paper, and aluminum, and can be sealed with a variety of different types of closures such as heat seals, cold seals, and ultrasonic seals. |

|

| Boxes

Boxes are a popular choice for packaging facial products such as sheet masks, facial wipes, and facial sponges. They can be made of a variety of materials such as paperboard, plastic, and aluminum, and can be sealed with a variety of different types of closures such as tuck-in flaps, glue, and snaps. |

|

It's important to note that these are not the only types of packaging that can be used for facial products and that the type of packaging used will depend on the specific product, its characteristics, and the company's preferences.

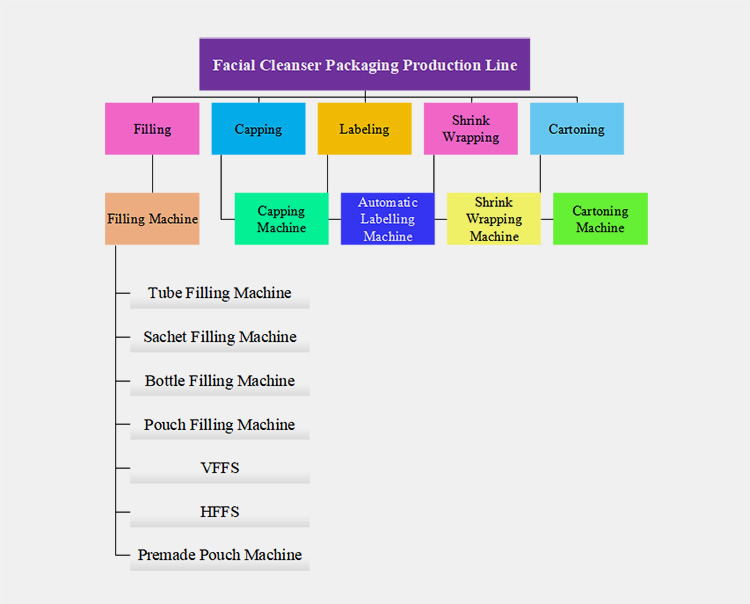

5.What are Various Facial Cleanser Packaging Machines?

There are several types of machines that are used in the production of facial cleanser packaging. We have categorized them into two parts:

- According to Automation

- According to Packaging Type

ACCORDING TO AUTOMATION

Automatic Facial Cleanser Packaging Machine

A fully automated machine that can handle all aspects of the packaging process, from forming and filling the package to sealing and labeling it, without any human intervention.It is equipped with advanced control systems and sensors that allow it to automatically detect and correct any issues that may arise during the packaging process.

It can operate at high speeds and handle a large number of packages in a short amount of time, making it suitable for high-volume production.

Semi-Automatic Facial Cleanser Packaging Machine

It is a machine that requires some level of human involvement in the packaging process.It may be used for specific stages of the process such as filling, or manual labeling of the package. Moreover it is generally less expensive than fully automatic machines, but comparatively less efficient than automatic machine.

ACCORDING TO PACKAGING TYPE

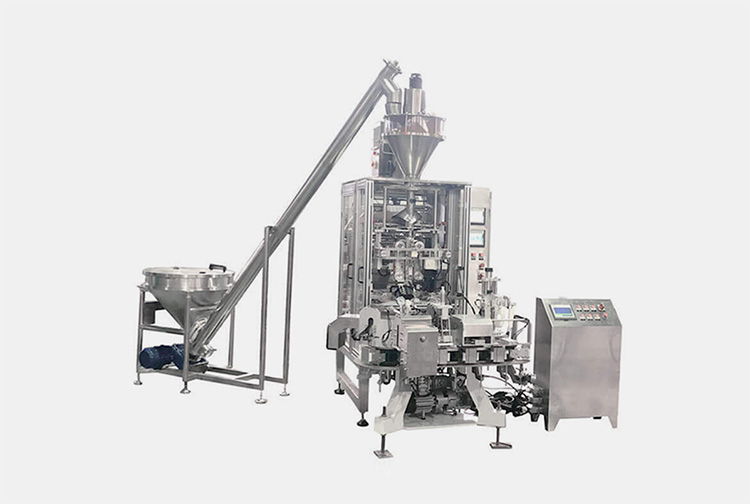

Vertical Form Fill Sealing Machine

A vertical form fill sealing machine is used to pack products such as cans, tubes, bottles, and jars right after they are filled. It restricts ingredients in containers or forms by sealing them vertically so that the shape of the product remains intact.

Working: The film unwinder supplies the plastic film to the machine. The film is then fed into the film former, where it is shaped into a tube. The product is then fed into the tube and the filling and sealing mechanism seal the top of the package.

Horizontal Form Fill Sealing Machine

Horizontal form-fill sealing machines are used to make many different types of paper and foil bags, fiberboard boxes and trays, corrugated tubes for packaging product.

Working: The film moves horizontally through the machine and is often fed into it on rollers that move in an elliptical pattern rather than a typical rectangular one. These machines can be used to make pouches out of film rolls, saving factories money down the line by not having to buy individual pieces of plastic or aluminum foil.

Stickpack Machine

Stick pack machines are used to package, fill and seal thin, flexible packets typically containing liquids or powders.

Working: The operator loads raw materials into the machine's hopper. The automated system then funnels these materials into containers. The film is formed into a tube shape, which then encloses the filling chamber. The ends of the tube are then sealed to create a stick pack. The machine cuts the sticks to size and then ejects them.

Sachet Packaging Machine

A sachet packaging machine is a type of equipment that packages small quantities of liquid, powder, or granular products into individual sachets.

Working: These machines typically use a form-fill-seal process in which the sachets are form where product is filled into it, then sealed and cut to create individual packages. The machine may use a variety of methods to fill the sachets, such as volumetric fillers or liquid fillers.

Tube Filling Machine

A tube-filling packaging machine uses tubes to fill and seal various products such as creams, gels, pastes, and adhesives.

Working: The filling system is responsible for dispensing the product into the tubes. This is done using a volumetric or gravimetric filling system, which dispenses a specific amount of product into each tube. These machines typically use a form-fill-seal process, in which the machine feeds each bottle with its contents before sealing it at the top and bottom.

Multi-Head Facial Packaging Machine

A multi-head weigher is a machine that accurately weighs and dispenses products into containers. It does this by using a vibratory feeder to place the product onto multiple weighing heads that each contain load cells for measuring weight, and an algorithm to select the optimal combination of weights to reach the desired target. This efficient process helps ensure accurate product packaging.

Working: A multi-head weigher holds the material in its hopper, which is then fed into the system. Vibratory feeders are typically used to distribute the product across multiple weighing heads. A set of load cells is attached to each weighing head to ensure accurate weighing. The multi-head weigher uses advanced algorithms to determine the optimal combination of weights from the different weighing heads, then dispensed into a sealed bag or container.

6.What Are The Benefits Of A Facial Cleanser Packaging?

There are several benefits of using facial cleanser packaging in the various industrial sector:

Consistency and Accuracy:Facial cleanser packaging is designed to ensure that products are packaged consistently and accurately, which is essential for providing product quality and consistency.

Cost Savings:Using a specialized packaging format can reduce the costs associated with precision and consistency.

Compliance:The use of facial cleanser packaging ensures that products comply with industry regulations and standards.

Safety:The use of facial cleanser packaging machines reduces the risk of human error, increases safety, and reduces the risk of injuries caused by repetitive manual labor.

Less Waste and Material Consumption: Facial cleanser packaging is designed to use a minimal amount of material and packaging, reducing waste.

Quality Control

A facial cleanser packaging ensures that the packaging is free from defects, this is accompanied by quality control features such as cameras and sensor.

7.Which Machines Are Involved In Facial Cleanser Packaging?

The production line process for facial cleanser packaging machines typically includes the following steps:

STAGE 1: Filling

This process is accompained by filling machine that dispenses the facial product, such as creams or lotions, into the packaging container.

Facial Cleanser Filling Machine

There are different series of filling machines as discussed above like tube filling, VFFS, HFFS, and others. All these equipment have many similar features i.e. accuracy and precision, high tech components, automation and versatility.

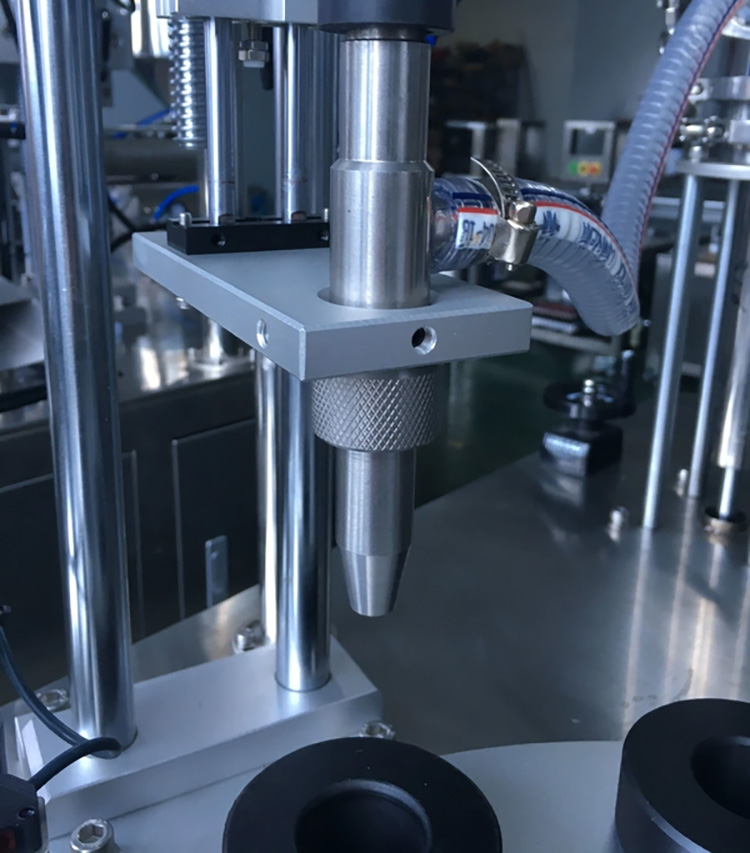

STAGE 2: Capping

A facial cleanser is secured and tightened properly with the help of a capping machine. This is an important equipment used by every company in order to provide ease of multiple openings to the end user.

Facial Cleanser Capping Machine

From automatic to semi-automatic a wide range of different models that can be customizable as per requirement is available in the market. These includes different types such as screw cappers, snap cappers, and press-on cappers.

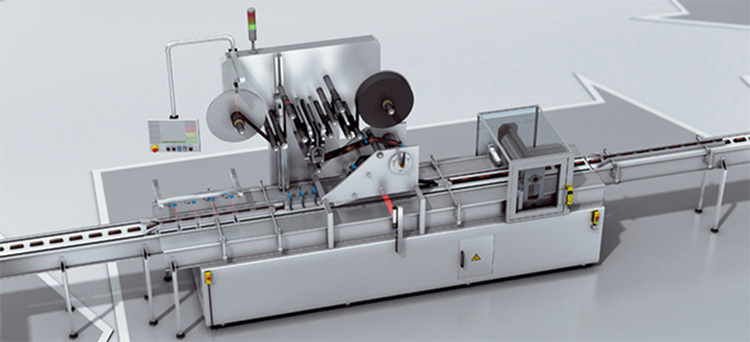

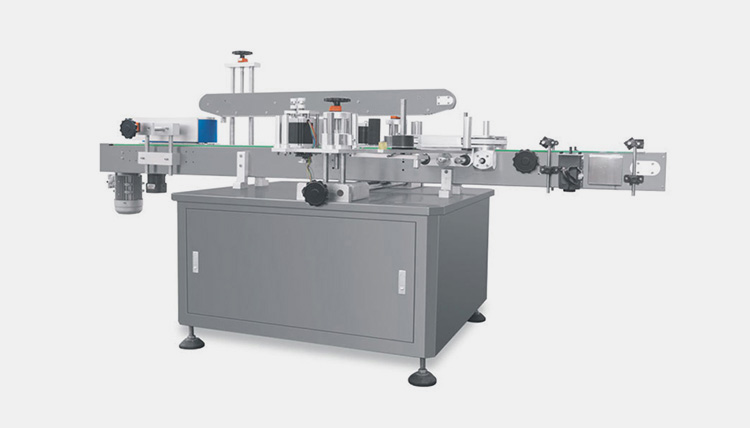

STAGE 3: Labeling/Printing

The labeling mechanism is applied to a consistent and high-quality label to ensure that the product appears professional and polished. Furthermore, labeling is critical for compliance with regulations and industry standards. Proper labeling is necessary to ensure that product is mentioned with the required information, such as; nutritional information, allergen warnings, expiration date, and contact information.

Facial Cleanser Labeling Machine

Like other units facial cleanser labeling machine is also powered by a series of mechanical and electronic systems to label primary containers of different sizes and shapes. Typical features of this unit include application of single label or multiple labels, print manufacturing, expiry and batch details etc.

STAGE 4: Shrink Wrapping

You can consider this process as secondary packaging where a shrink-wrapping machine applies heat to shrink a plastic film around a single or bunch of facial cleanser packages to secure and seal it for feasible and safe transportation.

Facial Cleanser Shrink Wrapping Machine

Facial cleanser shrink wrapping unit includes a conveyer belt that moves primary containers through the machine and shrink wrap and seal them.

As per requirement these units can shrink wrap single or multiple containers in a single cycle. Other than cosmetic industry, this unit is also employed in food and beverage industry.

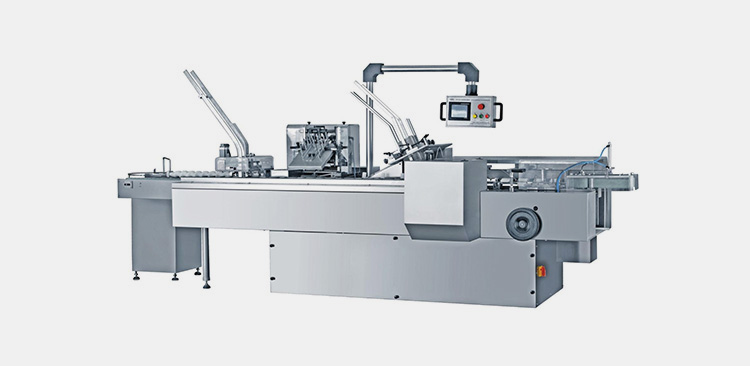

STAGE 5: Cartoning

The packaged and labeled products are then placed into boxes or cartons for shipping or storage using the cartoning machine. This is represented as a final step of packaging.

Facial Cleanser Cartoning Machine

Facial cleanser cartoning machine automatically fills empty cartons of any size and shape with the facial cleanser primary containers and seals them. These units have additional printing features that can incorporate manufacturing and expiry dates and batch number on each cartons. Cartoning machine also finds its uses in pharmaceutical and food industries.

8.What Are The Main Components Of Facial Cleanser Packaging Machines?

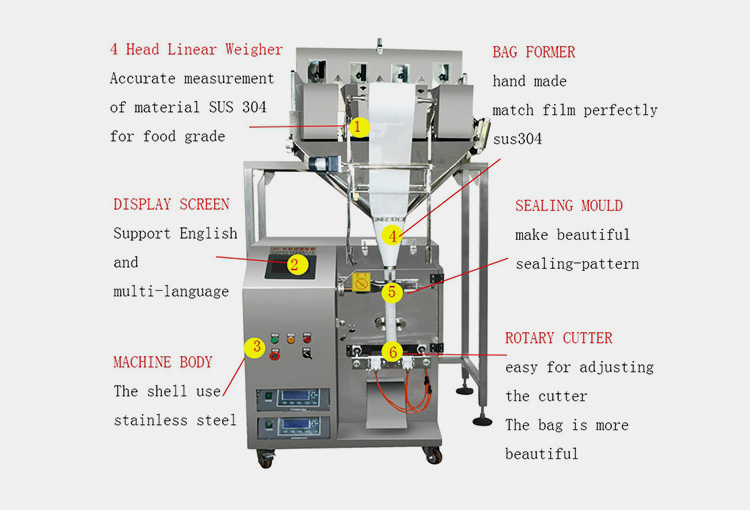

A Structural Drawing of Facial Cleanser Packaging Machine

The main components of facial cleanser packaging machines can vary depending on the specific type of machine, but generally include:

Display Screen/Control Panel

This is the central control unit of the machine, where operators can input and adjust settings, monitor the machine's performance, and troubleshoot any issues that arise.

Machine Body

Machine body is responsible to support entire structure of system. It is made up of stainless steel ensuring 100% safe production.

Bag Former

This unit is responsible for forming the packaging material into the desired shape and size. It can include a variety of different components such as a reel holder, a forming tube, and a cutting die.

Filling Unit

This unit is responsible for filling the packaging with the product. It can include a variety of different components such as a hopper, linear head weigher, and a filling nozzle.

Sealing Mold

This unit is responsible for sealing the packaging after it has been filled with the product. It can include a variety of different components such as a sealing bar, a heating element, and a cooling unit.

Rotary Cutter

Once product is filled and sealed inside the pouches, it is delicately separated by rotary cutters.

Labeling Unit

This unit is responsible for applying labels to the packaging. It can include a variety of different components such as a label dispenser, a label applicator, and a label sensor.

Conveyor System

This system is responsible for moving the packaging through the various stages of the production process. It can include a variety of different components such as a conveyor belt, rollers, and guides.

Coding Unit:This unit is responsible for printing expiration date, batch number or any other information on the packaging. It can include a variety of different components such as a printer, inkjet heads, and software.

Please note that this list is not exhaustive and different machines may have different components and configurations.

9.What Are The Main Features Of Facial Cleanser Packaging Machines?

The main features of facial cleanser packaging machines can vary depending on the specific type of machine, but generally include:

High Speed And Efficiency

Many facial cleanser packaging machines are designed to operate at high speeds, which allows for a large number of packages to be produced in a short amount of time.

Versatility

Facial cleanser packaging machines are designed to be versatile and can be used to produce a wide variety of different types of packaging, including bags, sachets, and pouches.

Easy Operation

Facial cleanser packaging machines are easy to operate and can be controlled through a user-friendly interface.

Precision

Many facial cleanser packaging machines are designed to be precise and accurate, which ensures that the packaging is consistent and of high quality.

Adjustable Parameters

Facial cleanser packaging machines are designed to have adjustable parameters, such as filling volume, sealing temperature, and cutting length, which allows for flexibility and adaptability.

10.What Are Problems and Solutions Of Facial Cleanser Packaging?

| PROBLEMS | SOLUTIONS |

| Leakage is the most common facial cleanser packaging problem that could be occurred due to insufficient twisting toque range or improper sealing. | Caliberate machine and a specified torque range is applied to secure the capping. |

| During filling procedure, foaming of product take place that causes variation in filling volume. | Proper fill time should be given to avoid foam formation. Also, check and caliberate filling nozzle and flow setting. |

| Facial cleansing dripping is also another packaging problem that affecting product’s quality and brand reputation. | Maintain or replace head dive of the machine (device that control smooth filling). |

| Product’s over flow normally goes during filling and packaging procedure. | Caliberate machine settings and adjust filling nozzle. |

Conclusion

There is no doubt that facial cleanser packaging is an essential procedure serving various industries for over many years. Today, great advancement and high competition have improved packaging machines in terms of innovations and compliance. AIPAK Pharmaceutical Equipment Promise to offer good quality and affordable packaging products. We’re here to offer a complete production line involved in the facial cleanser packaging process, i.e filling, capping, labeling, etc., Contact Us Now for More Information and Product Purchase.

Don't forget to share this post!

Tube Filling Machine Related Posts

Tube Filling Machine Related Products

Tube Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine