Eye Drop Filling Machine-We Still Have A Long Way To Go

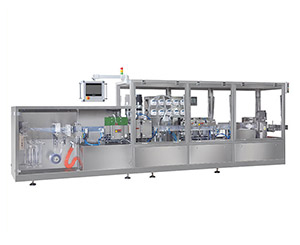

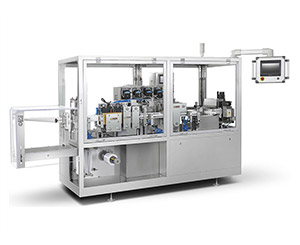

An eye drop filling machine is applied to the pharmaceutical, chemical, food and light industry, which is a device that uses vacuum negative pressure and self-priming liquid to fill glass, plastic, metal and other containers.

This machine can be used in filling and production needs of eye drops, nose drops, ear drops and other dosage forms, and it can also be applied to liquid sub-packaging in scientific experiments, component testing and other fields.

People in the industry said that because eye drops are a sterile preparation that directly works on the eyes, it should be accord with sterile preparation requirements according to the regulation. Ophthalmic preparations must be produced in accordance with aseptic technology to ensure that the product is sterile.

So, it is necessary to strengthen the sterile requirements of ophthalmic preparations. However, the sterility of packaged aseptic preparations mainly depends on the adoption of a reasonable sterilization process and a good aseptic packaging system in the production process. The eye drops filling machine plays an important role in it.

With the expansion of the demand for eye drops, the market of eye drops filling machines also ushered in good opportunities. In the context of the continuous strengthening of drug supervision in recent years, the automatic eye drops filling machine, as a new type of filling machine equipment, is gradually favored by the market due to its advantages such as less liquid pollution and strong sterilization. However, in order for the eye drop filling machine to perform stably, you need to pay more attention to scientific operation, rational use, and regular maintenance work in peacetime.

For example, when you use the eye drop filling machine, because this equipment belongs to an automatic machine, the pop-up bottle, bottle cushion and bottle cap’s sized are all required to be uniformed. You need to operate the handle by hand to turn the machine.

Checking whether there is any abnormality in its rotation, and make sure that it is running normally before driving. In addition, when adjusting the machine, the tools should be used properly, and it is strictly forbidden to use too large tools or excessive force to remove parts to avoid damaging the parts or affecting the performance of the machine.

During the maintenance time, every time the machine is adjusted, you must tighten the loose screws. Only by using the handle to rotate the machine and observing its action that meets the requirements can you operate the machine.

The machine must be kept clean, and it is strictly forbidden to have oil stains, liquid medicine or glass debris on the machine, so as to avoid damage to the machine.

Meanwhile, it is necessary to pay attention to the maintenance work of the equipment. During maintenance, when you disassemble and clean the piston, you need to remove the upper set screw at the same time, so as not to affect the process requirements of the other when dismantling one.

Before cleaning the liquid filling machine, the remaining product in the liquid filling machine should be removed, and then the material barrel should be filled with gentle cleaning liquid. The cylinder has been lubricated before leaving the factory. Do not open or add any lubricating oil to ensure that the surface of the filling machine is clean and. Power off when not working.

In addition, while insisting on maintaining and using the filling machine correctly, regular testing and debugging are also required. So as to ensure the healthy and stable work of the filling machine.

In addition, The industrial insiders recommend that all parts of the machine surface should be cleaned once before the shift, and clean lubricating oil should be added to each activity department. It should be scrubbed once a week, especially places that are not easy to clean in ordinary use or blown with compressed air.

After you open the box, it is recommended that you should check whether the random technical information is complete, and whether the machine is destroyed in the process of transportation so that these problems can be solved in time.

To install and adjust the feed assembly and discharge assembly according to the outline diagrams in this manual, and then add new lubricating oil to each lubricating point. " said that it is very necessary to use the crank handle to turn the machine to check whether the machine is running in the correct direction (counterclockwise facing the motor shaft), and the machine must be protected and grounded.

Currently, eye drops mainly include health protection eye drops and treatment type eye drops,

From the perspective of market consumption, as China’s aging population degree is deepened and a huge population base, there has been a steady increase in the types of eye drops for treatment in recent years.

In the context of the accelerated pace of life and work of modern people and the wide application of computers, mobile phones and other terminals, eye drops of health care type have become a major eye problem, driving the rapid growth of the market of health care type eye drops.

Data shows that in 2018, the sales revenue of the eye drops industry reached 8 billion yuan, and the industry consumption showed a trend of rapid growth. The market share of health care and therapeutic eye drops is 66% and 34% respectively. In recent years, the market share of treatment eye drops has continued to grow, while the relative share of health-care eye drops has decreased.

Eye drops are pharmaceutical products, especially the quality and safety of therapeutic eye drops. In the production process of this type of eye drops, the filling equipment for eye drops plays a key role, and it needs to be produced in strict accordance with the process requirements.

Therefore, for eye drops filling manufacturing enterprises, the future will present a situation of coexistence of opportunities and challenges.

If a production enterprise wants to stand out in the competition, it must improve the quality and production level of its products, and the relevant production equipment will also become an important "weapon". Only by polishing these "sharp tools" can the production of eye drops be made safer and more stable.

Don't forget to share this post!

Eye Drop Filling Machine Related Posts

Eye Drop Filling Machine Related Products

Eye Drop Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours