Everything You Need to Know About Cartoning Machine

Which industry you are in? It’s believed for any industries, there is a great need for cartoning packaging. With more concerns on sustainability and safety, cartoning machine are being paid more attention to as it is the first thing your products contact with. The need to know everything about cartoning machine is thus essential.

So what do you know about cartoning machine? The deep knowledge about cartoning machine can help you a lot in machine choose, purchase, operation, repairing, maintenance.

This is a post about everything you need to know about cartoning machine. What industries does cartoning machine serve? How cartoning machine work? How many types dose cartoning machine have? What are the advantages and disadvantages of cartoning machine? After reading, you can be the professor about cartoning machine.

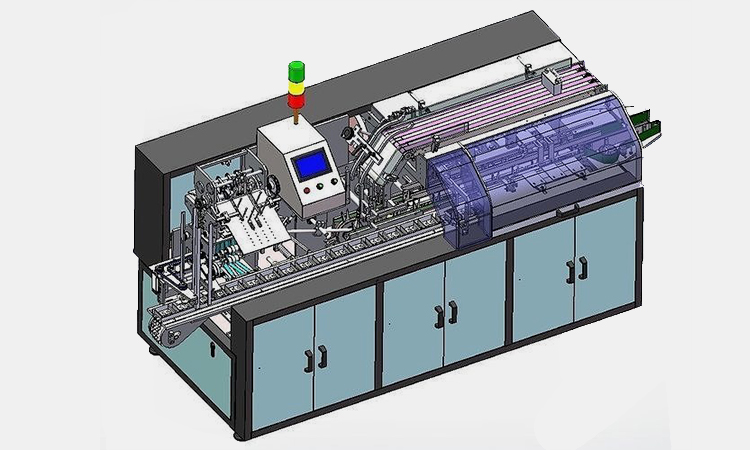

1.What Is Cartoning Machine?

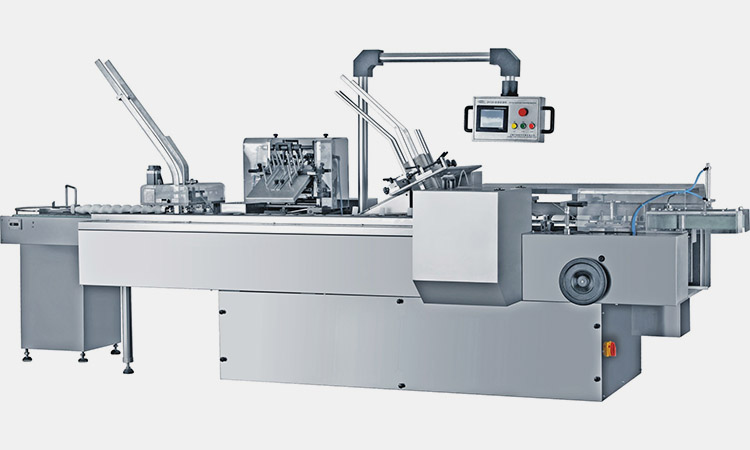

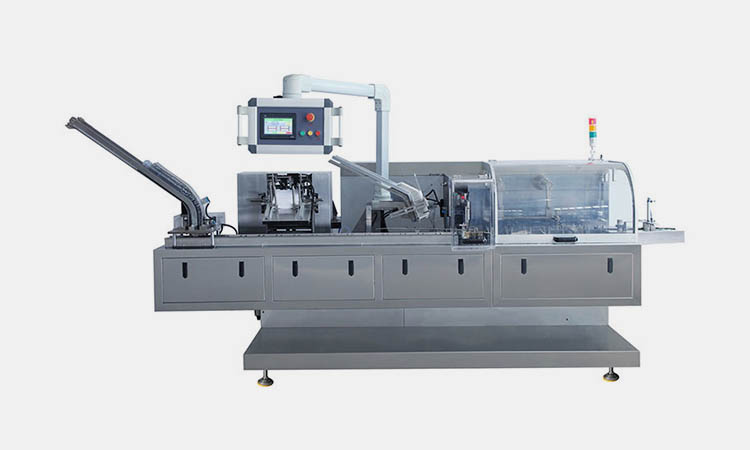

A Type Of Cartoning Machine-Sourced:sedpharma

Cartoning machine, also called as cartoner, is designated to package various products into carton. It can pack carton of different types and make packaging style for sundry need like tight or multiple packaging.

Cartoning machine can play a series of works like folding carton, filling products, sealing products and printing information. The single machine can fulfill the whole cartoning need, and is thus essential to many industries.

2.What Industry Can Cartoning Machine Serve?

Most industries have the cartoning need as products must have the cartons for protecting, appealing and transporting.

Food and beverage industry

Food And Beverage Cartons-Sourced:amithaprinters

Cartoning machine is essential for food and beverage products. The great protection of carton can reserve the nice condition of food and reduce the damage on product surface in transportation. Besides, the nice and appealing carton can also attract customers and improve sales.

Pharmaceutical industry

Pharmaceutical Carton-Sourced:qupackindustries

Pharmaceutical products have a great need of cartoning machine. Cartons can give a nice storing environment for it has higher standard on hygiene. For products which can not stand light, the cartons can also make light-shading environment. And the anti-counterfeit system solves the big problem for various medicine.

Electronic industry

There are various electronic products CD player, battery, phone, computer and so on. They have various shapes, but the precise structure and fragile appearance of them induce them to chase the same packaging goal: protective and attractive. Cartoning machine can fulfill both needs.

Toy industry

Toy Products Carton-Sourced:packagingprinting

Toy products need the attractive and bright packaging for appealing children and improving sales. Cartons have the outstanding performance in making different shapes and getting on colorful surface. Cartoning machines are thus very important in toy industry.

Cloth industry

Cloth Products Carton-Sourced:pixartprinting

Cloth industry has the strong cartoning packaging need as packaging can show the beauty principle of cloth designer and play the essential protective job for the fragile fabric. Cartoning machine can make the pretty and protective cartons for cloth industry.

3.How Many Types Of Cartoning Machine Are There?

There are various cartoning machine and its type can be divided according to the loading way, automation level and motion manner.

Loading way

- Vertical cartoning machine

Vertical Cartoning Machine-Sourced:endflex

Vertical cartoning machine has its products vertically. The rotary feeding way of it can reduce the damage on products greatly and is especially suitable for fragile products like bottle, can, ampoule or vials. Besides, it also rather suitable for the bare products packaging as the vertical loading saves products and assure precise weight.

- Horizontal cartoning machine

Horizontal Cartoning Machine-Sourced:penglaimachines

In reverse with vertical cartoning machine, horizontal cartoning machine gets its products in horizontally. It can make the versatile and efficient packaging work and suitable for most products. May be inferior in fragile packaging compared with vertical one, it can make the excellent tight and multiple packaging.

Automation level

- Semi-automation cartoning machine

Semi-automation cartoning machine has its whole packaging process made with the cooperation of workers. It needs workers’ help in loading and other process for smooth cartoning.

- Full-automation cartoning machine

Full-automation cartoning machine can finish the whole cartoning process without the help of worker. As it can finish the whole work all by itself, you can save time as well as expense in extra labors.

Motion manner

- Intermittent cartoning machine

Intermittent Cartoning Machine-Sourced:Benison

Intermittent cartoning machine has the intermittence in cartoning process. The products loading or carton folding can get the whole cartoning process interrupted. The speed is lower, so does its price.

- Continuous cartoning machine

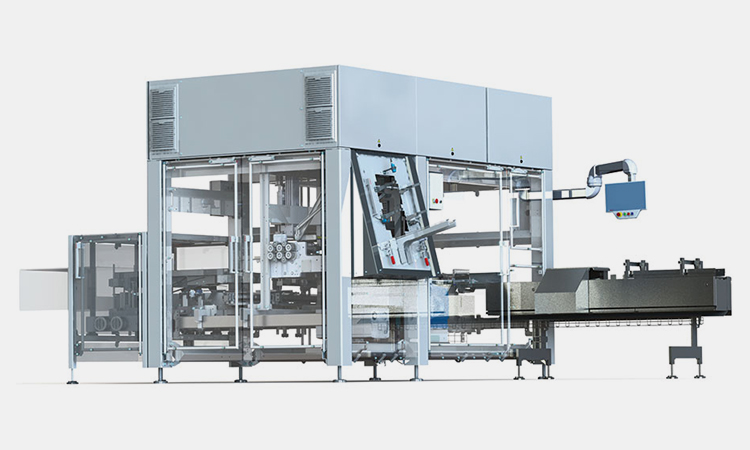

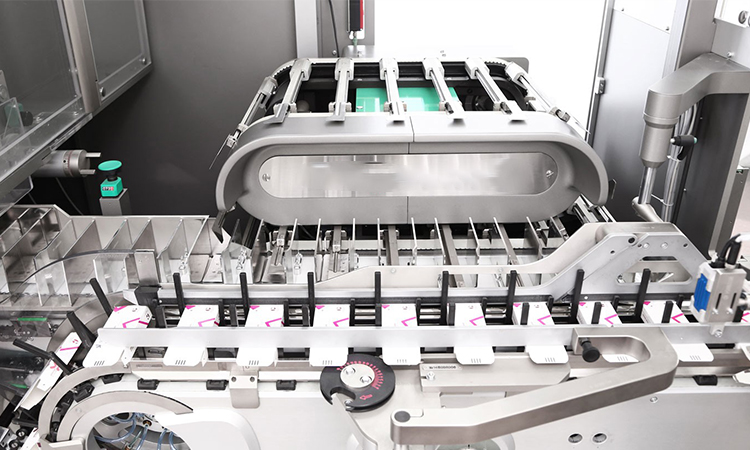

Continuous Cartoning Machine-Sourced:saintyco

Continuous cartoning machine has its all cartoning process go on with no interruption from loading or carton folding. It stops until all materials and products are run out. As gets little influence, continuous cartoning machine is more efficient and high-speed.

4.How Does Cartoning Machine Work?

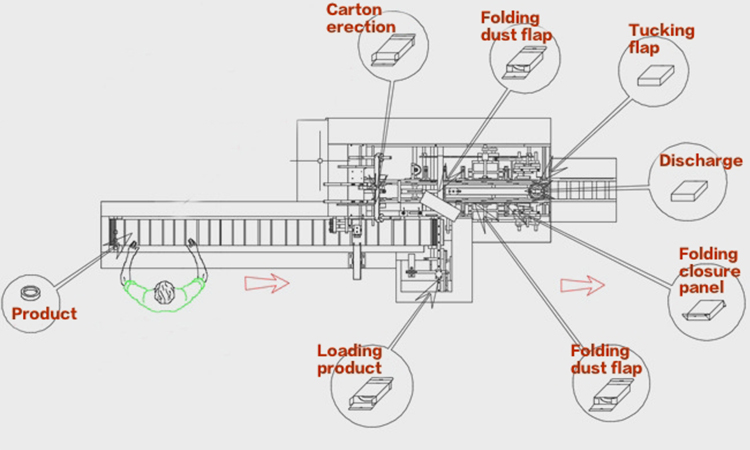

Cartoning machine works to pack products into carton. Here is the typical cartoning process of cartoning machine.

AIPAK Cartoner

- Products gets into the cartoning machine vertically or horizontally from the feeding system.

- A pile of carton sheet are waiting to be folded in the designated carton shape one by one and waiting to the coming of products.

- The mechanical hand gets the products transported by belt into carton.

- Carton filled with products have one side open for the further filling of instruments or brochures.

- After having all things filled, cartons are transported to next process and be sealed or locked up by glue or tape.

- The well sealed cartons are then transported to go out the cartoning machine. The carton chute is the last process which let out carton instead of piling them up.

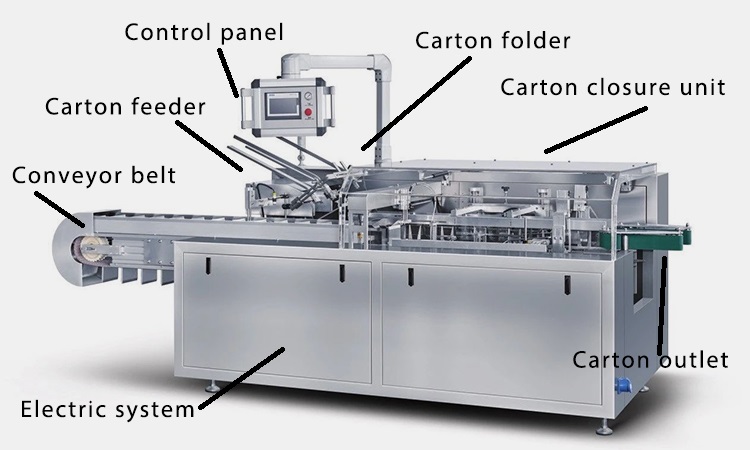

5.What Are The Key Components Of Cartoning Machine?

Cartoning machines share the similar components though it has different loading way, automation lever and motion manner. Below are the key components.

Control panel

Control Panel Of Cartoner-Sourced:ima

Control panel is the brain and power switch of cartoning machine. It sets parameters like number, folding manner, carton size, printing information and so on.

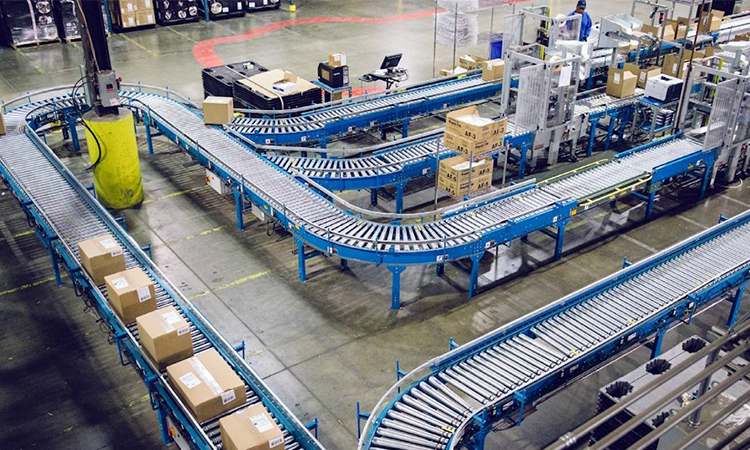

Conveyor belt

Conveyor Belt Of Cartoner-Sourced:massmanautomation

Conveyor belt makes the transporting system of cartoning machine and contacts the different process inside the machine. With it, the whole process goes on smoothly.

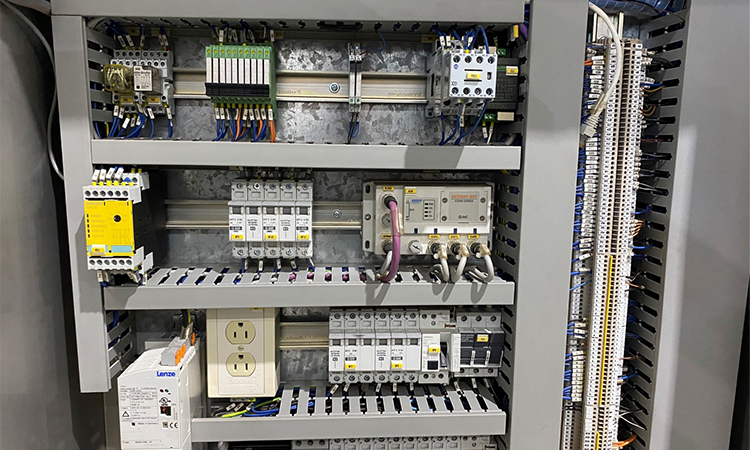

Electric system

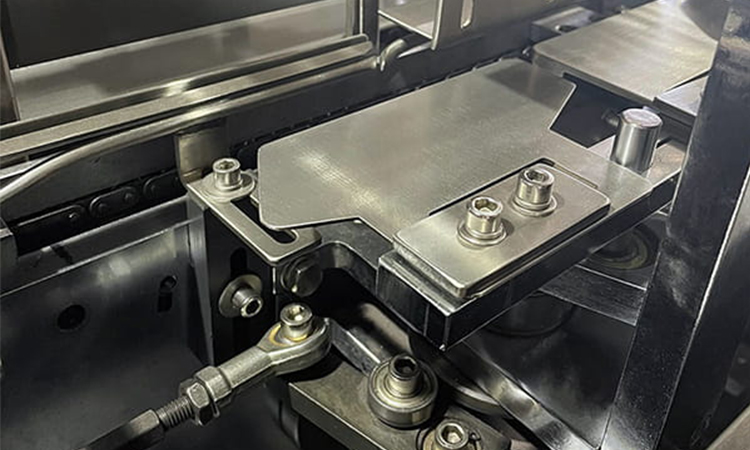

Electric System Of Cartoner-Sourced:ima

Electric system is the blood of cartoning machine. Without the continuous energy it puts in, the cartoning machine is the useless iron.

Carton feeder

Carton Feeder-Sourced:jornen

Carton feeder holds pile of carton sheet and send them to the cartoning process of cartoning machine.

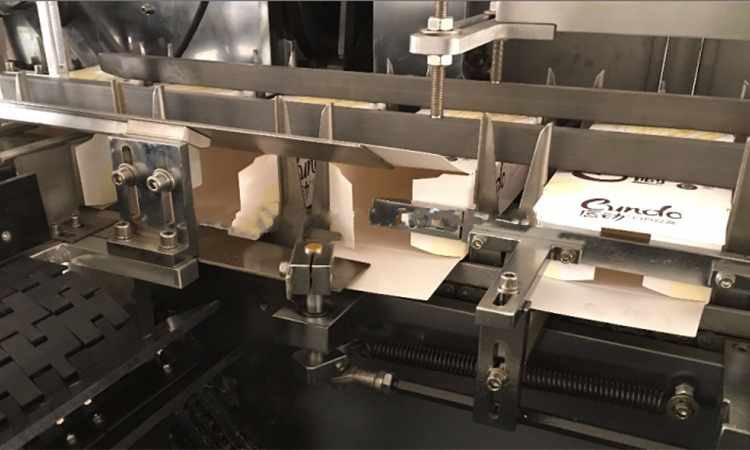

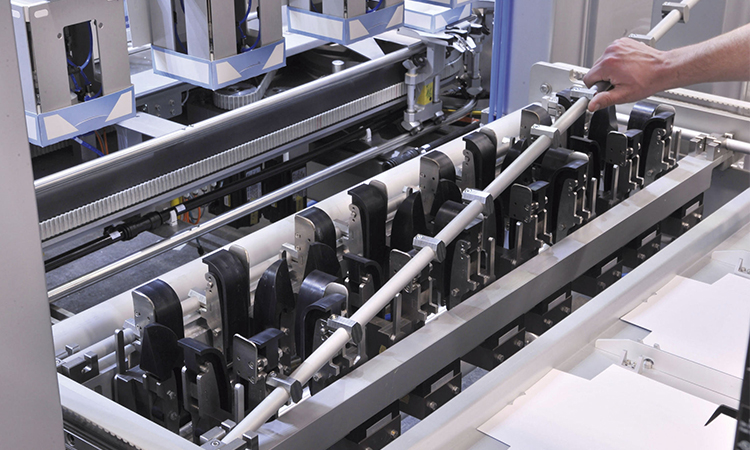

Carton folder

Carton Folding-Sourced:rajones

Carton folder is the mechanical hand inside cartoning machine which gets a piece of carton sheet from carton feeder to fold it into settled carton shape and waits for the filling of products.

Carton closure unit

Carton closure unit-Sourced:autopackmachinerys

Carton closure unit closes the last open carton flap when all materials have packaged well. It finishes the packaging of cartoning machine.

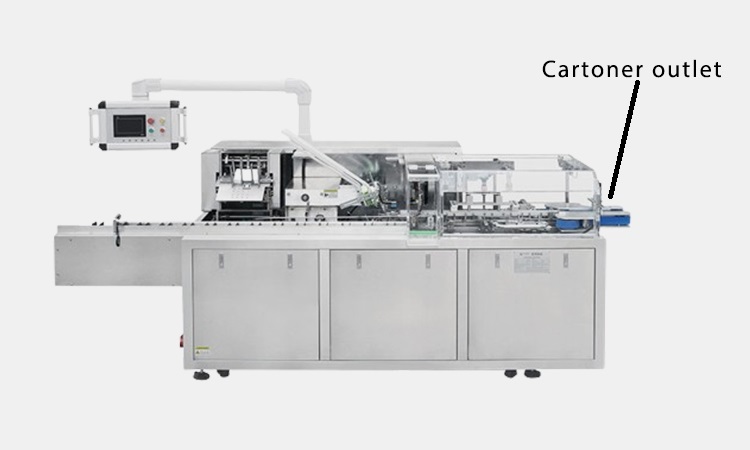

Carton outlet

Carton Outlet-Sourced: sedpharma

To avoid the piling of well packaged carton, carton outlet lead cartons go out the whole cartoning process. It’s the last process of cartoning machine.

6.How Can Cartoning Machine Benefit You?

Cartoning machine can benefit you in an all-around way. Here are its several outstanding benefits.

Assure quality

Quality-Sourced:cphi-online

Cartoning machine can assure the product quality as machine manufacturing avoids the uneven packaging of labor work and makes every carton unified standard. For products have higher need on hygiene, cartoning machine can prove the sanitary of products and package better.

Save cost

Cost Saving-Sourced:teamly

In a long run, cartoning machine can save you a lot money. It saved cartoning labors which is a big cost in manufacturing process. And the time it saved is also priceless.

High Efficiency

High Efficiency-Sourced:moglix

As powered by mechanical system, cartoning machine makes highly efficient cartoning process. In a short time, you can get your well-packaged products. The productivity and timeliness can both be proved.

Employee safety

Employee Safety-Sourced:bwintegratedsystems

The easy operation and safe working environment cartoning machine provide can ensure your employee’s safety. In other case, the sharp, heavy or harming products can affect your employee in their contact with products.

Great versatility

Great Versatility-Sourced:shinebenmach

Cartoning machine can handle products cartoning of different size, industries and kinds. It has little restrict on products category and you can use them to handling different condition with just little adjust.

7.What Are The Disadvantages Of Cartoning Machine?

Cartoning machine benefits your manufacturing greatly, but there exists also disadvantages.

High expense

High Expense-Sourced:vecteezy

The cost to design and buy the specific cartoning machine for your factory is not a small price and may be burden for some manufacturers.

Hard maintenance and repair

Hard maintenance and repair-Sourced:etwinternational

The complex structure and precise parts of cartoning machine need the careful and professional work in maintaining and repairing. The casual handling of them may make the machine crashed.

Technical support

Technical Support-Sourced:theamegroup

The operation of cartoning machine is easy, you should just set it panel and then put all material in place. But for the smooth operation and nice manufacturing, technical support is essential. And labor cartoning doesn’t need that.

Low flexibility

Low Flexibility-Sourced:packagingstrategies

The cartoning machine is huge, stable and fragile. The move or place adjust after its installation is a big project.

8.What Cartoning Materials Are Most Frequently Used In Cartoning Machine?

Cartoning material for cartoning machine is varied. Here are some frequent types.

Paperboard

Paperboard-Sourced:durafibre

Paperboard is widely used for carton packaging for its features like cheap, heavy holding and easy printing. There are various types of paperboard: corrugated paperboard, kraft paperboard, recycled paperboard, micro-flute corrugated paperboard. It is widely used in cartoning machine.

Cardboard

Cardboard-Sourced:crownhillpackaging

Cardboard, also called as corrugated cardboard or corrugated fiberboard, is composed by two flat layers and a wavy layer. It is thicker and can thus hold heavier products. Its steady and light weight make it welcomed in cartoning making and widely used cartoning machine.

9.What Carton Type Can Cartoning Machine Make?

Cartoning machine makes different carton type for the need of different industries.

Slotted box

Slotted Box-Sourced:shop.secureseal

Slotted box is the most frequently used carton type. It leaves one side open with four flappers half length of container.

Half-slotted box

Half-slotted Box-Sourced:acmebox

Half-slotted box is just like slotted one with one side open. It’s specially designed for particular objects.

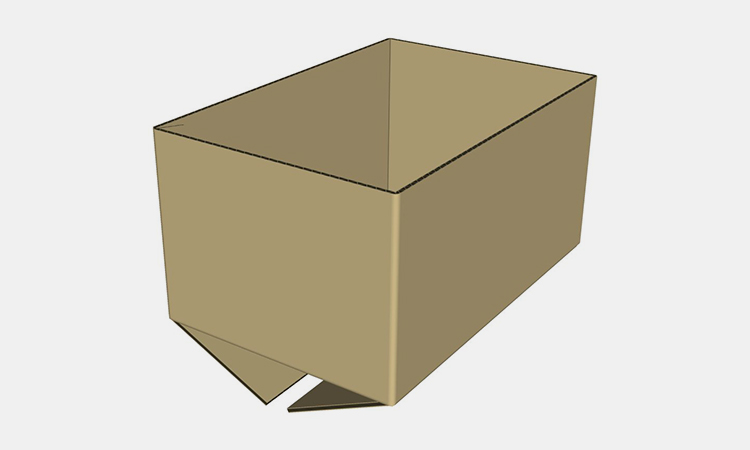

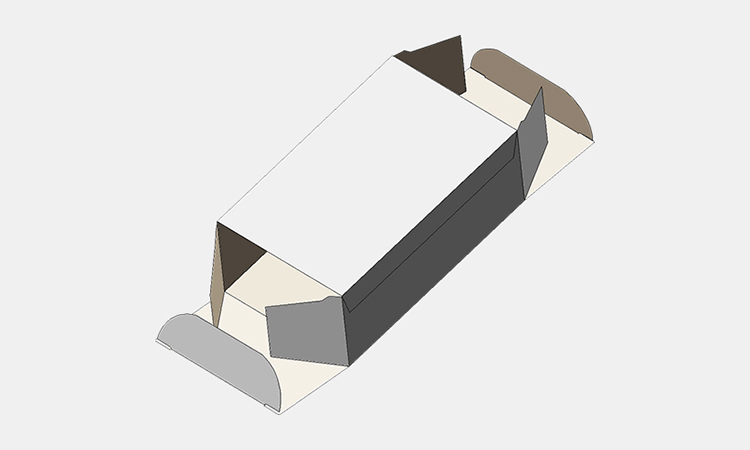

Lock bottom box

Lock Bottom Box-Sourced:printingcircle

Lock bottom box has its bottom side lock into each other. This makes a much stable holding of objects and is thus more suitable for heavy products packaging.

Seal end box

Seal End Box-Sourced:cpfoodboxes

Seal end box has its bottom side all sealed. This makes it can stand the high-speed filling or bare products packaging.

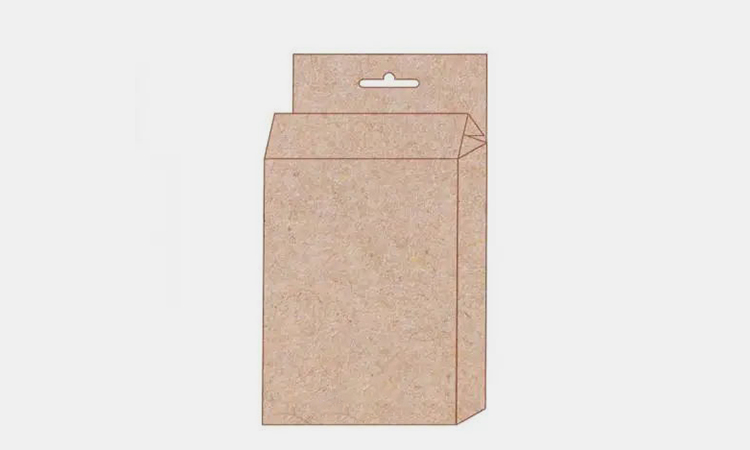

Hanger box

Hanger Box-Sourced:dnpackaging

Hanger box has the special design of a small hook on its top side. It suits for the small and light products have displaying need.

Tuck top box

Tuck Top Box-Sourced:papermart

Tuck top box is specially made by two pieces of board. They tuck into each other and thus made the rather stable carton.

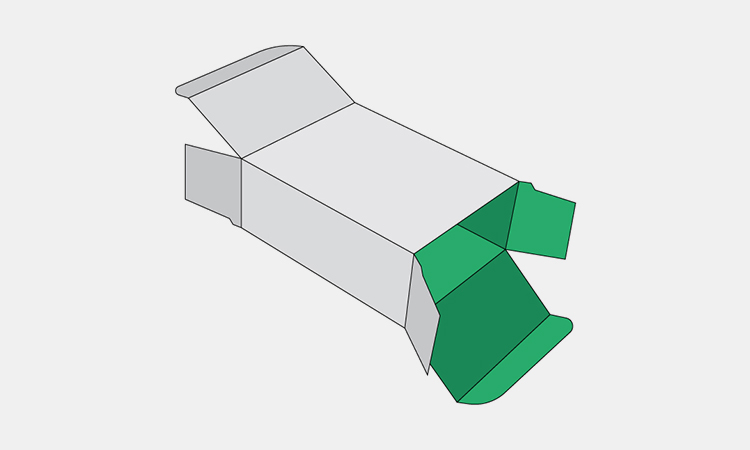

Straight tuck end box

Straight Tuck End Box-Sourced:anycustombox

Straight tuck end box has its bottom side and top side make the same panel direction. It is specially made to benefit taking.

Reverse tuck box

Reverse Tuck Box-Sourced:ibexpackaging

In reverse with straight tuck end box, reverse tuck end box has its two panels to reverse direction.

10.Why The Price Of Cartoning Machine Varied?

The cartoning machine market provides cartoning machines of different size and different price. Its varied price has relation with the below factors.

Machine type or size

Cartoning Machine Type-Sourced:br.freelancer

It’s a consensus that the larger size, the higher price. The larger machine can produce larger productivity and thus much expensive. Besides, the machine type which can provide more smooth and efficient packaging is of course not that cheap.

Cartoning speed

Cartoning Speed-Sourced:depositphotos

The cartoning speed decides the cartoning efficiency as well as the productivity of manufacturing. The continuous cartoning machine costs more compared with the intermittent one as the former is more efficient.

Technology

Technology-Sourced:forbes

Cartoning machine adopted the advanced and beneficial technology can give factory more profits and its price is naturally higher.

Brand

Brand-Sourced:emotivebrand

Bigger brand gives much better service and safeguard for cartoning machine. Its long lasting reputation continues its higher price.

After-sale service

After-sale Service-Sourced:indianretailer

You can of course choose the cartoning machine with lower price but you should also accept the unpleasant after-sale service it offers. The extra cost of cartoning machine is hidden in this place.

Machine material

Machine Material-Sourced:wisconsinmetaltech

The high-qualified, firm and durable material for cartoning machine making costs more and the machine that made by this material is naturally costs more.

Customization

Customization-Sourced:acumatica

Customization is the service offered especially for the products have special cartoning need. The design and cartoning machine making need more energy and time and its price is thus much higher.

11.How To Choose The Most Suitable Cartoning Machine?

There are so many different packaging manufacturers and types of cartoning machine. How to choose? Here are some tips for you.

Budget

Budget-Sourced:kventure

You should select the cartoning machine according to your budget. There are always machine with higher price and better performance. But the one over your budget will give you burden rather than benefit.

Product type

Production Type-Sourced:dribbbl

Different types of cartoning machine offer you different packaging type. You need what? Tight packaging, fragile packaging or multiple packaging? What products you produce? Food, medicine or cloth.

Producing scale

Producing Scale-Sourced:tsfsupply

The higher demand of production requires the cartoning machine with greater production capacity. You should select it according to your factory’s production need.

Brand

Brand-Sourced:lcca

The big brand offers cartoning machine with higher price, and also products with better reputation. It mostly offers good after-sale service which is so important for your later manufacturing.

Distance

Distance-Sourced:hatrabbits

Online or offline, which way you would choose? If you are in a hurry, you should choose the cartoning machine near you. If not, you can have a wider search.

Machine quality

Machine Quality-Sourced:marchesini

You should of course get the cartoning machine with good quality which is the assurance of your later product quality. And you can rank the quality by collecting the judges or checking it by yourself.

Machine size

Machine Size-Sourced:sirosilo

The cartoning machine size should fit your factory. Get a careful measure of the floor area you offer to cartoning machine and get the one fits it.

12.Can Cartoning Machine Combined With Other Equipment?

Cartoning machine can of course combined with other equipment. The nice combination gives great convenience. Here are two typical cartoning combination.

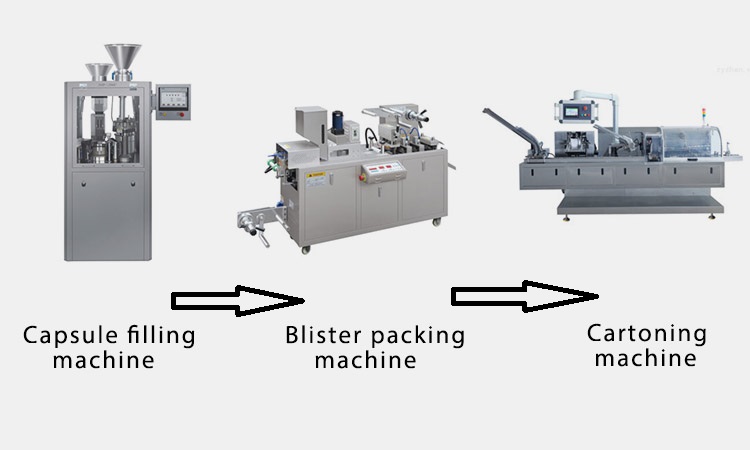

Blister cartoning line

AIPAK Blister Cartoning Line

The well packaged blister on market get the package from blister cartoning line. The capsule are firstly filled and formed by capsule filling machine. The qualified capsules then get packaged in blister packaging machine to make the well packaged blister. You can get blister into carton and let them be the real product using cartoning machine.

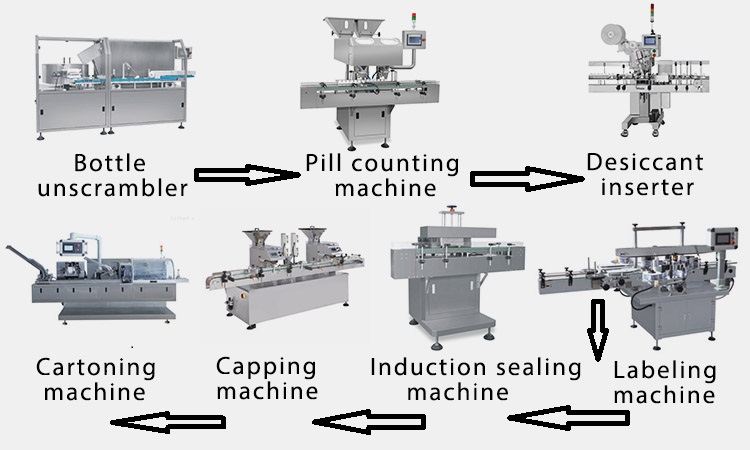

Pill counting line

AIPAK Pill Counting Line

Pill counting line are mainly played to fill pill or tablet in bottle and made carton package. It’s first step is to arrange and feed bottles into packaging process by bottle unscrambler. Later, pill counting machine makes right number of pill to fill them in the arranged and clean bottles.

After filled with capsules, desiccant packets are into bottles by desiccant inserter then bottle get labeled by labeling machine. The sealing of it is finished by two parts: induction sealing machine which make hermetic seal on capped bottle ,and automatic capping machine which sealed bottle with threaded cap.

The well done bottles then get into cartoning machine to make the preparation to get to market.

13.How To Maintain Cartoning Machine?

The nice maintaining of cartoning machine can prolong the life of cartoning machine and also improve its efficiency.

Regular examination

Cartoning Examination-Sourced:oceanproperty

The regular examination of cartoning machine can help find out the mistakes or wrong parts quicker and prevent the worse development. It can assure the nice condition of cartoning machine.

Regular cleaning

Carton Cleaning-Sourced:koerber-pharma

Cartoning machine needs regular cleaning. The cleaning and removing of residues can assure the nice performance of machine as it prevents rust and release the burden of machine.

Worn parts remove

Worn Parts Remove-Sourced:sirosilo

Worn parts appeared in the daily operating of cartoning machine. If you ignore it, it may cause more damage and worn of machine. The performance of machine will be influenced greatly.

14.The Leading Cartoning Machine Brand

If you are confused by so many different cartoning machine brands in market, you can get a reference from the below great and reliable global cartoning machine brands.

Mpac

Mpac-Sourced:mpac-group

Mpac is the leading packaging manufacturer which can make, build and design various packaging machines. It has years experience in this area and has various cartoning machine type which can fulfill the different packaging, production and size need.

Aipak

Aipak is pioneering in packaging machine manufacturing. It is professional in medicine packaging and produce the nice cartoning packaging machine with high quality and nice personal service. The various cartoning machine type can meet most factories’ need.

Syntegon

Syntegon-Sourced:syntegon

Syntegon is the old brand which has a good reputation in pharmaceutical and food packaging industries. They devoted great strength in tech innovation and efficiency improvement. You can get the cartoning machine with great performance form Syntegon.

ADCO

ADCO-Sourced:adcomfg

ADCO is the packaging manufacturer which specialize in cartoning and case packing. It established in 1958 and focus on this field for more than 60 years. The rich experience and craftsman spirit offer excellent cartoning machine for factories all over the world.

Massman

Massman automation, made of group of skilled worker and engineers, can produce reliable and qualified cartoning machine for a wild field of industries. It takes automation in an important state and offer personal design for customers. Its cartoning machine’s high versatility is widely welcomed.

15.The Future Of Cartoning Machine

With the more concern on health and beauty, great packaging attract more attention. The need for well-performed cartoning machine is rising and the future of cartoning machine is booming.

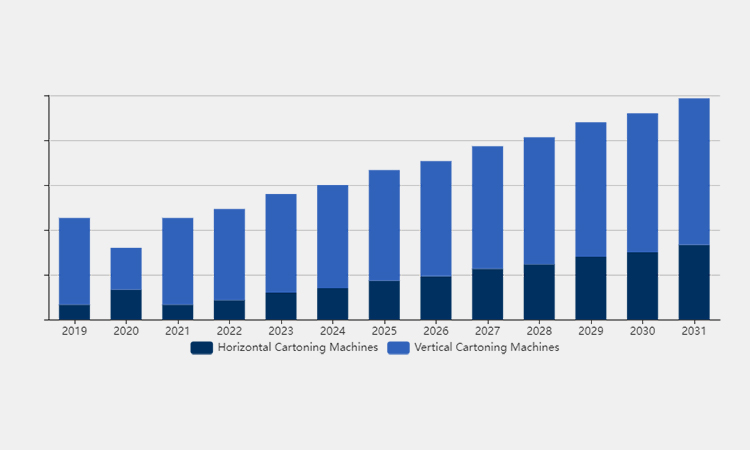

Cartoning machine future market by type

Cartoning Machine Future Market By Type-Sourced:cognitivemarketresearch

The major trend of future market is in a continuous growth. The growing need for vertical cartoning machine is steady for its versatile and fragile packaging ability. The horizontal cartoning machine has a faster growing speed for its great accommodation. All in all, the two types enjoy the different welcome in market.

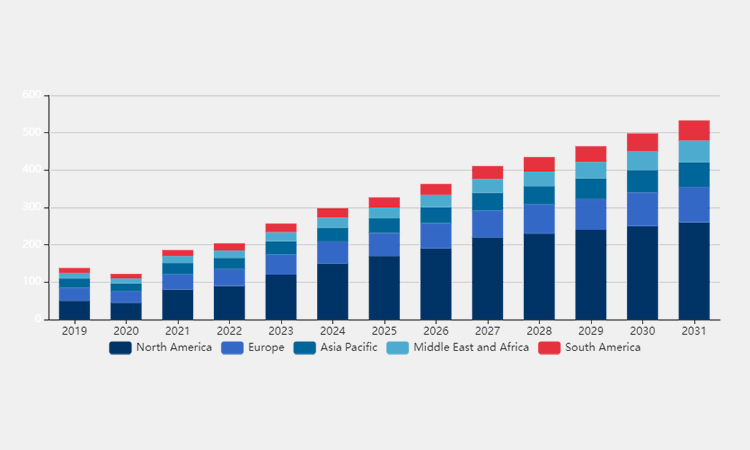

Cartoning machine future market by area

Cartoning Machine Future Market By Area-Sourced:cognitivemarketresearch

In the past few years and in future, North American is the major market for cartoning machine, its need for this machine will booming in next few years. Besides, for the improvement of living standard and more concern on packaging, almost all countries on world have the rising need for cartoning machine.

Conclusion

You can get the nice carton packaging service from cartoning machine and make your products the suitable and appealing carton. After getting everything you need to know about cartoning machine, you must have a further understanding about it, but if you have any questions about it, don’t hesitate to contact us.

Don't forget to share this post!

Cartoner Related Posts

Cartoner Related Products

Cartoner Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours