Empty Gelatin Capsule: The Ultimate Buying Guide in 2025

Today consumers across the globe following a healthy and natural lifestyle so they want to pursue the products of their choices and values.

Along with tablets, powders, and syrups, capsules are the most preferred delivery systems for dietary, nutritional, and pharmaceutical substances.

Two-piece gelatin capsules shells are pursuing the health and nutritional sector worldwide due to their reliable, robust, and outstanding performance.

Empty gelatin capsules meet the rigorous regulations and specifications of major pharmaceutical, health, and nutritional firms worldwide.

Several marine supplements increasingly have grasped the priority of consumers who are sensible about self-care. For this purpose, empty gelatin capsules are ideally suited such as unsaturated fatty oils include DHA, EPA, liver or fish oil, hyaluronic acid, and glucosamine, and so on.

Some key characteristics of empty gelatin capsules are as followed.

- The moisture content of empty gelatin capsules ranges between 13 to 16%.

- They are comprised of a variety of flavors such as menthol, grapes, lemon, or oranges.

- The disintegration time of the capsule mostly begins from 3-15 minutes.

- The empty gelatin capsules should be stored in a well-tight container at a temperature that should not be exceeded from 30°C.

By following specific key characteristics of empty gelatin capsules, you will get the right capsules that will meet your requirements.

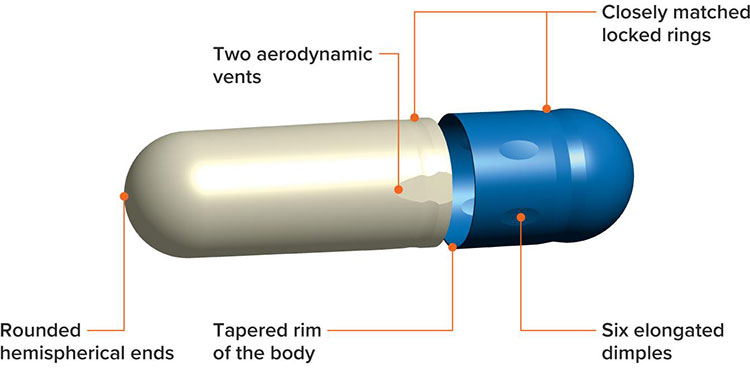

Skeleton of empty gelatin capsule

In this blog, we have discussed an ultimate guideline to introduce all vital aspects you must know about empty gelatin capsules. Thus, you can choose the best quality empty gelatin capsules that will enhance your product quality, shelf life, and patient compliance.

So, let’s get start it!

1.What is an empty gelatin capsule?

Empty gelatin capsules are high-quality pharmaceutical preparation comprised of a two-piece hard shell. This hard-shell is made up of gelatin extracted from collagen present in connective tissues and bones of animals. Gelatin is a prime element used in manufacturing empty gelatin capsules.

Empty Gelatin Capsules

The commercially available gelatin is typically obtained from tissues of cow/beef and porcine.

2.What are the uses of empty gelatin capsules?

A hard gelatin capsule is an ideal vehicle to deliver a variety of medicines and therapeutic products.

Hard gelatin capsules are widely used in pharmaceutical, cosmetic, food, and nutraceutical industries to fill the drug and give the finished product.

The uses of hard gelatin capsules are as followed.

- In pharmaceuticals when a drug cannot be compatible with a tablet form, they use capsule as the best substitution.

- Capsules are easy to swallow and accepted by adults and children.

- Certain active ingredients are prone to interact with excipients, hence capsule containers are normally used to support drug delivery in their original form.

- Capsules instantly release and rapidly produce their action soon after absorption.

- During the filling process, empty gelatin capsules do not necessitate complicated processes, machinery, or ingredients. Many industries use empty gelatin capsules as a cost-effective mode of drug delivery.

- Empty gelatin capsules are used to attain 100% bioavailability. Capsules tend to dissolve more quickly due to reduced incorporation of the disintegrating agent as compared to tablets.

- In the pharmaceutical industry, empty gelatin capsules are preferred to dispense non-aqueous substances. Such as powder, granules, or water-sensitive drugs.

- Empty gelatin capsules have a longer shelf life with minimum maintenance requirements. These capsules can stay longer if stored in a humidity-free environment.

- Empty gelatin capsules are used in many industries as their filling procedure requires less time, small manpower, and they are easy to fill.

3.How empty gelatin capsules manufactured?

The manufacturing of empty gelatin capsules is a complex process that requires several steps to achieve perfect outcomes.

Discussed below are the major steps involved in the manufacturing of empty gelatin capsules.

#1 Preparation of Gelatin- A Dipping Solution

Gelatin is the most commonly used substance for making empty gelatin capsules. The manufacturing of empty gelatin capsules initiates with the preparation of gelatin. The key characteristic of gelatin solution is viscosity and temperature of gelatin.

For this, you need to used hot demineralized/de-ionized water heated up to 60–70°C in a jacketed pressure.

The purpose of using demineralize water is to reduce the ionic interaction of water with gelatin molecules.

Allow the mixture of gelatin with water, the following solution contains 30-40% of gelatin W/W that is extremely viscous ultimately catches the air bubbles.

A dipping solution- Picture Credit- R&J Engineering

Once mixed then allow some intervals to eliminate the air bubbles with the help of a vacuum. If you ignore the presence of air bubbles, the mixture will yield inconsistency in weight and becomes problematic during filling and storage.

After settlement of air bubbles transfer the mixture into a service tank that is made up of stainless steel.

In meantime, you can incorporate other mandatory ingredients such as colorant and pigments to get a final appealing look. Sodium lauryl sulfate is also used to overcome surface tension.

You can use hot demineralize water if needed to adjust viscosity and target specification. Viscosity is an important parameter that requires special attention as it affects the overall downstream of manufacturing steps ultimately forms a damaged capsule shell with weakened strength. After achieving viscosity, physical, chemical, and microbiological testing are done.

Then allow gelatin solution to be transferred into temperature-controlled hoppers of manufacturing

machine.

Manufacturing steps of empty gelatin capsules

#2- Dipping

Once you achieve target viscosity, start with the next step. A solution is transferred into a manufacturing machine which is 10 meters long with 2-meter width having approximately 3 meters height. This machine is divided into two parts, upper and lower parts.

This mould is known as ‘PINS’ that is made up of stainless steel mounted on a metal strip known as BARS. Each machine has approximately 40,000 mould pins. The entire process is carried out in a humidity and temperature-controlled environment. These pins are deeply submerged in a gelatine solution. Allow few a seconds for the gelatine mixture to coat on PINs.

Dipped Pins after being split from dip pan- Picture credit- Medical key

Note, the thickness of coating around the pin is attained by a controlling time of mixture coating. There, you should carefully monitor how long the pin is dip in the gelatine solution.

After achieving a coating, allow the upper part of the machine to rise and release the capsule while its body gets a fix on the pins.

Once the gelatine is uniformly distributed, pins are removed and rotated numerous times to get an even dipping solution around the pins.

#3-Drying

Following an even gelatine distribution on the mould, a blast of chilled air is allowed to set the gelatine over the mould. During this time gelatine is dried and pins are gone through several drying processes to attain a defined moisture content.

Drying of Empty Gelatin Capsule- Picture credit- CPHI online

umidity and Moisture Controller

This process also required a controlled environment and critical monitoring of the machine for releasing an accurate circulation of air.

#4- Stripping and Trimming

After gelatine is dried, the capsules are stripped off the mould. Here capsules are segregated into two equal parts. Whereas some of the capsules are roughly stripped off.

Once, capsules are stripped off the moulds, trimming of shells into targeted length is performed by machine. After trimming of capsules shells, the machine automatically joins the separated parts of shells (Cap and body) with the help of a pre-lock mechanism.

Cutting Blades for Empty gelatin capsule trimming- Picture credit-Xiamen

The lengths of cap and body are specifically trimmed up to ±0.15 mm tolerance.

At this point, these shells are pushed into conveyor belt leads to transfer out of the container for printing if needed.

#5- Printing

For identification, the printing of capsules is done soon after the trimming process. In this step, printing criteria are based on the requirement of the manufacturer. Such as it can be done either promoting the brand or identifying the dosage formulation.

A Printed Empty Gelatin Capsule

Empty Gelatin Capsule Printing Machine- Picture Credit - Sinojoin

Printing helps in reducing the risks of mishandling, confusion of products, and users of products.

This step of empty gelatine capsule is not mandatory, it is mainly dependent upon consumer and manufacturer need.

The print on capsules can be done in several ways such as axially or radially.

There are several colors of ink are used for empty gelatin capsules, but the palette size is limited.

The print designs are mostly consisting of narrow lines while larger printing on capsules is not considered a decent practice as it increases the chances of ink transfer to surrounded capsules.

#6- Testing & Inspection

Once the product is manufactured, a batch of capsules is then transferred to the testing chamber.

Empty Gelatin Capsules Inspection- Picture Credit- Huizhou

At this chamber, the quality of manufactured capsules is measured to assess shelf life and quality. Inspection of empty gelatine capsules is done to monitor the defects visually. Defective capsules are manually removed. The most serious defect may cause a stoppage of the filling machine.

Testing and inspection of empty gelatin capsules- Picture Credit- CapsCanada

#7- Packaging

After testing, conventionally packaging of capsules is done according to capsules size and quantity under controlled environmental conditions. Empty gelatine capsules are packed into cardboard in which capsules are sealed in an inner liner that is heat-sealed using aluminium foil or polythene material. The packaging process is designed that maintains the moisture content such as 13-16% w/w. the important factor to store the empty gelatin capsule is to avoid harsh temperature and humidity. The ideal storage temperature is 15- 30°C. otherwise, temperature fluctuation can worse the cases and cause failure in the filling of capsules.

Packaging of Empty Gelatin Capsule- Picture Credit- Erawat Pharma

4.What do you know about the basic composition of empty gelatin capsules?

The composition of empty gelatin capsule contains the following main ingredients

1- Gelatin; the main ingredient

2- Plasticizers

3- Opacifiers

4- Colorant

5- Flavouring agents

6- Sweeteners

7- Preservative

8- Water (Adjusting Viscosity and mixing)

1- Gelatin

Gelatin is the main ingredient of empty gelatin capsules has a long history of applications in the pharmaceutical and food industry. Gelatin is extracted from a protein of skin and bones of cattle and porcine and a byproduct or derivative of the meat industry.

Empty Gelatin Capsules- Picture credit- Gelita

If you further assess the protein of gelatin, it is primarily composed of collagen. Collagen is a structural protein that is readily soluble in water and softens at 30 ⁰C release their action. Gelatin is a popular ingredient utilized to get a two-piece empty gelatin capsule shell.

The property of gelatin depends upon the following factors:

- Method of extraction

- A parent collagen

- pH value of gelatin

- A thermal degradation

- An electrolytic content

2- Plasticizers

Plasticizers are incorporated into gelatin to produce firmness, reduce the rigidity of the gelatin capsule shell and make it more flexible. Water is also known as a good plasticizer that is naturally available in gelatin. The common examples of plasticizers are glycerin, propylene glycol, polyhydric alcohol, and sorbitol.

3- Opacifiers

The opacifiers are utilized to provide opacity to the empty gelatin capsules, such as titanium dioxide commonly used to opacify capsules shell.

Opacifier- Picture Credit- Amgeen

Opacifiers allow the protection of filling ingredients against the light as well as mask an unpleasant appearance of the fill.

4- Colorants

Colorants are commonly used to impart a prominent appearance to the body and cap. These may be used alone or in combination. For example, vegetable dyes, water-soluble dyes, or insoluble pigments.

To create a range of colorants, various pigments are incorporated as solutions or suspensions. Generally, the color of the capsule is preferred to be dark than the color of filling ingredients. Colorants can surmount the absorption of light, so it is beneficial to protect the photosensitive ingredients.

5- Flavouring Agents

Flavoring agents are used to enhancing the flavor of the capsule shell. The shell of capsules is most often tasteless and may give little odor of chemical substance which is unpleasant for users. Hence, the taste of the drug may be mask by the incorporation of flavoring agents. The concentration of flavoring agent for empty gelatin capsules should no more than 2%. E.g., ethyl-vanillin and essential oils.

6- Sweetening Agents

Empty gelatin capsules also contain sweetening agents such as sugar to enhance the taste (optional). The concentration of sugar should not more than 5%. These sweetening agents are commonly intended for pediatric formulations.

7- Preservatives

Preservatives are used to improve the shelf life and safety of empty gelatin capsules. Such as Methylparaben, propylparaben, or potassium bisulphite.

8- Water

Water is an important component used for adjusting the viscosity of gelatin and manufacturing empty gelatin capsules.

5.What are the standard sizes and weights of empty gelatin capsules?

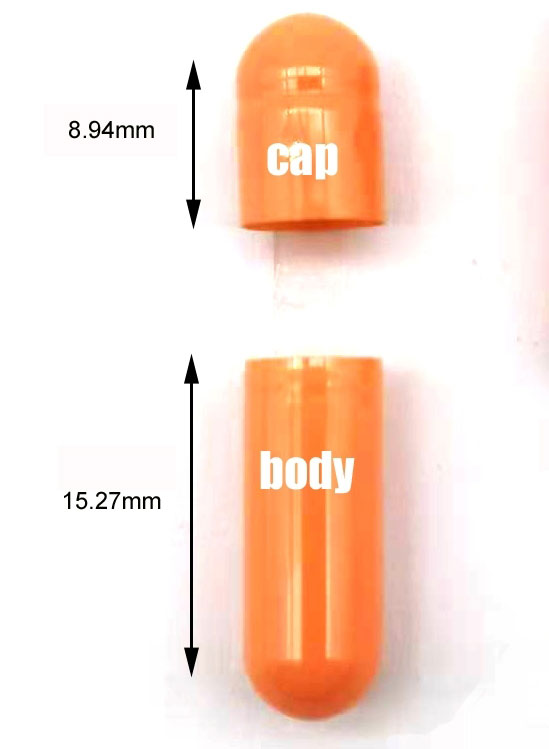

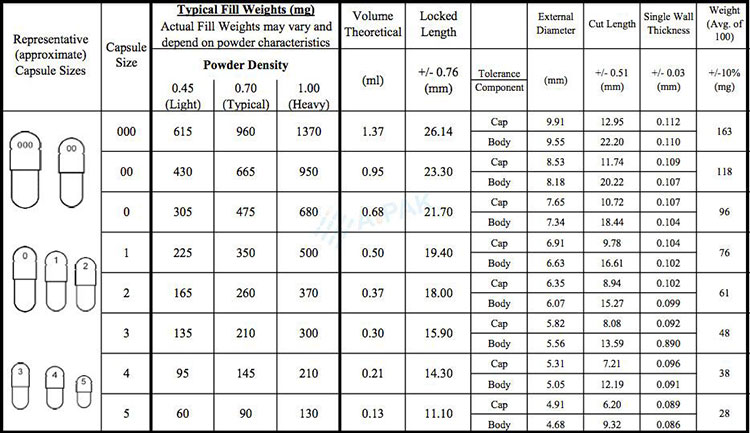

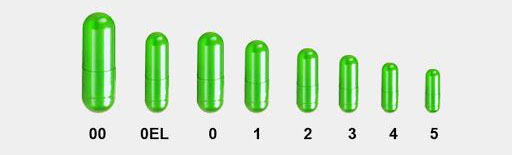

Empty gelatin capsules come in various sizes that range from an arbitrary

number of 000 to 5 considering 000 as the largest size and 5 as the smallest.

The shape of empty gelatin capsules is virtually same since its inventions. The selection of sizes is basically determined by need of formulation such as dose of active substances, density, compaction, and other components.

A first step to estimate an optimal capsule size is to assess the density of formulation using tapping density of powder and bulk density for granules and minitablets. So, an appropriate density is calculated by measuring the density of formulation and targeted weight and volume of capsule.

To lodge the special requirement some intermediate size capsules are produced. These capsules sizes are having extra 10% filling volume as compared to standard sizes. A tablet below mentions the capsule volume and filling weight of formulations with various tapped densities.

Sizes of Empty Gelatin Capsule

6.What is the disintegration time of empty gelatin capsules?

Upon administering empty gelatin capsules, it rapidly disintegrates in the body which takes few minutes and produces its action quickly.

Empty gelatin capsules generally take 3-13 minutes of disintegration time which is entirely based on the size of the capsule, type of gelatin, plasticizers, and its concentration.

The plasticizer is a chief element that manifests release and disintegration time such as how fast or slow the capsule releases its action.

7.What are the advantages of empty gelatin capsules?

The advantages of empty gelatin capsules are as follow:

- Empty gelatin capsules are the type of dosage form that protects and safely stores medical and dietary supplements.

- It contains gelatin,which is absolutely pure, tasteless, gluten and GMO-free, protein. These capsules offer pleasant properties for consumers.

- Empty gelatin capsules are available in multi-colors, shapes, and various sizes to meet the standard requirement of active fills with targeted demographics.

- Gelatin is also capable to produce a diverse range of physiological actions such as from sustain release (enteric) to rapid release of active substance that meets the consumer’s needs.

- This is the reason why many consumers select capsules over conventional tablets.

- Some consumers prefer the evidence of being natural/organic ingredients, for this capsule provides transparency or a clear capsule to attain consumer’s satisfaction.

- Capsules are easy to swallow and a preferred form of medication by adults and children.

- Capsules provide easy work for many powdered formulations.

- Capsules are cost-effective dosage formulations available in many shapes, colors, and sizes according to the need of requirement.

- Empty gelatin capsules are often considered to have a better bioavailability than a conventional tablet. As gelatin is a pure protein derived from animal sources, it tends to dissolve rapidly and ruptures in the body and release active ingredients rapidly.

- Empty gelatin capsules have a high degree of flexibility with the easier formulation.

- Modern capsules shells have a tendency to accommodate multi-filling products such as beads, small tablets, granules even semi-solid dosage formulation.

- They release active ingredients in the body in their original form since they are incorporated into capsules without being passed through compression therefore, particles could not be ruptured.

- Empty gelatin capsules are ideal for pre-clinical and clinical studies. In blind studies, tablets are hidden in empty gelatin capsules.

8.What are the disadvantages of empty gelatin capsules?

Despite many advantages, empty gelatin capsules have some disadvantages which are as follows:

- The filling of empty gelatin capsules is a slower process than tablets manufacturing, but this problem is being treated in recent years by the advent of modern technologies such as high-speed automatic filling machines.

- Empty gelatin capsule is an expensive form of dosage formulation than conventional tablets.

- Highly soluble salts can not be dispensed in empty gelatin capsules as it causes gastric irritation.

- Empty gelatin capsule is sensitive to humidity and temperature ultimately cause stickiness and damage to the capsule shell.

- You cannot dispense aqueous or liquid formulations in empty gelatin capsules.

- Empty gelatin capsule is only available in a standard shape (cylindrical), sometimes it is unsuitable for a marketplace demand.

- Empty gelatin capsules are not suitable to dispense hygroscopic substances.

- Due to rapid release upon reacting with gastric fluid which sometimes leads to cause gastric irritation if taken in high concentration.

9.What is the difference between empty gelatin and soft gelatin capsules?

The difference between empty gelatin capsules and soft gelatin capsules are as follow:

- Empty gelatin capsules can fill solid dosage formulations such as granules, powders, or minitablets. Whereas softgel capsules can fill solid and semi-solid formulations such as oils, or aqueous preparations.

Soft and empty gelatin capsules- Picture credit- The manomet

- Empty gelatin capsules are composed of two parts, body and cap which is firmly joined upon filling, whereas soft gelatin capsules are manufactured as a single piece instead of two halves.

- Empty gelatin capsules have a hard capsule shell, on the other side soft gelatin capsule carries a softer texture.

- Empty gelatin capsule has a standard shape such as cylindrical, whereas you can find soft gelatin capsules in diversified shapes such as oval, circular, star shape, etc.

- The manufacturing procedure of an empty gelatin capsule is simple and easy. On the other side, soft gelatin capsules required lots of ingredients with careful monitoring throughout the procedure.

- Empty gelatin capsules are available in multiple sizes ranges from 000 to 5, whereas soft gelatin capsules have limited size variation.

10.What are the major types of empty gelatin capsules?

Empty gelatin capsules are available in four different types

#1- Transparent Empty Gelatin Capsule

#2- Opaque Empty Gelatin Capsule

#3- Colored- transparent Empty Gelatin Capsule

#4- Colored- Opaque Empty Gelatin Capsule

#1- Transparent Empty Gelatin Capsule

These are two-piece empty gelatin capsules available in size #5. These capsules are cleared that have no color and you can easily visualize the filling substances. They are ideal for filling organic or those substances where you want to show the content texture and color. The filling content of these capsules should be light resistance that demonstrates stability in the presence of light.

Transparent Empty Gelatin Capsule- Picture credit- India Mart

#2- Opaque Empty Gelatin Capsules

These capsules are attractive that are used by many manufacturers for brand identification. Empty gelatin capsules are available in a variety of colors available alone or in combination for dispensing of supplements. These capsules contain opacifying agents that make them non-transparent

These capsules are suitable to fill those substances that are sensitive to light. The opaque nature of capsules ensures that the content of capsules is protected and safe from degradation.

Opaque Empty Gelatin Capsules

#3- Colored-Transparent Empty Gelatin Capsules

These empty gelatin capsules are incorporated with colorants to enhance the aesthetic properties. Consumers also prefer these capsules as they provide a transparent view with bright colors.

Colored-Transparent Empty Gelatin Capsules

#4- Colored- Opaque Empty Gelatin Capsule

When you want to classify distinguish brand then colored- opaque empty gelatin capsule is an ideal choice. These capsules are easily identified by consumers simply by visualizing the color of the product. These capsules are safe for light-sensitive substances with an appealing marketing tool. These capsules are useful to fill dry ingredients such as light-sensitive herbs and powders.

Colored- Opaque Empty Gelatin Capsule

11.What are the benefits of empty gelatin capsules in the cosmetic industry?

In the cosmetic industry, empty gelatin capsules are basically used to dispense powders, granular substances, or organic ingredients. By fixing these substances in capsules have several advantages over general packaging.

#1- The appearance of the capsule is novel in cosmetics. Every capsule of cosmetics has their distinct color to attract and identify the brand to the consumer. Due to enrich features and different theme for cosmetic has now become a popular gift for friends and family.

#2- The packaging of cosmetics is elegant and compact, and the content of cosmetics will not affect by any environmental factor. Thus, consumers after using the product at one time get real-time results and avoid unnecessary contamination that may affect the potency.

#3- The product safety is maximum with empty gelatin capsule packaging. Because products in traditional boxes may harm the content by several environmental factors and they are susceptible to microbial invasion.

Cosmetic Capsules

As organic formulations do not contain sufficient or even no preservatives, therefore, manufacturers must use possible safety packaging to improve product safety and efficacy.

#4- Empty gelatin capsules are easy and simple to use. Consumers prefer those cosmetic products that are properly packed and easy to carry for vacation, tour as well as to work. Because they are unbreakable and safe.

12.What is the filling principle of empty gelatin capsules?

Have you ever wondered how medicines are filled in empty gelatin capsules?

The filling of capsules with active ingredients is known as encapsulation. This process is achieved by a variety of ways to enclose medicine in the body with a tight cap over that make it available to use for oral administration. Empty gelatin capsules are commonly used for filling desirable powder or medication preferred by many pharmaceutical industries.

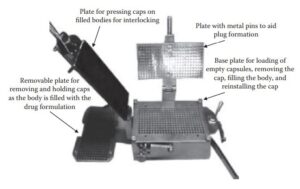

These are capsules are filled manually on a smaller scale. For this purpose, many hand-operated types of equipment are used that is capable to fill capsules ranging from 24-2000 capsules/ hour depending upon type of machine.

Hand operated encapsulation machine- Picture credit – India Mart

While many pharmaceutical industries use specialized filling machines known as automatic gelatin encapsulation machines for accurate, efficient and fast filling. The capacity of automatic filling machines ranging from 3000-150,000 capsules per hour. Here two dosing equipment are used such as dosator and tamping device.

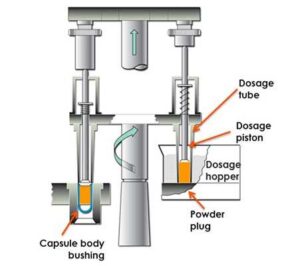

#1 Dosator

This device helps to dip an empty gelatin capsule into a powdered bed. A piston of dosator helps to form a plug of powder which is then transferred into the body of the capsule and releases.

Dosator- Picture Credit- Pharma approach

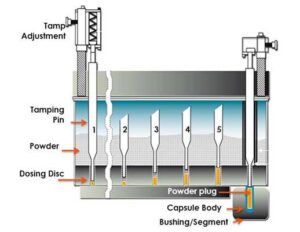

#2 Tamping Device

This equipment facilitates the filling of capsule cavities bored into a dosing disk same as filling of tablet die. A tamping punch gently compresses a powder filling repeatedly. This is accompanied by the ejection of a plug into a capsule body.

Flow chart of a tamping machine- Photo credit- Pharma approach

13.What are the storage requirement of empty gelatin capsules?

The most essential storage requirement of empty gelatin capsules is to protect the capsules from the extreme environment such as humidity and temperature. The ideal storage temperature ranges from 15 to 30°C.

Critical care should be taken to keep stored capsules at their specified temperatures. The fluctuation in temperature may lead to forms moisture content inside the sealing containers and cause distortion or failure in the separation of body and cap during the filling process.

Storage of empty gelatin capsules- Picture Courtesy- Medicine making

14.Can you manufacture capsules from other ingredients than gelatin?

Capsules can manufacture from gelatin (protein) and other ingredients than gelatin such as hydrocolloids that is also known as gelling agents. But gelatin is a prime ingredient that has been used since decades ago and is preferred by many consumers around the globe. Although in the past few decades after the emergence of new techniques and research protocols plant gelling agents are introduced. Such as starch, HPMC, or hydroxypropyl -methylcellulose, pullulan, and so on.

These gelling agents are preferred for vegetable formulation.

15.What is the mechanism of action after administration of empty gelatin capsules?

Upon oral administration of the capsule, it takes two three minutes to dissolve in the body. Depending upon the formulation of empty gelatin capsules the process of dissolution is estimated. For example, some gelatin can dissolve faster than others when they contact acid in the body. An enteric-coated capsule demonstrates stability under a low acidic environment of the stomach, although it solubilized rapidly under alkaline conditions such as small intestine. You require a fast-dissolving capsule shell for fast action whereas, those drugs that targeting the small intestine require a sustained release capsule shell.

Empty Gelatin Capsule- Picture Credit- Shopee

16.How to troubleshoot softening and adhesion problems associated with empty gelatin capsules?

Problems with Empty Gelatin Capsule

As you know, the capsules are the dosage form used frequently at industrial and health sectors for product filling. They also meet several problems especially softening and adhesion that commonly occurred in the spring and summer seasons.

The target reason for this problem is improper storage condition that is mainly affected by temperature and humidity of the air.

The softening of capsules not only breaks the capsules but also facilitates microbial growth. Indeed, these factors can affect the filling process and disturb the overall finished product

Troubleshoot with Softening and Adhesion of Capsules

- First, find out the root cause of adhesion, if the reason is moisture, then it is better to use a desiccant that can absorb the moisture. A desiccant should place in a jar where capsules are treated and seal it tightly.

- If a storage environmental temperature is too intense due to excessive heat. Then it can be solved by cooling the storage area. An airtight capsule container should be placed in a refrigerator for some time and shaken gently. Additionally, you can add incorporate a small amount of powder such as corn star or flour in a box for storing capsules. A powder coating can also eliminate the stickiness problem of capsules.

17.What are global trends of empty gelatin capsules in the market?

According to an estimated analysis related to empty gelatin capsules, it has been forecast to 2023 the market is expected to meet up to 2.7 billion USD with a higher annual growth rate of up to 7.4% recorded from 2018.

The reason for the growing trend is as follow:

The global population of elderly individuals is rising, and it is expected to be three-time more by 2050. Therefore, the fitness of these populations is comparatively a renowned concern than the younger generation. The increasing demand of drug development is intensifying.

At the same time, the popularity to capsules as a dosage form is also getting higher due to easy swallowing, pleasant taste, and improved drug stability. Therefore, demand for empty gelatin capsules in the pharmaceutical industry has drastically increased.

Secondly, the uses of empty gelatin capsule in the nutraceutical industry have also become higher. This is because of growing awareness related to health and rising of health care development sector. The nutraceutical is developed to prevent certain ailments such as obesity, blood sugar, cholesterol, and other diseases. These capsules are useful to deliver efficient and convenient nutrition to consumers.

18.How to select a capsule size and specification as per requirement?

Empty gelatin capsules are most often composed of gelatin and other excipients. They can hold powders, granules, tablets, and semi-solid preparation.

Selection of empty gelatin capsule according to size and specification- Picture Credit- Arab Cap

Additionally, capsules provide sufficient bioavailability and able to dissolve and disintegrate quickly. The safe filling of capsules facilitates a good convenience, but they are available in variety, so it is difficult to choose a particular size of the capsule. Therefore, capsules are categorized into eight prime specifications, such as

- 000 can hold up to 1.37cc

- 00 have the capacity to hold up to 0.95cc

- 0 have the capacity to hold up to 0.68cc

- 1 have the capacity to hold up to 0.50cc

- 2 have the capacity to hold up to 0.37cc

- 3 have the capacity to hold up to 0.30cc

- 4 have the capacity to hold up to 0.21cc

- 5 have the capacity to hold up to 0.13cc

In addition, 0E is a special mode that can hold up to 0.78cc.

19.What is HPMC capsule?

HPMC is globally known as ‘Hypromellose’ that is manufactured chemically from cellulose. These capsules are considered as safe for human consumption. It is the most common substitute of gelatin, derived from vegetable sources and gives physical appearance like a gelatin.

HPMC Capsules- Picture credit- Manufacturing Chemist

These capsules are highly resistant to temperature and humidity thus they are appropriate for moisture-sensitive active ingredients.

HPMC capsules achieves enteric properties via incorporating with gelling agents that facilitates protection against acidic environment of stomach and completely solubilize in intestine or in alkaline medium.

20.What is pullulan empty capsule?

Pullulan capsules shell is made up of a polysaccharide polymer known as maltotriose. This is a naturally occurring polysaccharide which is tasteless and edible. This is easy to solubilize in water, safe and non-toxic. These capsules are difference from conventional gelatin capsules as their polysaccharide is based on a natural fermentation process.

A pullulan empty capsule – Picture credit ExecelBiz

There are following benefits of pullulan capsule:

- Pullulan is three hundred times greater oxygen barrier than HPMC as well as nine times stronger than gelatin.

- These capsules are finest choice for those material that are sensitive to oxygen.

- They are chemically inert, and do not crosslink with ingredients of capsules.

- They are safe, environment friendly and natural form of drug delivery.

- The finished product with pullulan capsules is visually appealing

- These capsules are stronger than gelatin and perfect to run via high-speed automatic filling machine with 99% run rate.

21.What innovative future applications of empty gelatin capsule are expected?

The physiological characterization related to drug absorption in the body is of prime importance. This is a challenging factor to develop a certain device or equipment that can allow you to characterize the controlling and targeting the drug delivery. For instance, measuring pH, capture the details of release and absorption, and diagnosis of diseases.

An electronic capsule device is introduced since 2001 that contain an empty gelatin capsule filled with swallowable camera connected to powered battery. These capsules provide control release of drug, visualizing patient and facilitates real-time communication. They are applicable to assess the rate and site of action of drug within gastrointestinal tract.

An electronic Capsule- Photo credit- Newatlas

In future, electronic capsules will be further exploited in monitoring patient behavior, drug delivery, track the doses, diagnosis ailments and data integration. Furthermore, targeted drug release at specific site and potential benefits for the treatment of locally confined diseases of GIT, such as IBD or inflammatory bowel disease, intestinal cancer as well as localized ulcer of GIT. This technique offers a less invasive criteria and a best substitution of endoscopy and colonoscopy. Moreover, these empty gelatin capsule with detecting sensors will also ensure the presence of protein, enzymes, secretion of hormones and other metabolite. It will also access a ton of bacterial cell that may influence on human health system. Therefore, making of therapies and prevention would be safer and more effective.

Empty Capsule Related Products

Empty Capsule Related Posts

Empty Capsule Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine