Discussion On The Technology Of Tablet Film Coating Machine

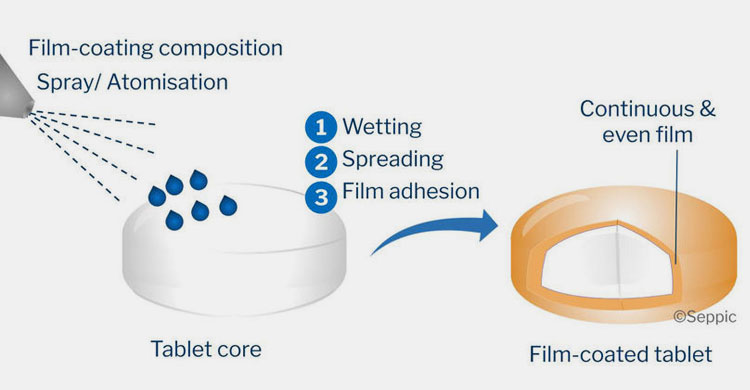

The tablet film coating process is to spray a layer of relatively stable polymer coating material uniformly on the surface of the tablet core by spray method, forming a plastic film layer several microns thick, so as to achieve certain expected effect.

Compared with the traditional sugar coating technology, the tablet film coating machine has advantages of short time consumption, moisture, light, drug stability and so on.

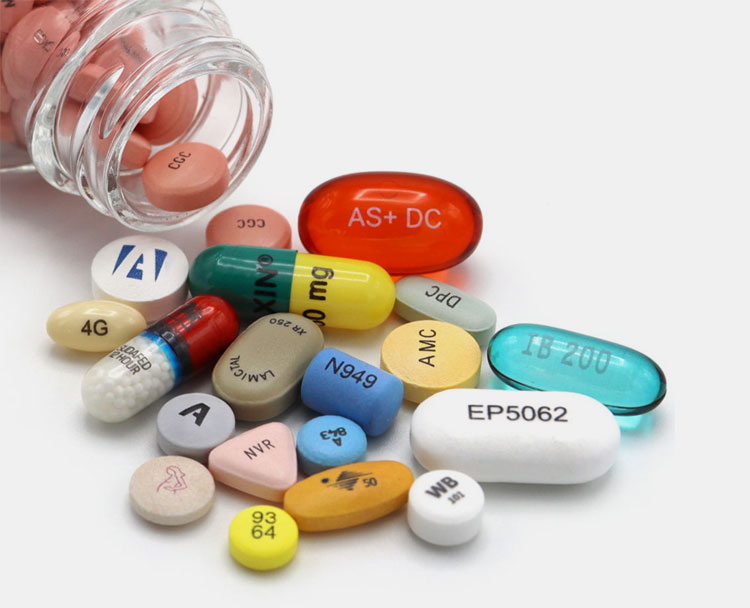

With the fast development of the pharmaceutical industry, tablet film coating machines are widely used in tablets, pills, granules, especially for traditional Chinese medicine with strong temperature absorption, easy to crack and fade.

The industrial professionals indicate that the tablet film coating machine, as a new technology, is more strict with tablet core, including all the requirements for the coordination between various processes, adjustment of a series of technical indicators and requests in the production process and mutual matching.

So if you want to achieve the ideal effect of tablet film coating, you must strictly observe the manufacturing standard.

Pay attention to the quality of tablet core

A good quality of tablet core has a decisive influence on tablet film coating. When the quality of the tablet core is too bad, you can’t or it is too hard to proceed with tablet film coating work. And the quality of the tablet core is related to the tablet’s hardness and friability. The friability is more important.

The industry professionals introduce that generally speaking, the hardness of traditional Chinese medicine tablets that are suitable for tablet film coating should be 5kg/cm3 and the hardness of western medicine tablets should be about 4kg/cm3.

So how can you check the hardness of tablets? The simple method that is advised by industry professionals is using a hardness tester or throwing the tablet vertically upward for 2 meters to make it fall freely, and the hardness is qualified if it does not break for more than two times.

The way to check the friability of tablets is by using your fingers to scrape the edge of the blade or the surface of the blade, no flakes of powder off is appropriate.

The other way is to put about 30 tablets into a 250ml glass, shaking violently for 2 minutes, with the surface of the piece, the edge of piece is not worn is appropriate. For the hygroscopicity of large plain tablets, the hardness requirements are higher.

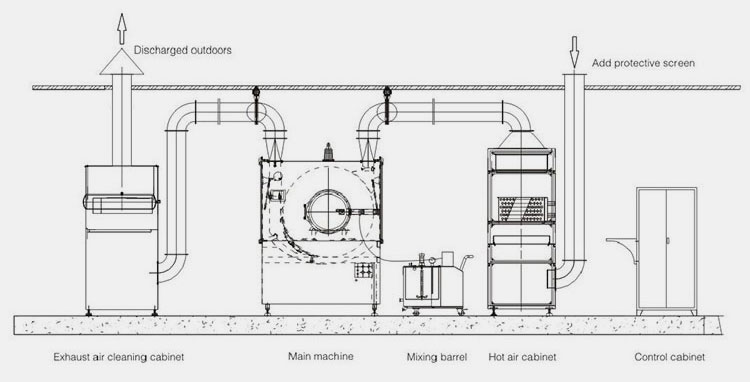

Pay attention to the principle of tablet film coating machine

At present, there are various types of tablet film coating machine, but no matter what device, they all need to obey the coating principle.

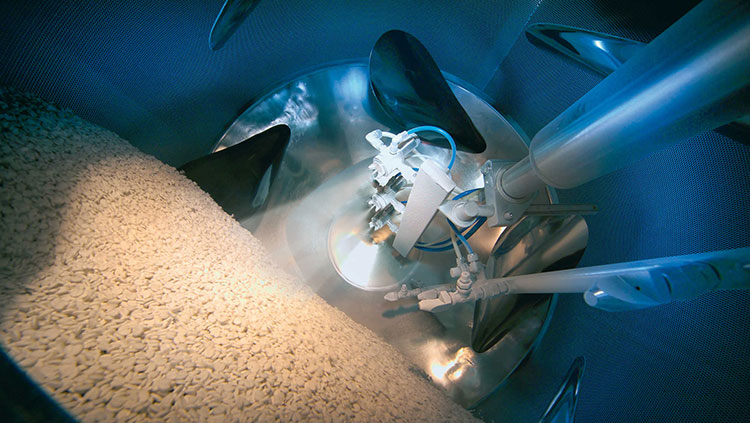

Some experts said that the key to keeping the coating one-sided smooth and delicate is to master the whole process, including the relationship between pan temperature, spray volume and speed, which is the most important in the film coating operation process.

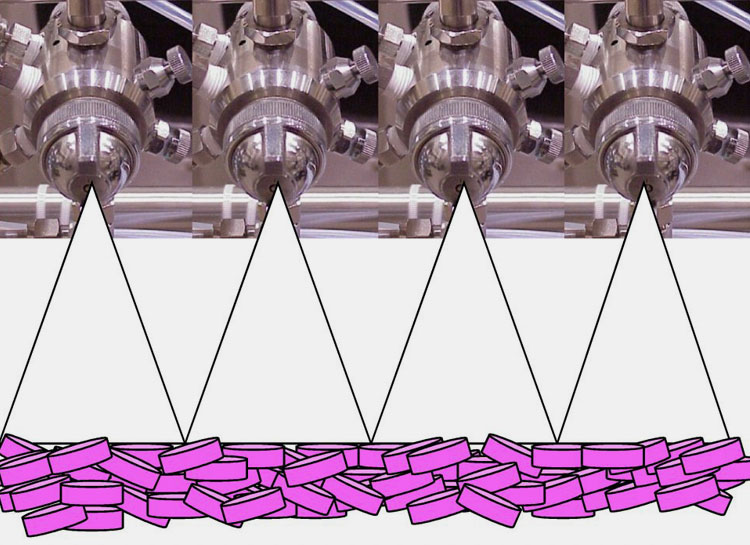

During operation, the appearance quality of tablet coating film is influenced by the degree of atomization of the coating liquid and the spray liquid atomization is directly decided by atomization pressure and atomization system.

Therefore, at the beginning of spray, it is necessary to master the principle of spray speed and hot air temperature first, so as to make one-sided slightly wet, pay attention to prevent one-sided adhesion, and the temperature should not be too low.

If the temperature is too high, the drying is too fast, the film is easy to rough, uneven color; if the temperature is too low, or the spray speed is too fast, it will make the humidity in the pot too high, and soon there will be adhesion and other phenomena.

The relationship between the rotated speed of pot and the operation of tablet film coating is: Low speed, strong adhesion of film; high speed, poor adhesion of film, easy to peel. In the process of tablet film coating, if the temperature is too low, the amount of spray is too large, and the wafers flow is retained, the phenomenon of sticking may occur.

At this time, you can increase the speed to improve it. If necessary, you can also adjust the temperature and the amount of spray, spray range and so on to overcome it.

Get to know the common problem of tablet film coating

It is reported that, in the use of coating powder quality, unchanged tablet film coating often appear problems including sticky sheet: mainly due to the amount of spray too fast, in violation of the solvent evaporation equilibrium principle and make the sheet mutual adhesion.

When this happens, you need to reduce the amount of coating liquid spray, increase the temperature of hot air, speed up the speed of the pot, etc.

When it appears "Orange peel" film: it is mainly due to improper drying and low spray pressure of coating liquid, so that the spray droplets are heated and concentrated unevenly, resulting in film ripples. In this case, the evaporation rate should be controlled immediately to increase the spray pressure.

When it appears ”bridge”, it means the film on the lettering piece caused the logo to blur. The solution is to slow down the coating spraying speed, reduce the drying temperature, and pay attention to controlling the temperature of hot air.

When it appears color spot: This situation is due to mixing with coating liquid is not uniform or solid characteristics of the fineness caused by insufficient. The solution is: coating liquid should be fully stirred evenly.

Cracks, flaking of the coating on the surface or edge of the tablet or wear at the edge of the tablet:

If the liquid and solid content of the coating is not properly selected, the speed of the coating machine is too fast, and the spray amount is too small, the appropriate liquid and solid content of the coating should be selected, and the speed and spray amount should be adjusted appropriately.

If the tablet core hardness is too poor, the core formula and technology should be improved.

Film performance appears "frost spray": this situation is due to the hot air humidity being too high, the spray process is too long, the atomization effect is poor. At this time, the temperature should be appropriately reduced, the spray range should be shortened, and the atomization effect should be improved.

Color difference between tablets: this situation is caused by uneven fan spray or excessive coating liquid and solid content or slow speed of the tablet film coating machine. At this time, you should adjust the angle of spray gun injection, reduce the solid content of the coating liquid, appropriately improve the speed of the coating machine.

There are pinholes on the coating surface: This is caused by too much air involved in the preparation of the coating solution. Therefore, excessive air should be avoided when mixing liquid.

Don't forget to share this post!

Tablet Coating Machine Related Posts

Tablet Coating Machine Related Products

Tablet Coating Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine