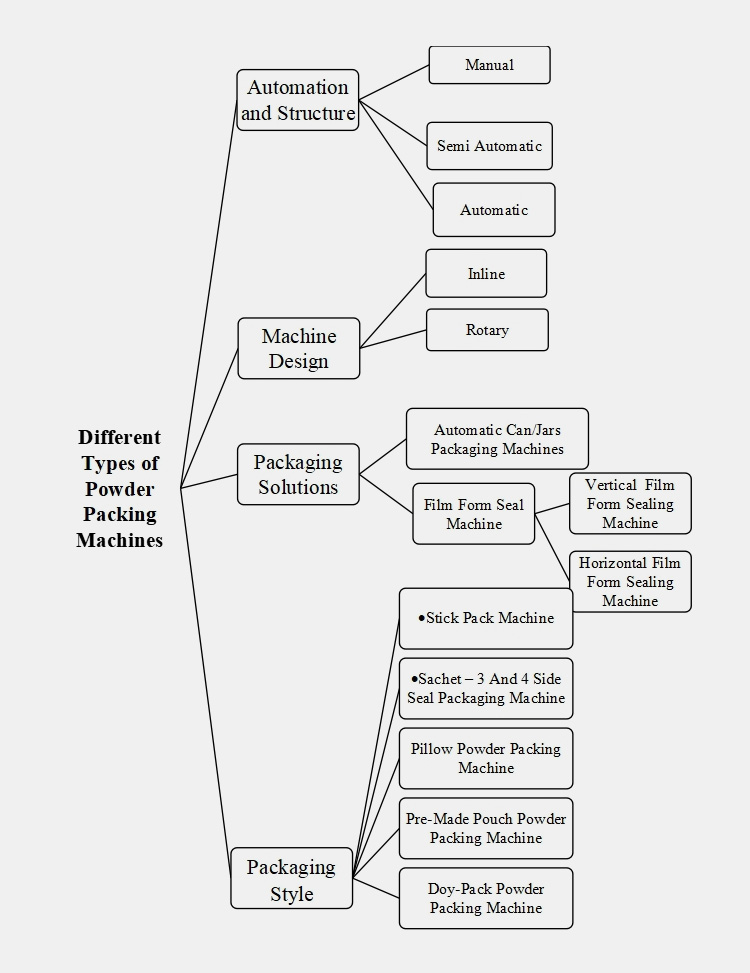

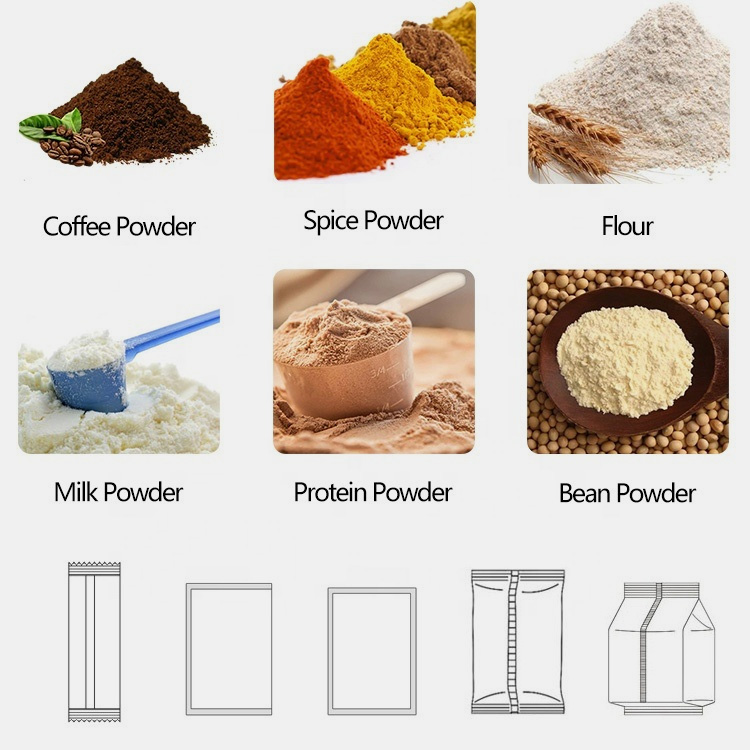

Different Types Of Powder Packing Machines And Applications

When looking for a powder packaging machine, you see a variety of brands, and models, around you that can be overwhelming. From medicines to foods, powder packaging machine plays an integral role in any production success, this is because of high filling accuracy, fast dispensing, and high automation.

In this article, we highlighted different types of powder-packing machines and applications used in different industries across the globe.

If you’re interested to know various types of powder packing machines, for your understanding, we have classified them into different categories.

1.According to Automation and Structure

For an easy understanding; we should begin the classification of the powder packing machine from the basics i.e., automation and structure.

There are three major types discussed below:

Manual Powder Packing Machine

Also known as the hand-held machine or traditional powder packing machine; an operator is required throughout the packaging process to load, monitor, and discharge the packet after being filled.

This machine is compact, simple, cost-economical, and handy. For home-based businesses and small entrepreneurs must consider this option for powder packaging as it requires lesser space and gives you an excellent result.

Basic Parts of Manual Powder Packing Machine

| Hopper | Packaging product is stored in a hopper. |

| Handle | The quantity of powder is transferred from hopper to bag by movable handle. |

| Auger Filler | Helps in filling and packing powder into bags. |

| Frame | Supports whole structure of the machine |

Applications

The hopper of the manual powder packaging machine is limited with an average dispensing rate. Therefore, this machine is ideal for small scale herbal, agricultural, pharmacies, cosmetics, food, and veterinary businesses.

Semi-Automatic Powder Packing Machine

This machine is an efficient solution to reduce the production cost, thus it is highly recommended for small businesses or limited-budget firms. A semi-automatic powder packing machine gives you an accurate and fast outcome like an automatic machine but some of the tasks can be done manually and you need to rely on the technician. For instance, loading and adjusting film or pouches and initiating the process.

Basic Parts of Semi-Automatic Powder Packing Machine

| Hopper | The feeding material is stored in a hopper. |

| Weighing Platform | The quantity of the sample is measured by an electronic scale weighing platform. |

| Operating Panel | It helps the operator to put data/protocol into the machine. |

| Filler | It allows filling material into each packet. |

| Dust Controller | It helps in reducing dust emissions in the air that generate airborne and fugitive dust. |

Applications

A semi-automatic powder packing machine is a flexible solution for small production lines; including laboratories, pharmacies, food and beverages, cosmetics, chemicals, herbals, and nutraceuticals industries.

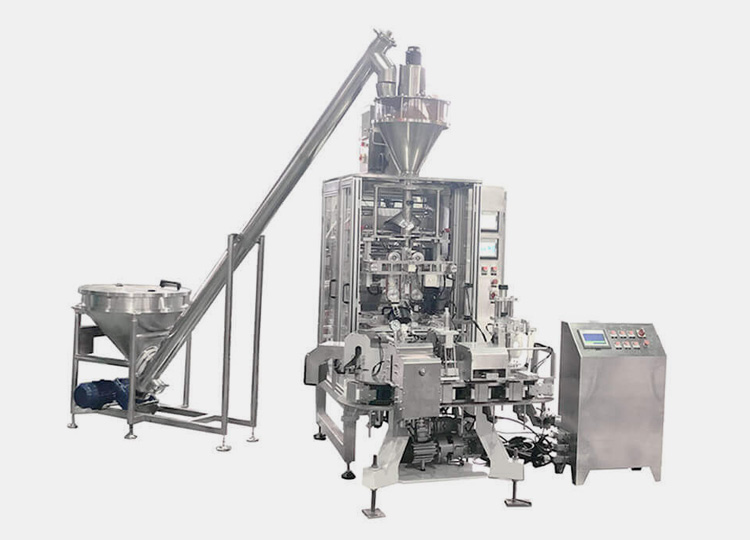

Automatic Powder Packing Machine

The entire work process of powder packing is done automatically where no human interaction is required throughout the procedure. The operator is only required to feed the data with appropriate assigned parameters while the rest of the task is done by the machine.

This machine can run long production with accuracy and precision, where a sensor is responsible to detect the error if occurred. For e.g, the machine itself stops when facing a technical problem. Moreover, the sensor helps in the filling of an accurate product and runs the process smoothly and continuously.

Basic Parts of Fully Automatic Powder Filling Machine

| Hopper | Before feeding, the powder is stored in a hopper. |

| Bag Former | A narrow cylinder helps in the formation of the bag. |

| Filling Heads | It dispenses the material into packets from a hopper. |

| Measuring Cup | It ensures 100% accurate dispensing of the product. |

| Level Detector | It determines the level of the material in the filled bags. |

| Filler | A filling station ensures the automatic filling of the product into each assigned bag. |

| Sealing | Vertical and horizontal heat sealers facilitate the closing of pouches/bags. |

| PLC Touch Screen | An operator feeds the process protocol using an adaptable touchscreen. |

Applications

Fully automatic packaging machines can manufacture packing products like salt, sugar, spices, washing and detergent powder, baby powder, various cooking premixes, and milk powder.

2.According to Powder Packaging Machine Design

Powder packaging is a growing field where you see innovation and the emergence of new machinery every day. Discussed below are two basic types of powder packaging equipment that are designed differently but offer the same job. Let’s see what the best for you!

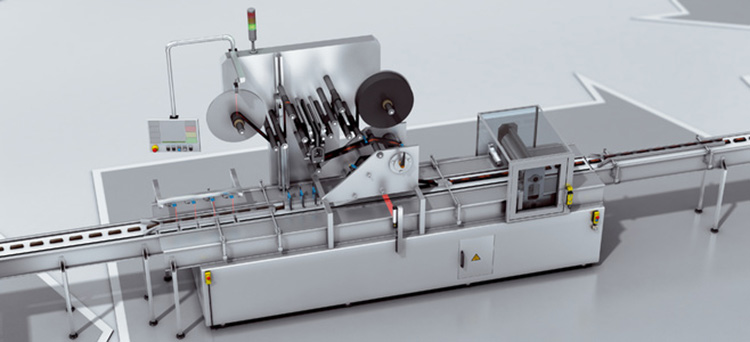

Inline Powder Packing Machines

An inline Powder Packing Machine Line

A quite straightforward and durable design where the operation takes place in an orderly manner; means starting and ending of the procedure take place in the same location and in opposite directions.

For i.e., feeding of material from the top whereas filling and discharging at the opposite lane.

This machine required high space for installation and production, but this machine is quite simple in terms of operation and inspection offering maximum visibility.

Inline machines are equipped with automated clamps that lift the container i.e., bag, box, or drum for filling. Once the powder is filled to the final weight, the head of the clamp gently lowers the container.

Hence, machines ensure reduced disturbance ultimately limiting dust emission and subsequent loss of product. A surplus air is removed via vacuuming reducing chances of product contamination and thus producing a finished and safe packaging.

Applications

An inline powder packing machine is a versatile packaging solution broadly accepted on a large industrial scale to pack the powder into bags in order to achieve a presentable packaging look. It is used in packaging products like pharmaceuticals products (powders, granules, or dry syrups), food items (milk powder, coffee, protein powders, flour, cocoa powder etc.,), household material (detergent, bleach, etc.,) and so on.

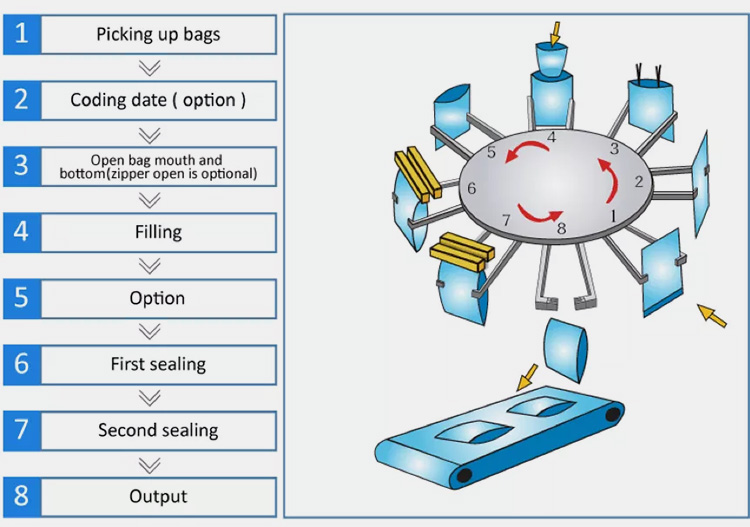

Rotary Powder Packing Machines

A Rotary Powder Packing Machine

An ergonomic format where the entire procedure is performed in a circular or rotary motion. Here, you don’t need to worry about space issues as this machine occupy less area and offering a large production.

Thus, it is suitable for large companies. The machine is commonly featured with one to four different feeding lanes popular among medium to large enterprises. Typically, feeding stations varies from one machine to other or from brand to brand.

The filling process begins when the rotary nozzle receives an accurate amount of product via auger while rotating funnels help in filling and passing by the next bottle/bag/container.

Applications

This machine is capable to manage large production lines and is widely acceptable to pack powders such as detergent, protein, flour, medicinal powders, nutraceuticals, ground coffee, agricultural products, and chemicals.

3.According to Packaging Solution

Pharmaceutical engineering has introduced a variety of turnkey solutions for powder packaging. For clear understanding, we have classified them below:

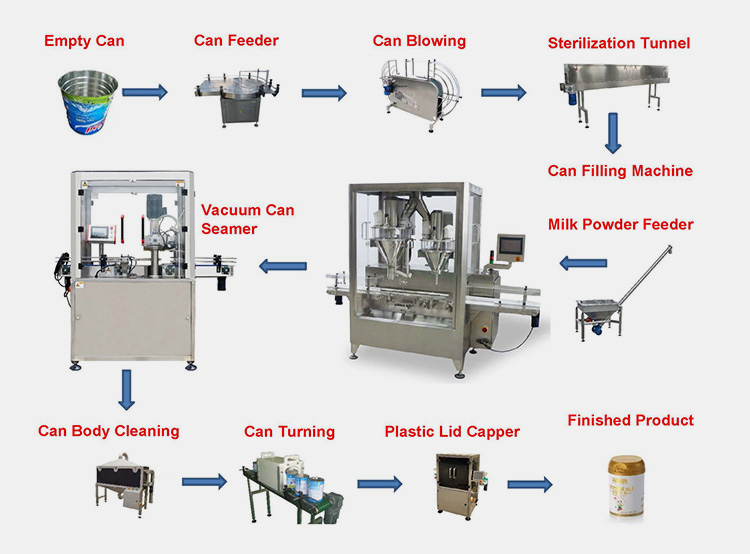

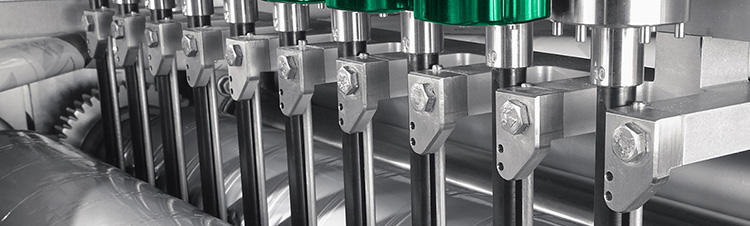

Automatic Can Packaging Machines

Many companies prefer using automatic can packaging machines to run the process of powder packaging into can, bottles, jars. The machine helps in filling and closing or sealing the jars after being treated with the material.

The packaging procedure follows screw-type-mechanism for smooth flow of powder into the cans.

Process of Powder Filling and Packaging in Cans

There are various features that assures the smooth procedure for various sizes and shapes of packaging cans. Instead of forming bag, the machine pack the powder material directly into the can where a sealer mechanically join them to save the product inside.

Basic Parts of Can Packaging Machine

| Hopper | The feeding material is stored in a hopper. |

| Auger Filling Head | Equipped with filling wheels to adjust the can for filling purposes. |

| Control Panel | For feeding data into the machine. |

| Sensor | It allows accurate filling of powders, also notifies the absence of a can or jar. Mean, No can No filling. |

| Weigher/Measuring Cup | Powder weighing is done by measuring a cup for an accurate quantitative filling into cans. |

Applications

This machine is suitable for treating free-flowing powders or with a high flowability ratio including pharmaceuticals, and foods department for packaging products such as protein powders, milk powder, spices, flour, nutritional supplements, medicinal powders, etc., thus suitable for efficient packaging.

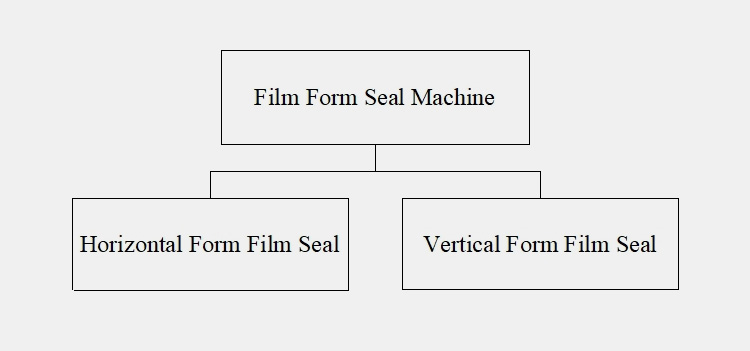

Film Form Seal Machine

Film Form Seal or FFS machines are automated innovations that emerged as a modern packaging solution subjected to treat a constant and smooth powder packaging solution and produce a better packaging output with more profitability. There are two categories of FFS machines such as:

Horizontal Form Fill Sealing Machine

A Horizontal Form Fill packaging machine is an equipment that manufactures a packet from wheel of stock film, here the filling and sealing of the package take place in the same machinery. The film moves in a horizontal direction and so its name accounts for horizontal form fill sealing machine.

These machines are able to produce standing pouches from film roll stock. It saves both labor and materials costs. Due to the in-line filling and sealing it maximizes productivity as well.

Basic Parts of HFFS Machine

| Hopper | The powder is introduced, and it transfers into pouches, sachets, or jars. |

| Film Unwinder | A simple tension-controlled clutch that unwinds the film into the machine. |

| Dancer Arm | A free moving roller allows film mechanically or pneumatically that depends upon the film’s tension. |

| Pouch Former | A wide range of bags are formed in this section it is like a collar of a human dress. |

| Film Registration | It is used to align the film that has been subjected to graphics or print to avoid slipping. |

| End Crimp Sealing Jaws | The main job of this tool is to seal and cut the packet after being packed. |

| Flighted Conveyor | It allows easy bag discharging to avoid jam-up and downtime. |

Applications

It can also be employed to fill and package powder-based products such as milk powder, coffee, drinks and also for liquid type products. Horizontal Form Fill Sealing machine for liquids permits dense fluid to be filled into 4 sided sachets. It is most appropriately selected for packaging food items and nonfood items like stationery products, cosmetic products, medicinal items, and chemicals.

Another advantage is that it can package a wide variety of different goods like meat, cheese, fruits and vegetables, cereals, broths, and as above-mentioned liquid and non-liquid foods too.

Vertical Form Fill Sealing Machine

The VFFS machine is a kind of wrapping device that uses a film sheet to form a tube-like bag and then fed with a material vertically. First, the bottom of the film is sealed then the material is introduced with a force of gravity.

Once the material is introduced, the film is sealed and cut simultaneously and discharged from the machine. These are quite efficient machines where you can adjust the width and length of each bag accordance to the consumer’s requirement and the product’s amount. The machine can produce various packaging styles like pillows, gusseted, square, zipper bags, etc.,

Vertical Form Fill Sealing machines are instructed with a PLC control system which makes them easy operability. Industries consider this equipment for good reason as it is economical and at the same time conserves precious space on the plant floor. Because machines are designed vertically covering small floor area therefore preferred by small, and medium, and can be utilized by high-efficiency synchronous businesses. Most often, equipment is recommended for free-flowing powders, which must be non-sticky in nature.

Basic Parts of VFFS Machine

The basic components of the VFFS machine is near to similar with HFFS machine except powder dispensing into the pouch.

| Hopper | Hopper allows the entry of powder into the bag. |

| Film Pulling Unit | This unit includes film unwinding/ rolling and film tension. |

| Bag Former | This unit helps in bag formation and filling of the bulk powder into it. |

| Filling and Sealing of the Bag | It has two set of the heating device; one is vertical sealer while other is horizontal ensuring perfect sealing up to consumer’s demand. |

| Cutter | Inside the horizontal sealer, a cutter is present that cuts the edges of the bag. |

Applications

Vertical Form Fill Sealing machine can produce and insert assortments of product into bags or pouches such as powder-based items, granules, and even solid pieces of food items such as confectioneries, coffee beans, frozen foods, snacks like biscuits, crackers, and also tool like screws. Powders that are filled by VFFS can be those of non-sticky in nature like spices, cocoa powder, coffee powder, flour, dessert powder, and powder used for agricultural and pharmaceutical purposes as well.

4.According to Packaging Styles

To make the product more aesthetically acceptable, there are various packaging styles offered by the following machines such as:

Stick Pack Machine

Stick packs are usually three-sided sealed pouches and the packaging material can be made of plastic, paper or even aluminum. A stick pack machine comes with either single or multi-lane production depending on the consumer’s requirements of pouch width.

A stick pack machine works almost similar to a vertical form fill sealing machine. A wheel of the film is cut and changed into several stick packs, the pouches are then filled with the desired product and sealed with a speed of packing and filling about eighty pouches per lane.

Basic Parts of Stick Pack Machine

| Feeding Section | A hopper or feeding section allows the introduction of powders into stick packs. |

| Pouch Former | A tube where a narrow stick is formed from a film. |

| Multi-Lane Filler | It is designed for free flowing of the material for the stick packs. It is commonly used for viscous and liquid products also. |

| Vertical Sealer | A vertical sealer bar joins the stick pack vertically once formed. |

| Horizontal Sealer | The top and bottom of the stick pack are sealed by a horizontal sealing bar. |

Applications

Stick pack machines are employed for packaging products that are conveniently used such as free-flowing powders, some fluids, and some semi solid products too.

They are exceptionally utilized for single-use purposes and for providing sample products. A stick packaging machine can be used to manufacture various kinds of products such as candy bars , coffee packets, detergent powder, granola bars, mints, spices, nuts, packets of ketchup and sauces, mustard. A stick pack keeps the powdered items safe from any hazard like explosions.

Sachet – 3 And 4 Side Seal Packaging Machine

Machine forms a sachet entirely and seals all four corners of it. This packaging machine can automatically generate four cornered square or rectangular shape sachet packets. It also contains a PLC control system that can give up to 100-120 sachets per minute or depends upon the brand to brand. Sachet – the 4-side sealing machine is versatile and also economical. It is employed by industries to package any type of free flowing or nonflowing powders and also some liquid or semi liquid products.

Basic Parts of Sachet Machine

| Hopper | A container that stores the material for packaging purposes. |

| Film Unwinder | Its name indicates that it helps in the opening of the film for sachet formation. |

| Sachet Former | After printing the film, it enters this section where the sachet is formed with the help of the former. |

| Filler | An auger filler is used to fill the powders into the sachets. |

| Cross Sealing Jaws | A set of vertical and horizontal sealers joins the sachet side by side and top to bottom. |

| Cutter | A cutter is present within horizontal sealer cuts and separates the sachet from each other. |

Applications

It can be used for the perfect packaging of products like coffee, salt, sugar, black pepper, baking powder, ketchup, mayonnaise, beverages, and some chemical products utilize this packaging too.

Sachet packs are usually employed to fill goods based on powder form, liquid form, and some granules too such as; honey, jams, cream or chocolate paste, oil, instant soups, etc. These four sides sealed sachet packets can also cover packaging for the pharmaceutical and cosmetic industry sector by packaging products like shampoo, body lotion, and creams, disinfectant gels, vitamins, collagen powder etc.

Pillow Powder Packing Machine

It is an economical and widely accepted machine for powder packing across the globe. This machine is especially accepted by food industries as a standard packaging solution that offers many advantages over other packaging machines.

Pillow packaging machine is a very simple and flexible machine to make packaging bags in a low cost because it is easy to switch the machine to make one size pillow bags. It has a simple forming tube procedure and uses less film when setting up the bag than other bag styles.

Simply, click on the PLC touch screen, feed the data i.e., number of bags, amount of powder to be filled, filling speed, etc., and the rest of the task will be done itself; so it is not necessary to learn how to operate the machine.

Basic Parts of Pillow Powder Packing Machine

| Feeder | Material is supplied to pillow packs via feeder/hopper. |

| Film Roller | A film is subjected to a film roller which allows smoothness to the former. |

| Pillow Pack Former | A former is a cone shaped structure where bags are formed according to requirements. |

| Filler | After pack formation, the material is filled into it with the help of a filling tube. |

| Sealing Jaws | Pillow packets are sealed by the help of vertical and horizontal sealing jaws. |

| Cutter | Once the material is packed, the cutter supports in their separation for final delivery. |

Applications

The flexible and versatile machine is employed for a diverse range dry free flowing powders. Due to cost saving and high-performance properties, pillow packing machine is used in the packing of food products (coffee, spices, flour, salt, Etc), daily chemicals, herbal powders, pharmaceuticals, nutraceuticals, and cosmetics items.

Pre-Made Pouch Powder Packing Machine

A compact pre-made pouch packing machine is the fastest packaging solution must for any production industry. A machine can fill powders and seal them in one or single process that grants great preservation, quality, and performance to your business.

Unlike Vertical Form filling machines, they make use of rolled film to make pouches. These are incorporated with various fillers like piston fillers, auger fillers, and electronic weighers and are available in many styles of pouches such as stand-up, zip bag, gusset, quad.

They ensure quick filling and sealing with great precision and accuracy. Here, you don’t require rollstock for pouch making so it gives an ultimate modern look to your product.

Basic Parts of Pre-Made Pouch Powder Packing Machine

| Material Pump | Material is pumped into the pouches with the help of a material pump |

| Pouch Loader | That accepts pouches from the feeding area |

| Dosing System | An auger filling system is used for the dosing process. |

| Gassing Unit | Distinguishes whether the pouch is opened or not. |

| Pouch Opener | It inflates the premade pouches with an air-blowing system. |

| Grippers | It delivers the pouches to the opening unit. |

| Filler | Material is filled into premade pouches by-products filler. |

| Sealing | Filled pouches are sealed either by heat sealer or cold sealer. |

Applications

They are known for packaging a wide range of products from powder to snacks, granules to liquids, for pharmaceutical, chemical, and agricultural products as well.

Adding different fillers to this equipment aids in the packaging of several products by rotary packaging machine like incorporating of auger filler for powder packaging, volumetric filler for grains packaging, multiheaded weigher for granular items like candies, chips, piston pump for packaging of liquid products, etc.

Doy-Pack Powder Packing Machine

Doy-pack is designed to pack bulky or free flow powder products. This machine is designed with multi-headed technology allowing you to pack different products.

This is all about the superior properties it has like metal detector, weight control, transportation, vacuum unit, auger filling unit, etc.,

By using PLC controlled touch-screen system it offers easy operation for difficult tasks in no time thus optimizing the product’s quality. All process stages such as sucking, opening, and filling of powders in the bag followed by sealing are carried out by the machine itself. The entire structure is made up of stainless steel ensuring the product’s safety during packaging.

Basic Parts of Doy-Pack Powder Packing Machine

| Reel Unwinder | It opens the film in hassle-free manner. |

| W- Fold and S-Fold | It helps in the folding of the bottom of the pack. |

| Vacuum Suction | It helps in the opening of the doy-pack before filling. |

| Hopper | This unit holds the product for the filling procedure. |

| Filler | The doy-pack machine is equipped with multiple filling channels where more than one product is treated to ensure 100% maximum productivity. |

| Detector | It ensures whether the pouch is present for filling or not. |

| Sealing Bars | They punch the packets after being treated with the filling process. |

Applications

Doy-pack powder packing machine is used for a variety of materials around you including foods, medicines, chemicals, household products such as spices, dried fruits, electrical tools, dried meat, cheese, oils, soup, meals, protein powders, etc., ensuring high-level of hygiene and protection to your product.

Conclusion

So far, we have discussed a comprehensive overview of different types of powder packing machines and applications. A powder packing machine is a versatile and multi-purpose solution for packaging in a hygienic way. Aipak Pharmaceuticals offers an extensive packaging line according to your product size, budget, speed, and frequency of size changing. Make sure to meet current challenges with our best services. We are here to help! With just a few details our customer team will be able to respond to you soon.

Don't forget to share this post!

Powder Filling Machine Related Products

Powder Filling Machine Related Posts

Powder Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine