Different Types of Packaging Methods

Whether a product’s market, brand, transportation, or safety; you can count packaging as an important weapon that combats all these factors effectively.When you’re talking about its role, it offers superb advantages. These include protection, aesthetic appearance, beautiful designs, customized packaging styles, smooth material, etc.,

If the packaging is unique, it grabs the attention of the customer and they’re willing to buy your product. Always remember, the packaging is as significant as your product.

So, What Different Types Of Packaging Methods every manufacturer must know?Read the article to find interesting knowledge about packaging types and methods.

1.Market Insight Of Packaging

Packaging is essential to the marketing of goods since it helps keep them safe and intact while also acting as a channel of communication between businesses and their target audiences.

Also, as customers are becoming more environmentally aware and looking for sustainable solutions, eco-friendly packaging is growing in popularity. Over the forecast period of 2022-2027, the global packaging market is anticipated to have a CAGR of 3.94%.

The Asia-Pacific zone is the pharmaceutical packaging market with the highest growth rate, according to a Grand View Research analysis, with a CAGR of 7.4% from 2020 to 2027. This growth is attributed to factors such as the region's growing geriatric population, rising healthcare expenditures, and increasing demand for generic drugs. According to a 2020 Nielsen poll, 85% of customers in the Asia-Pacific region are willing to pay more for items that utilize sustainable packaging. This figure is higher than the global average of 73%.

Additionally, new design options for packaging are now available thanks to technological improvements, with smart packaging providing advantages such as increased product freshness and safety. The smart packaging market is projected to reach $52.83 billion by 2025.

2.The Importance of Product Packaging

Packaging is an essential element in the marketing and protection of products, with several critical functions that make it a crucial aspect of the consumer experience. It typically refers to the process of creating, analyzing, and developing packages. Items that are frequently used for packing include boxes, cans, bottles, bags, wrappers, and containers.

Protection and Safety

One of the primary functions of packaging is to protect products from damage during transportation and handling. This protection also ensures the product's safety during storage, preventing contamination and preserving the product's quality.

Attract More Consumers

Packaging plays a significant role in branding and marketing by providing consumers with visual and tactile cues about the product. Packaging design can influence consumer purchasing decisions, with creative and attention-grabbing packaging often standing out on store shelves.

Information and Communication

Packaging also serves as a means of communicating vital information to consumers, such as ingredients, nutritional information, and usage instructions. This information can help consumers make informed decisions about their purchases.

Convenience and Functionality

Packaging can also provide convenience and functionality to consumers by offering features such as resealable closures, easy-open designs, and portion control. These features can increase customer loyalty and satisfaction.

Environmental Sustainability

As consumers become increasingly environmentally conscious, packaging sustainability has become a crucial aspect of the consumer experience. Eco-friendly packaging can demonstrate a company's commitment to sustainability and appeal to consumers who prioritize environmentally responsible choices.

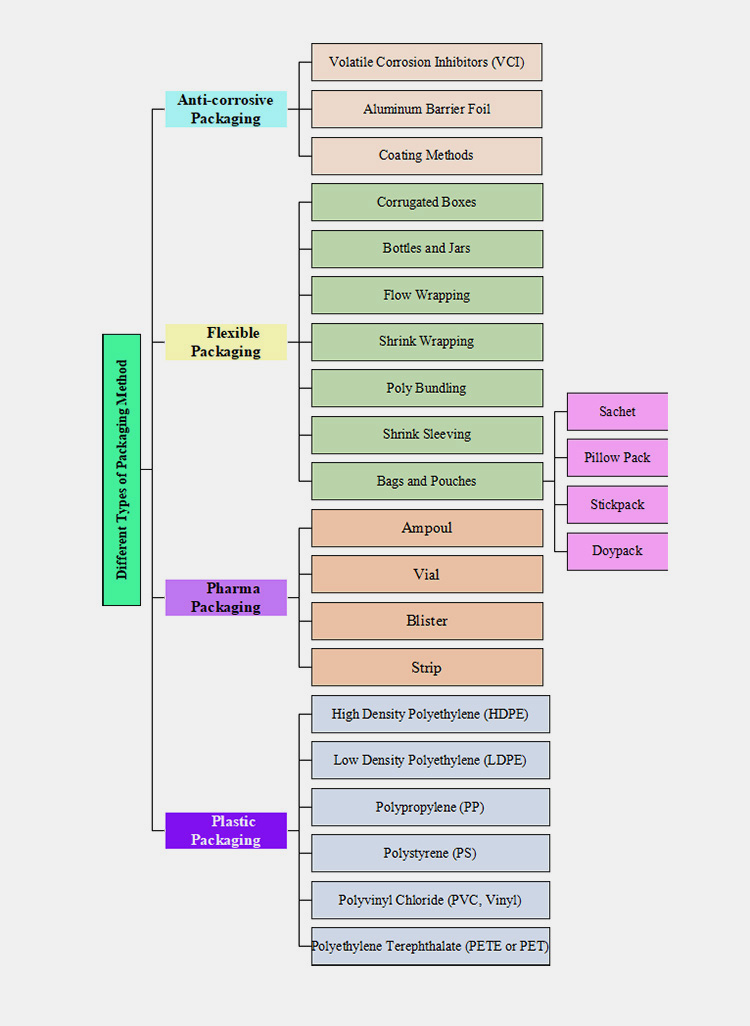

3.Different types Of Packaging Methods

We have simplified the complex classification of packaging methods below:

ANTI-CORROSIVE PACKAGING

This is a new emerging trend in the packaging era especially utilized in the production sectors of foods, pharmaceutical, paint, etc industries. This is popular in packaging those items that are needed to export over a long distance or stored in moisture-prone environments. Additionally, anti-corrosive packaging ensures a100% fresh products by preventing exposure to all climatic zones.

4.Different types of Anti-corrosive Packaging Methods

Volatile Corrosion Inhibitor

VCI (Volatile Corrosion Inhibitor) packaging, is a type of packaging that uses special materials and technologies to protect products from corrosion. VCI packaging is commonly used in the storage and transportation of metal products, such as steel, aluminum, and copper.

The packaging works by releasing VCI chemicals into the air around the product. These chemicals are designed to react with the metal surface, creating a thin, invisible layer that protects the metal from corrosion. The VCI chemicals can be used with processed foods without becoming hazardous.

Aluminum Barrier Foil

Aluminum Barrier Foil is a type of packaging material that is designed to protect products from external factors that could damage them, such as moisture, oxygen, corrosion, light, and odors. It consists of multiple layers of materials, including aluminum foil, which provides a high level of barrier protection.

Desiccants are often used in combination with Aluminum Barrier Foil to provide additional protection against moisture. To absorb any moisture that could have seeped in through any tiny cracks or leaks in the packaging, desiccants like silica gel and clay can be used. Pharmaceuticals and food are frequently packaged with aluminum barrier foil.

Coating methods (oils or liquids)

To give products more protection, coating techniques are frequently utilized in packaging. In coating procedures, a product's or packaging material's surface is coated with a liquid or oil to protect it from external elements like light, and oxygen. The coating is applied using various methods, depending on the type of coating and the packaging material being coated. The liquid coating can be done using a variety of methods, such as spraying, roller coating, or dip coating.

Oil-based coating involves the application of an oil-based material to the surface of a packaging material or product. This can be done using methods such as brush coating or spray coating.

5.Flexible Packaging

An increasingly gained form of popular packaging amongst many industries like food and beverages, pharmaceutical , nutraceutical is this flexible type of packaging.

Flexible packaging as the name indicates provides customizable options for packaging your products in various styles at a cost effective way. They are manufactured using materials like plastic, glass, cardboard paper, aluminium foil to develop packaging containers like boxes and carton, bottles and jars , liners, wraps, roll stocks, etc.

This form of packaging has developed production efficiency, introduced recyclable options, provides less bulkier material for enclosing products and enables safety to the products against environmental degradation factors.

6.Different types of Flexible Packaging Methods

The basic types of flexible packaging methods include:

Corrugated Boxes

Corrugated boxes present a customizable, recyclable and flexible option for your product’s packaging.

There are four types of such packaging types:

- Single phase corrugated box,

- Single wall corrugated box,

- Double wall corrugated box

- Triple wall corrugated box.

They are manufactured using rigid three layered material of cardboard sheet designed to make different shapes and sizes of boxes.

The three layers of a corrugated box has an outer liner, inner liner and space between these two liners is fluted. The fluted space is categorised into different sizes A,B,C,E,F which determines the width of layered wall. Corrugated boxes present shockproof resistance to the products inside and also prevents temperature and moisture like factors from affecting it.

Bottles and Jars

One of the most famous packaging choices for many industries including pharmaceutical, nutraceutical and food companies constitutes of bottles and jars.

Various types of bottles and jars are present which you can choose according to your product’s demand. They are made of plastic or glass, available in different sizes, shapes and even colours.

A bottle has narrow mouth opening and is used for storing of liquid products due to it’s narrow neck size. Various types of bottles include Boston round bottles, long necked bottles, sauce bottles , injection bottles, medicine bottles , pill bottles, syrup bottles, dropper bottles.

Jar has a wide neck according to it’s container size and it can store solids and liquids both. Various types of jars are economy round jars, paragon jars, french square jars, standard spice jars, hexagon jars, mason jars, straight sided jars. These all types can hold upto different volumes of products. Both bottles and jars provide abrasive resistance and inertness to the product.

Flow Wrapping

Flow wrap packaging encloses the product in plastic composed of:

- Polypropylene,

- Polyethylene,

- Polyethylene Terephthalate.

A flow pack consists of heat sealed wrapping at both sides of the packet and also in the middle of the packet. It offers versatility in packaging of various products like medical products, food products etc. A flow wrap packing protects the substance from air contaminants and prevents moisture affecting it.

Shrink Wrapping

Shrink wrap packaging is used to wrap around materials using heat which provides reliable and protective barrier of covering to the product. Shrink wrapping film is present in many variables of thickness, shrink ratios and strength.

The shrink orientation determines whether the shrink film will cover the product from both directions or will cover either of the direction in preferred choice. Three types of shrink films are used to package any products which are:

- polyolefin,

- polyvinyl chloride, It can produce wrapping for rollstock, bags etc.

Shrink films offer tamper resistant barrier and can pack multiple items or separate items with great durability. It can cover variety of different products in many sizes and shapes.

Poly Bundling

In this type of packaging multiple items are gathered together in a bundle using printed or clear films to wrap around the products. Poly bundles have an opening at one side of the packaging which is known as ‘bull’s eye’.

There are two types of poly bundling:

- Supported packs,

- and Unsupported packs.

Unsupported pack of poly bundling can stay directly within the film without requiring any support whereas Supported pack of poly bundling requires supporting materials like trays or pads to allow the products to sit within the film.

Poly bundling packaging can assemble similar sized products for the purpose of bulk quantities packaging. It comes cost effective for packing many products.

Shrink Sleeving

Shrink Sleeving has been in use since long times for packaging of many products across many industries. A shrink sleeve pack involves the use of plastic or polyester film to wrap around the product by using heat which then takes up the shape of the product.

There are certain types of shrink sleeves such as:

- Full body shrink sleeves,

- Neck band sleeves,

- Partial body sleeves,

- Multipack sleeves.

Shrink Sleeving provides durability to your product protecting it from extreme temperatures and moisture, at the same time giving it a tamper evident seal. It also prevents the unwanted movement of product during it’s transportation or storage. This type of packaging is used widely in many industries like in pet care, nutraceutical, food and beverages, personal care and products packaging.

Pouches and Bags

Very commonly used types of flexible packaging are created from cardboard paper, foil sheet, and plastic, and some bags or pouches have caps or sliding zip that preserves the liquid.

They are bespoke designed packaging solutions depending upon consumer wish i.e sizing, colors, plastic layers, and shelf life of the product. They are not only environmentally friendly, and cost-friendly but space friendly as well.

This way of packaging method is mainly used for powder and granular materials like oatmeal, beans, coco crunch, coffee, etc.

There are various categories of pouches and bags:

Sachet

A single-serving solution used to pack small amounts of product. Additionally, this is an economical packaging type that ensures airtight outcomes that help to preserve the quality of the product inside it. Moreover, it is user-compliant packaging that allows carrying the product anywhere they want. Whenever a consumer does open the packaging, they can rest assured that the product will be fresh and ready to use. Sachet packaging is used in many other fields mainly food, nutraceuticals, and, cosmetics.

Stick pack

A narrow-shaped flexible packaging is generally used to pack dry powders and sometimes used to pack liquids, gels, and semi-solids. It is beneficial for marketing, creating brand identification, and easy dispensing of upcoming new products. That’s why this unique and aesthetically appealing packaging is popular among pharmaceutical, food, and cosmetic companies.

Pillow pack

Unique pillow packaging is one of the most economical and most valued forms of packaging that is widely used in the market. Due to the broad beneficial spectrum, this is considered a pliable packaging solution. This packaging protects the items against physical and environmental hazards by offering an airtight mechanism. Hence whether it is taste, color, potency, or quality; it will be remained intact for a longer time as it is guaranteed by the manufacturer.

Doypack

A convenient form of flexible packaging d can perfectly preserve the products inside. Due to the large space and high preservation quality, it is mainly used in the pharma and food sector.

Doypacks are bags available in different materials that have a flat bottom that helps the package stand on the shelf that effectively grabs the attention of the consumer. These packs usually are zip-locked and sometimes cap fitted, which makes the product easy to handle and use for consumers.

These types of pouches are mainly double or multi-layered that are made from aluminum foil and polyethylene.

PHARMA PACKAGING

Pharma packaging, medicine packaging, or drug packaging is the procedure of packing pharmaceutical goods for safe distribution worldwide. It includes life-saving medicines, surgical and non-surgical items, nutraceutical or nutritional supplements, topically applied products, liquid, and solid dosage formulations. Pharma packaging is generally utilized in the dosing and dispensing sector.

7.Different types of Flexible Packaging Methods

Ampoules

Even though vials and pre-filled syringes have been competing, ampoules have been a popular choice in the pharmaceutical industry for delivering of injectable medicines. Glass ampoules are a way of enclosing drugs in the small container by heat and opening it through breakage at a certain point.

There are three types of ampoules which are One Point Cut (OPC) Ampoules, Colour Break Ring (CBR) Ampoules, and Scored Ring (SR) Ampoules.

These can package volumes up to 1-30 ml of drug and come in transparent or amber coloured glass bottles and are available in various shapes.

Glass ampoules have been beneficial to protect photosensitive products, provide inertness to the material present inside and provide impermeability to gases and other media.

Vials

Vials are another pharmaceutical packaging option used to contain medicinal products like vaccines, powders, anesthetics and other drugs or hold laboratory samples. They are made up of glass or plastic container and come in various shapes and sizes. The storage volume of vials is more than ampoules as they’re larger in size than the former one. These pharmaceutical vials are beneficial compared with bottles as they’re easier to transport.

Blister Packaging

Blister packs are a popular method amongst pharmaceutical company for packaging of a solid dosage form of drugs like tablets,capsules and lozenges.

They are composed of aluminium foil or plastic film which contains drug inserted in small cavities which are then thermosealed by plastic or aluminium wrapping. They’re available in two forms, Thermoform blister packaging and Cold stretch blister packaging .

It can be easily squeezed open when required for use. Blister packs have increased popularity due to it’s cost effective packaging material, providing safety and tamper resistance to the drug inside and more over nowadays it has included sensors to prevent medication errors.

Strip Packaging

Strip packaging offers a single dose unit of pharmaceutical packaging which is composed of a drug being entrapped between two thermostable films of aluminum, cellophane or plastic material. It provides greater protection to tablets and capsules as the cavities in the strip pack are more compact. Strip packets can be opened by tearing, therefore they offer great child and tamper resistant properties.

Carton Packaging

Once the main medicines are packed in their respective forms of packaging styles, they’re then placed in cartons and boxes with inserted leaflets for further transportation. This is called secondary pharmaceutical packaging. These cartons are available in different sizes and shapes offering excellent protection against environmental factors. Carton boxes are printed with important details like the drug name, dosage instructions, storage conditions, expiry date, batch number, etc.

PLASTIC PACKAGING

Plastic packaging refers to the use of plastic materials to contain and protect a product for storage, transportation, and sale. Plastic packaging can take many forms, including plastic bags, bottles, containers, and wraps. Plastic packaging is widely used in various industries, including food and beverage, personal care, pharmaceuticals, and household products. It is popular because it is lightweight, durable, and versatile.

8.Different types of Plastic Packaging Methods

There are six basic different types of plastic packaging methods:

High-Density Polyethylene (HDPE)

A typical thermoplastic material used in the production of plastic packaging is high-density polyethylene (HDPE). High-density polyethylene, or HDPE, is renowned for its sturdiness, toughness, and ability to withstand chemicals and UV rays.

Bottles, containers, caps, and closures are just a few examples of the diverse packaging goods that can be made from HDPE. HDPE bottles are commonly used in the packaging of household and personal care products.

Because HDPE bottles and containers can withstand pressure and shock, they are perfect for packaging goods that need to be protected during transportation and handling.

Low-Density Polyethylene (LDPE)

A popular kind of plastic used in packaging is low-density polyethylene (LDPE). In comparison to other varieties of polyethylene, LDPE is less dense and has a great deal of flexibility.

Due to its lightweight, elasticity, and resilience, LDPE is frequently used in plastic packaging. Shrink wrap, plastic bags, and other flexible packaging are frequently made with it. LDPE is an attractive option for packing goods that need to be shielded from the environment during transportation because it is also resistant to moisture, chemicals, and damage.

Polypropylene (PP)

Polypropylene (PP) is a flexible substance with several advantageous qualities that make it a popular option for a variety of applications, including the packaging of food, medical supplies, and consumer items.

The exceptional resistance of PP to moisture, chemicals, and impact is well known. It can be employed in applications that call for high-temperature resistance because it is also lightweight and has a high melting point. In addition to its physical properties, PP is also a cost-effective material, which makes it a popular choice for manufacturers.

Polystyrene (PS)

The advantages of polystyrene (PS) are its light weight and superior insulating capabilities. Foam trays, cups, and food containers are just a few of the packing materials that may be made from polystyrene.

The capacity of polystyrene to maintain constant temperatures for items is one of its main benefits. It has superior insulating qualities, making it a great option for packaging goods that need to be kept hot or cold. This is why it is commonly used in food packagings, such as foam trays for meat and poultry.

Polyvinyl Chloride (PVC, Vinyl)

PVC, commonly referred to as vinyl, is a thermoplastic polymer utilized in a number of plastic packaging applications.

PVC is frequently utilized in the production of a variety of packaging materials, such as bottles, cling wraps, and food packaging films. It is the perfect material to use for packaging things that need to be protected from the environment because of its resistance to moisture and chemicals.

Polyethylene Terephthalate (PETE or PET)

A variety of packaging products, such as water and soda bottles, food containers, and packaging films, are made from PET. It is the best option for packing things that need to be displayed because of its clarity.

One of the key advantages of PET is its recyclability. PET can be recycled easily and has a wide range of potential uses, including the production of new plastic products, fibers, and films.

A SUMMARY CHART

| Type | Description | Application |

| ANTI-CORROSIVE PACKAGING

|

One of the important packaging types where the surface of the covering material is protected against corroding factors such as air, moisture, etc., that ensure safety and ease in distributing goods across the globe. | Pharmaceutical

Food Chemical Automobile |

| FLEXIBLE PACKAGING

|

Flexible packaging is the most popular type that can fill, form, and seal the items and capable to retain the freshness for longer time. Here, you can mold packaging in variety of shapes. Moreover, it is considered as safe for all logistic aspects. | Food

Cosmetic Pharma Agriculture Beverage Nutraceutical Chemical |

| PHARMA PACKAGING

|

A specialized pharma or drug packaging is used to dispensed medicine and preserve their integrity, quality, and potency for a longer time. | Pharma

Food Nutraceutical Veterinary |

| PLASTIC PACKAGING | A recyclable plastic material is used for products packaging i.e fragile or non-perishable items. |

Food and Vegetable

Beverage Paint & Chemical Toys |

Conclusion

Packaging is one of the integral elements of the production sector. When choosing the right packaging option; you will find various amazing options that ultimately puzzle anyone. Different Types of Packaging Methods has a comprehensive discussion to help you in understanding each type. Take your time, and estimate your budget, capacity, and product type to decide the best packaging for you. Still, having questions? Need to Know Packaging Machinery? Please Post Us or Fill in Our Quotation. Our expert can help you with a fast Solution.

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine