Dietary Supplements Market: Gummies Are The Trend

In the last two years, 'gummies' have definitely become the star of the health and nutrition industry, appealing to consumers of all ages, especially children and young consumers, with their soft and cuddly appearance.

In the dietary supplements market, gummies play an important role. When they were first marketed, they were conceived as a fun, easy-to-absorb delivery system for vitamin supplements for children. Subsequently, gummies have expanded further into the adult market, covering a wider range of nutritional categories.

Transparency Market Research forecasts that the gummy candy market could grow at a compound annual growth rate of 6% over this decade, reaching a global market size of US$5.8 billion by 2029. It also predicts that adults will account for two-thirds of fudge consumers during this period1.

Importantly, as an innovative product dosage form, the application of gummies can encompass most popular functional ingredients and is fast becoming an important food vehicle for health and nutritional functionality.

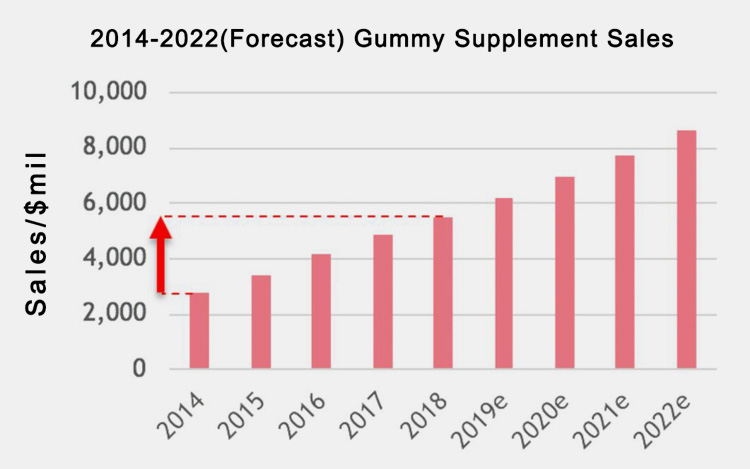

Public data shows that it took just four years (2014-2018) for global sales of nutritional gummies to double, and in fact, gummies oem overtook chewable tablets to become the third largest non-pharmaceutical dietary supplement dosage form globally a little earlier (the top two were softgels and powders respectively).

Another figure predicts that in two years' time, in 2022, global sales of nutritional gummies will exceed US$8.6 billion. Who would have thought that the "unimpressive" nutritional gummies would have risen to the top and become so "fierce", but in reality, the crossover between "snack" and "dietary supplement" has long been predetermined.

In fact, the crossover status of "snack" and "dietary supplement" has long predetermined the true "hardcore" competitiveness of nutritional gummies underneath their seemingly "soft" appearance.

Gummies are arguably the biggest trend in today's delivery system. So, how are they being updated? And more importantly, how are manufacturers meeting the massive demand and continuing to innovate?

The evolution of low-sugar products

In addition to being functional, nutritional products,gummies also need to be consumer friendly and be 'pleasant' dosage form.

Sugar content is a concern for gummy products.

"Low-sugar" or "sugar-free" products, especially those "free of artificial flavours and sweeteners, are expected to become more popular.

Hubei Aiapk Pharmaceutical Machinery Co.,Ltd has also developed and launched a "sugar-free gummy" formula to meet market demand, with high selling points that will make it easier to capture the hearts of female consumers.

A strong wave of "nutritional gummies" from the North American market came across the Pacific to Asia in 2020, and the "fierceness" has not only not abated, but has become more and more aggressive.

The trend of "snacking" on nutritional supplements is becoming clearer and clearer, with taste-focused, non-burdensome experiences becoming the new direction for young people to choose nutritional supplements.

Non-gelatin options

Traditional gummies are made using gelatine, but new plant-based gummies are available to meet the needs of vegans. While plant-based ingredients offer a huge range of options, manufacturers need to adapt to find the best solutions for using these ingredients.

Michael Jinks, application specialist at ingredient supplier IFF Nourish, says: "When using ingredients like pectin or carrageenan instead of gelatine, the processing time and temperature of the fondant may need to be adjusted." Other ingredients in the recipe, such as vitamins and minerals, may affect the gum-forming process. Therefore, at some point, the recipe will also need to be adjusted.

However, plant-based ingredients can offer unique advantages over gelatine, and Jinks says: "Pectin and carrageenan are good alternatives to gelatine, offering production advantages such as having shorter setting and drying times, which can save time and costs."

No starch, shorter setting times

Liz Clarke, Technical Marketing Manager at ingredient supplier Nitta Gelatin, says: "There is a growing demand for fondant that can be produced quickly in small batches with clean labels. Therefore, promoting the development of ingredients that can be used in starch-free systems will help meet these needs."

Her company offers ingredients such as XactSet gelatine to solve some of the associated challenges.

She explains, "The use of traditional hydrocolloids in fortified gummy formulations is challenging, especially in starch-free systems.

While traditional gelatine does not have specific pH requirements, it can take some time to cure in starch-free systems."

To facilitate this, Nitta Gelatin's XactSet brand offers a new range of gelatine ingredients designed for use in starch-free systems.

Registered in 2019, XactSet's gelatine ingredients can be cured quickly in starch-free systems and, at the same time, can be used with other hydrophilic materials to create special shapes and textures.

Clarke says: "XactSet reduces moulding and curing times from days to minutes, while providing more options and scope for active ingredients in fondant."

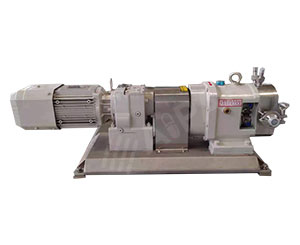

Changes in the manufacturing process

The manufacture of nutritionally enhanced fondant has evolved in recent years as equipment has been upgraded to make it easier to manipulate nutritional doses. But nutritional formulations are facing consumer demands that have not been encountered in the confectionery industry, which means that they will have to continue to overcome a number of challenges.

Edward Shneyvas, Vice President of Research, Innovation and Business Development at contract manufacturer Best Formulation, notes: "Manufacturers are producing nutritional fondant with equipment that is typically used for confectionery rather than pharmaceuticals, so this requires specific improvements and know-how. "

Shneyvas added: "The high temperature and low pH production conditions lead to degradation of the active ingredients during manufacture and the overall gelatinous matrix can also pose a challenge to the stability of some nutrients.

Fondant also requires temperature and humidity control during storage and transport, which is often a part of the process that can be overlooked as it is not required in other forms of pharmaceuticals."

Centre-filled gummy

The latest fondant products offer both functional benefits and artistry. Karla Acevedo, marketing manager at manufacturer Sirio Pharma, says: "Sirio's new range, centre-filled fondant, is manufactured using in-house equipment that separates the functional ingredients between the fondant shell and the filler.

This method of separating ingredients reduces the risk of ingredient incompatibility and protects key ingredients from oxidation and humidity. And the fondant shell encases the filled ingredients, providing protection."

Acevedo added: "The materials also add artistry and the centre-fill fondant is more visually appealing, we can use different colours for the fondant shells and fillings, and the fondant tastes better and can provide a pleasant experience for the consumer with different textures of the fondant shells and fillings. "

Don't forget to share this post!

Gummy Making Machine Related Posts

Gummy Making Machine Related Products

Gummy Making Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine