Development History Of Medicine Cartoning Machine Technology

In recent years, with the continuous development and strength of pharmaceutical industry in China, the number of types of medicines continues to increase, the dosage forms of medicines continue to enrich, the quality of products produced by major pharmaceutical factories continues to improve.

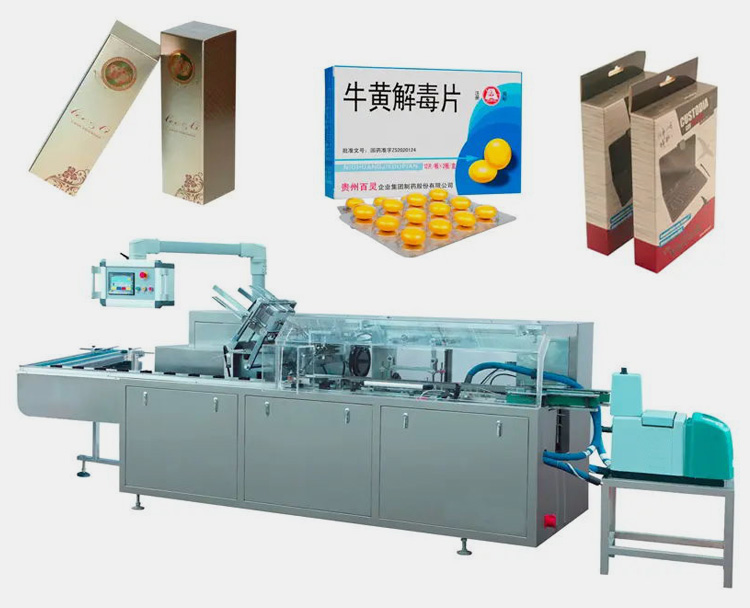

The requirements for pharmaceutical packaging are also continuously enhanced, especially for pharmaceutical cartoning machines. Multifunctional automatic cartoning machines have also begun to gradually enter the use of various pharmaceutical companies.

The increase in labor rate and the reduction of production costs in the field of pharmaceutical production have made the impact of pharmaceutical cartoning machines more far-reaching.

Our journey

In the early stage of China’s pharmaceutical production and packaging, manual packaging was main used. Later, with the development of production and technological progress, mechanical packaging was gradually adopted.

The cartoning machines that used in China in the early days were mainly imported from abroad. Because the quality of packaging materials and the processing and production of medicine boxes in China could not meet the requirements of machine packaging at that time.

The cartoning machine could not be used normally, so the automatic cartoning machine has not been widely used in China.Production had to abandon automatic cartoning for a long period of time and use manual operations, which was extremely inefficient.

In the 1980s, especially after the reform and opening-up, the relevant technology in medicine production area has developed rapidly in China. Significant progress has been made in the quality of pharmaceutical packaging materials and the processing and production of medicine boxes.

Automatic cartoning machines have begun to be fully used. At this time, the drug cartoning machine also changed the situation that foreign products dominated the world, and the domestic drug cartoning machine began to be marketed and widely used.

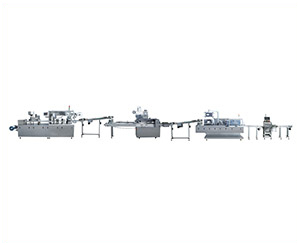

In the late 1990s, some large-volume companies began to use domestic automatic cartoning machines instead of manual packaging. Some domestic related pharmaceutical production firms are also constantly developing. Production of a new fully automatic drug cartoning machine with more comprehensive functions.

Our current situation

At present, there are a wide variety of domestic drug cartoning machine in China, and the number is compete, which can basically meet the packaging needs of drugs of carious dosage forms produced by the domestic drug manufacturers.

According to different classification methods, the automatic cartoning machines currently produced in China can be divided in several types. If there are four main series according to the different packaging materials, they can be divided into B. P. K boxed G type, that is, blister plate type, injection type and ointment type automatic cartoning machine, etc.

From the running speed of thee cartoning machine, it can be divided into 3 categories, the first category is medium and low speed type, the speed speed is about 60 ~ 80 boxes/min;

The first type is medium and high-speed type, with a speed of about 80~120 boxes/min; the third type is high-speed type, with a speed of more than 150 boxes/min. Each model has its own advantages and disadvantages, and the uses are not consistent.

At present, although there are many domestic manufacturers of medicine cartoning machines, there is also a big gap between the technical content of their products and similar foreign products.

In terms of market competitiveness, it only has a slight advantage in the low-end market. In the aspect of market share, the domestic drug cartoning machine has only about 30% of the market share, and the rest of the market is divided up by imported products. Now, many large-scale domestic drug manufacturers still use imported drug cartoning machines.

How to choose a cartoning machine?

Today, drug cartoning machines are widely used, but there is still a lack of drug cartoning machine products in China. Therefore, you should also consider comprehensively when purchasing.

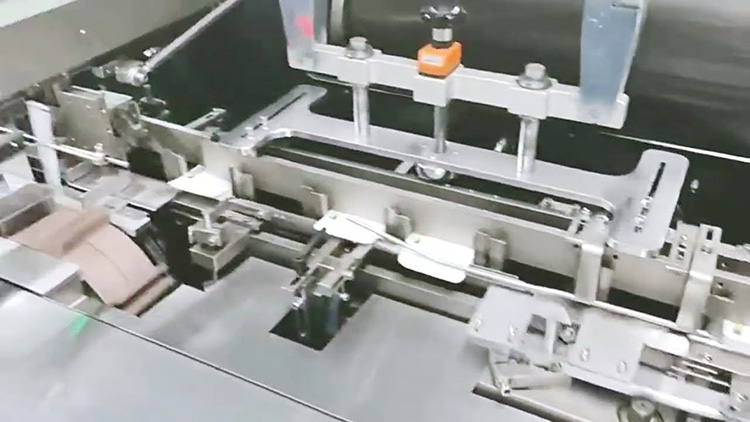

Rugged design and construction of the cartoner to better resist external forces and vibrations and adapt to harsh production environments. Therefore, when purchasing, make sure that the cartoning machine supplier uses high-quality parts.

The industry professional pointed out that you can ask for the type of parts and the name of the manufacturer. Some suppliers also provide a standard spare parts list if requested by the user.

When selecting equipment, you should also consider their supplier's cartoner design and application experience.

Make sure the supplier takes into account all requirements, from space, budget constraints, to packaging format and speed, and more. Additionally, making sure the supplier understands carton manufacturing and what materials are needed for their cartoner production.

You can choose a supplier who can customize the cartoning machine to meet their needs by making small changes to the design. The so-called customization may only need to change the size or replace an electronic component when it is easy, or even redesign an important part of the cartoning machine when it is complicated.

Therefore, the cartoning machine suppliers should also have the necessary experience and customization capabilities to provide comprehensive solutions.

Improving the added-value

The automatic cartoning machine used in China in the early days was imported from Italy in the mid-1970s, but it was not widely used because the domestic packaging materials and medicine box processing and production could not meet the requirements of machine packaging at that time.

Until the 1980s, the quality of pharmaceutical packaging materials and the processing and production of medicine boxes have made significant progress, and automatic cartoning machines have begun to be fully used.

At present, the market share of domestic medicine cartoning machines is still small, and most of them are still divided up by imported products.

Many large-scale domestic drug manufacturers still rely on imported drug cartoning machines. Faced with the current situation of the industry, pharmaceutical cartoning machine companies need to increase investment in scientific research, enhance scientific research capabilities, introduce mature foreign technical principles, and develop forward-looking advanced equipment.

In recent years, in addition to some manufacturers specializing in the production of pharmaceutical cartoning machines, some domestic universities and research institutes have also participated in the development and production of pharmaceutical cartoning machines.

It is believed that relying on the scientific research strength of various universities and research institutes, the development and production of domestic drug cartoning machines will have a major breakthrough in the near future and will also have a place in the market.

Don't forget to share this post!

Tablet Coating Machine Related Posts

Tablet Coating Machine Related Products

Tablet Coating Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine