Detergent Packaging Machine: The Complete FAQ Guide in 2025

First launched during World War 1 when there was a shortage of oils and fats of organic sources that were then used for making soaps, detergents are chemicals that have a wide range of applications from common household chores to industrial usage.

In this era of automation, packaging industry has come a long way since its actualization in industrial revolution and often it proves to be difficult to select a packaging equipment from hundreds of available options. To ease your troubles bringing you Detergent Packaging Machine: The Complete FAQ Guide in 2023. In this blog we will cover common queries related to detergent packaging equipment. Without further ado let’s begin.

1.What Is A Detergent Packaging Machine?

Falling under form fill and seal portfolio (FFS) and also known as powder packaging machine, it is one of the key equipment of packaging industry that can dispense powder / liquid, make packages and fill them with the product all in one go.

Detergent packaging machine is available in semi-automatic / automatic versions having either horizontal or vertical orientations possessing all features that provide exceptional work efficiency.

Depending on supplier a detergent packaging machine can be customized to meet buyers’ demands and can be incorporated with advanced accessories to reduce errors as per regulatory requirements.

2.What Are The Industrial Applications Of Detergent Packaging Machines?

Due to their versatility, detergent packaging machines are used in various industries like pharmaceutical, nutraceutical, food, agriculture, chemical, veterinary, cosmetic, textile, electronic, etc. Let us discuss each of these industries below.

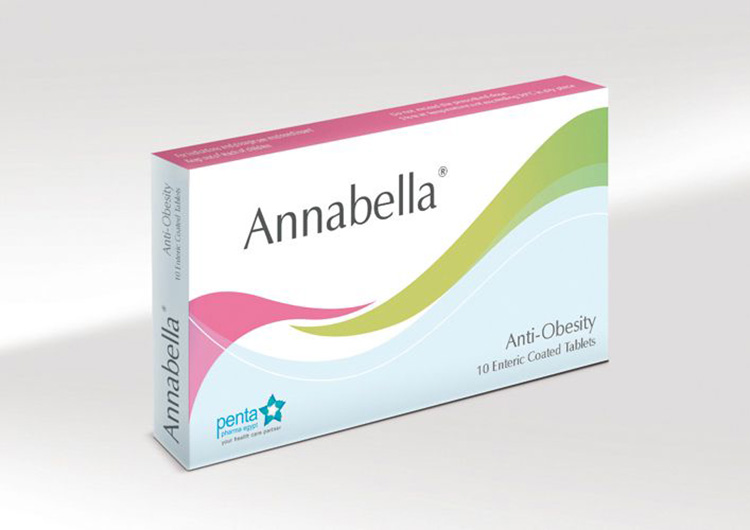

Pharmaceutical Industry

This industry produces medicines and drugs which are used to cure diseases and improve the standard of living. These medicinal drugs are highly vulnerable to the external environment and would lose their efficacy if they come into contact with any harmful factor.

To prevent this, detergent packaging machines are used to pack these medicines to ensure that they are easily transported to their final destination without getting damaged, thus maintaining their potency.

Chemical Industry

The chemical industry deals with products that are sensitive to moisture, temperature, dust and oxygen and would chemically degrade if they come into contact with any of these factors. Some chemicals are volatile too and would evaporate if exposed to air.

To counter this, these products are packaged by detergent packaging machines in style boxes which ensures the safety of these products.

Food Industry

This industry deals with various food items like meat, chicken, soda drinks, sauces, etc. These food items have a shelf life and an expiry date after which they would become inedible.

To preserve their freshness, they are quickly packaged which provide strong protection to them from any damage.

Nutraceutical Industry

The nutraceutical industry makes various vitamins and food supplements. These supplements are then packaged into cartons after which they are shipped for sale in a safe and hygienic way. A detergent packaging machine is a great solution to pack them efficiently.

Agriculture Industry

This industry is involved in the production of a variety of products, ranging from food items like rice, wheat, corn, and even fertilizers which are used to increase crop yield.

In order to ensure safety and security of agricultural good detergent packaging machine is utilized.

Cosmetic Industry

Many beauty products such as shampoo, lotions, moisturizers, serums and creams are manufactured in huge quantities by the cosmetic industry. These high-volume products need a safe packaging to ensure their maximum protection.

A detergent packaging machine can easily pack these high volume products for sale.

Veterinary Industry

The veterinary industry manufactures a number of products like medicines and vaccines to cure animals’ diseases and increase their lifespan. The best way to package these products to ensure their potency and efficacy is to use carton style boxes. A detergent carton machine can use these pack them, thus providing a protective method for their safe and easy transport.

3.What Are Different Detergent Packaging Formats?

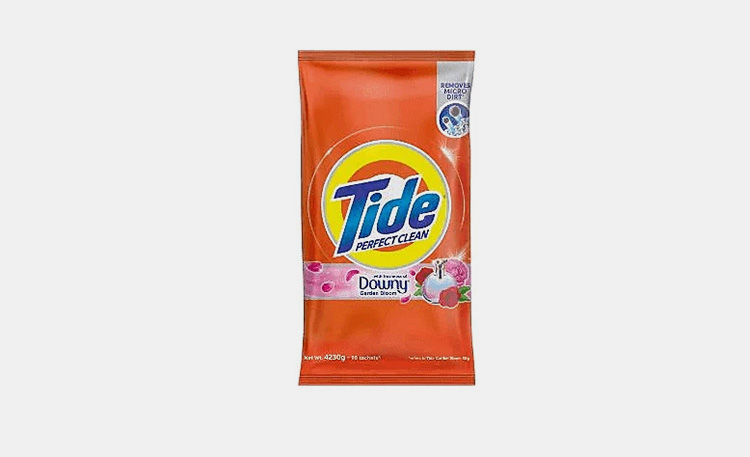

Detergent is a common household product used for washing clothes and dishes. There are many types of packaging used by the detergent industry like

- Sachet packaging

- Bottle packaging

- Stick packs

- Premade pouches/ doy pack or stand-up bags

- Can packaging

Sachet Packaging Style

Sachet detergent packaging is space convenient, Suitable for Travel Use, and also used for publicity purposes. They are available easily at an economical price.

Sachets are small sealed flexible bags with three- or four-layer packaging. These are manufactured from materials such as aluminum, plastic, cellulosic, and non-plastic.

Bottle Packaging Detergents

This style of packaging is used to pack liquid detergents. These bottles are made of rigid plastic. A handle is included on some bottles to make them easier to hold. Plastic-made bottles can resist any type of detergent chemical effects. This style of packaging makes the product more attractive to consumers.

Stick Pack Style

In case of convenience, you can’t beat stick-pack packaging. Whether you’re looking to create a sample package or add single-serving size pouches to your product line, a stick pack is a unique way to package your products and attract new customers.

Stick pack pouches are a type of flexible packaging characterized by their small size and narrow shape. They are typically used to pack dry detergent powders and sometimes occasionally liquid and gel form detergents.

Pouch packaging

Pouch packaging is space-convenient and shelf friendly with different size options with custom-designed pouch packaging. This type of packaging is leakage-proof and highly effective packaging designs grab the attention of prospective consumers. Bag forms available for detergent pouches are stand-up pouches, flat-bottom pouches, spout pouches, pillow pouches, and many more.

Can Packaging

Plastic can ensure that environmental factors such as dampness do not penetrate the can and the detergent remains in its original condition. Detergent Packaging products such as powder, granular or liquid detergents must be packaged in materials like plastic, which never affect detergents and is not affected by them in return. Liquid and Synthetic Detergents are never to be sold in open bags that’s why they should be packed in protective plastic Cans.

4.What Are Different Types Of Detergent Packaging Machine?

A detergent packaging machine can be divided into two major types such as:

- According To Automation

- According To Machine Style

ACCORDING TO AUTOMATION

FULLY AUTOMATIC DETERGENT PACKAGING MACHINE

Fully automatic detergent packaging machine is heavy duty equipment that carries the entire mechanism of detergent packaging by working independently. Thus, it can give you higher output and end perfect amount of filling as well as good sealing of filled bags.

SEMI-AUTOMATIC DETERGENT PACKAGING MACHINE

Semi-automatic detergent packaging machine is precise equipment utilized for medium size production with user friendly method of processing. This machine is cost-effective and designed to process pre-made bags.

ACCORDING TO MACHINE STYLE

VFFS MACHINE

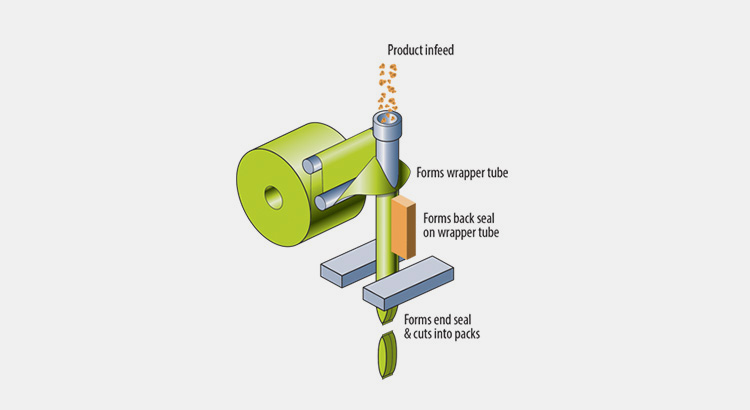

A VFFS (vertical form fill seal) machine is a type of automatic packaging equipment commonly used for packaging detergents. It operates by forming a pouch from a roll of flexible packaging material, filling it with the detergent product, and then sealing the pouch to create a final product that is ready for sale.

PREMADE POUCH FILLINGMACHINE

Premade pouch filling machine for Detergent Packaging is a fully automated machine designed for the efficient and precise packaging of detergents into pouches.

CAN PACKAGING MACHINE

Can Packaging Machines are versatile machines used for the packaging of detergents and other similar products. These machines are designed to handle a wide range of can sizes and shapes, ensuring that your products are packaged efficiently and effectively.

HFFS MACHINE

HFFs (Horizontal Form Fill Seal) machines are automated packaging systems used for packaging detergents. These machines offer a cost-effective and efficient way of packaging detergents, by filling and sealing the detergent products in a continuous process.

LIQUID DETERGENT PACKAGING MACHINE

Liquid Detergent Packaging Machine is a high-speed, efficient, and automated system that is used for filling and packaging liquid detergent into various containers such as bottles, pouches, and sachets. This machine features advanced technology, user-friendly operation, and high accuracy to meet the needs of modern packaging production.

5.What Other Devices Used In The Detergent Powder Packaging Production Line?

The detergent packaging line is described below:

DETERGENT CAPPING MACHINE

Detergent Capping Machine is a state-of-the-art packaging solution designed for the production of high-quality detergent bottles. This machine utilizes advanced technology to cap and seal bottles with precision, ensuring consistent and reliable results.

The working principles of the Detergent Capping Machine are based on the Bottle loading, capping where a cap crimped onto the bottle neck, ensuring a tight and secure seal.This helps to ensure consistent capping and prevents damage to the bottle or cap.

DETERGENT LABELLING MACHINE

A Detergent Labelling Machine is a highly advanced and automated device designed for the labeling of detergent containers with high precision and efficiency. The machine operates on a unique combination of cutting-edge technology and mechanical engineering principles to achieve seamless and accurate labeling of detergents at high speeds. The labeling process is carried out at high speeds, ensuring that a large number of containers can be labeled in a short amount of time.

CANS SEALING MACHINES

Nevertheless, quality of detergent packaging can be enhanced by this supporting machine. Can sealing machine is significant for sealing job of various cans and containers made up of either tin, aluminium, glass or paper. However, the lid is commonly made up of tin coated steel.

CAN CODING MACHINES

The can coding is considered as mandatory equipment for many manufacturing sectors as it helps in coding important details about the product and ensuring tamper proof packaging. QR code, bar code, or logo can easily be imprinted on packaging allows hassle free purchasing.

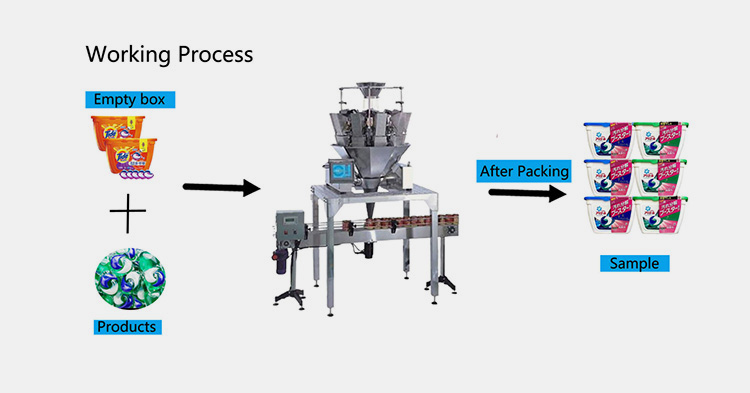

6.What Is The Working Principle Of Detergent Packaging Machine?

The working procedure of a detergent packaging machine is simple that is based on certain principles which can be easily understand by the steps mentioned below:

Material Loading

The initial step is no doubt the setting of machine including material amount, sealing temperature and speed etc. After that, the practical process of detergent packaging starts with the loading of material into feeding machine.

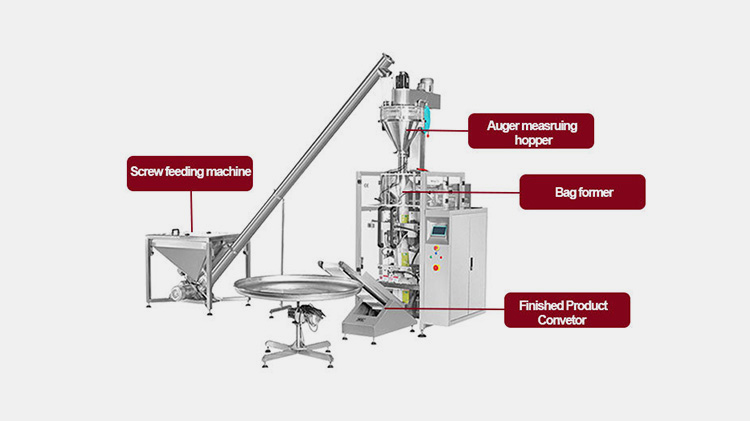

Material Weighing

After the loading of large volume of detergent powder, now you can start the mechanism by turning switch on. Through vacuum pump, the material will be transported to the hopper of main machine after passing through the large tube. Now, the auger filler measure the exact amount of material according to the fixed parameter.

Bag Forming

The measured material is stored in auger filling device until bag is formed. The formation of bag get started when film is released by the film roller towards bag forming tube. The bag forming station turn the flat film into circular shape around the tube. The bag gradually moves below for filling.

Material Filling

The downward side of bag is sealed through heat after which accurate amount of load is delivered into it.

Bag Sealing

Just after filling, the sealing devices on both sides of bag come into action and tightly seal the bag. Along with that that cutting of bag is occurred and bag falls down into conveyor belt.

Bag Discharging

Finally, the finished bags are taken by guide rail and discharged in the finished product conveyor.

7.What Are Major Components Of A Detergent Packaging Machine?

A detergent packaging machine is composed of several components each playing crucial role in the accomplishment of detergent packaging. These components are as follows:

| Control Panel | Control Panel is located on the front side of machine that provides the user with a touch screen display. Through this part, entire processing of machine can be controlled like filling amount, temperature for sealing and filling speed etc. |

| Feeding Machine | Feeding machine is a separate tank that is linked to the main machine through long stainless steel tube. Detergent powder is first loaded in feeding machine after which it is gradually transported to filling machine through pump. |

| Hopper | Hopper is located in the upper side of main machine. When machine is started, the product is first brought into hopper before it is loaded into bags. |

| Auger Filling Device/ Volumetric filling Nozzle | Auger filling device is particularly integrated to the detergent packaging machine for purpose of filling the exact amount of powder. For instance, all the bags have the same amount of detergent powder which is the result of auger filler function.

For liquid detergent, this section is replaced by the volumetric nozzle. |

| Vacuum Pump | This component is used to clear areas free of air or unwanted gas to ensure safe sealing. |

| Electromagnetic Valve | A ferromagnetic plunger uses electrical energy to produce mechanical pull and push. |

| Bag Former | Bag former is a large round stainless steel tube which forms the bag when film is dispensed from the roller. It turns the flat film into round shape and deliver downside where sealing and filling occurs. |

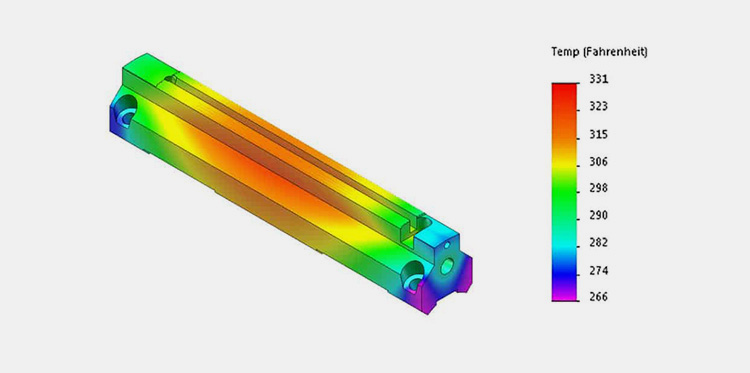

| Temperature Controller | This components helps in heat regulation by estimating difference between set point and sensor output of a heater. |

| A Weigher | This device is used to ensure a measurable amount delivery into each pouches/containers. |

| Film Roll | Film roll is an important part that is actually used for the formation of bags, so they could easily hold the desired amount of detergent powder. |

| Sealing Device | Sealing device is located below the bag forming tube which seals the bags with heat on both upper and lower sides. |

| Finished Product Conveyor | Finished product conveyor is the last component of detergent packaging machine where all the filled and sealed detergent bags are discharged as finished bags. |

8.How Can A Detergent Packaging Machine Benefit Your Business?

A detergent packaging machine is a one stop packaging solution that offers multiple options to a potential buyer i.e. from offering different packaging styles to type of products being packed to the availability of spare parts this equipment will never let you down in terms of operational efficiency.

To jot down a few, given below are some benefits that you can expect while purchasing a detergent packaging machine;

Efficiency guaranteed

Detergent packaging machine is an outstanding example of technological advancement in packaging industry. It is equipped with latest electronic features, programmable software and fail-safe features that increases it working efficiency hundred folds more.

Economical purchase

Buying a detergent packaging machine is a one-time investment for a decade. With reduced maintenance and operational costs and ease of availability of spare parts this equipment will give you trouble free working for many years thereby reducing the overall cost of purchase.

Production capacity

From small to large production output detergent packaging machine offer variable operations that can cater any business plan. Apart from production upscale this equipment also can produce increase number of unit in a given time.

Low maintenance

Other than routine oil change and greasing of moving parts, detergent packaging machine does not require costly outsource maintenance i.e. parts replacement for at least three years or repairing of critical units. If properly taken care of this machine can function without major malfunction for nearly a decade.

Multiple packaging options

Detergent packaging machine is a versatile instrument equipped with PLC control system that can package different type of products be it powder or liquid. This machine is not only simple to operate but allows quick changeover between products.

Customization

Every customer has different requirements that are to be addressed in order to not only satisfy the buyer but also increase equipment’s value. Detergent packaging machine is designed in such a way that at any time and place it could be customized, upgraded and attached to other units to form a complete packaging line based on manufacturer’s discretion.

9.Differences Between Liquid Detergent Packaging Machine And Powder Detergent Packaging Machine.

|

|

| Liquid Detergent Packaging Machine | Powder Detergent Packaging Machine |

| Can produce sachets, bottles and pouches. | Can produce sachets and boxes. |

| Equipped with dosing pump for accurate filling. | Equipped with auger fillers for accurate dosing of powder. |

| Can be attached to other units to form a complete production line i.e. robotic arm for stacking. | Can be attached to other related accessories for environment safety like dust collector. |

| Product is stored in tanks just above high viscosity piston fillers (dosing pump). | Product is stored in hopper before dispensing into desired packages. |

| Can be used for liquid detergent, paste and other chemicals. | This machine is only used for powder and granules. |

10.What Are Troubleshooting Of Detergent Packaging Machine During Operations?

Machines often malfunction during operations. Such issues can be attributed to several factors, including mechanical errors (for example a worn gear or broken spring), mistakes, etc. Some of these breakdowns are catastrophic, whereas others are relatively minor faults—like loose wires on the control panel.

There are various problems with the detergent packaging machine that you should be aware of. To maintain equipment in good working order, it's important to perform regular maintenance, lubrication, and cleaning.

Let us however, briefly cover some of the main problems found in detergent packaging machines:

Faulty Seals

When the seals are faulty or loose, follow the following steps to fix it:

- Check the alignment of the sealing jaws, using a ruler as a guide, and make sure that they are parallel.

- Keep the temperature of your sealing jaws consistent.

- When making adjustments to the temperature or pressure, do them together or in a similar fashion.

- Clean sealing tools.

- When checking the pressure on a machine with a gusset, ensure that you are looking at the area in which it is located.

- To fix a weak seal, one must adjust the temperatures correctly.

Hot–Tack Issues

What about when the packaging material beneath the seal is damaged, and cannot sustain the contents of a heated container?

- Increase the temperature of the seal to make it more durable.

- A cold blast of air can increase the hot-tack strength.

- When applying pressure to the sealing jaws, increase the amount of air in them.

- If the old seal has broken or is otherwise no longer functional, you may need to install a new seal.

Inconsistent Bag Length

Keep the film in good condition. Properly adjust the feed belt tension to ensure consistency. Clean all belts regularly, especially after working with oily materials.

Film Doesn’t Track

Centering the roll on the spindle, tighten it down. Carefully threading film onto the carriage.

Longer Bag Lengths

- Adjust the bag length.

- Reset the bag length.

- Maybe the registration photo-eye isn't set accordingly, check it.

You should also conduct inspections regularly so that you can diagnose problems early on. By following the above steps and the manual provided with your model, you’ll be able to troubleshoot any problem in no time.

Conclusion

Detergents can be an irritant, corrosive or toxic based on intended usage and have the potential to raise health related concerns that is why as per global regulations detergents are packed using detergent packaging machine. In this blog we have provided you all the relevant information pertaining to detergent packaging machine gathered from authentic resources.

For queries related to purchase and what machine would be suitable for you contact our 24/7 customer care services. Happy hunting!

Don't forget to share this post!

Powder Filling Machine Related Products

Powder Filling Machine Related Posts

Powder Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine