Delayed Release Capsules: How Will Your Business Benefit From?

Do you know how pharmaceutical innovation has embraced with making of delayed release capsules?

Maybe many of you won’t know how capsules are treated inside your body due to chemicals and enzymatic reactions. So how delayed release capsule prevents itself from the stomach environment and enters the small intestine directly. Why there’s need for it? In this blog, you will find all the information about delayed release capsules and how it is effective in boosting your business. So come on and read the article!

1.What are delayed release capsules?

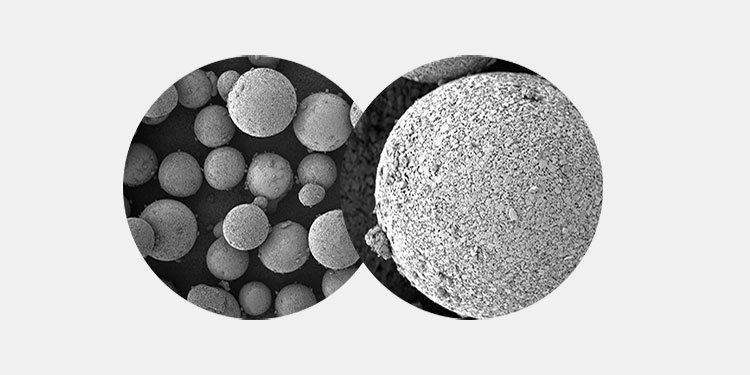

Delayed release capsules- Picture courtesy: Biopharma

Delayed means late; the delayed release capsules are meant to produce a therapeutic response with a slow and gradual release of active in your blood circulatory system. Before narrating the exact answer, you should understand that everyone feels tired when it comes to administering high frequency doses. Therefore, it gives a slower and steady response than immediate release capsules.

For that purpose, delayed release capsules are manufactured which is a modified way of providing dosing with an altered rate of inducing therapeutic effect and absorption.

Many years ago, it was introduced by injectables that are formed by modified release insoluble products.

Due to so many health benefits, the delayed release capsules are now available in prescription medications as well as OTC products. These capsules are designed in a way that can cross many sites of the digestive tract without disturbing its stability. It can only reach and be capable of reacting at specific sites of your GIT.

2.Delayed Release Capsules: How Will Your Business Benefit From?

While delayed release capsules are offered with numerous health related benefits, side by side your business benefits from the manufacturing and packaging of these capsules. We have highlighted the reason why and how it is possible to extract amazing advantages from them.

Capsules with Improved Releasing Profile

Good releasing profile

Do you know what amazing product you’re offering your customers? The delayed release capsules are capable of acting at the specific sites of your digestive tract simply bypassing the local sites and enzymatic activities. There are many people among you who feel an aversion to frequent dosing.

When you are manufacturing and supplying delayed release capsules. The customers can take medication with almost lesser dosage. They may be requiring one or two doses in 24 hours. Hence, they will prefer your brand to opt for when it comes to avoiding frequent medication.

Excellent Therapeutic Response

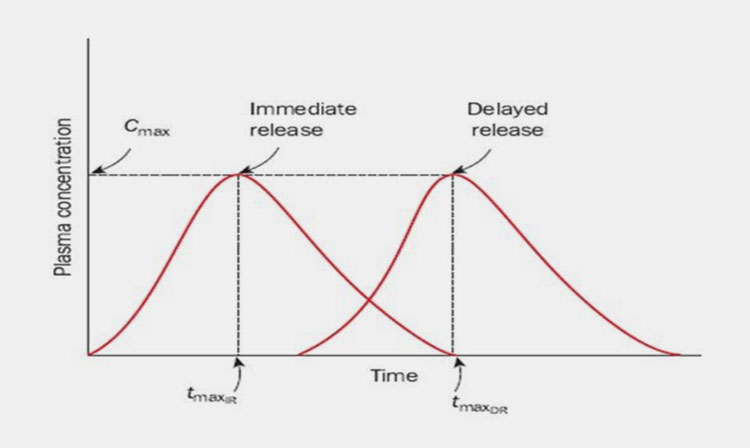

Therapeutic response- Picture courtesy: Pharma Excipients

Your products will be offering a sustained therapeutic response, which means the patients can enjoy their general life chores without fluctuation of dose intervals or repetitive frequencies. Such medication mainly shows a delay or slow absorption rate therefore you can design high doses that keep releasing over time and show a maintained therapeutic response.

No Adverse Effects

No Side effects- Picture courtesy: Express pharma

When your drug produces a slow and maintained response, it directly protects you against developing unwanted reactions. For example, when you consume immediate release medication it reaches the circulation fast and their greater concentration may induce some adverse effects such as in the case of hypertension. the fast-acting nifedipine gives hypotension along with some major hemodynamic alterations in your physiological system that may result in reflex tachycardia.

Therefore, by designing delayed release capsule you offer a safe medication without any risk of adverse effects due to releasing of active at a slow and gradual pace.

Improved User compliance & Cost Saving

Patient compliance

There’s a direct relationship between taking lesser doses and user conformance and saving your health expenditure. Today in a busy world, everyone loves to have stress stress-free routine with greater savings. People will opt for your brand when it comes to attaining delay release capsules as it offers fewer dose intervals with a safety profile. Moreover, by taking this medication you are offering our customers with high economical medication with improved compliance as compared to conventional medicines.

Providing a Promising Bridge for Clinical Objectives

Unlimited profit

Your business will be getting unlimited success and profit when hooked to delayed release capsule. This is all because of offers a gateway to get clinical objectives than old fashion way of drug releasing profile. You are making the same drug, the same excipients, with the same API but in a new way. This is what we call a modern way of manufacturing.

By delayed release capsules you can get effects with time; also, there is an optimized balance between greater efficacy and safety. Thus, it offers unlimited positive effects on your health as there are fewer chances for blood side effects due to the lower release of active.

Your Stomach is Safe

Stomach safety

You know there are many drugs that are acidic in nature; the delay release capsule would be an excellent option for those patients as it bypasses your stomach and may protect the reaction with an inner lining of the stomach wall. The drug is designed in a way that resists reacting under lower pH thus producing therapeutic effects in the alkaline pH of the intestine and making you protective against stomach irritation.

You can Produce Fixed Dose Combination or FDS.

Multiple and fixed doses- Picture courtesy: Genius health

The delayed release capsules method can also be used in fixed dose combination or simply in FDS to generate a more effective strategy of oral administration. Here, multiple active ingredients can be combined to form a particular formulation and can be prescribed to many users.

3.How delayed release capsules work inside your body?

The delayed release capsules work by inducing a delayed response than immediate or fast acting capsules. As discussed above the desirable response mainly starts attaining inside your body after a specified period of time and gets absorbed at specified sites of your GIT. How it is working- let’s see step by step just right below:

Oral Administration

Oral administration- Picture courtesy: Good mockups

The physiological process of delayed release capsules starts when you take them orally. The medication is not able to react or dissolve in the secretion of salivary glands. According to various research studies, the pH of your salivary gland is neutral and does not cause any reaction with your drug.

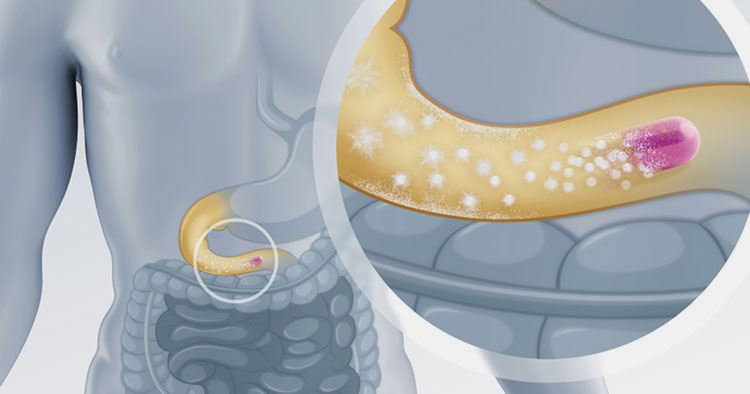

Gastric Response

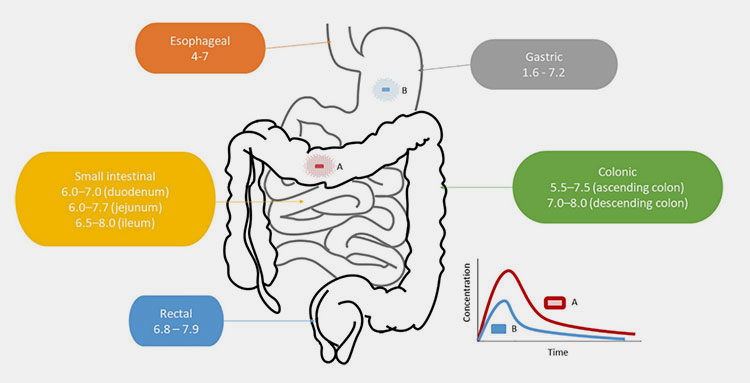

Stomach response- Picture courtesy: Evonik health care

Your capsule now bypasses the oesophagus and allows an easy passage to enter your medication towards the stomach. Here the environment is changed, and the pH of the stomach is entirely different. It is way more acidic and observed with a range of 1.5 to 3.5 and the volume of acidic fluid is approximately 20 to 100 mL.

This environment may be responsible for the dissolution of many drugs but when it comes to releasing delayed release capsules, it resists. These capsules also bypass the stomach and move further without ensuring premature dissolution of capsules.

Intestinal Response

Delayed release capsules

As capsules move, the pH of the physiological system keeps changing. In your intestine, the pH environment is more alkaline, and the levels range between 6 to 8. In this state, the capsule walls start losing and dissolving. The formulation which is composed of active pharmaceutical ingredients now starts targeting the specific target site and penetrates slowly.

Releasing Response

Releasing action

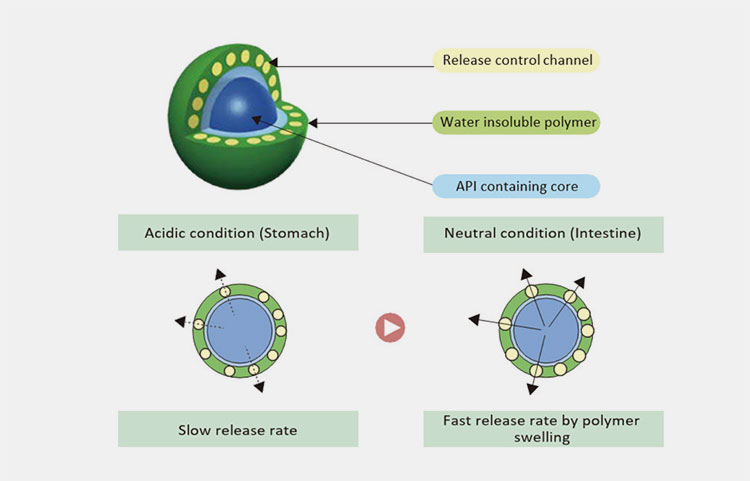

The makeup of delayed release capsule is quite a controlled process that mainly depends on the concentration of polymer utilized in the designing of the coating agent. There is a certain target agent used in the coating formulation of delayed release capsule which ensures gradual release of the formulation once reaches the target side.

Absorption Response

Delayed release capsule absorption- Picture courtesy: European medical journal

Upon releasing the active pharmaceutical ingredients inside the intestinal environment, it can start producing a slow response. Therefore, this releasing action gives steady and maintained plasma concentration of the API inside the blood circulation with improved bioavailability of the medication.

Therapeutic Response

Therapeutic response- Picture courtesy: ResearchGate

From above above-stated points, the medication starts producing its action which is mainly observed as maintained effects without any variation. Therefore, it is mainly used for certain ailments where sustained and prolonged effects are required such as anti-depressants, Ulcerative colitis, diabetes, etc.

4.How do you manufacture delayed release capsules?

Delayed release capsules- Picture courtesy: capsulin

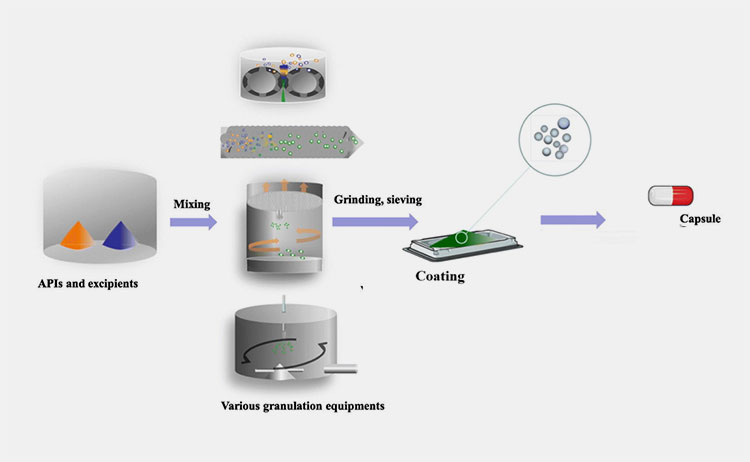

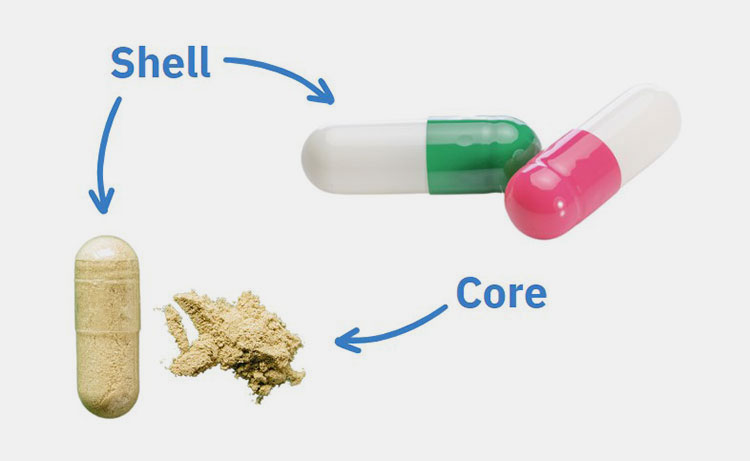

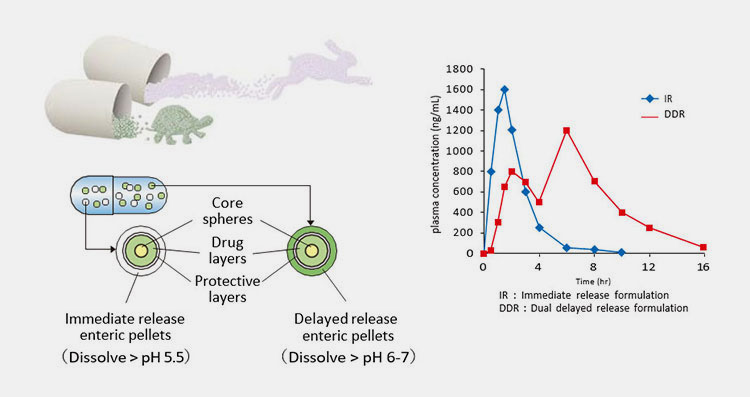

The delayed release capsules are mainly prepared by an extensive series of working steps to produce a controlled release profile of the active inside your physiological system. The inside materials of delayed release capsules are homogeneously coated with specialized coating substances to produce even layers that do not dissolve but produce a slow dispersion to offer a prolonged profile.

Now have a look at the following steps to understand the working process of delayed release capsules.

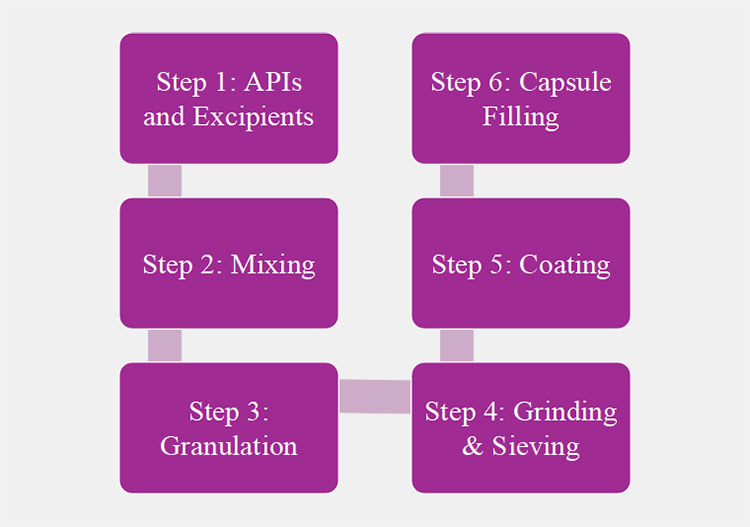

The process steps involved in the making of delayed release capsules- Picture Courtesy: ResearchGate

Flow chat demonstrating process steps of delayed release capsules

Step 1: APIs and Excipients

APIs and Excipients – Picture courtesy: Biosynth

When formulating a delayed release capsule, you commonly select two parameters to induce a slow response. One is the active ingredient and the other is excipients. In excipients, most importantly you’re considering polymeric chain coated materials which are entirely resistant to the acidic environment of your gastric lining or stomach.

So, the design must be in a way that pH sensitive coating formulation makes your APIs to prevent acidic action of the stomach. Mostly, the polymers are composed of carboxylic agents which makes the drug insoluble under pH 5 and strictly inhibits the release around pH 2.

Therefore, it is ideal when the formulation has to reach pH 5.5, thus it can be solubilized. This condition is simply explained as the delayed release capsules would be able to bypass your stomach and ideally release in the intestine. When you’re using multi-actives then it can be designed in a way where one of the active can be released at pH 5.5 (intestine), while the other active can be at 7 means in the colon.

Step 2: Mixing

Mixing- Picture courtesy: gattefosse

You need to choose the right way to achieve the right and consistent distribution of API and excipients. This has mainly occurred with the available blenders or mixers. The treatment of the mixer ensures that appropriate characteristics will be maintained till the final procedure, and you must be stress free about the segregation of APIs and excipients.

Step 3: Granulation

Granulation- Picture Courtesy: Powderpro

Your materials currently might be uneven and without uniformity in terms of shape and size. To make the texture and smooth shape, you need to subject them to granulation. It depends upon the situation if you need wet or dry granulation.

In wet granulation, the process of making granules is mainly dealing with subjecting binding solution, and a series of steps are involved. Whereas in dry granulation, the powder is compressed. The layer or slug of powder is further milled to form smooth and uniform granules.

Step 4: Grinding & Sieving

Grinding and Sieving

What ensures the uniformity of the granular size? This is mainly done by a grinder and sieving machine which is also known as a con mill. To make delayed release capsule the particular and same sizes granules or particles must be there, that’s why particular characteristics for formulation can be achieved.

Step 5: Coating

Coating- Picture courtesy: Caleva

These are the major steps that help you in the releasing of active pharmaceutical ingredients of delayed release capsules depending on the specific site and time. The application of coating mainly ensures the controlled releasing of the medicines with a specified dissolution rate.

Once the coating is decided it must follow the way to inhibit the APIs releasing action in the stomach environment. This procedure is considered a versatile method and widely used for delayed release capsules in pharmaceuticals and various other industries.

A very thin layer of coating material is applied over each particle including granules, or pellets that must be involved in encapsulation. It will simultaneously provide so many properties such as a smooth appearance, protecting the medication against the negative effects of the physical environment. Side by side, it offers you the aforementioned delayed releasing action.

Step 6: Capsule Filling

Filling- Picture courtesy: SE Tylose

The final obtained properly mixed and coated materials are filled in the capsules with the help of a capsule-filling machine. It can be filled in two piece hard gelatin capsules which mainly rely on your decision and your production demands. The accuracy of the dose is promised by the machines used in the process.

This step allows you to achieve a predetermined quantity of medication without any risk of error as well as contamination.

5.What type of Machines are involved in the Delayed release capsules manufacturing?

There are various different types of equipment are involved in every step manufacturing of delayed release capsules. For example, from mixing to the final filling of the capsules needed specific types of machinery to bring the quality job with accuracy. Remember, when manufacturing any product related to your health, accuracy, and quality must be the paramount objective of yours! Please look at the following machines.

| Mixers and Blenders

|

Picture Courtesy: Aipak Pharma As discussed above, the process is considered as the initiative for any product processing. Whether it is capsules or tablet formation. You can’t ignore the mixers and blenders for thorough mixing of the particles including APIs and excipients. In the manufacturing of delayed release capsules, you will be required to use machines such as, a V blender or it is also known as a tumbler blender, high shear mixer, ribbon mixer, double-cone mixer, bin mixer, or planetary mixer for the uniform distribution of APIs in excipients and get surety that powder particles are homogeneously mixed. |

| Granulators

|

Allpack high speed mixer granulator To attain ideal flow properties of the powdery particles, this is an important step to follow. You can achieve excellent texture, particle size, and flow characteristics once the particles are passed through granulators. There are various types of granulators available in the market that are used in the manufacturing of delayed release capsules manufacturing. For example: fluidized bed granulator, high shear mixer granulators, swing high shear mixer granulators, rotating mixer granulators, dry high shear mixer granulators, etc., are mainly used to give uniform size for various polymeric substances and controlled released ingredients used in the process. |

| Grinders and Sifters

|

Allpack centrifugal screen sifter machine To ensure that all particles subjected to the process are of the same and uniform size, the grinders and sieving machines are used to filter out different or unwanted material sizes and allow unvarying particles to offer promising consistency. For example: cone mill, jet mill, vibratory sieving machine, centrifugal sieving machine. |

| Coaters

|

Allpack standard coating machine This is the key equipment used for the manufacturing of delayed release capsules and makes your medication well protected against unwanted pH interruption and GIT environment. The various layers of polymer are coated properly over the particles to offer a uniform application of the formulation around the material. The machine used in applying coating materials included: pan or conventional coater, fluidized bed coater, Wurster coater, etc., |

| Encapsulation Machines

|

Allpack capsule filling machine Another important equipment used for the making of delayed release capsules are encapsulator. It helps in the loading of an accurate concentration of filling material inside the capsules. There are various machines available in the market ensuring the encapsulation process ranges from small batches to large production batches. Moreover, you can opt for the machine depending on the types of capsules are subjecting them. For example: manual, semi-automatic, and automatic capsule filling machine. |

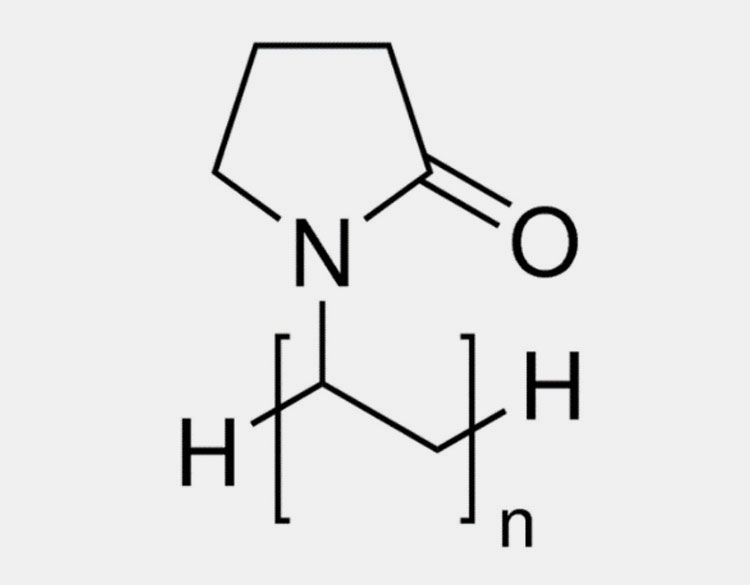

6.What types of essential polymers are used for delayed release capsules?

It won’t be surprising to know the broad spectrum of polymers used to control the drug delivery system. It plays an important role in the delayed release capsules method and is sometimes used in various other modified releases medication.

Picture Courtesy: Spera Pharma

The some of very important and commonly used polymers are:

| Name of Polymers | Ideal pH for Dissolution |

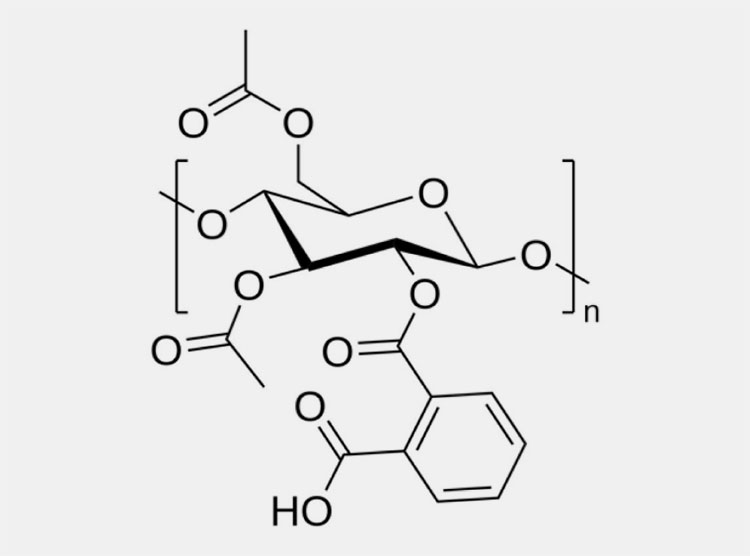

| Cellulose acetate phthalate or (CAP) | 6.2 |

| Cellulose Acetate Trimellitate or (CAT) | 5.5 |

| Hydroxypropyl methylcellulose phthalate or HPMC | 4.5 -5.5 |

| Shellac | 7 |

| Polyvinyl acetate phthalate or PVAP | 5 |

Name of polymers commonly used for delayed release capsules

Cellulose acetate phthalate or (CAP)

CAP

This is prevalent in industrial applications for making delayed release capsules. It makes your medication disintegrate only at pH above 6 and is a natural polymer. Due to being hygroscopic in nature, it resists solubilizing in moist environments as well does not respond to gastric moisture.

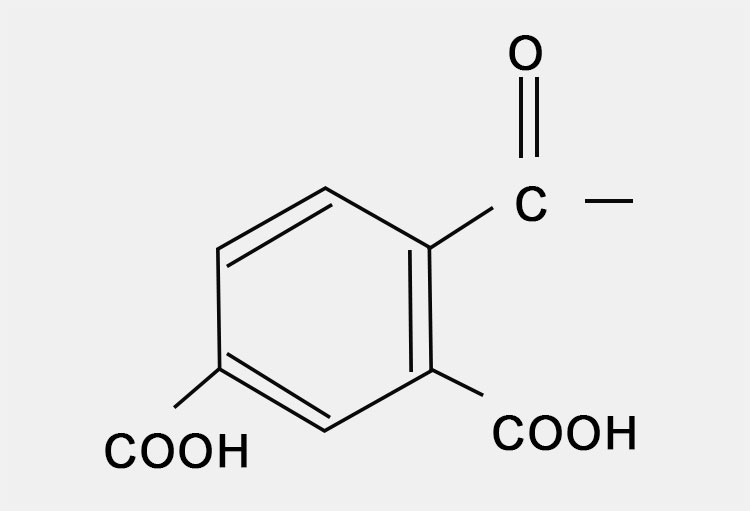

Cellulose Acetate Trimellitate or (CAT)

CAT

Due to the presence of an additional aromatic carboxylic group CAT is formed and it shows similar properties as CAP. This is best known for preparing delayed release capsules as it is capable of dissolving at a pH of 5.5 means its active site is the upper part of your small intestine.

Hydroxypropyl Methylcellulose or (HPMC)

HPMC

This is absolutely an alternative to natural polymer and is water soluble in nature which ensures a controlled release of medication. Moreover, this is also used in various film coating formulations for tablet micro-granules and produces its action in two ways. For example, ensuring drug diffusion from the gel layer produces from polymer and secondly allowing drug release from the coating by swelling of the layer.

Shellac

Shellac

This is a novel structured polymer with unique coating properties. Due to the high binding action in pH 7, it mainly resists the acidic environment or makes it uneasy for the drug to dissolve in the stomach at pH 2. This is mainly obtained from animal sources and possesses distinguished characteristics from regular polymers such as unavailable compounds such as aromatic, phenolic, resinotannol, etc.

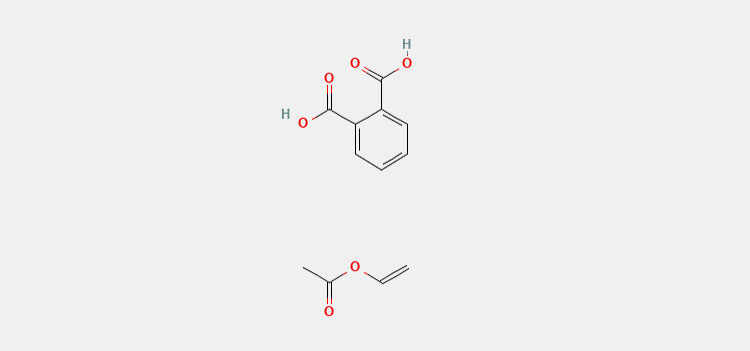

Polyvinyl acetate phthalate or PVAP

Polyvinyl acetate phthalate or PVAP- Picture Courtesy: benchchem

This is a mainly used ingredient for delayed released capsules and making pH dependent solubility. It is mainly dissolved at a pH of 5 and resists an acidic environment for releasing the action of API. That’s why it is used for broad range formulation that has to be released with specified target sites.

7.How long delayed release capsules take to dissolve?

The releasing time for delayed release capsules- Picture Courtesy: Spera - Pharma

The delayed release capsules basically are designed to protect the API from the acidic environment of the stomach and reach the intestine safely. Therefore, the drug can only be effective in the small intestine and it mainly takes one to two hours to dissolve once it binds to a target site and produces its releasing action.

However, this dissolution time is different for different polymers used in the coating of manufacturing delayed release capsules. For instance, shellac is observed to release within 35 minutes. On the other side, HMPC matrices make slow dissolution noted with two hours releasing time.

Conclusion

In conclusion, the delayed release capsules make your business successful in various ways, by offering safe products, improving user compliance, promoting well-being, minimizing long and complicated manufacturing steps, and reducing the process cost. These capsules not only enhance the performance of the APIs but also offer broad-spectrum bioavailability by the gradual release of medication and maintaining its effects on blood concentration as compared to standard drugs. However, the making process might be challenging but not impossible if you use good and excellent machinery like AIPAK offers you. Do you know how our machines can significantly skyrocket your business? Just contact our experts now and find the amazing series of equipment we are offering you for the making of delayed release capsules to get profit on investment.

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine