High-Efficiency Pharmaceutical

Pulverizer Machine

Reliable, High-Performance Pulverizers for Consistent Powder Quality

AIPAK Pharmaceutical Pulverizer Machine

AIPAK Pharmaceutical pulverizer machine is applied for material crushing in such trades as pharmaceutical, chemical, foodstuff, etc. The machine is of hammer type with high speed and not affected by the fiber or oil of raw material, can grind most of the materials and reach better effect.

AIPAK offers many series of pharmaceutical pulverizer machines for specialized applications, whether you need a customized or standard pharmaceutical pulverizer machine. All AIPAK pharmaceutical pulverizer machines have smooth operation, convenient movement, low noise, good crushing effect, and low power consumption.

AIPAK Pharmaceutical Pulverizer Machine Working Principle

Applications of Pharmaceutical Pulverizer Machine

Pharmaceutical Industry

Ideal for pulverizing raw medicinal materials, tablets, capsules, and granules into fine powder.

Ensures uniform particle size for better dissolution, absorption, and formulation stability.

Food Industry

Used for grinding spices, herbs, grains, and health supplements.

Maintains flavor, aroma, and nutrient integrity with hygienic processing.

Chemical Industry

Suitable for fine crushing of chemical powders, intermediates, and raw materials.

Delivers consistent particle sizes for stable chemical reactions and product quality.

Herbal & Nutraceuticals

Efficiently processes dried herbs, roots, and plant extracts into fine powder.

Enhances bioavailability and ease of encapsulation or tableting.

Cosmetics Industry

Applied in the grinding of raw ingredients such as pearl powder, botanical extracts, and minerals.

Provides ultra-fine powder for creams, lotions, and beauty formulations.

Laboratory & R&D

Compact models widely used in research institutions and labs.

Enables accurate small-batch grinding for formulation trials and product development.

AIPAK-Your Best Pharma Processing & Packaging Machinery Supplier In China

Download Our Latest Catelogue

Discover our full range of pharmaceutical processing&packaging machinery. Download the catalogue to explore specifications, features, and applicatons.

- Full product range

- Detailed technical specs

- Industry applications

Pharmaceutical Pulverizer Machine FAQ

1.What is a pharmaceutical pulverizer?

A pharmaceutical pulverizer is a precision grinding machine designed to convert solid pharmaceutical ingredients into uniform fine powders. With over 10 years of experience in pharmaceutical equipment manufacturing, AIPAK pharmaceutical pulverizers are trusted by factories in more than 50 countries to ensure consistent particle size and drug quality.

2.What materials can be processed with a pharmaceutical pulverizer?

Our pharmaceutical pulverizers handle a wide range of materials including APIs, excipients, herbal powders, and nutraceutical ingredients. They are suitable for both hard and soft materials, ensuring consistent quality. All processing meets GMP and ISO 9001 standards, which guarantees compliance with global pharmaceutical regulations.

3.Why is particle size important in pharmaceuticals?

Particle size directly affects solubility, bioavailability, and dosage uniformity. For example, in a recent project, our pharmaceutical pulverizers processed over 500 tons of API annually, achieving ±5% particle size variation—helping clients maintain predictable therapeutic effects and regulatory compliance.

4.What types of pharmaceutical pulverizers are available?

We provide multiple types based on material properties and production requirements:

Hammer Mills: Medium-to-fine powders with high-speed impact.

Ball Mills: Ultra-fine grinding, suitable for heat-sensitive APIs.

Jet Mills: High-speed air grinding for ultra-fine, contamination-free powders.

Pin Mills: Uniform particle size for low-to-medium hardness materials.

All machines comply with GMP and CE standards.

5.How do you maintain hygiene and prevent contamination?

Our pharmaceutical pulverizers are made of stainless steel with smooth surfaces, supporting CIP (Clean-in-Place) and SIP (Sterilize-in-Place) systems. These features are verified by multiple pharmaceutical clients to prevent cross-contamination and meet strict GMP standards.

6.How do you choose the right pharmaceutical pulverizer to meet your production needs?

Consider:

Material properties: hardness, moisture content, heat sensitivity. Desired particle size. Production capacity (kg/h). Compliance requirements (GMP, ISO, FDA)

Our engineers provide personalized recommendations based on over 500 client installations worldwide, ensuring optimal efficiency and regulatory compliance.

7.Can pharmaceutical pulverizers process herbal powders?

Yes. Herbal and nutraceutical powders are routinely processed using our pulverizers, maintaining bioactive compound integrity. Recent studies show our machines retain over 95% of active ingredients, meeting both quality and safety standards.

8.What maintenance is required for a pharmaceutical pulverizer?

Regular maintenance includes:

Cleaning after each batch to prevent contamination. Inspecting and replacing worn grinding parts. Checking motors, bearings, and seals. Lubricating moving components according to manufacturer guidelines

Our technical team provides detailed maintenance manuals and remote support to ensure long-term reliability.

9.Are pharmaceutical pulverizers safe to use?

Yes. Safety is a top priority. Machines include emergency stop functions, interlocks, and dust containment systems, protecting operators and maintaining a clean, safe production environment. No accidents have been reported in 10+ years of installations.

10.Can pulverizers handle high-volume production?

Absolutely. Our industrial-grade pharmaceutical pulverizers can process hundreds of kilograms per hour, while maintaining consistent particle size and full compliance with GMP and FDA standards. Many global pharmaceutical factories rely on our machines for large-scale API production.

The Buyer's Guide

Pharmaceutical Pulverizing Machine:The Complete Buying Guide in 2024

Let's dive into the details of the Pharmaceutical Pulverizing Machine. It will give you all the details whatever you need to know about the Pharmaceutical pulverizing machine to make your decision ASAP.

1. What is a Pharmaceutical pulverizing machine?

AIPAK Various Pharmaceutical pulverizing machine

A pulverizing machine otherwise called a crusher is utilized for crushing, smashing, grinding, and beating many different types of materials so you can get the ideal sort of finesse.

It is a significant mechanical gadget for some ventures without which the assignment of granulating the various materials would have been exceptionally troublesome and these enterprises are development, power age, agribusiness, reusing, printing, clinical research facility, plastic businesses, and drug items advancement.

Regardless of whether you need to squash or granulate the material into granules or minuscule pieces will rely upon the kind of pulverizing machine that you select as there are a wide range and different sorts of them that are planned and made by the pulverizing machine makers.

Additionally, there is an extensive rundown of materials that are utilized by this mechanical gadget for granulating or pulverizing which incorporates plastic, aluminum, glass, coal, solid, rock, metal, elastic, rock, limestone, grains, wood, tires, sap, and clinical waste.

These are some of the most regularly utilized old crushing plants. It is an exceptionally precise machine that is utilized in pounding, smashing, and beating solids and granules.

It comprises in any event four sledges also called a hammer associated with a focal shaft covered with a tight metal case. Size reduction is the major function of the machine.

The inner strikers of the machine together strike the items as they move on at an extremely rapid pace inside the chamber. The high turn of the mallets brings about a fragile break of the materials.

2. What are the Advantages of Pharmaceutical pulverizing machines?

Herb Medicines by the Pharmaceutical pulverizing machine

- Just like many other machines a pulverizing machine doesn’t require lots of space to occupy. It can be operated in a small place as well. Nothing to worry about of course.

- This machine can be modified for some special requirements.

- Depending on your type of material pulverizing machine can be used with or without a duster.

- Its self-classification also offers you a high to totally fine size which depends upon the crusher attached to the whole setup.

- It does have the capability of producing many different sizes.

- According to the grinding capabilities of the machine, it can be used for just some basic, moderate, or total powder conversion type of grinding.

- Use of the less power while running and before coming into the running also makes it a very unique machine.

- The pulverizing machine offers the grinding of many different types of material.

- Due to not much of technicalities, this type of machine is easier to install, use, and run without causing any problems in the machine.

- A pharmaceutical pulverizing machine is quite easy to clean, whereas maintenance is also not rocket science.

- This drug hardware is generally less expensive in contrast with different machines.

3. What are the disadvantages of a Pharmaceutical pulverizing machine?

- Not suggested for the fine crushing of hard and grating material because of inordinate wear.

- Not reasonable for low-dissolving clingy or plastic-like material because heat is being generated in the factory head because of plant fouling.

- The plant might be choked if the feed rate isn't controlled, prompting harm.

- The presence of unfamiliar materials like stone or metals discovers its way into the material because of an insufficient garbling process.

- There is a chance of stopping up on the screen.

4. What is a Pharmaceutical pulverizing machine used for?

These machines have been discovered helpful by numerous enterprises, including the drug or pharmacy business.

Its standard of activity stays the same regardless of the business utilizing it.

The following is a portion of its usage.

Grind and Crush Wet and Dry Granulations

The drug items consist of fixings from various substances which are blended and packed into the end product.

These items may either require wet or dry granulation.

The ideal size of the material is shown when this machine is utilized paying little attention to the granular size.

Utilized in Ingredient Size Reduction

A few materials in drug handling require a size decrease.

This is because it will be better to make them fit well in the bundles they are intended for.

Aside from this, the decrease in the sizes builds effectiveness in the medicine items prepared.

Due to that fact, the pharmaceutical pulverizing machine is a significant unit in sizing the items to the ideal size.

Creating Intermediate Powder Grades

Various evaluations of fixings are utilized to perform various applications in the drug or pharmaceutical businesses.

A bitter fact about pharmaceutical pulverizing machines, this machine can't create moderate powder grades from sticky types of materials.

However, luckily, it can create moderate powder grades from other nonsticky materials.

This is a bit of a factor in business considering it is not exclusively to drug enterprises but additionally to both cosmetic and food organizations as well.

Dissolution or Formulation is enhanced with this machine

A decent consequence of blending requires an enough surface zone.

The machine has enough place that ensure an intensive blending of drug fixings.

With it, you can make certain of getting a suggested molecule decreased size.

Utilized for Mixing the Powder in a High Shear Mixer

This is conceivable because this machine can deliver a steady and uniform same type of little particles all through the cycle.

The little particles are suggested in light of the fact that they guarantee uniform dissemination of fixings in the last formulation.

Active Ingredient Substrates Reduction

For certain items to accomplish the ideal viability, the vigor of certain fixings substrates must be decreased.

This is a typical cycle attempted in drug organizations.

The Pharmaceutical Product Manufacturing Process is Easy by this machine

Huge volumes of prescriptions can be delivered in an exceptionally brief term since the machine is proficient.

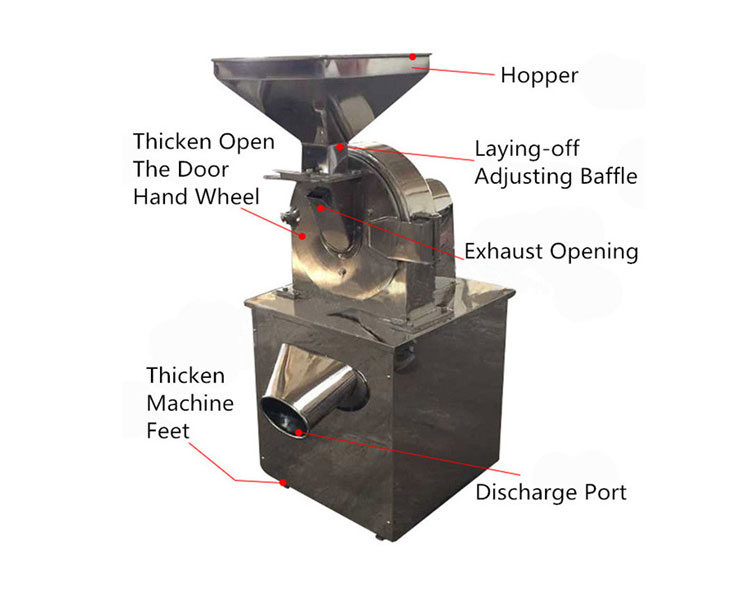

5. What are the Parts of Pharmaceutical pulverizing machines?

This machine is composed of four main parts.

Even though the quantity of principal parts may change contingent upon the plan of the machine, each part assumes a particular function in material handling.

Consequently, beneath are a few of the parts and the job every single one of them plays.

Parts of Pharmaceutical pulverizing machines

Feeding Hopper

The items are conveyed into the chamber of the machine for preparation through this part.

It is otherwise called a feeding tray or feeder chute.

They are then determined through a revolving valve in the grinding chamber.

The chute fee is significant because it decides the quantity of materials the machine can create at a time.

Feed container configuration may contrast if a specific machine development is unique.

Luckily, this part can be acclimated to empower you to locate a decent plot for emptying materials into the machine.

Pneumatic Rotary Valve

This is a part that furnishes an airtight chamber between frameworks with various pneumatic stresses.

These valves permit the pharmaceutical fixings to go through the zones with various pneumatic forces.

It helps in encouraging the metering system and feeding system usefulness of the hopper of feeding.

The significant function of the air valve is to look after the air pressure.

Aside from that, it additionally gives a sealing function between different item transmission transformations.

A decent isolated space given by this part protects against loss of pneumatic pressure in both temperature conditions and high weight.

Rushing Chamber

The actual process of grinding, crushing, and pulverizing takes place here.

This is where the hammers are located, and it’s where they rotate at very high speed to perform their functions.

It creates a vacuum for grinding and pulverizing various types of materials.

There are different sizes of crushing chambers, which are influenced by their design and other elements.

The hammers are driven by an electric power via a motor causing the rotation and crushing of the ingredients.

Control Box

This is an extremely important portion of a pharmaceutical pulverizing machine.

Numerous switches that are utilized in controlling the machine give you more control.

Diverse machine functions are likewise decided here with the goal that you can set the correct conditions for handling the ingredients.

Numerous boundaries that permit you to synchronize the Machine in a wide scope of points of view are likewise available here as well.

The pulverizing machine control box has a display screen from where the machine is controlled.

It likewise empowers you to handle machines completely.

6. What are the different types of pharmaceutical pulverizing machines?

Grinding Machine

AIPAK Grinding Machine

This machine is appropriate for pounding warm delicate material and grinding soggy material. It is less the warmth and the powder dust. The sifter of the stator is made of a tempered steel plate. It is difficult to harm. The hole between the smashing edge and the strainer can be changed. Can treat material that is cement or in gum or warmth or clammy state. It is generally utilized for wet and dry granulation pulverization and so forth.

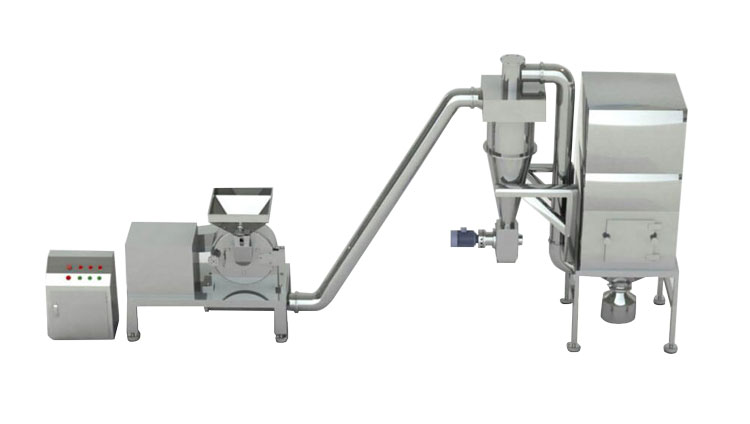

Universal Pulverizing Machine

AIPAK Universal Pulverizing Machine

Accuracy machines handle all alveolus inside the fenced-in area to accomplish smoothness on the surfaces, to be cleaned effectively, the customary processor generally has the harsh inward smasher, simple to gather powder and hard to clean, this machine can change these terrible wonders, the creation of food, drug and synthetic compounds can more readily meet the safety necessities.

Herbal Crushing Machine

AIPAK Herb Crushing Machine

This kind of crushing machine is mostly used by clinical production lines, food factories, and chemical processing plants and it has the capacity of air licensing and no screen.

There is no restriction for the material of consistency and hardness, All of the material can be used in that type of machine.

Too Fine Pulverizing Machine

AIPAK Super Fine Pulverizing Machine

This machine is applied for wet material excessively fine pounding in exchanges, for example, drug, staple, compound, and others exchanges, and reasonable for emulsifying, blending, and smashing a wide range of semi-clammy or emulsions materials. Its fundamental strategy boundaries have arrived at the worldwide progressed standard.

The pounding fineness can be changed by changing the tear between the upper and down factories. It can well arrive at the necessary impact of super-fine pounding fineness can be changed by changing the tear between the upper and down plants.

Micro pulverizing Machine

AIPAK Micro pulverizing Machine

Superfine micro pulverizer mill machine is another sort of fine pulverizer without a sifter, used to smash material into a fine powder (60-300mesh), which is utilized broadly in pharmaceutical, chemical, and food businesses and so forth.

7. How do Pharmaceutical pulverizing machines work?

The medical and pharmaceutical Pulverizing Machine adjusts the vertical low system for the crude material releasing gear.

A very efficient Pulverizer makes some crude materials with good fluidity.

Its guideline for working is like this: when crude material goes into the grinding chamber.

Under this part of the process impacting breakage is done with mobile and fixed fluted plates that move into the circle at a speed in fast turns into the required crude material through the screen.

Stainless steel is the core of the making of this pharmaceutical and medical pulverizing machine.

Its internal mass of the lodging is smooth and level being prepared through prevalent innovation.

Accordingly, a pulverizing machine can make the powder release all the more streaming and is advantageous to be crafted by clean as well.

The stuff circle of rapid and versatile teeth is welded through unique welding, which makes the teeth solid, long-lasting, and safer.

8. How do you Achieve Powder Homogenization using Pharmaceutical pulverizing machines?

Having the same size as the pharmaceutical pulverizing machine firstly you need to grind the items separately before doing any kind of mixing. It’s just because machines do have a very low hold-up capacity.

If we do any kind of mixed grinding beforehand the chances are very high that we might lose the active ingredient as well.

In the wake of crushing the purest of the ingredients, you would now be able to proceed and remix the materials after condemnation in the pharmaceutical pulverizing machine.

This would cause a similarity in the material.

9. Which Factors Control Particle Sizes in a Pharmaceutical Pulverizing Machine?

Some certain factors might affect the size of the particle size in this machine.

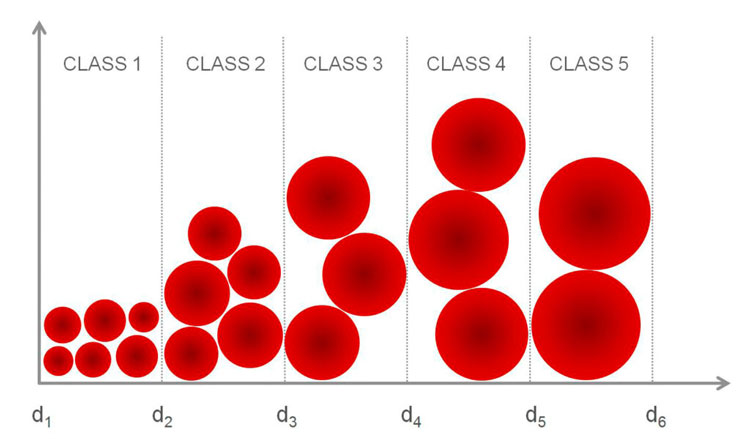

Particle Sizes

Some of them are the following:

How much material is being fed into the machine?

What is the speed per minute of the machine?

The opposition of the hit and material being cleared between the plates inside the crushing the materials.

It likewise relies upon the initial size of the screen, and lingering time for ingredients is of course a deciding factor.

10. What determines the Quality of Material crushed by the pulverizing machine?

Just like many other factors material quality also relies upon the many possible factors.

For instance, it depends upon what exactly is the design of the machine, for which purpose it has been designed for you, the number of the crusher used within the machine, speed of the tip and area of screening.

Other than that, quality of the material also relies on the humidity upon the material being crushed, engine into the machine and things like sieve are another deciding factor.

Lastly, the speed with which material enters into the machine can affect the quality of the material.

11. What are Pharmaceutical pulverizing machine Specifications?

At the point when you are new in this field, you may discover trouble in picking a decent-quality pulverizing machine.

This machine's consideration of specification is a significant thing.

This is because they will permit you to reach the amazing standard machine which does own the capacities of productively.

Accordingly, before buying this machine, guarantee your decision meets the particular specialized details.

Coming up next are some of them.

Yield Type

It's critical to consider drug pulverizing machine yield when you need to buy one. This will manage you on the amount of the ingredient you will hope to process. Additionally, it will give you a thought of how to measure the ingredients.

Various sorts of machines have various yields.

Along these lines, it is significant for you to design one that meets your prerequisites. The most essential things that will assist you with deciding the yield are the screen size and shaft speed.

Shaft arrangement is likewise significant.

Limit of Production

This is the most extreme amount of items the machine can run inside a predetermined duration of time.

Little, medium, and huge scope creation are 3 ideal sorts of equipment that can be used.

Production limit is significant because it helps in making it simple to choose the volume you need to measure.

12. What Influences the Capacity of Pharmaceutical Pulverizing Machine?

Many factors determine the capacity of this machine. They include:

Material characteristic

The capacity of a machine can be defined as what type of ore is being used in the machine. For instance, it can be alloy, stainless steel 300 series and it does impact the capacity of the machine.

Crushing shaft type

The capacity can be changed as per the rule of the crushing shaft used inside the machine. For instance, if it is a jaw crusher it can be soft to hard and reduction can go from 3/1 to 5/1.

Size of the feed

How much material a pulverizing machine takes in at once is defined as the size of the feed in a machine. If the size of the feed is bigger you can take in more material and the other way around it is less.

Many rows of a crushing shaft

If there are more shafts and rows the influence will be different whereas if it is less it would be different.

13. What is a Vertical Pharmaceutical pulverizing machine?

AIPAK Vertical Pharmaceutical pulverizing machine

This is a sort of pulverizing machine that uses less force.

It has an elevated level of production capacity, which is conceivable in a little space.

It's accessible in three adaptations.

These are restricted wind streams, mallets, and screens that are handily supplanted and simple to clean and examine crushing chambers.

Specialized Characteristics of Vertical Pharmaceutical Pulverizing Machine

The plants are fitted with a metal expulsion framework and dispenser stone.

An adaptable coupling interfaces with both the engine and the impeller.

This machine has generally excellent security principles where the bearing temperature is observed by a sensor that is known as PT100.

It delivers less commotion in contrast with the same type of things.

Pharmaceutical pulverizing machines should conform to which Quality Standards?

Some certain standards need to be met whenever we talk about the quality standards of the machine.

Some machines hold many standards while others just should have few.

Consistency with CGMP must be made. This is because the items target people and should be protected from any mishap.

Material endorsed by the FDA must be used for the machine. For instance, hardened steel most of the time 304 material.

This machine ought to have safety gadgets with the machine as well that can be utilized to halt the machine if there should arise an occurrence of any crisis.

14. Can Pharmaceutical Pulverizing Machines Produce Intermediate Grades of Particles?

Indeed, it is possible with some customization of the machine.

Intermediate grade particles can be produced just by attaching the first crushing machine whereas for the finer.

Some particles have a specific size of the diameter, that are neither enormous nor little.

This may occur when you mean to have some particular applications in the drug organization.

The machine can create moderate evaluation particles from numerous ingredients.

15. What are the Properties of Materials you can Process using Pharmaceutical pulverizing machines?

- A wide range of food contains sesame seed, pecan, rice, dark rice, beans, mung beans, peanuts, lotus seed, corn, sorghum, grain, buckwheat, oats, and so forth;

- A wide range of dried spices containing almonds, Poria cocos, red jujube, Gordon Euryale seed, medlar, hawthorn, HuaiShan, radix polygons multiflora, red bean, jackass shroud gelatin, frankincense, dodder, angelica, dang shen and astragalus membranaceus.

- A wide range of compound crude materials including coal, gypsum, salt, and corrosive.

- All sorts of flavors, pepper, pepper, Chinese thorny debris, star anise, cinnamon, huai xiang, and so on.

16. Why sometimes duster is attached to the Pharmaceutical pulverizing machine?

A duster is normally an additional attachment with the pharmaceutical pulverizing machine being used to collect the sand and dust within the material.

A duster is a framework used to improve the nature of air delivered from modern and business measures by gathering dust and different contamination from the material being crushed.

Intended to deal with high-volume dust stacks, a duster framework comprises a blower, dust channel, channel cleaning framework, and dust repository or residue evaluation framework.

It is recognized from air purifiers, which utilize dispensable channels to eliminate dust.

Normally if a material is a plant and it is taken out from the soil the material dust needs to be removed by using the duster.

The other way around, if a material doesn’t hold any contamination like soil it can be handled easily with a duster.

17. What factors will affect the production efficiency of the pulverizer?

The following six factors may be common problems affecting the efficiency of the pulverizer.

Operation is not done in a proper manner

In the usage of pulverizer, because of lacking comprehension of the working rules of the smasher, the ill-advised activity of the smasher in everyday production makes it difficult to give full results to the ordinary creation execution of the smasher, which influences the efficiency of production.

How hard is the material

The harder the material is, the more difficult it is to break it is to break, and the more genuine the wear on the gear, the lower the rate of grinding is, the more modest the grinding limit is, and the better the grinding impact of the moderate material is.

Material is humid or not

At the point when the dampness content in the material is huge, it is anything but difficult to hold fast to the material in the grinder and it is anything but difficult to hinder during the time spent taking care of it, which brings about the decrease of the crushing limit and influences the typical production.

The humidness of the material is carefully controlled when the material is chosen and uses daylight or air drying to decrease the humidness of materials.

Material finest after crushing

The better the material is, the more modest the grinding limit will be. If there is no exceptional necessity, the fineness of the material can be set as medium and fine.

Material thickness

The higher the thickness of the material, the simpler to adhere. The high consistency of the material in the grinder will stick to the inward mass of the grinder, if not ideal cleaning, which will truly influence the effectiveness of the grinder.

Genuine will likewise influence the typical activity of the smasher. In this way, in the determination of materials, it is important to focus on the consistency of the material must not be excessively huge.

Composition of materials

The more fine powder in the material before smashing, the more it influences the grinding process because the fine powder is anything but difficult to hold fast to influence the transportation.

In this way, for the material with a high substance of fine powder, the material ought to be filtered ahead of time and the fine powder ought to be screened out from the material beyond what many would consider possible.

Try not to influence the ordinary activity of the crushing.

18. How do you Troubleshoot Pharmaceutical pulverizing machines?

Proper maintenance is required for this machine to work in a good manner.

Coming up next are a portion of the issues that may emerge during the activity of this machine, which may require troubleshooting.

1) Lots of the vibration of the Machine

At the point when this occurs, you ought to find the part of vibration by eliminating all the mallets, poles, and spacers.

Put them back and run it, and if the vibration vanishes, it implies the source was the mallet and bars.

On the off chance that the vibration doesn't stop, at that point stop it and check the balancing out bars and spanner nut fitness.

Welds on the rotor likewise ought to be checked.

Only if the chance that the issue isn't fathomed, rebalance the rotor or supplant it if it is showing the warning.

2) Using Shred Parts

This is another extraordinary test.

At the point when the parts being utilized are running out, the nature of items might have quality issues.

The screens are out of service when the openings become round.

Crusher demonstrates warning in the pharmaceutical pulverizing machine when the corners are adjusted, and the primary driven engine amperage has broadened.

A decrease in the thickness of the wear plates by half is likewise a sign that they are rusty and no more of the usage within the machine.

The solution for this is to change these parts before they become excessively rusted.

Another arrangement is to switch the revolution of the machine rotor consistently to build its life expectancy.

You can likewise guarantee the same feeding of items into the plant.

The uneven spread of materials in various pieces of the machine will in general cause screen and mallet issues.

Aside from these, guarantee sufficient air volume into the machine to encourage uniform feeding into the pulverizing machine and crushing.

3) Issues with the Grinding Process

This ought to be checked to guarantee the effectiveness of the machine.

This should be possible affirming the machine limit and checking screens and crush heads.

You can likewise check the granulating chamber temperature, and air volume, and take care of drive.

Additionally, check the chance of release deterrents and don't utilize abundance power.

19. What is the way to reduce the size of the material?

There are four basic ways to reduce a material, namely (i) impact, (ii) attrition, (iii) shear, and (iv) compression. Most crushers employ a combination of all these crushing methods.

Impacts

In any type of grinding and crushing terms, impact means the sharp, prompt crash of one moving article against another.

The two items might be moving, or one article might be still. There are two varieties of effects, specifically

1. Impact of gravity

2. Impact of dynamic

When the items are dropped on the soil surface let's say on the steel surface is an example of gravity impact. The impact of gravity is frequently utilized when it is important to isolate two materials that have generally unique friability (Ability to easily break down).

Friable material turns into pieces whereas material does not turn into less friable pieces. Detachment should then be possible by screening.

Material dropping before a moving mallet (the two items moving), shows dynamic effect. At the point when squashed by gravity, the free-falling material is immediately halted by the fixed item.

Yet, when squashed by powerful effect, the material is unsupported and the power of effect quickens the development of the diminished particles toward breaker blocks and additionally different crushers.

The dynamic effect has preferences for the decrease of numerous materials.

Attrition

The terminology applied to the decrease of materials by rubbing it between two hard surfaces.

Pulverizing machine work with close clearances between the mallets and the screen bars and items diminish by shear combined with attrition and impact reduction.

Even though attrition requires more force and claims heavier wear on mallets and screen bars, it is a common strategy for pulverizing the less grating materials, for example, limestone and coal.

Shear

It comprises a managing or separating activity instead of the scrubbing activity related to wearing down. Shear is generally joined with different techniques.

For instance, single-move smashers utilize shear along with effect and pressure. Shear grinding is typically called for under the conditions when the material is to some degree friable or when a moderately coarse item is wanted.

It is typically utilized for essential squashing with a decreased proportion of six to one.

Compression

As the name implies, pounding by pressure is done between two surfaces, with the work being finished by one or the two surfaces.

20. What are some of the features of the pulverizing machine?

Strong squashing capacity, usage of energy is low and item fineness generally is little.

The crushing chamber is larger, turbo pressure created during the activity of high-quality, not exclusively to build creation limit and lessen the over-pulverize marvel, and can viably dodge the material delivered in the pounding cycle on the screen statement and stopping up. You can likewise boost quality and strain to remove the warmth created by pulverizing pits.

Due to upgraded shear, and thus for the stringy material and the pounding limit gear than the normal high.

Screen establishment advantageous, dependable situations are utilized. Will ring sifters as for the type of life much higher.

The motor is built in, bringing down the machine's focal point of gravity, viably diminishing gadget clamor.

21. Why sometimes do we use the fine crusher and other times don't?

A fine Pulverizer is suitable for fine-grinding powder. Fine Pulverizers (Screenless equipment ) are precisely built for grinding soft to medium-hard materials into amazingly fine powder.

Built-in water circulation jackets retain grinding temperature lower than otherwise, permitting handling of some heat-sensitive applications. Design permits ease of cleaning & quick change over of products, thus savings through a minimum of downtime. Feed is controlled via a screw feeder. The air-swept product passes through a complex grinding contour where attrition force combined with turbo (jet) effect ensures ultra-fine particle size. The annular gap plate controls the flow of material through the Mill.

Depending on the type of the requirement of the customer and type of material of can use the finest of the machine.

It also depends upon the end usage of the product. If the product requires to be fine it has to be done.

22. What is the price range of the Pharmaceutical pulverizing machine?

The cost factor of not only pulverizing machines but also many other machines is decided by many factors like what type of machine you want, what is material being used in the machine, or if you have some special kind of requirement when buying a machine.

23. How far this Pharmaceutical pulverizing machine can go?

As an innovative and high-mix machine, with the constant progression of materials science, fabricating innovation, and PC data innovation, items will be coordinated into new advances, and new pharmaceutical pulverizing machines will be continuously redesigned.

Later on, the crushing apparatus will utilize the coordination of multidisciplinary advances to improve plan effectiveness and plan quality, upgrade the free development ability and market intensity of the venture, and the future crushing machine will create the advancements.

A detailed video about Pharmaceutical pulverizing machines:

Conclusion

It is very clear from this buying guide, that every given detail given here is very simple to use. Buying this machine will help you in every aspect. Pharmaceutical pulverizing machines are the most well-known machines utilized with the end goal of size decrease. It has a wide range of utilization in granulating seeds, nuts, and beans, and different materials for more modern purposes. It has the benefit of High viability in the most brief time.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586