Cosmetic Tube Filling Machine: The Complete Buying Guide In 2025

In this evolving world, people are more concerned about their look and appearance. For this concern, we have seen increasing growth and new innovation in cosmetic industry. In cosmetic industry, precision and accuracy is really crucial. Cosmetic tube filling machine is essential part of production line which ensure accuracy, consistency and fulfill customer satisfaction.

You wonder how these tube filling machine work? What is the best option available in market of cosmetic tube filling machine? We got you. In this article of Cosmetic Tube Filling Machine: The Complete Buying Guide in 2025, you will learn every tit bit of this machine. Without further delay let’s begin this topic.

1.What Do You Know About Cosmetic Tube Filling Machine?

Cosmetic Tube Filling Machine

Cosmetic tube filling machine is highly automated equipment which is used to fill product in tubes like cream lotion and gel. A cosmetic tube filling machine work on two basic process which is filling of tube or sealing the edges of tubes.

This machine can fill different sizes of tubes and can handle different viscosities of liquids. It mainly consists of hopper which hold the product, a plunger to dispense the cream and a sealing station which close the end of tubes.

This machine is an essential component of production line of cosmetic industry because it can fill each tube with precision and cleanliness just in fraction of time. This way reducing chances of waste and contamination and can boost production outcome.

2.What are Beneficial Outcome of Using Cosmetic Tube Filling Machine?

Increasing productivity

Increasing Productivity

If you are looking for ways to increase production speed? Cosmetic tube filling machine is best fit for it. This automated machine work at high speed and can increase productivity of your product resulting in manual labor reduction without compromising on quality.

Maintaining hygiene and quality

Maintaining Hygiene and Quality- Picture Courtesy: Good Mockups

In cosmetic industry, contamination can create problem in product which lead severe consequences. Cosmetic tube filling machine is automated machine decreasing manual contact which lead to least chance contamination.

You will get clean and hygienic product with quality in each batch.

Handling various tube sizes

Handling Various Tube Sizes- Picture Courtesy: Psfreebies

Cosmetic tube filling machine is designed in a way so that they can adapt to handle different product and tube sizes. This feature help manufacturer to increase range of product and can help manufacturer to remain competitive in market.

Reducing wastage of product

Reducing Wastage of Product- Picture Courtesy: Health

Cosmetic tube filling machine can fill each tube accurately with product without spilling or overflowing. This feature of machine reduces wastage of product and increase productivity.

Maintaining precision and accuracy

Maintaining Precision and Accuracy- Picture Courtesy: Package mockups

Cosmetic tube filling machine is an efficient equipment which can fill product in each tube with great precision and accuracy resulted in consistent product in each batch and building customer trust.

3.Elaborate Application of Cosmetic Tube Filling Machine in Other industries

Cosmetic tube filling is a versatile equipment which used in various industries. It is used to increase productivity of you filling unit and reduces operational expenses. In this we will learn about other industries which are benefitting from cosmetic cream filling machine.

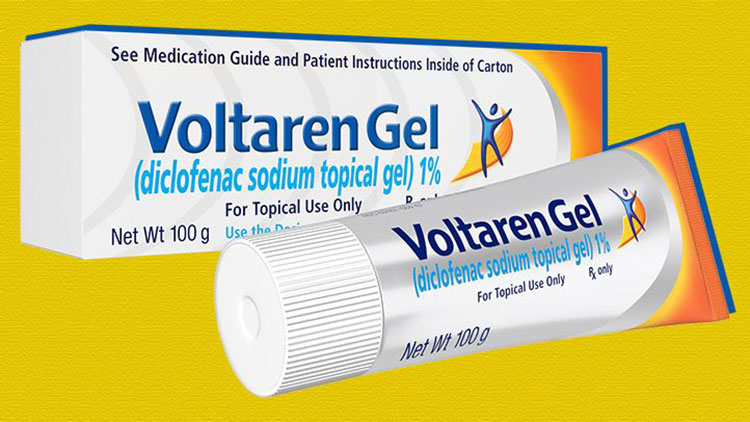

Pharmaceutical industry

Pharmaceutical Industry- Picture Courtesy: Backtrack boys

In pharmaceutical sector, cosmetic tube filling machine is widely used to fill medicinal product like medicated cream, lotion and ointment. This equipment enhances overall production rate of pharmaceutical unit without compromising in quality.

Cosmetic industry

Cosmetic Industry

Your most of cosmetic products like foundation, cream, sunscreen, moisturizer and hair gel all comes in tube packaging. Here you can see another application of cosmetic tube filling machine. Due to its customizable option, it can handle different sizes and shapes of tubes without spilling of product.

Food industry

Food Industry- Picture Courtesy: Lazada.com

Many food industries are using tube packaging for sauces or spread like ketchup, mayonnaise, honey, butter and different spreads. Cosmetic tubes filling machine is widely used to fill sauces without spilling and contamination.

Chemical industry

Chemical Industry- Picture Courtesy: Shopee Singapore

There is a wide range of chemical product like adhesive, lubricant and other chemical products that comes in small tubes are filled with the aid cosmetic tube filling machine. It ensures safe packaging of harsh chemical without leakage.

Self-hygiene industry

Self-Hygiene Industry- Picture Courtesy: Betches

This cosmetic tube filling machine is used to fill self-hygiene products like sanitizer, toothpaste, conditioner and many more products. This machine is highly appreciated for its safe, mess-free and contamination-free feature in filling process.

4.What Is the Step-By-Step Process of Cosmetic Tube Filling Machine?

Cosmetic tube filling machine is a series of multiple steps combined for efficient and smooth processing of machine. Let’s learn all basic steps involved in this process.

Preparing material

Preparing Material- Picture Courtesy: PolarSeal

The process of cosmetic tube filling machine starts with loading empty tube through tube feeder. On the other side, hopper is filled with product needed to fill. After that, you start the equipment, set all integration through control panel according to requirement.

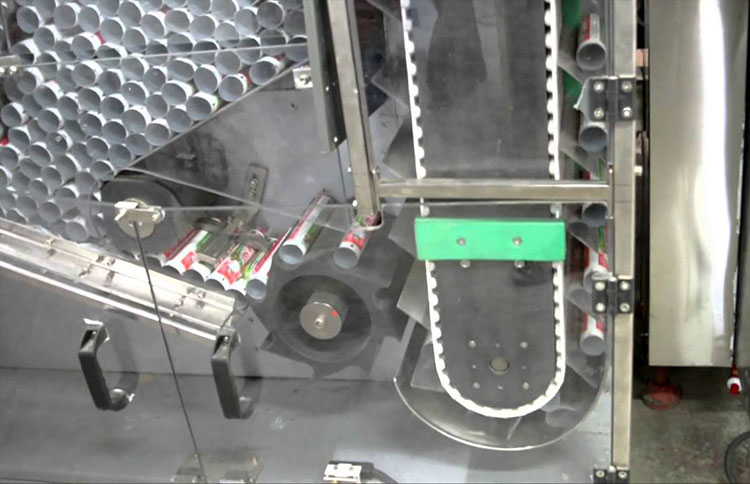

Inserting empty tubes

Inserting Empty Tubes

In second step, loaded empty tubes are grip by machine through gripper and place in holding cavity. The tubes are placed in position where open side is facing upside down for proper filling of tube.

Product filling

Product Filling

Now the actual filling process take place. Tubes are filled with precise and accurate amount. The main component involve this step is filling nozzles which ensure same amount filled in each tube by up-down or rotating movement of filling nozzles.

Sealing of tubes

Sealing of Tubes

After filling, tubes are moved to sealing station where open end of tubes are sealed by number of method like pressing with pressure and heat sealing. This secure edges of tubes and reduces chances of leakage.

Trimming and coding of tubes

Trimming and Coding of Tubes

After secure sealing of tubes, they are moved to coding station where they printed with basic information like name, product quantity, ingredient, expiry and batch number. Finally trimming tool cut the edges of tube. In this way you will get neat and clean packed tubes.

Discharging of tubes

Discharging of Tubes- Picture Courtesy: Pharmec

In the end, packed and filled tubes are discharge and collected on trays. From there, it can be proceeding to next packaging step.

5.How Many Types of Cosmetic Tube Filling Machine Available in Market?

The filling machine classified on the basis of level of automation and mechanism of filling method.

On the basis of automation level

Manual tube filling machine

Manual Tube Filling Machine

Manual tube filling machine is most simple and easy to use version of cosmetic tube filling machine. It is well-suited for small scale production unit. This type of machine in small production unit can help to attain consistency and productivity which is not possible by hand.

Working principle

This machine operated manually. You need to place an empty tube below the filling nozzle. Then operator dispense product with help of plunger or lever. When operator press lever a pre-set amount is dispensed in tube. After filling, tube is manually removed and sealed manually by heating or crimping depending on the material of tube.

Semi-automatic tube filling machine

Semi-Automatic Tube Filling Machine

Semi-automatic tube filling machine is simple yet efficient type of cream tube filling machine. It is good option for small scale business where speed is not as important as accuracy. This machine works on both automatic and manual principle. It is ideal for medium size business that want to increase their production speed.

Working principle

In this type of cosmetic tube filling machine, you need to place empty tube manually on tube holder and rest filling and sealing process done automatically. When tubes are filled with product, tubes are removed manually from holder and collected.

Automatic tube filling machine

Fully-Automatic Tube Filling Machine

Automatic cosmetic tube filling machine is highly efficient version of tube filling machine and suitable for large scale production unit. Due to automation, it need very less manual labor intervention and filled tube efficiently with in fraction of time with precision and accuracy. This machine work at very high speed and beneficial for increasing production capacity.

Working principle

This automatic cosmetic tube filling machine can be easily operated by simply installing instruction in control panel once. The product is loaded in hopper and empty are tubes are loaded in tube feeder. When you start machine it collect tube from tube feeder and with help gripper place in tube holder. It rotates and place tube below filling nozzle and then filled tube are lead to sealing station where sealing is done. Then tubes are coming out from discharge outlet. This complete process done automatically.

On the basis of filling mechanism

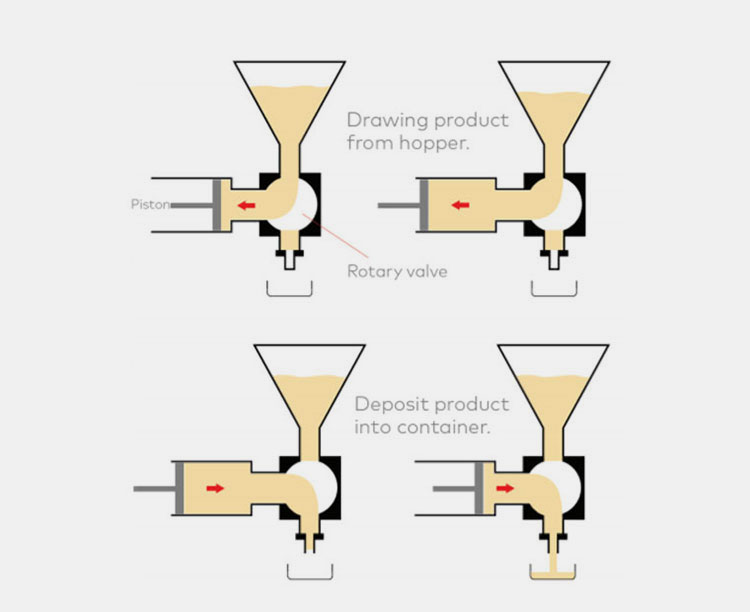

Piston-based tube filling

Piston-Based Tube Filling- Picture Courtesy: VKPACK

This method is used for highly viscous creams and ointment. In this method through piston product is incorporated in cylinder then dispense through lever in tubes. This method attains high level of precision and accuracy.

Gravity filling mechanism

Gravity Tube Filling Mechanism- Picture Courtesy: Elnova

This type is used for free flowing lotion and less viscous cream. It worked on principle of gravitational force. This mechanism is dependent on the weight and volume of fill amount. They are extensively used due their simple and low maintenance structure.

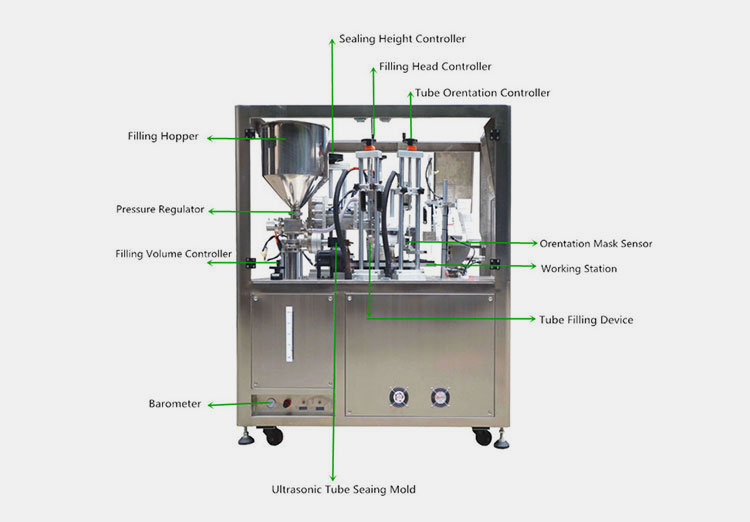

6.What Are the Main Components of Cosmetic Tube filling Machine?

Cosmetic tube filling machine consists of various complexed parts assembled together for efficient and smooth working of machine. Here are some key components of machine are discussed below for your learning.

Main Components of Cosmetic Tube Filling Machine- Picture Courtesy: VKPAK

Hopper

It is the parts of machine which looks like a funnel-shaped structure. It is used to hold bulk quantity of product and provide to filling nozzle when needed. It may be assembled with self-stirring mechanism to keep the product homogenous and prevent from settling or separation of product.

Tube feeder

This part located on top of machine. It stores bulk quantity of empty tubes and provide one by one for next stage of filling process. This function can be done manually or mechanically.

Nozzle filler

The filling nozzle is main component which is use to fill each precisely with accurate amount without spilling. Product filling in the tube through nozzle filler depend upon size and shape of the tube.

Some filling nozzles are elongated tube designed to reached bottom of tube to avoid product dripping from nozzles.

Pressure regulator

It is a knob-like structure below hopper which is use to regulate pressure of filling product. It is crucial to maintain a constant pressure for accurate filling of cosmetic tubes.

Tube orientation controller

It is a circular cavity to hold tubes I upright position for filling of product without spilling

Working station

It acts as a working table for machine. Its consist of various components like nozzle filler, tube holder, trimmer and sealing station which work in circular process for tube filling.

Control panel

It consists of small touch screen which is used to control the filling process. It enables controller to set size, speed and filler setting from single touch. It also helps to monitor progress during filling process.

Sealing unit

This part seals filled tube. It is done by various method like heat sealing r simple crimping. This step can be adjusted according to size, shape and material of tube.

Collection tray

It the last station where filled tubes are collected. From this tray tubes are collected manually for further process.

7.What Tube Material Are Used in Cosmetic Tube Filling Machine?

Cosmetic tube filling is a versatile equipment which can easily handle different tubes material depending on manufacturer demand. Listed below are common material that used in cream tube filling machine.

Plastic tubes

Plastic Tubes

Plastic tubes are widely used in different industries from food to pharmaceutical. It is preferable choice for cream for so many reason like easily available, less expensive, light weight and easier to squeeze.

Metal Tubes

Metal Tubes

Nowadays these metal tubes are not widely used but few industries like automobile and paint industry still using due its durability. It is highly preferred due anti corrosion property for packaging specialized products like lubricants, sealants and adhesive.

Laminated tubes

Laminated Tubes- Picture Courtesy: Freshpack Solution

These are also made up of plastic but with extra layer of lamination. It covers plastic, gives shiny and luxurious appearance to make it eye appealing. Other than that laminated tubes more durable, increases integrity and lifetime of product.

Aluminum Tubes

Aluminum Tubes

These aluminum tubes are widely used in pharmaceutical industry for product like medicated cream and ointment. They also crimped from opening to give temper proof seal. Moreover, its environmental friendly due to its high recycling rate.

8.What are The Key Feature You Need to Consider Before Buying Cosmetic Tube Filling Machine?

Now you are confused after seeing so many option, which cosmetic tube filling machine you should buy or what main features you need consider before buying? Here are some key features, you must consider before buying.

Product consistency and viscosity

Product Consistency and Viscosity

Viscosity of cream lotion highly impact choice of cosmetic tube filling machine. Like piston tube filling machine is preferable for highly viscous creams and ointments. On the other hand, gravitational tube filling is preferable for less viscous or free flowing lotion.

Cost effective or budget friendly

Cost Effective or Budget Friendly- Picture Courtesy: WBM App

When you are considering to buy cosmetic tube filling machine, you must evaluate cost effective option with your desirable features, capabilities and performance. Always select an option which is retainable in future in term of cost.

Shape and size of tube

Shapes and Sizes of Tube

The size and shape which is used in cosmetic tube filling machine must consider, when selecting a machine. There are so many option available of filling machine in market which can accommodate different shape and size of tubes, ensure to select which is right fit for your packaging unit.

Easy to handle and maintain

Easy to handle and Maintain

You should look for cosmetic tube filling machine which easy to operate and maintain. Always select machine which comes with features like user friendly and cut downtime.

Production speed and outcomes

Production Speed and Outcome

Cosmetic tube filling machine comes with variation in production speed and outcome. You must consider a machine which can fulfill your production demand in desired period of time with maintain high level accuracy and efficiency.

9.What are Common Malfunction Which You Encountered In Cosmetic Tube Filling Machine?

No machine is perfect and is made by humans and error must be there but the proper information may cover this error in cosmetic tube filling machine. Now let discuss some major problems which you will be facing during cosmetics tube filling machine along with its solution.

Poor material of tube

Poor Material of Tube

Quality of tube material is crucial I tube filling process because low grade material can lead improper sealing or irregular shape of tube which result in higher chances of contamination and can raise serious skin risk.

Solution

Always use high grade tube material which enable proper sealing hence eliminating risk of contamination.

Improper placing of tube

Improper Position of Tubes- Picture Courtesy: Filling Machine

Due to machine error or some system hiccups there will be a major chance of improper placing

of tube and it may lead to blockage of whole machine and can cause to stop filling the tube.

Solution

Attentiveness is necessary till to the completion of process and proper alignment in tube setting must be checked all hindrance during the process must be cleared otherwise it may cause error in the process and also activate the sensor which may control automatically the machine error

Resistance in nozzles during cream filling

Resistance in Nozzle During Filling- Picture Courtesy: Jarsking

This may happen due to clean of machine and proper clearance of debris from machine nozzles. It may also happen due to the proper pumping of cream from nozzles due to cream consistency.

Solution

This error will be resolve due to machine proper cleaning on schedule basis and secondly proper pumping of cream from nozzles and check the consistency of cream follow all these above mention instructions may reduce the system error.

Improper sealing of tube

Improper Sealing of Tube- Picture Courtesy: Racked

Sealing is also the most common issue and it is the cause of contamination because of leakage of tube and effect the product quality.

Solution

Rectify the problem and resolve the issue on time, must proper maintain the pressure and temperature of tube sealing unit to get more desired result clean up the machine on schedule

Air bubbles in cream

Air Bubble in Cream

Variation in tube filling is the major cause of entrance of air bubbles in cream tube it affects the quality and weightage of product

Solution

The solution of this problem always blend the product properly and uniformly to prevent from entrance of air bubbles in the product and must maintain the pressure during filling tube

Conclusion

A Cosmetic tube filling machine is a great investment to boost your production outcome as well to compete in market. It is an efficient tool to fill tube with precision and accuracy, without compromising on quality. In this article, “cosmetic tube filling machine: the complete buying guide 2025” you will learn basic feature, benefits and some commonly facing problem in cosmetic tube filing machine. Now you are well equipped with knowledge. Still thinking which model to buy? I will encourage to contact our ALLPACK customer services team, because we are expert in manufacturing high quality industrial equipment which is serving many businesses.

Don't forget to share this post!

Tube Filling Machine Related Posts

Tube Filling Machine Related Products

Tube Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine