Coffee Packaging: The Complete FAQ Guide in 2025

With so much demand and popularity for coffee, there’s no wonder its market value has reached up to more than 160 million of 60 kilograms bags recorded in the last year. With that, huge competition is faced by brands and manufacturing companies. In short, your coffee packaging must be eye catching to grab customer’s attention and offering aromatic coffee. In this guide, we’ll talk about the entire anatomy of coffee packaging, i.e., packaging styles, packaging machines, working, and much more. So, let’s have a deeper look at important aspects in an excellent coffee packaging process and design.

1.How to Keep Coffee Fresh?

Many coffee connoisseurs want to have a good aromatic cup when they crave it! For that, you need to keep them away from its greatest enemies that we discussed later in this blog. Before that have a look at some tips for coffee freshness:

Resealable Tops

These are like plastic stripes or zipper tapes for resealing the container once it is opened. These packaging types are imperative in decreasing the exposure of coffee powders to environmental agents.

Modified-Atmosphere Packaging

By using this technology, you can preserve the quality and freshness of your coffee powders. It also minimizes the chances of coffee going bad. This is usually employed by flushing the mixtures of inert gases inside the packaging to avoid powder reaction with oxygen. Specialized materials are also used for preventing the reaction of gases with coffee powders.

Degassing valves

These valves are like one way vents for the release of carbon dioxide by coffee powders. This upholds the quality of your coffee for long period.

2.What is Coffee Packaging?

Coffee packaging is a process of enclosing roasted coffee either in jars, containers, or pouches. It helps in protecting the efficacy, potency, and flavor of coffee against sunlight, moisture content, or other factors.

The prime goal of coffee packaging is to preserve aroma and taste; besides this, great packaging raises brand awareness and ensures to stand out your company from the crowd to allure new consumers.

Good coffee packaging is one that narrates the journey from roasting warehouse to end user and sustains the beans' freshness and quality.

3.What Are Different Packaging Styles For Coffee Powders?

There are numerous kinds of packaging styles for holding coffee powders. You can choose your own favorite packaging style depending on the powder characteristics of your products.

Details of some packaging styles are penned below:

Quad-seal Pouches

These pouches greatly resemble their side fold counterparts but unlike them, they are sealed from all the edges thus coining their name. This sealing style gives them a pronounced rectangular appearance. Quad-seal Pouches are used for packing bulk amount of coffee powders.

Pillow Pouches

These are extremely low-priced pouches and are shaped like a pillow having three types of sealing-bottom, top, and back sealing. Back sealing is positioned across the entire length of bag. It is the most convenient form of fractional packaging.

Side Fold Bag

It is a traditional, inexpensive and useful packaging style which plays a vital role in increasing partiality of brand owners towards this packaging format. Its exceptional geometry and dimension make it a suitable candidate for minimalist styling. However, its bottom folding contributes towards its instability on flat surfaces.

Flat Bottom Bag

This pouch has a flat bottom and is like box thus is one of the most stable packaging type and is quite favored among designers due to the presence of more space for graphics. It is a popular option among USA packaging market. Resealable zipper or tin tie makes resealing of this bag easy when opened.

DoyPack

Doypack or standup pouch is the unorthodox packaging style with a somewhat round bottom and sharp top. They like flat bottom bags and can stand on their own. However, former has 2-3 seal while flat bottom pouches usually have 4-5 seals. Doypacks are extremely popular packaging format in recent years since they are easily produced.

Glass Bottles

Glass bottles are available in many shades and shapes that are chosen by consumers for their clean look. These coffee packaging complement kitchen or dining table. These bottles are best for storing coffee powders.

Bag-In-Bag

Coffee powders also dispense in tea bags for affordable fractional distribution. These small bags are packed inside a large box and are available in numerous flavors that are easily identified by their unique colors. Multiple colors create an artistic effect that is fancied by creative patrons.

4.What Is the Shelf Life of Coffee Packaging?

Shelf life is the time duration between coffee production and the time when coffee loses its safety and nutritional status due to microbial growth, chemical contamination, and environmental conditions.

Packaged coffee powders or beans last longer than opened coffee powders. The shelf life of products usually depends upon packaging material.

- Unopened coffee packaging last about 5 months. Open coffee powders have an expiry date of up to 3 to 5 months in pantry and 2 years in a freezer.

- Glass is an inert material and does not require extra chemicals for protecting coffee powders hence coffee powders in glass jars or bottles can last about 18 months.

- Aluminum foil pouches usually have shorter shelf life than their laminate multilayered counterparts.

5.What Benefits Of Coffee Packaging?

Coffee packaging has several benefits such as:

Safe Transport

Coffee packaging allows them to reach consumers in the safest and most economical way while providing ease of storage. Packaging bulk quantities of material can also save you on transportation expenses.

Product Information

Labeling on packaging will present the user with several information facts about coffee powders such as its nutritional value, expiry date, date of production, manufacturing company information as well as ingredients.

Protection

By packaging coffee powders, you can save them from physical damage such as bruising and hitting while shipment, handling, and delivery.

Hygiene

Coffee powders are essentially packed to ensure their hygienic nature. It prevents spoilage of coffee powders by dust, debris, as well as micro-organisms.

Product Appeal

Striking, colorful graphical packaging is the best means for increasing product appeal. Distinct and optimal packaging style creates brand identity which increases sale chances of coffee powders.

6.Why Do You Need Coffee Packaging?

Coffee packaging is a way of extending the nutritional quality, aroma, taste, as well as color till its expiry period. Packaging is essential in protecting coffee powders from an environmental condition such as:

Moisture

Absorption or removal of water can impact the quality of coffee powders. With a gain of moisture, the powders become lumpy or cakey. Packaging preserves the moisture content of powders that can otherwise change texture and chemical reactivity

Oxygen

The reactivity of coffee powders with oxygen can alter color, taste, and nutritional value, as well as their physical characteristics. Packaging presents a superior barrier against oxygen for maintaining the shelf life of coffee powder. One way of doing this is by flushing nitrogen inside the container before its sealing.

Light

Coffee powders have small quantities of riboflavin or vitamin B12. This vitamin is sensitive to light and can be degraded in excess light. Packaging is an effective and strong shield against a visible and invisible spectrum of light wavelength.

Temperature

High ambient temperatures cause acceleration in chemical reactions of coffee powder with environmental chemicals. Packaging provides protection to coffee powders against high temperatures.

7.What Are Common Coffee Packaging Machines?

Numerous kinds of coffee packaging machines exist in the market nowadays, each processing a different container style. Furthermore, these equipments can differ in its dosing volume. This creates confusion while selecting coffee packaging machines for your business.

Here is a description of some common coffee packaging machines that will aid you in your purchase process.

Jar or Bottle Packaging Machines

These equipments are the most commonly used packaging machines especially for coffee packaging. They can dose large quantities of powders or granules in plastic jars and bottles.

The objective of jar or bottle packaging machines is to fill and seal powders for protection against external environmental agents. These machines enhance the aesthetic appearance of products while preserving the nutritional quality and freshness of coffee till their expiry date.

Coffee packaging by Jar or Bottle Packaging Machines

| Step 1

In first step, the jars or containers are loaded on the conveyor belt that is then moved to sterilization unit. |

| Step 2

In sterilization unit, the containers are sterilized to get rid of microbial growth inside them by heating or using steam. |

| Step 3

The next step is the filling of coffee packaging that is carried out by auger fill. The material move from hopper to the fillers where screw wheels are present that control the filling volume of coffee powders. |

| Step 4

These filled containers then are transported to a capping area where closures like caps and lids are fixed on open mouth jars. After capping, the containers are removed from the machine to shipment area. |

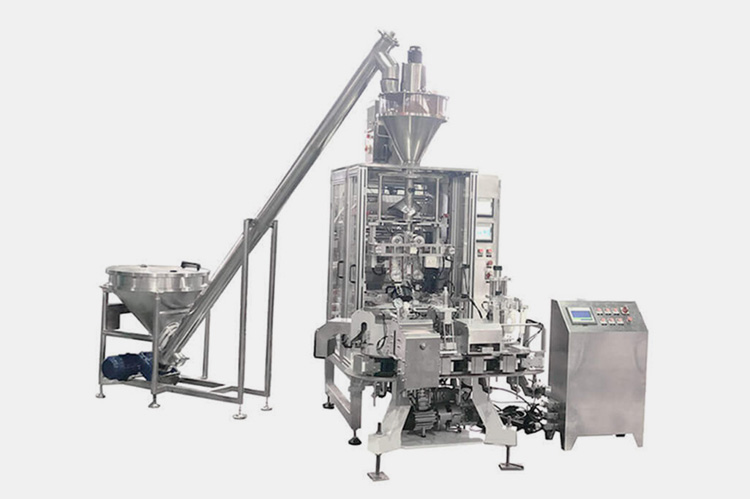

Vertical Form Fill and Seal (VFFS) Machine

VFFS machines are one of the commonly used packaging equipment that are routinely utilize for carrying out packaging of products belonging to different spectrum. These equipments have advance technologies that speed up packaging with minimal product wastage.

These instruments follow hygienic protocols for processing and packing products. This aspect makes them the number one choice of manufacturers for their packaging line. Furthermore, they can conveniently dose coffee packaging in wide ranging pouch styles such as gussets, standup, and doypack.

Coffee packaging by VFFS Machine

| Step 1

First laminated, aluminum, or paper film is fixed on the unwinding device. This gradually unwinds the film and passed it over rollers that aid in the movement of the film towards forming unit. The rollers are responsible for holding the film under right tension. Step 2 The film on reaching forming tube wraps around it and pressed into required bag style. The side and bottom sealing is carried out by the movement of vertical sealing jaws. Step 3 After partial sealing, coffee powders are filled inside the bag by the auger filler attached with VFFS machines. Then horizontal sealing jaws are used for sealing top end of the bag. Finally cutters cut and trim the sides of formed bag. |

Stick Packing Machines

These machines are best known for packaging small quantities of coffee in a stick pack. This packaging is high in demand among on-the-go consumers. These equipments use less film material so these are known for their running expenses saving benefit.

These instruments are a precise system of preparing and dosing coffee powders that are efficient, cost-cutting, and increasingly productive. Stick packing machines offer both tangible and intangible benefits to your packaging lines thus generating a large return on investment.

Coffee packaging by Stick Packing Machines

| Step 1

In first step of packaging, the film roll stock is placed on the unwinding roller. Cutting knifes are used for cutting film into smaller fragments or strips. Afterwards, each individual strip is transported across the series of film rollers. These rollers are essential in keeping the film strips under appropriate tension so that it does not slip up. Step 2 When the strips reach forming structure, these are folded into forming tube. This conical tube produces stick pack from these strips by pressing and folding them. The stick packs are sealed at the sides and bottom by using vertical jaws. Step 3 After partial formation of stick pack, HMI signals for moving material from the hopper to auger fillers. Then these fillers gradually load coffee powder to stick packs by means of gravity or using volumetric filling. Step 4 Horizontal sealing jaws seal the stick pack at the top and cutting blades separate two immediate stick packs. |

Sachet Packing Machines

These instruments are usually employed for forming 3 or 4 sided economic sachets for retail distribution. The sachet packing machine fills 2-3 serving of coffee powders in the sachet and seals all four edges.

These machines are not only affordable but are also quite environment friendly since they cut and seal powders into sachet which reduce huge amount of film material in turn saving your operational expenses. Moreover, sachets can be customized in variety of ways depending upon your brand identity as well as your target market.

Coffee packaging by Sachet Packing Machines

| Step 1

As with all other packaging machines, the working of the sachet is begun by loading of packaging film on rollstock. Then film is unwound by film unwinder and is folded and cut into two halves. These travel on film rollers towards forming the unit. Step 2 This unit is a dome like structure on which two pieces are shaped into sachets. Before filling, the sealing element glues the sides and bottom portion of sachet. Step 3 As soon as sachet is ready, the signal goes to hopper region which moves coffee powders to auger fillers. These machines gradually drop powder particles in sachet. Step 4 Once filling is completed, the top end of sachet is sealed by sealing jaws which weld the two overlapping sides of opening together. Finally, cutting knives are used for cutting two edges of overlapping sachets |

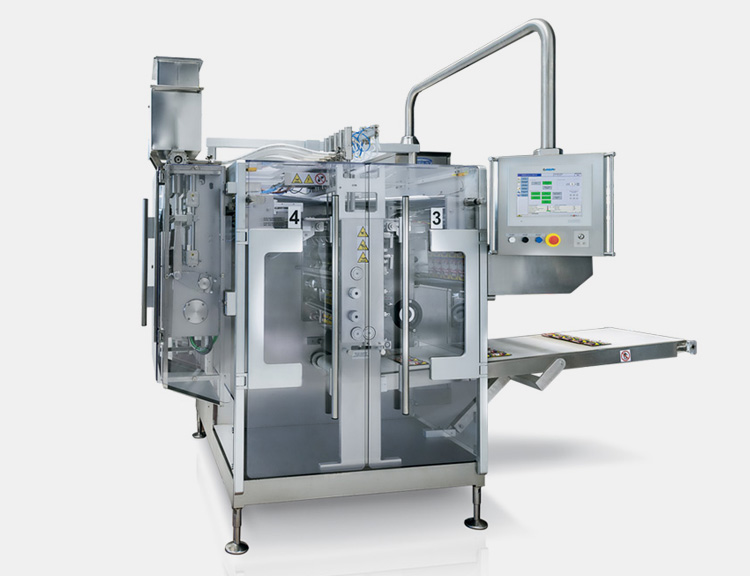

Pre-formed Pouch Packaging Machine

These equipments do not form pouches during packaging operation but fill already manufactured fabricated bags. This cuts down your operational expenses consequently resulting in convenient and customized packaging. These can package and seal every kind of solid, granular, and powdery material.

Premade pouches have a distinctive modern look with easy opening options thus they add value to your products and aid in their prominence on market shelf. These equipments are often supplied with volumetric pumps and multi-head fillers.

Coffee packaging by Pre-formed Pouch Packaging Machine

| Step 1

Preformed pouches are placed on bag magazine. These bags are moved one by one to interior of machine with bag feeder. The grippers hold the bag and moved it to pouch filling station. Step 2 Vacuum suction system gradually open these preformed pouches. A blast of air is blown inside these opened pouches for their full inflation. Step 3 Auger or volumetric fillers gently dose the predetermined quantities of coffee powders inside these opened pouches. After this, extra air is discharged from filled pouches by means of deflators. Step 4 Heat sealing jaws seal top end of pouches by heating and joining two layers together. This results in complete and tear-proof closure. |

8.What Industries Used Coffee packaging Machines?

Coffee packaging machines are the need of the hour and these equipments have found their use in almost every consumer industry. Manufacturers use these systems in their packaging lines because of their ease of operation and precise filling.

Some chief applications of coffee packaging machines are:

Pharmaceutical Industry

Accurate dosing of pharmaceutical powders such as antibiotics, gastric, etc is essential for patient safety. This dosing aids in the right treatment and reducing drug side effects. For this purpose, coffee packaging machine are utilized for dosing precise quantities of medication in sachets, bottles or stick pack.

Food Industry

For efficient and speedy packaging, various food manufacturing lines employ coffee packaging machines. These machines are beneficial in upholding aroma, savor, and nutrition of various food powders and granules such as coffee, milk powders, juice powders, nuts, snacks, chips etc.

Personal Hygiene Industry

Bath salts, teeth whiting powders, shampoos, face cleaners etc are packaged using coffee packaging machines. Packaging created by these equipments is imperative in protection of powders especially hygroscopic ones against moisture and other chemicals.

Cosmetic Industry

This industry is depended upon packaging of face masks, hair dyes, face powders, perfumes, fragrances, and skin care products in attractive and striking containers that captivate and allure customers. These machines handle gentle and delicate powders with great care for reducing their fragmentation.

Pet Industry

Various animal feed, snacks, and bathing powders are packed inside protective packaging by coffee packaging machines for preventing their damage and contamination by microbes.

Agriculture Industry

For shielding agriculture goods such as seeds, organic feed, fertilizers, pesticides, etc. coffee packaging machines are routinely employed in the agriculture industry. The packaging of agricultural powders and granules aids in decreasing their deterioration from environmental conditions.

9.What Are the Parts Of Coffee Packaging Machines?

Coffee packaging machines come with a variety of parts and accessories. Each component has particular job for carrying out efficient and elegant packaging. This includes everything from cables or HMI panels, levers and rollers.

It is essential to have basic understanding of parts present in coffee packaging machine since this can be useful in purchasing and maintaining part inventory.

Some essential parts offered with coffee packaging machines are described below:

| Part | Description | Picture |

| HMI Interface

|

This part aids in easy and trouble-free commanding of operational parameter. Data recipes can be stored on this smart HMI for an easy format change. Moreover, the display screen reports full working progress at regular intervals. |  |

| Forming Tube | This dome like part resembles like human collar and form and shape pouch or bags. The film goes around forming tube and which then get transformed into pouches or other containers such as stick or sachet. |  |

| Sealing Jaws | These sealing jaws provide airtight and tear proof superior quality sealing. The pressure and temperature excreted by these sealing bars glues the two sides of film together. |  |

| Sensors | Coffee packaging machines are equipped with cutting-edge sensors that identify film spillage as well as under tension in the film. These also notify users of electric and mechanical faults by ringing out alarms. |  |

| Cutting Knifes | These are blade like structure with sharp ends for cutting and trimming edges of bags or pouches. |  |

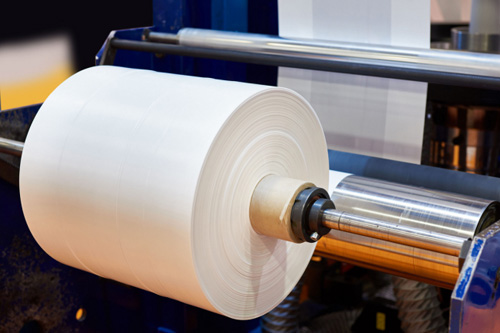

| Film Roll Device | Laminated plastic, paper, or aluminum film is placed on shaft assembly that helps in gradual unwinding of film. |  |

| Film Pull Belts | Two pairs of pull belts present on left and right side of machine assists in keeping the film under desired tension and minimizing the chances of film spillage. |  |

| Hopper | It is a conical device which is often used for storing the coffee powders before filling. |  |

| Feeder or Fillers | Auger Feeders are the parts which assist in accurate and precise loading of coffee powders in the containers. These have screw wheels for adjusting metering volume of powders before every batch. |  |

| Gas Flush Device | These devices are often employed for inflating the pouch or bag. Moreover, it replaces oxygen with nitrogen for retaining the freshness and flavors of coffee till expiry period. |  |

10.What Materials Are Used For Manufacturing Coffee packaging?

Brand owners are always in search of perfect packaging material and spend millions of dollars on their pursuit. Eco-friendly materials add value to your packaged product on the market shelf and are well-liked by consumers all across the globe.

Some basic raw materials for packaging coffee powders are:

Rigid Plastics

Manufactured from HDPE and PET, these are more strong, durable, and rigid than other plastic kinds. They both form firm barrier and have high moisture resistance. Rigid plastics are unbendable thus impart highest protection to coffee packaging against mechanical damage.

Flexible Plastics

These include LDP and LLDP and are considered among best material for offering puncture resistance. These vary in thickness, flexibility, and stretching properties and thus can be bended in various styles generating distinct geometric shapes for packaging.

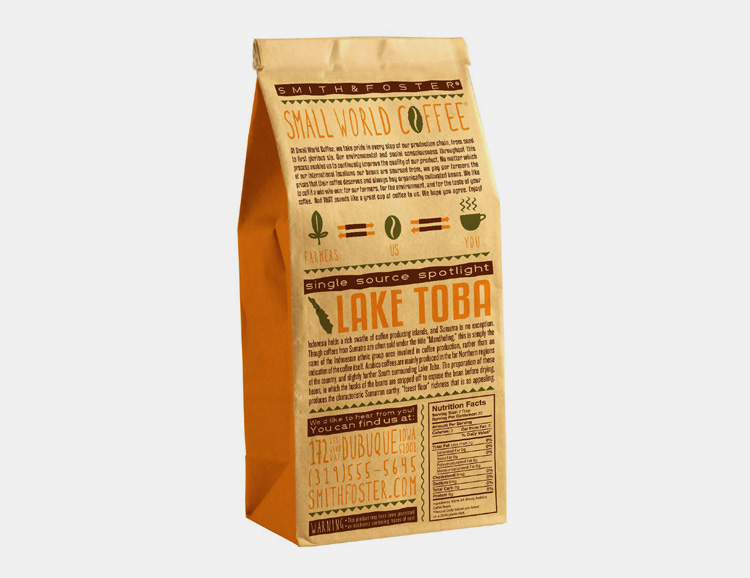

Paper or Fiberboard

This material is highly in packaging world for both primary and secondary packaging. This comes in range of thickness. Some paper types for packaging include kraft paper, plain paper pouches, and more. This is the most favorite contender material for green and climate friendly packaging.

Glass

Although industries have switched from glass to plastic for producing packaging containers still various traditional manufacturers prefer to use glass for holding coffee powders. It is the most inert material that forms a superior barrier against external agents and environmental conditions. Bottles and jars produce by glass have a 100% recycling rate.

Aluminum or Tin

Cans for packing coffee powders are predominately made of aluminum or tins. Moreover, aluminum foil is also employed for making bags or pouches. These metals have the best protection characteristics that aid in reducing product spoilage. These metals are the ideal choice of manufacturers since they can withstand recurrent movement throughout the delivery chain.

11.How Coffee Does Come in Sustainable Packaging?

With introduction of many climate awareness initiatives, people are becoming more and more environmentally conscious. They are going for packaging that generates zero carbon during its production as well as materials that are green and eco-friendly.

- Today, aluminum and tinplate are considered as best materials for developing sustainable packaging. These materials are repeatedly recycled and reused which cut down pollution.

- Manufacturers prefer to use these materials for their packaging as they both are extremely durable and flexible. Furthermore, these metals are malleable and are molded into different contemporary shapes and designs. These can last through multiple supply chains.

- Innovations are carried out all across the globe for creating sustainable plastic packaging for coffee powders. These plastic bio-filled plastics and bioplastics are broken down in presence of UV light and heat by the action of bacteria and fungi.

12.What are the Trends in Coffee Packaging Design?

Companies are introducing innovative trends in coffee packaging design that give them an edge on their competitors. Artistic and minimalist packaging ideas and colorful graphics are considered to be useful tool for increasing product appeal among chic and stylish consumers.

Topographical-Printed Designs

Topographical or typeset packaging design gives packaging a distinguished appearance and creates brand exclusivity. This type of designing becomes trendy in recent years and is distinctive approach to grab attention of coffeeholic patrons. You can count on this tried-and-true way of printing for improving your packaging allure.

Minimalist Design

Minimalist designing has become a new go-to approach of designers when designing the packaging. This does not have funky graphics to divert consumer attention but rather have simple design that focus their concentration on product information.

Traditional Austere Raw Materials

Eco-friendly campaigns have increased in number in recent years and people are now opting for brands that adopt green approaches in packaging. Traditional compostable materials are now becoming fashionable in this era. There has been progress for developing packaging that reflects raw materials of coffee such as earthy textures and tones.

Color Layering

In 2022, there has been emphasis on color layering and geometric pattern when it comes to packaging. This patterning creates a ripped off arty effect that is admired and appreciated by artistic consumers. These raw textures generate the essence of recyclability and beauty that go with subtle and energetic brand image.

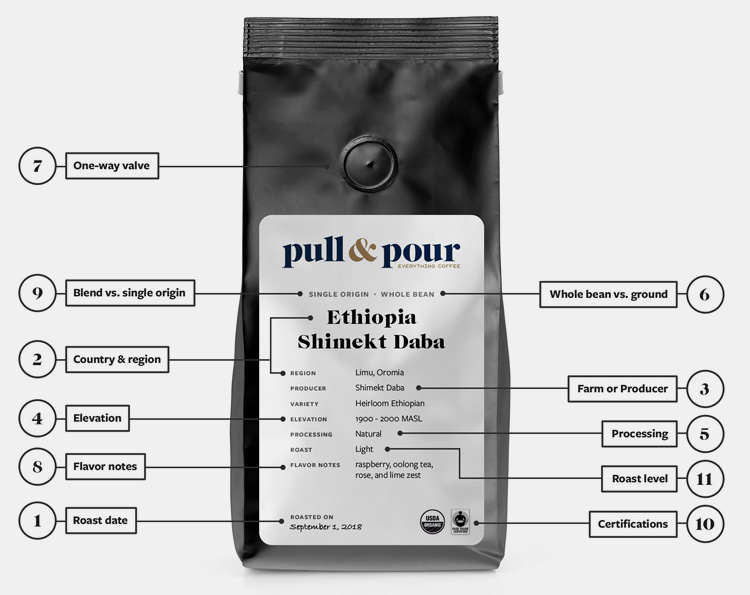

13.What Are Details on The Coffee packaging Label?

Once you have selected the suitable packaging style for packing your coffee powders, next step is to decide what informational facts you want to put on your packaging labels.

Some ideas for printing graphics are:

Flavor and Roost Profile Particulars

Roost type is customary information usually found on coffee packaging label. It is a way to inform consumers about which roost kind (light, medium or dark) is present in coffee powder package. Beside this, you can include information regarding taste note of your product and its recommended brewing way.

Coffee Origin

Coffee comes from various countries such as Brazil, Ethiopia, Vietnam, Colombia, etc. Coffee lovers have their favored coffee producer. It is good move to incorporate details about the origin countries for your coffee powders. You can go step beyond and add in specifics of your coffee processing method.

Ingredient and Nutritional Profile

It is routine to mention ingredient and nutritional information on your food packaging label. This notifies the coffee lovers about the amount of caffeine and calories they are going to consume per serving.

Brand Journey

Short description about your brand is a unique opportunity to connect and build repute among your customers. Interesting facts about your travels in order for finding best combination of coffee make you stand out among your competitors. Highlighting your sustainability and eco-friendly efforts will earn you brownie points among earth loving patrons.

Expiry Date and Certification

Last but not least, it is crucial that you print the expiry date on your packaging label. Thereby, consumers know under what time duration they should consume coffee powders for making best use of nutrition and flavor. Placing certification on packaging addresses the concerns of fair trade, sustainability, and quality harvesting.

Conclusion

In brief, great coffee packaging plays a pivotal role in keeping coffee fresh for a longer time and allowing consumers to experience the product as they intended. With so many coffee connoisseurs around you, we recommend manufacturing brands choose the right coffee packaging designs and machines for perfect outcomes. Want To Get the Perfect Coffee Packaging Machine For Your Production Line? We can help you! Drop us a short message for further details.

Don't forget to share this post!

Powder Filling Machine Related Products

Powder Filling Machine Related Posts

Powder Filling Machine Related Videos

10 Inspirational Graphics About Powder Filling Machine

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine