Choosing the Right Capsule- A Story from Gelatin to a Polymer

The pharmaceutical industry always strives to meet the therapeutic requirement of the patient and better formulation development. Let’s talk about choosing the right capsule! The manufacturer must be familiar with every component and the behavior used in the manufacturing pharmaceutical capsule. In order to understand the role and response of ingredients employed in pharmaceutical capsules, we will examine the material of the shell used in the capsule i.e., hard gelatin, soft gelatin, etc., and critically discuss its importance.

1.Selecting A Capsule Type

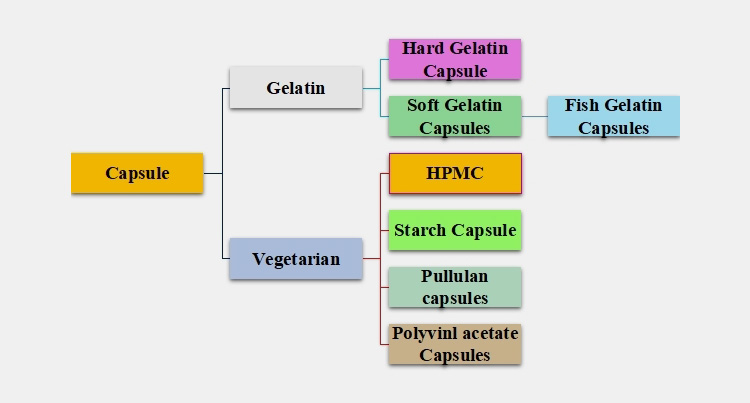

Selection On the Basis of Shell Material

Capsules are categorized into two major kinds based on the composition of shell coat material. Your customer preference plays a significant role in selecting capsule on the basis of shell material.

Types Of Capsules on The Basis Of The Shell Material

Gelatin Capsules

The shell of these capsules is formed by the material derived from animal sources. This material is gelatin which is made from collagen protein present in animal bone marrow tissues.

These capsules do not protect humidity sensitive compounds from moisture because water vapors can easily move inside the shell.

Customers prefer these capsules as they are more fairly priced than their vegetarian counterparts.

These are widely used form of capsules and are further divided into two types.

Hard Gelatin Capsule

They are two part capsule and are formulated by hydrolysis of collagen protein. The outer shell of hardgel capsules has body and cap which are tightly fitted together for encapsulation of materials inside them.

These are cylindrical or oblong in shape. The proportion of plasticizer is hardgel capsules is 0.4:1.0

Soft Gelatin Capsules

These are one piece capsule. They are employed for dispensing oily formulations and supplements. Softgel capsules are generally soft, round or oval and the shell of these capsules is much thicker than hardgel ones.

They contain more plasticizer than their hardgel counterparts and the ratio of plasticizers is 0.8:1.0.

One specific kind of softgel is fish gelatin capsules.

Fish Gelatin Capsules

These are also known as marinecaps and are usually manufactured from the gelatin source found in fish. These are commonly used today since these do not pose the risk of bovine spongiform encephalopathy (BSE) or transmissible spongiform encephalopathy (TSE)

Marinecaps are used for filling fish oils such as EPA (eicosapentaenoic acid) rich fish oil, glucosamine, omega 3 fatty acids etc. These are beneficial since they give a lot of boost to health

Vegetarian Capsule

Plant derived materials are used for making vegetarian capsules. These capsules are good for people who are on vegan or vegetarian diet. Sub-kinds of vegetarian capsules are:

HPMC

HPMC or Hydroxypropyl methyl cellulose is a kind of vegetarian capsule usually formulated from the cellulose component found in the cell wall of plants. These are typically employed for encapsulating various nutraceutical supplement, herbs and dietary nutrients.

These are ideally best for delivering hygroscopic powders as their shell is resistant against moisture. Secondly, since they are not manufactured from animal source so they do not cause BSE or TSE.

Starch Capsules

These capsules are unique as their shell material is derived from potato starch. These are the best capsules for formulating enteric coating capsules since their disintegration is not dependent upon acidic pH.

Starch capsules have numerous benefits over traditional gelatin capsules such as moisture protection and low charge. They are one of the safe vehicles of administrating pharmaceutical and nutraceutical products. These capsules have moisture content about 12–14% w/w.

Pullalan Capsules

They are made from tapioca, a sugar which is fermented to produce pullalan. It is organic capsule and good alternative to animal-based gelatin capsules.

These capsules offer best protection to fill material in oxidative environment.

Polyvinl acetate Capsules

They are manufactured from wood glue and are used for encapsulating poorly soluble or insoluble drugs. These drugs are dissolved in polyethylene glycol (PEG) 400 solvent.

PVA capsules provide superior barrier against oxygen as PVA is impermeable to oxygen.

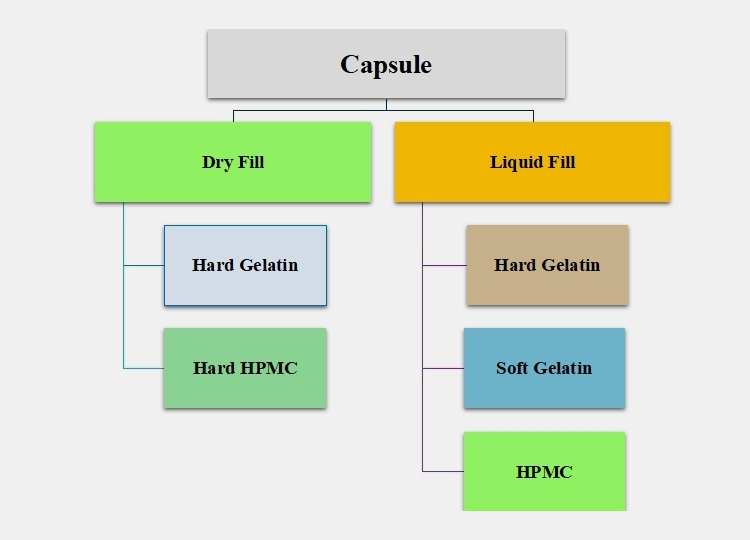

Selection On the Basis of Encapsulation Material

It is usually depended upon the physical state of the fill drug. There are different kinds of capsule available in market on the basis of nature of encapsulation material.

Major types of capsules based on characteristics of fill material are given below:

Selection On the Basis of Encapsulation Material

Dry Fill Capsule

They are utilized for filling solid ingredients such as pellets, powders, minitablets, beads, granules. These ingredients are encapsulated either in combination or one at a time.

Liquid Fill Capsule (LFC)

These are two piece or one piece hardgel, softgel, and HPMC capsules employed for encapsulating liquids of various kinds such as solutions, emulsions, suspensions, oils, pastes, etc.

These are also used for filling liquids in combination with beads, pellets, and granules. Moisture liable drugs are encapsulated using LFCs..

They offer several benefits and are cost-effective substitute to softgel capsules. They boost the bioavailability of ingredients and are often employed for increasing ingredient stability. LFC have protection against mechanical wear and tear and rough handling.

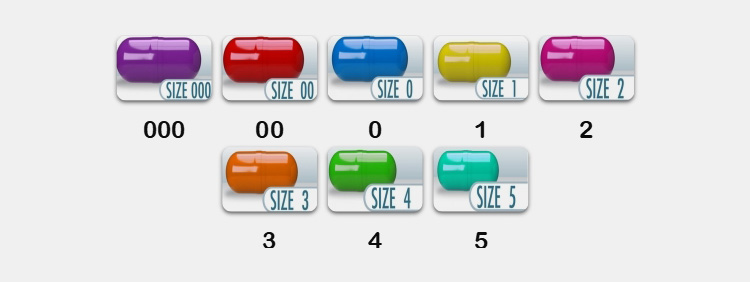

Selection on the Basis of Size

It is important to know about the volume of formulation liquid before selecting the size of capsule as sizes are depended upon the amount or volume of fill material.

If you have large volumes for encapsulation then opt for 000 or 00 sized capsule. But if you are dealing with small doses then select 4 or 5 sized capsule.

Knowing weight (amount of dose in milligram) and formulation density will aid you in selecting right sized capsule. Density is estimated by equation

Density = Mass (g) /Volume (ml)

| Empty Capsule Sizes | ||||||||||

| Capsule Size | 000 | 00E | 00 | 0E | 0 | 1 | 2 | 3 | 4 | 5 |

| Locked Length (mm) | ||||||||||

| Length | 26 | 23.4 | 23.3 | 23.1 | 21.7 | 19.4 | 18 | 15.9 | 14.3 | 11.1 |

| Empty Capsule volume (ml) | ||||||||||

| Capacity | 1.37 | 1.00 | 0.90 | 0.78 | 0.68 | 0.48 | 0.36 | 0.27 | 0.20 | 0.13

|

| Formulation Density (g/ml) | ||||||||||

| 0.6g/ml | 822 | 600 | 540 | 468 | 408 | 288 | 216 | 162 | 120 | 78 |

| 0.8g/ml | 1096 | 800 | 720 | 624 | 544 | 384 | 288 | 216 | 160 | 104 |

| 1.0g/ml | 1370 | 1000 | 900 | 780 | 680 | 480 | 360 | 270 | 200 | 130 |

| 1.2g/ml | 1644 | 1200 | 1080 | 936 | 816 | 576 | 432 | 324 | 240 | 156 |

Selection of capsules on the Basis of Size

Calculate the density by above mentioned formula if your density is assuming 0.6g/ml, and then look for your formulation volume (600) in the row next to 0.6g/ml density. Based on the assumption you should select 000E capsule.

2.Beneficial Features Capsules Offer Over Other Dosage Forms

Looking at the actual formulation trend manufacturers and formulators prefer choosing tablets over capsules as they are cost -effective, but when developing medicines, or require special like speed of absorption, taste, or bioavailability, capsule can have more importance over other dosage form. A strict timeline in development prefers use of simple, effective, and potent capsules.

Special Dosage & Ease of Formulation

Without compromising the special consideration to pediatric or geriatric population who require modulatory doses and special strength; capsule is preferred dosage form.

Granular and Sprinkle Dose

You can make your own formulation, dosage requirement, use material like powders, oil, sprinkle substances, or mix doses using capsule dosage form.

Customized and Unique

Different sizes, multi-colors and various imprint option will make your product unique using capsules. Similarly, you can employ capsules for inhalation drug therapy where dry-powder-inhaler substances are filled using equipment. This technique is preferred and used all around the world.

Better Releasing Characteristic

Multiparticulate substances like pellets, mini tablets, can efficiently release their response via capsule dosage form without compromising its functional release. On large manufacturing scale mode of delivery is used and bespoke solution to serve different category population and capsule needs.

3.Manufacturing of Capsules Requires Specific Formulation Adaptations

Capsule is a useful oral solid dosage form whether your manufactured product existing as liquid, granules, powders, or gel etc., It gives you combine advantages with greater flexibility, patient compliance, and delivers ‘Active Pharmaceutical Ingredients’ (APIs) in an ideal condition.

The special formulation requirement of capsules as per manufacturer aspect is discussed below:

When it comes to hard gelatin capsule, there are various special consideration are addressed. Most significantly, it must not be comprised with percent solvent that could react with plasticized gelatin and interact with capsule’s structure to damage. You must have heard about cross-linking! That’s because of reactive aldehyde results in cross-linking on capsule’s shell overcoming its ability to dissolve.

All hygroscopic material has capability to absorb excessive moisture from plasticizer. This creates brittleness in the capsule structure as well as it affects physiochemical modification in active ingredients. To deal this challenge manufacturers have limited the use of moisture content and prefer using polymers i.e., HMPC or non-hydrous plasticizers.

In a nutshell to induce pharmaceutical response, you’ll be required single active component and various material used into the formulation, processing, and packaging. You can adapt and use formulation requirement once you fully understand the properties of the material and process parameters.

4.Capsules Aid in Speeding Up Drug Development Timelines

Capsule dosage forms have evolved to an extent where furthermore and newer kinds of capsules and their excipients have come across. To no astonishment, encapsulated drug or even a conventional blend is still considered to be the choice of preference for first human trials. Many amongst them of Phase I preparations are getting the coveted accomplishment and the rest of the capsules reach and makeup to the markets successfully.

Pharmaceutical experts favor additionally challenging preparations rather than any casual blending and capsulation process. Owing to the obvious increased cost and expenses, it seems evitable to be questioned about over-manufacturing certain types of products under construction.

5.What Are the Advantages of The Soft Gel Capsules Versus Hard Gel Capsules?

Today, soft gelatin capsules and hard gelatin capsules offer you more and more innovations that are being offered by pharmaceutical and biological sciences. Each innovation is made for patients belonging to different age categories. Here are a few advantages of soft gelatin capsules versus hard gel capsules that will tell why they’re in trend!

- Soft gelatin capsules are appropriate for water-loving liquids but unsuitable for heat liable products. Hard gelatin capsules have comparatively a wider range of options available when it comes to its liquid filling.

- Oil based formulations can be contained usually in soft gel capsules. In hard gel capsules, volatile substances cannot be filled whereas soft gel capsules can hold such volatile liquids.

- Soft gel-manufactured capsules are costly to produce. Hard gelatin capsules are not appropriate for bulky materials. In hard gelatin capsules, unique form of mix fills is possible whereas soft gel capsules are not adaptable to mix filling.

- Softgel capsule offering a high degree of reproducibility which is not possible with powders or granules to manufacture tablets or hard-gel capsule. This is because liquid fill is measured into assign capsules via positive displacement pump.

6.Significant Innovations in Capsule Formulation

Currently great discovery has been found in the area ofan upgraded therapeutic system called as 505(b)(2) or hybrid type application. Drugs that are identified or known are being remodeled involving advanced technologies to attain a good effectiveness and drug safety profile by skipping medicinal errors. Many advancements are arising in capsules. Life threatening diseases can now be combatted by high dose drug molecules with the help of their delivery via spray particles.

Research based on microbiota indicates that capsules would be the chosen preference due to its protective ability against gastric juices and moisture, and because of its release at intestinal site.

7.Specific Regulatory Considerations Surrounding Capsule Formulations?

Capsules are one of the widely recognized and acknowledged dosage formulations. However, still, regulations are constantly growing globally towards more patient-oriented approach and for the quality maintenance and effectiveness of drugs.

European Medicines Agency has stated pharmaceutical development regarding medications for the older population and FDA has also started an approach towards developing a more patient-centric drug.

Conclusion

In terms of manufacturing and marketing, the capsule is a versatile drug delivery system that can be optimized for a broad array of formulations contributing great market value. Moreover, the capsule impacts a cost-effective and time-effective mode of delivery throughout the development phase of the drug. In conclusion, selecting the right capsule exerts notable advantages considering the entire drug’s Lifecycle (manufacturing to consumer). If you have any queries or need assistance related to capsule manufacturing; we suggest contacting our manufacturing team for a free consultation.

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours