The Most Comprehensive Buying Guide of Sachet Filling Machine in 2025

When you're eating at a fast food restaurant or when you're traveling, a ketchup sachet or lotion sachet can be a lot more convenient for you rather than a large bag or bottle. However, have you ever wondered what machines are used to make these convenient sachet products? That's right, the Sachet Filling Machine. Let's explore this amazing machine together. Here are some tips for you below.

1. What Is Sachet Filling Machine?

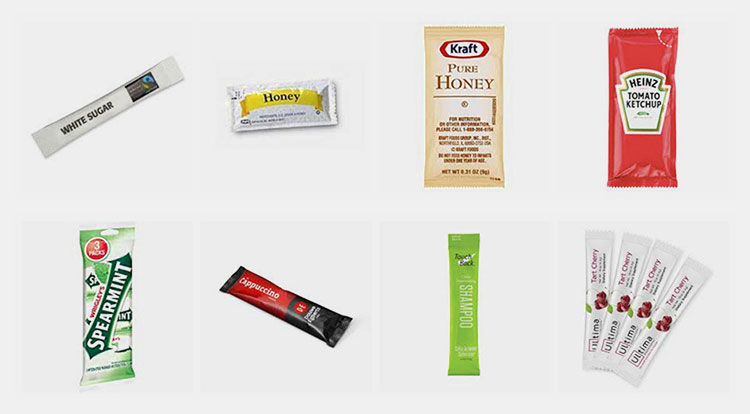

Sachet Filling Machine also can be called Pouch Filling Packaging Machine and is a kind of filling and sealing machine for materials such as granules, powder, and liquids or sauces with little pouches.

A variety of heat-sealable composite materials can be used for the package with low noise, clear sealing texture, and well sealing.

Sachet Filling Machine is suitable for automatic or semi-automatic packaging of liquids, powders, granules of foods, medicine, and chemicals, such as shampoo, bath foam, body lotion, facial cream, shower gel, skin lotion, toothpaste, cosmetic cream, fruit jam, tomato sauce, ketchup, and honey, etc.

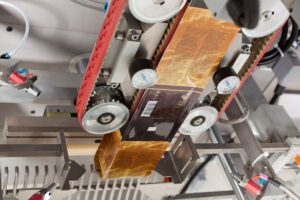

Sachet Filling Machine Filling Process:

Forming bag - measuring - material filling - sealing - counting - date code printing, all the work automatically. And it will stop automatically if it is out of film or running out of time.

Sachet Filling Machine can be installed to code printer for 1-3 lines characters such as production and expiry date according to your special request.

How are you feeling about Sachet Filling Machine? This kind of machine can helps your life with multiple functions.

2. Which Fields Are Sachet Filling Machines Mostly Applied?

The Sachet Filling Machine is mainly applied in three kinds of production lines. Including daily chemical production lines, food production lines, and pharmaceutical production lines.

Daily chemical production lines: It is suitable for the filling of products such as liquid washing, washing care, lotion, and cream.

Food production lines: It is suitable for filling various sauces and beverages.

Pharmaceutical Production Lines: It is suitable for filling reagent tubes such as sampling tubes.

Sachet Filling Machine is widely applied in daily chemical, oil, and other industries, and can be used for filling different high-viscosity fluids, powder, granules, and paste. Such as hand soap, care solution, oral solution, hair care solution, hand soap, skin care solution, disinfectant, liquid foundation, antifreeze, shampoo, eye wash, nutrient solution, injection, pesticide, medicine, cleaning, bathing Dew, perfume, edible oil, lubricating oil and liquid filling in special industries.

There are so many materials that you can fill and pack with Sachet Filling Machine. It will bring a lot of convenience and fun to your life.

There are also so many industries and lines to that you can apply the Sachet Filling Machine with.

3. How Many Types of Sachet Filling Machines Are There?

Sachet Filling Machines are mainly a small category of products in packaging and filling machines.

There are many types of Sachet Filling Machines. Different materials require different Sachet Filling Machines. The types of filling are mainly divided into solid, gas, liquid, paste, powder, and so on.

From the perspective of packaging materials, they can be divided into Liquid Sachet Filling Machines, Powder Sachet Filling Machines, Granule Sachet Filling Machines, and Sauce Sachet Filling Machines.

Liquid Sachet Filling Machine can fill a variety of fluid items in the food industry, beverage industry, medical industry, chemical industry, etc., such as antifreeze, glass water, alcohol, 84 disinfectant, disinfectant, mineral water, pesticides, eye drops, and other items.

Powder Sachet Filling Machine is suitable for the quantitative filling of powdery and small granular materials in chemical, food, agriculture, and by-product industries. Such as pesticides, veterinary drugs, disinfectants, washing powder, grain, seeds, milk powder, condiments, monosodium glutamate, salt, sugar, additives, etc.

Powder Sachet Filling Machines have microcomputer control and accurate quantitative. Parameters can be adjusted, and errors can be automatically corrected. The strong and weak electricity are separated without interference.

High reliability and wide adaptability. The filling parts are made of all stainless steel with high machining accuracy, good interchangeability and reasonable grading. Modular design, flexible combination.

Granular Sachet Filling Machine is suitable for medicine, daily chemical, food, pesticide, and special industries, it is ideal filling equipment for granular slurry viscosity fluid. This machine is an automatic piston-filling machine, which can fill granular slurry fluid materials.

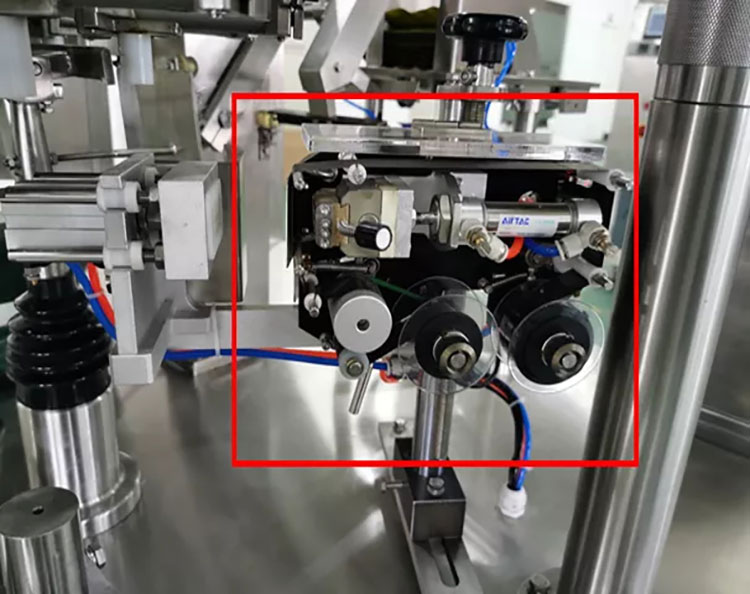

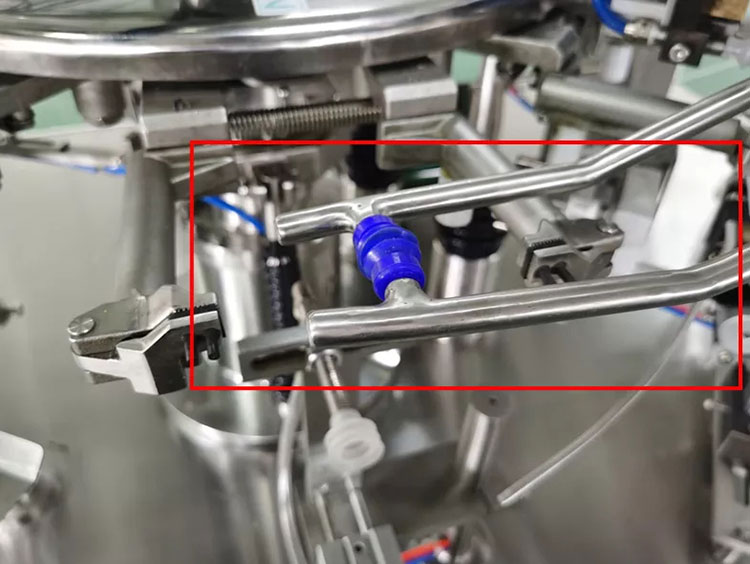

Material contact parts of the Granular Sachet Filling Machine are made of 316L stainless steel, which meets GMP requirements. The filling valve is controlled by a pneumatic valve, and the filling accuracy is higher. The filling volume and filling speed can be adjusted arbitrarily. The filling head adopts the anti-drawing and lifting filling device.

Granular Sachet Filling Machine is a small model with a vertical structure, saving space. It is easy for you to operate, and the pneumatic components are all made of German FESTO and Taiwan AirTac pneumatic components.

Sauce Sachet Filling Machine is suitable for the filling of viscous sauces such as chili sauce, bean paste, peanut butter, sesame sauce, jam, butter hot pot base, red oil hot pot base, and other substances with particles and high concentrations in condiments.

Sachet Filling Machines also can be divided into Food Sachet Filling Machines and Chemical Sachet Filling Machines.

The general price of Food Sachet Filling Machines is relatively cheap, but Chemical Sachet Filling Machines are more expensive. Food Sachet Filling Machine is generally filled in small packages, and the chemical type is generally filled with chemical products. And the standards of enforcement are all different.

According to the operation process, it can be divided into Automatic Sachet Filling Machine and Semi-automatic Sachet Filling Machine.

Semi-automatic Sachet Filling Machines require manual operation and are relatively slow. Usually, it requires one to two staff in site to control. Depending on your own requirements and the actual production materials, the semi-automatic packaging machine equipment used for different products is different.

But the price is lower. If you have a limited budget and use it in a small area, then we recommend you choose the semi-automatic type.

Automatic Sachet Filling Machine is a kind of weighing filling machine, suitable for liquid materials with low viscosity. For example, paints, coatings, resins, and various chemical raw materials.

Automatic Sachet Filling Machine generally does not need manual operation, the speed is relatively fast, and the price is relatively high; it can automatically complete feeding, bag making, measuring, filling, sealing, coding, etc., and requires one person to monitor.

This machine is suitable for factories with large output; if you have a large demand for material packaging and commercial use, then we recommend you choose the fully automatic type.

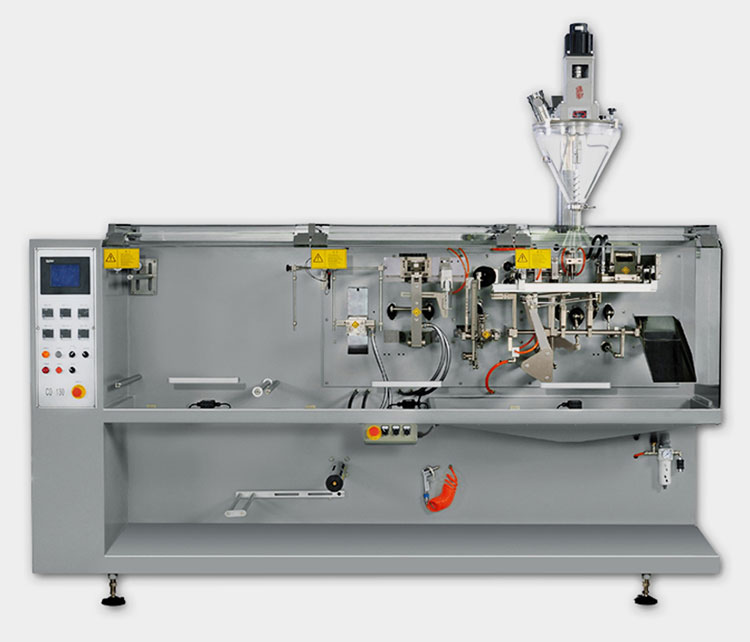

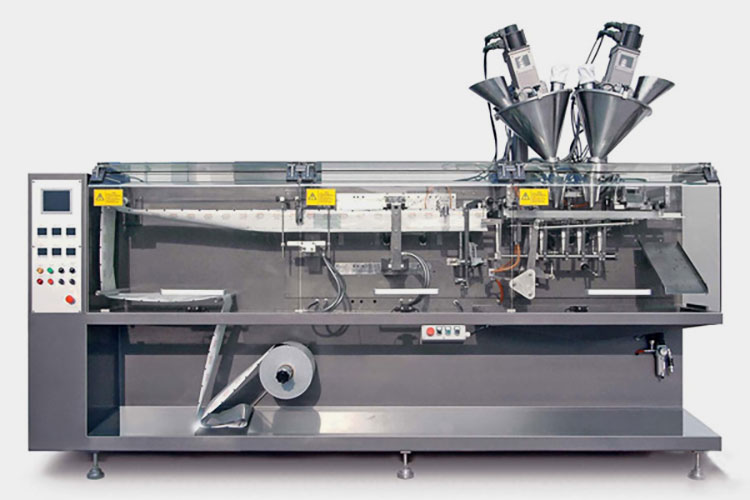

From the design of the machine, there are Vertical Sachet Filling Machines and Horizontal Sachet Filling Machines.

Horizontal Sachet Filling Machine is suitable for packaging various liquid products in special-shaped bags, such as various emulsions, essences, beverages, jams, yogurts, etc.

With different needs that there are so many types of Sachet Filling Machines, so you really need to think about how to choose the perfect Sachet Filling Machine to suit your own needs.

4. What Are the Main Structures of the Sachet Filling Machine?

Different Sachet Filling Machines have different structures, do you know their structural differences?

Here we will take examples of the Vertical Sachet Filling Machine, Horizontal Sachet Filling Machine, and Vertical Automatic Sachet Filling Machine below.

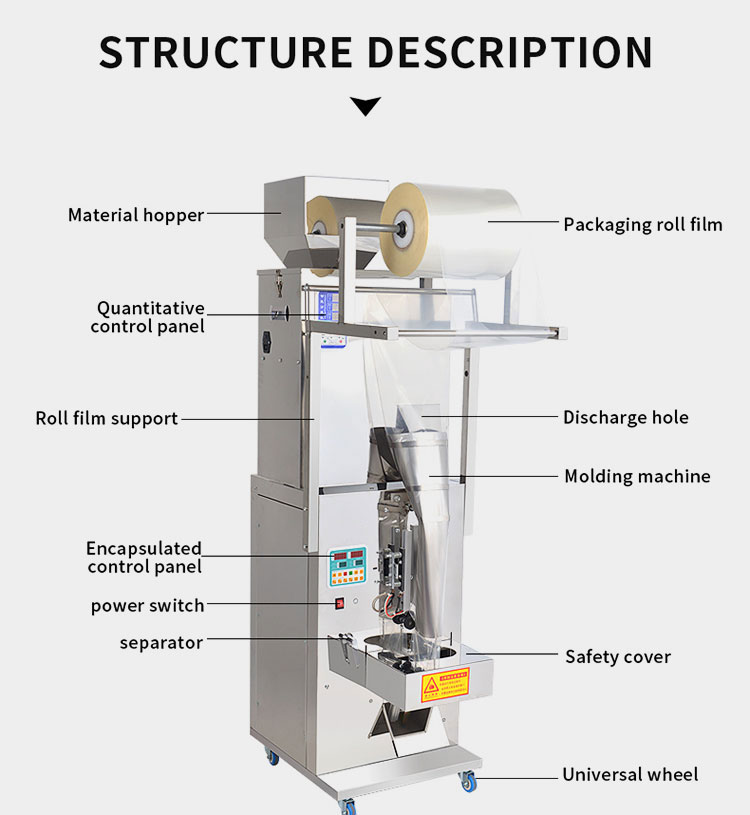

Vertical Sachet Filling Machine: There are 11 main parts of this type.

Including Material hopper, Packaging Roll Film, Quantitative Control Panel, Roll Film Support, Discharge Hole, Molding Machine, Encapsulated Control Panel, Power Switch, Separator, Safety Cover, and Universal Wheel.

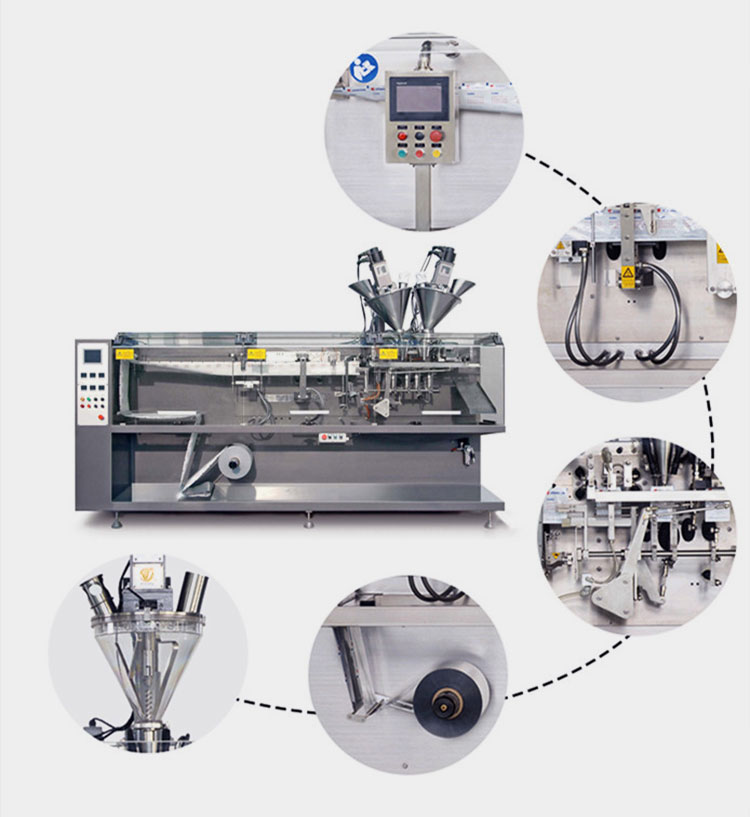

Horizontal Sachet Filling Machine: There are 5 main parts of this type.

Including Switch Panel, Power Supply, Pull Belts, Winding Rollers, and Hopper.

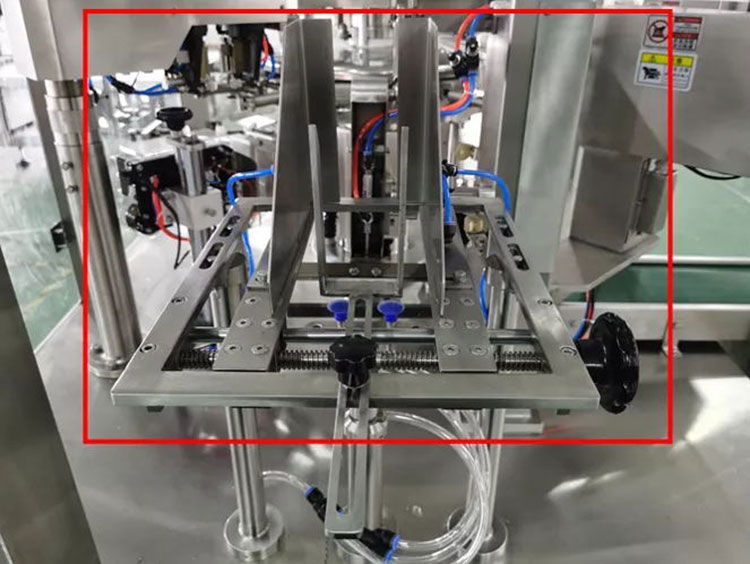

Vertical Automatic Sachet Filling Machine: There are 6 main parts of this type.

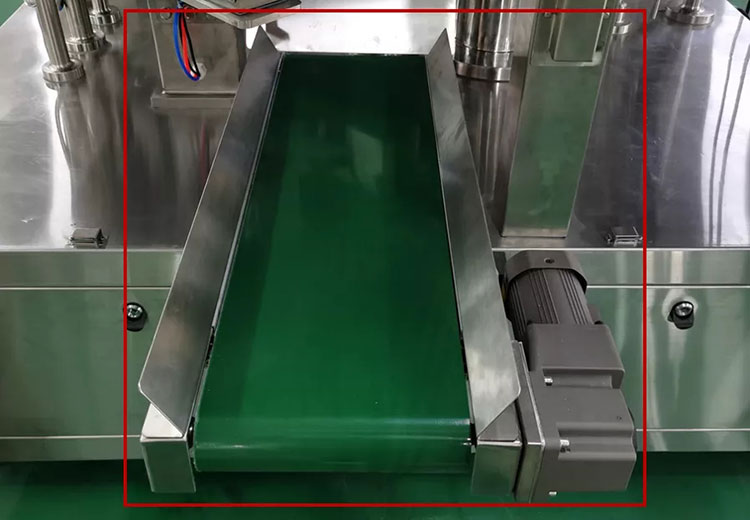

Including Touch Screen, Vertical Type Premade Pouch Magazine, Date Coder, Pouch-top Open Device, Heat Sealing Bar, and Output Conveyor.

This machine is a fully automatic Sachet Filling Machine without human work. It is suitable for large commercial use at an expensive price.

The structure of Sachet filling machines is not complicated and most of them are automatic. The operation is not difficult with the help of the operation tutorial, and it's easy for you to learn, so you don't have to worry about it.

5. What Filling Methods Does Sachet Filling Machine Have?

Atmospheric Filling Method: This type of equipment usually raises the storage tank to increase the pressure. Filling is powered by your own body weight. This kind of filling machine can be divided into timing filling and constant volume filling. This filling machine is suitable for the processing of milk, grape wine, and other products with good fluidity and low viscosity.

Pressure Filling Method: This type of equipment is filled under conditions of higher than atmospheric pressure. One is to use the pressure in the storage tank to be equal to the pressure in the bottle, and the liquid material flows into the bottle by its own weight, also known as isobaric filling. The other is to add a booster piston at the top of the storage tank to help complete the process. Common filling products are beer, champagne, beverages with gas, etc.

Negative Pressure Filling Method: This type of equipment is also called a vacuum-filling machine. It is necessary to ensure that the pressure in the bottle is lower than the atmospheric pressure, and then the product is filled and filled according to the principles of air pressure balance. This type of equipment is generally simple in structure, but has strong air-tightness between components, and does not require a large amount of material viscosity. It can complete the processing of syrup, oil, sauce, and other products.

6. What Are the Advantages of the Sachet Filling Machine?

Different people will definitely have different needs when you use Sachet Filling Machine. While I don't know why you are interested in Sachet Filling Machine, I do know that Sachet Filling Machine must have the features and benefits that you need.

Automation: The automation of the sachet filling machine can complete all processes, such as filling, weighing, etc. Intelligent PLC controls the speed of the entire production line.

Low Cost: It can reduce your labor costs, save space, reduce your rent, etc., and reduce the waste of raw materials.

Job Simplification: If you use Sachet Filling Machines to help your work and business, it can simplify your manual process, and the operation is simple and easy for you to learn.

High quality: Through mechanization, the hygienic environment inside the mechanical conveying system is very stable, which reduces the risk of contamination.

Improving Production Capacity: Through mechanization, the sachet filling accuracy is increased and the operating rate is increased. It can greatly improve your work and business efficiency.

Flexible Production System: The production line can be adjusted. You can adjust the speed of the production line in the peak season and slow down the production line in the off-season.

Production Process Visualization: It can improve your work and business efficiencies, such as improving product safety and reliability, inventory, and quality control through the production process visualization.

Sachet Filling Machine is currently widely used in the food industry, beverage industry, daily chemical industry, and chemical industry.

Stable Performance: This machine has the high degree of automation, high efficiency, stable performance with good materials, excellent quality, accurate filling and measurement, and durability and stability in processing and production operations.

Personalized Customization: Sachet Filling Machine is very suitable for filling some small bag products. At present, professional Sachet Filling Machine manufacturers support various output specifications for your personalized customization.

Well-known Brand Parts: Sachet Filling Machine manufacturers use well-known electrical brands for machine parts, such as Schneider, Siemens, Mitsubishi, Autonics, AirTac, etc., to achieve modern man-machine control.

Production Line Connection: Sachet Filling Machine can be used alone or connected to the production line. The equipment is made of stainless steel, with a compact structure, perfect control system, convenient operation and high degree of automation.

If you choose professional high-quality equipment that will be, a powerful guarantee for realizing your value.

High Filling Precision: Sachet Filling Machine adopts automatic filling, with high filling precision. You can adjust the size of the whole bag according to the materials of different specifications.

Sachet Filling machines can be used with automatic assembly lines.

Simple and Convenient: Its operation, accuracy error, installation adjustment, equipment cleaning, maintenance, and other aspects are simple and convenient. The design of the Sachet Filling Machine is compact and reasonable, and the appearance is simple and beautiful, and the filling volume adjustment is simple.

Sachet Filling Machine can obtain packaging with consistent specifications according to the requirements of the packaging items, according to the required shape and size, but manual packaging cannot be guaranteed.

Labor Protection for Workers: For some products that seriously affect health, such as dusty, toxic products, irritating and radioactive products, manual packaging will inevitably endanger health, while the Sachet Filling machine can be avoided, and can effectively protect the environment from being polluted.

Reducing Storage and Transportation Costs: It can reduce packaging costs and save storage and transportation costs for loose products. Such as cotton, tobacco leaves, silk, hemp, etc.

When you use a Sachet Filling machine, it can greatly reduce the volume, thereby reducing the packaging cost. At the same time, because the volume is greatly reduced, storage space is saved, storage costs are reduced, and transportation is facilitated.

Product Hygiene Guarantee: Sachet Filling machines can reliably guarantee product hygiene. For example, the packaging of food and medicine is not allowed to be packaged by hand according to the Sanitation Law.

Because it will contaminate the product, automatic packaging avoids direct contact with food and medicines and ensures the quality of hygiene.

Therefore, Sachet Filling Machine is suitable for various plastic composite films or plastic aluminum foil composite films, such as polyester/polyethylene, etc. They should have certain air tightness, pressure resistance, and mechanical adaptability.

With so many advantages, are you still not excited?

7. What Materials Can Be Filled by Sachet Filling Machine?

Materials can be filled by Sachet Filling Machine: Sachet Filling Machine is suitable for most liquids such as soy sauce, vinegar, juice, milk, etc.

Sachet Filling Machine uses 0.08mm polyethylene film, and its forming, bag making, quantitative filling, ink printing, sealing and cutting are all automatic. The film is UV sterilized before packaging, which meets the requirements of food hygiene.

For Liquids:

The whole machine is made of high-quality stainless steel, with a novel and beautiful appearance. And the quantification is accurate, the packaging error is low, and the adjustment is simple.

Sachet Filling Machine is also used for quantitative pharmaceutical powder, etc., refreshing beverages, cosmetics, etc.

For Powders:

Sachet Filling Machine can also be used to pack and fill granular items. For example, the nuts, peanuts, and dried fruits that you usually eat.

For Granular:

There are so many kinds of materials that the Sachet Filling Machine can fill. There is no specific data on how many kinds of products this machine can fill, but I believe there is always one that can suit your needs.

Materials cannot be filled by Sachet Filling Machine: There are some materials that cannot be used for filling by Sachet Filling Machine. If these materials are filled, it will cause a major filling accident. So you need to pay attention when you are using Sachet Filling Machine.

Toxic Liquid Solvents

Mixed solutions of toxic liquid solvents, such as toluene and xylene, which are easily poisoned and suffocated, cannot be filled by Sachet Filling Machine. Because when you are filling this liquid, if the sachet bag or bottle ruptures, you may be poisoned and suffocated during the process.

Flammable Solvents

Mixed solutions of flammable solvents cannot be filled. When the solution flows from the high-level static tank into the filling machine, static electricity may be generated if the flow rate is too fast. The combustible gas formed by the mixture of volatile gas and oxygen reaches the limit of flammability, and fire and explosion accidents may occur in case of open flames.

So when you are in the process of operation, you must remember these points to ensure your safety.

8. What Kinds of Packaging Materials Are Sachet Filling Machines Mostly Applied?

When you need to fill liquid contents, we recommend you use heat-sealable composite packaging materials such as paper/polyethylene, cellophane/polyethylene, BOPP film, etc.

This material makes it easy for you to complete three-sided,four-sidede, and flat bags. It is safe and convenient. This material can keep your bag pattern intact.

There is now a very popular package called Tetra Pak. This packaging was invented by the Swedish company Tetra Pak. This material is widely used in filling milk, fruit juice drinks, and other fields. Its many advantages have been widely recognized by people.

In terms of environmental protection, color realization, hygienic standards, and nutritional preservation of product packaging, this packaging form can be trusted. There are many types of packaging in this way, such as Tetra Pak cans, Tetra Pak pillows, Tetra Pak cups, Tetra Pak Bricks, etc.

Tetra Pak packaging material consists of cardboard layers, polyethylene, and aluminum foil. For each form of packaging, the only material that comes into contact with food is food-grade polyethylene.

Cardboard provides toughness to the packaging, plastic acts to prevent spillage of liquids, and aluminum foil blocks the entry of light and oxygen, thus preserving the nutrition and taste of the product.

This material is very environmentally friendly. In foreign countries, the recycled Tetra Pak packaging has been decomposed and separated by hydro pulper to disperse fibers, plastics, aluminum, and platinum for decades.

The recovery and recycling ratio of post-consumer beverage boxes has also increased year by year. 200,000 tons of Tetra Pak bags were collected. Paper mills in Taiwan, South Korea, and Japan also started recycling many years ago, and their fiber recycling products mainly include packaging paper, envelope paper, corrugated paper, fruit bagging paper, pulp board, and other forms.

All in all, there are many materials that can be used for filling and packaging on the market, but we still recommend that you use environmentally friendly, healthy materials and adhere to sustainable development.

9. What Is the Filling Dose of the Sachet Filling Machine?

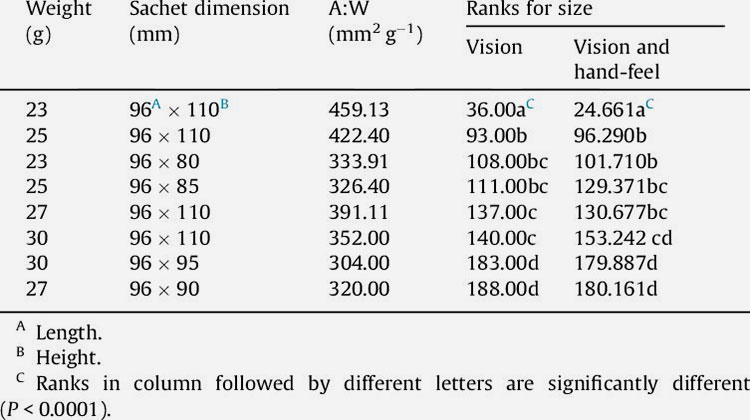

The filling dose of Sachet Filling Machine is generally determined according to the size of the packaging bag. The size of the bag can be customized according to your needs.

Sachet Filling Machine produces most of the products in small bags, so the bag size is generally on the small side. At the same time, different grams of material have different requirements for the size of the bag.

Here is the specification table:

10. How Does Sachet Filling Machine Seal?

Different materials are recommended to use in different packaging forms. Puffed foods like potato chips are recommended to use pillow bags.

For small doses of granular or powdered food, 3-side sealing is recommended. For liquids like ketchup or toothpaste, 4-side sealing is recommended.

For large-grained foods such as candy or nuts, you are recommended to use a triangle bag, so that the packaging bag will not damage the appearance of the food. For delicate brewing powders such as coffee or juice, stick bags are recommended, which is convenient for you to take and use.

For larger snacks or other foods, a quarto bag is recommended. For food that is difficult to remove or unpack, it is recommended to use a gusseted bag.

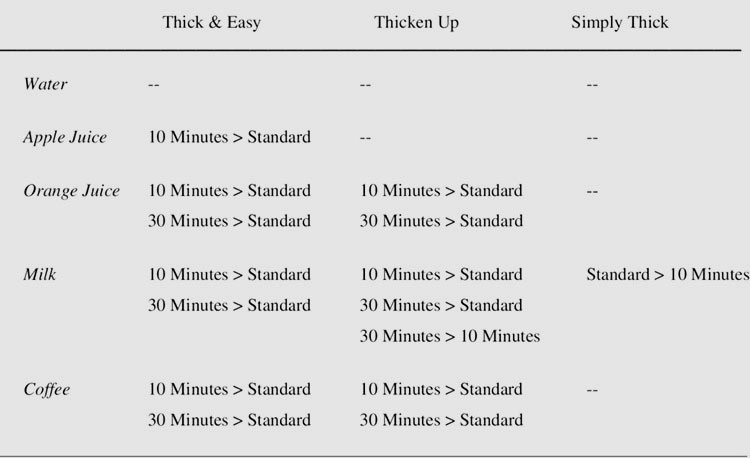

11. What Are the Main Influences on the Filling Accuracy and Speed of the Sachet Filling Machine?

Extraction Speed: The pumping speed directly affects whether the filling is smooth and fast. When you are operating the machine, the machine does not discharge smoothly, sometimes fast and sometimes slow, then there is a problem with your machine's discharging equipment. This time pay attention.

Tables:

The reason for its influence depends on the viscosity of the product and the length of the feed tube. At this time, you need to adjust the size of your material or configure a larger outlet.

The size of the caliber of the interchangeable mouth: The larger the diameter of the interchangeable mouth of the Sachet Filling Machine, the faster the filling speed.

How much to fill? The Sachet Filling Machine has a large filling volume, and the corresponding speed is slow.

The accuracy of filling volume: The higher the filling accuracy requirement is, the slower the filling speed should be.

12. What Problems Will You Encounter During the Use of Sachet Filling Machine?

If Sachet Filling Machine is used improperly or overuse, you will definitely encounter problems. Don't worry, these problems can be handled well with our guidelines.

Noise: Noise occurs during Sachet Filling Machine use. Parts may be displaced due to a lack of oil in the machine or loose screws. If the noise still exists after adding lubricating oil to the Sachet Filling Machine or tightening the screws, it may be caused by excessive wear and tear of the parts after the machine has been used for a long time.

Solutions: At this time, you need to replace the worn parts of the machine.

Sachet Filling Machine Suddenly Sops Working: This is because the power supply is not connected or there is no air pressure.

Solutions: You should check the power supply and air supply to ensure that the machine is working properly.

Sachet Filling Machine’s Quantitative and Filling Volume Are Inaccurate: The quantitative inaccuracy is due to the fact that the filling hopper is blocked by debris at the entrance of the material inside.

Solution: You need to clean the hopper; if the filling volume is not accurate, you need to close the ball valve above the small filling head or increase the material volume, and set the time again to slow down the filling speed.

13. How Do You Maintenance Sachet Filling Machine?

How to make the filling machine last longer? Here are the answers.

Check and Replace: The most important and avoidable method for mechanical failures is to check frequently to prevent loosening of screws and fasteners, and to replace mechanical seals frequently to prevent problems before they occur.

A good machine also needs maintenance and cleaning to extend its life of the machine. First of all, Sachet Filling Machine needs to be maintained in summer.

Cleaned Frequently: Because of high temperatures and rain in summer, it is easy to breed mosquitoes and bacteria. Therefore, Sachet Filling Machine needs to be cleaned frequently during production and use;

When cleaning the Sachet Filling Machine, be careful not to scratch the surface of the machine to avoid rust.

Disinfection: Otherwise, it is easy to contaminate the filling container and filling liquid; if there are stains on the surface of the body equipment, it can be scrubbed with alcohol and disinfectant cotton.

Daily Maintenance: The temperature is high in summer, and Sachet Filling Machine is prone to various failures when it runs at high temperatures for a long time, which has a great impact on the work.

Therefore, attention should be paid to the daily maintenance of the filling machine to ensure that there are fewer problems.

Ventilation and Temperature of Working Environment: You need to pay attention to the ventilation and temperature of the working environment.

According to the different filling products, the requirements for the environment are also different, but in summer, the filling machine is best to run in a ventilated and cool place.

Obey the Guidelines: The automatic filling machine should ensure the equipment line safety of the aerosol filling machine and the powder filling machine should also strictly abide by the environmental requirements of their respective product filling.

Finally, the cylinder of the filling machine is usually filled with lubricating oil when it leaves the factory. You need to try to avoid disassembling and adding it without permission, so as to avoid damage to the cylinder or leakage of lubricating oil;

Sealing Rings: You need to pay attention to the maintenance of the sealing ring of the filling machine. If any abnormality is found, it should be replaced in time.

Sachet Filling Machine that has been filled with oil should try to avoid long-distance closed transportation during the summer and daytime.

Filling Failure of Sachet: You should check whether there is no material in the storage hopper, if there is running out of the material, you should add it in time; check whether the circuit of the blanking equipment is faulty;

Solutions: Checking whether the material hoist or metering device of the equipment is normally energized and whether the relevant switches are turned on; checking whether the air pressure of the equipment is faulty.

You should check whether the blanking button on the touch screen is turned on; check whether the blanking port is blocked.

Film Problem: The film material is easy to shift and cannot be fed normally when the equipment is working.

Solutions: Some technicians from the manufacturer said that if the film material is offset in the equipment, and the adjustment of the film roll position and the tension balance bar is invalid, you can solve this problem by adjusting the angle of the upper triangle.

If the upper film material deviates from the clamping chain, you can adjust the upper triangle plate clockwise; if the lower film material deviates from the clamping chain, you can adjust the upper triangle plate counterclockwise.

Shrinker Problems: Shrinker heats up slowly or fails to rise to higher temperatures.

Solutions: The circuit of the heater is where the main power line passes through a magnetic switch and then to the electric heating tube.

Therefore, when the shrinking machine heats up slowly or cannot rise to a higher temperature, you should first check whether the contacts of the magnetic switch are normal.

If the line does not pass through one of the phases, the above phenomenon will occur; if the magnetic switch is normal, you can check the meter again to see if the ohmic value of each phase is the same as that of the machine.

If each phase is connected but the line or electric heating tube is still abnormal, it means that the heater needs to be replaced.

Sealing uneven or failed: The reason for this failure is related to whether the heating time is adjusted well and whether there are impurities on the heating isolation cloth.

Solutions: You need to adjust the heating time and heating temperature. If there is any attachment to the heating isolation cloth, you should clean and replace it in time to prevent the normal work from being affected.

14. How to Effectively Avoid Accidents During the Use of Sachet Filling Machine?

Accidents will also happen when workers operate machines without proper training. Here we take the fully automatic Sachet Filling Machine as an example.

Firstly, you should make good staff arrangements: Safety incidents that may be caused by the use of the fully automatic Sachet Filling Machine. It's all about the human operation.

If you can arrange the personnel when using the fully automatic Sachet Filling Machine equipment, and ensure that the corresponding professionals are responsible for the operation, maintenance, and repair of the equipment, you can effectively avoid accidents under the condition of ensuring the correct operation.

Secondly, you should use the fully automatic Sachet Filling Machine according to the regulations: For all mechanical equipment, in order to achieve safe application and avoid personal injury accidents, you are required to pay attention to using the equipment in accordance with the regulations.

Especially the automatic Sachet Filling Machine, which requires manual operation, needs to be used in accordance with the regulations to effectively prevent accidents.

Lastly, you should avoid using the Sachet Filling Machine in the event of a malfunction: If there is a problem with the fully automatic Sachet Filling Machine, it is likely to cause personal injury during operation; use the device in the event of a malfunction.

If you obey all the suggestions and regulations we advised, then you can fully make good use of the Sachet Filling Machine.

14. What Are the Best Manufacturers of Sachet Filling Machines?

There are many goodmanufacturerss of Sachet Filling Machines. Including German ROVEMA, Syntegon, and GEA Group.

The German ROVEMA brand is a leading international manufacturer of packaging machinery and equipment, headquartered in Germany. Its products include packaging machines, feeders, etc.

It has delivered more than 30,000 ROVEMA packaging machines worldwide by 2021. Almost all branded manufacturers in the food and non-food industries are equipped with ROVEMA.

Syntegon Technology GmbH (formerly Bosch Packaging Technology) is a leading global provider of process and packaging technology, headquartered in Weiblingen, Germany.

For more than 50 years, it has been providing solutions for the pharmaceutical and food industries. The portfolio of intelligent and sustainable technologies includes stand-alone machines, complete line systems, and services.

GEA Group is one of the world's leading suppliers of machinery and process technology in the energy and food fields, and is also a market and technology leader in this field.

It focuses on high-standard production processes and provides users with efficient solutions. The group generated 5.4 billion euros in 2011, with 70% of its sales coming from the long-established industrial sector in the energy and food industry.

There are also other good and famous manufacturers in theseareass. If you know any other good manufacturers or brands, we are pleased to have a good talk about this.

Conclusion:

Sachet Filling Machine is a kind of filling and packaging machine that is versatile and easy for you to operate. The design is compact and reasonable, and the appearance is simple and beautiful. More importantly, it can improve your productivity. Are you excited about the Sachet Filling Machine with so many advantages? If you are interested in more about this type of machine, please feel free to consult us.

Don't forget to share this post!

Sachet Filling Machine Related Posts

Sachet Filling Machine Related Products

Sachet Filling Machines Related Videos

Have you ever seen how Sachet Filling Machine works?

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest Sachet Filling Machines buying guide, tips and trends sent straightly to your box? Sign up for Aipak’s monthly newsletter, we’re free for your consultation and offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply to you ASAP within 24 hours.