Gummy Counter:The Complete FAQ Guide In 2025

Have You Ever Wondered Why Your Gummy Packet Has A Certain Number Of Filled Gummies Only?

For managing the whole manufacturing process of gummies this operation comes necessary to count the gummies to place in each packet or container according to per serving size. Now the question arises, how will it be possible?

Gummy Counter is a machine that aids in following this step and offering smooth functioning with good productive speed. In this article, you will explore informative literature about the gummy counter. Let’s get to read this post to find out more!

1.What Is A Gummy Counter?

A Gummy Counter is an essential part of the gummy manufacturing production line which assists the packaging process of gummies by counting them per serving size. It has an automatic rejection system for any gummy which is not suitable for packing.

This machine would assist you by improving your production rate as the counting speed demands to fill the gummy bottles speedily fulfilling your orders. Gummy Counter is manufactured of stainless steel and is very simple to operate.

2.When Gummy Counter Started? Where It’s Going?

If you see the start-up, all pharmacies, employees, and production fields had to count every single piece of gummy manually; using the tray and spatula method. Indeed, this old way wasn’t considered an ideal one when it comes to a robust, reliable, and speedy answer.

According to a study, it was estimated that the hand counting method was approx 43% slower than the elementary handheld counter. So you can imagine how semi-automatic or automatic machines would be faster than utilizing high level automation.

The basic digital concept of a gummy counting machine was initiated in 1967 when john and Frank Kirby (brothers) brought up the idea of a portable and digital tablet counting machine. You guessed it right; the same used for counting capsules, pills, gummies, etc.,

Today, it is exciting to see everyday modernization and efficiency in the accuracy and precision of the counting aspects of digital machinery. Additionally, new challenges and competition is still going to open the new horizon.

3.Why Gummy Counter is Important?

Gummy counter is important for easing your production process and aiding in gummy manufacturing. There are many benefits of incorporating a Gummy counting machine into your gummies making machine line. They are:

Offers Precision and Accuracy: Instead of counting your gummies manually which poses a tiresome process with chances of error and inconsistency, the gummy counter offers precision and accuracy while counting each gummy carefully and efficiently.

Increased Productivity: The automatic functioning of this machine presents counting rate parameter which can be set according to your requirements. This means if you want large quantity batch of gummies to be counted and filled in bottles , it can be carried out quickly allowing greater productivity and chances of good profitability.

Cost-effective: Although the one time cost might seem expensive to you while buying a Gummy Counter, it would save your labor cost in long run. A gummy counter provides cost effective solution for counting gummies without any interference or need of humans working.

Serves Variety of Purposes: Gummy counter is a multipurpose equipment which can be used in many industries such as for pharmaceutical counting of capsules and other products, confectionery products such as chocolate beans, lollipops etc.

Reduces Wastage: Due to its automatic operation chances of wastage are minimized during gummies packaging process.

Simple Maintenance: This equipment has it’s simplest construction which makes it easier for maintaining and also because of it’s great reliability regular checking is not required.

4.What Are the Industrial Applications Of Gummy Counter?

Due to their versatility, gummy counter is used in various industries. Let us discuss each of these industries below.

Pharmaceutical Industry

This industry produces medicines and drugs which are used to cure diseases and improve the standard of living. These medicinal drugs require strict counting and packaging procedure to balance dose dispensing and avoid extra expenditure. Gummy counters are used in pharmacies for accurate in-patient dose-dispensing.

Chemical Industry

The chemical industry deals with products that are sensitive to moisture, temperature, dust, oxygen and would chemically degrade if they come into contact with any of these factors. You cannot directly touch them for the purpose of counting. Moreover, to protect environment and operators, gummy counters are used for fast and efficient chemical dispensing. Such as pH tablets, buffer salts pellets.

Food Industry

This industry deals with various food items like beans, nuts, etc. These food items are commonly prone to degradation in case of mishandling. Gummy counters are made up of stainless steel that not only helps you with accurate counting, but also offers a safe way of giving your product.

Agriculture Industry

This industry is involved in the production of a variety of fertilizers in the form of seeds.

To ensure you are getting fast and correct product; agricultural industry prefer gummy counters.

Cosmetic Industry

Beauty products packaging, such as wax beans, facial masks, pedicure kits, serums capsules, requires gummy counters for safe and accurate outcomes.

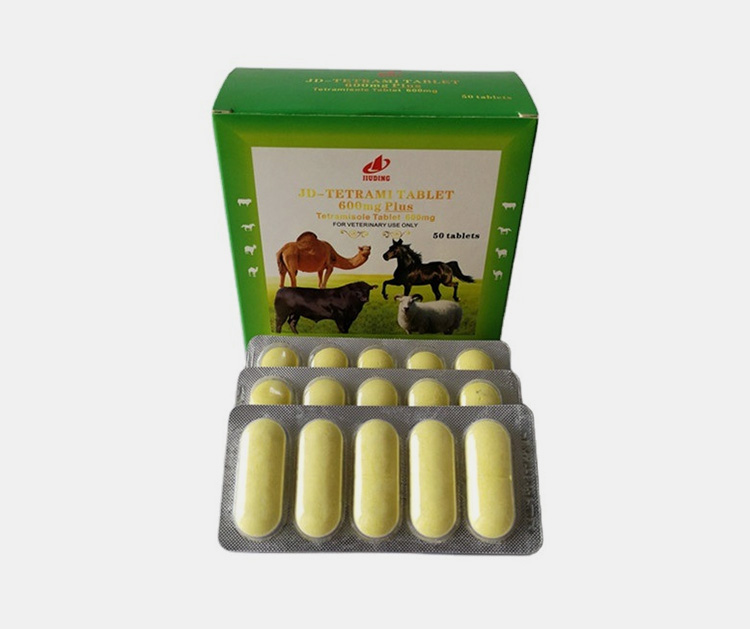

Veterinary Industry

The veterinary industry manufactures a number of products like medicines and vaccines to cure animals’ diseases in capsules, tablets, pills form The best way to dispensing the material require use of gummy counters.

5.What Are the Essential Components Of Gummy Counter?

Today, the gummy counter machine is available with day-to-day modern features: But we tried to present some very basic parts of the gummy counter. Mentioned below are the main components and the description of the gummy counter.

PLC TOUCH SCREEN

A PLC touchscreen is a programmable logic controller, which is a computerized operating system that is controlled by humans to input and monitor the process. This device is known as the brain of the machine where you can feed the input and monitor major operations,. i.e. speed, batch size, number of gummies, and notifications.

THREE STAGE VIBRATOR

This device moves with vibratory movement to shake the gummies inside a rotating glass.

GUMMIES FEEDING CHUTE

Gummies chute is a device which has an access passage that receives products to be counted such as tablets or gummies, to be dispensed directly into containers.

DUST COLLECTION

Dust collection captures the unwanted dust particles from the air and filters it and prevents pollution of workplace area.

BOTTLE PHOTOELECTRIC DETECTION EYE

This device involves the use of sensors that detect light and convert it into electrical signals in order to count the gummies accurately. As they detect the presence of a gummy candy they count it registering the number of gummies while each count.

This part of the machine finds any damaged or unwanted gummy for e.g. that is chipped off and separates it. The automatic rejection unit does not allow bad pieces of gummies to be transferred for packaging.

CONVEYOR BELT ADJUSTER

This ensures that gummies are transported from station to station during the whole manufacturing as well as the counting process.

6.What Is the Working Principle of Gummy Counter?

The construction of a gummy counter is very simple therefore it’s working steps are also carried out with convenience. The working of the gummy counter is as follows:

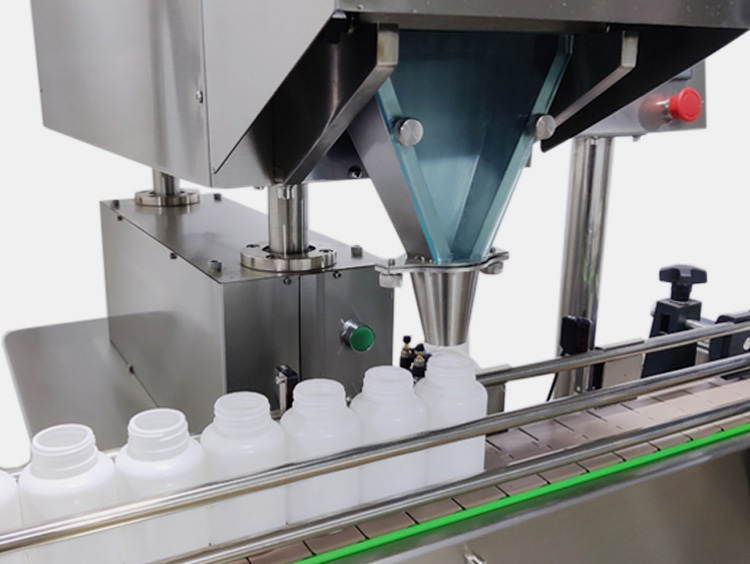

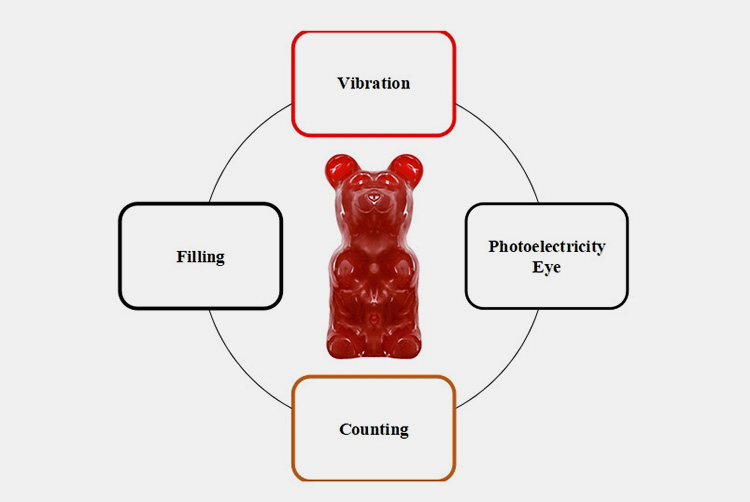

The gummy counter follows the working principle of ‘photo-electricity eye’ for seeing gummies to count, ‘dispensing’ them accurately, ‘monitoring’, ‘setting parameters’, and ‘recording in real time’.

The movement of gummies in different vibratory channels induces the working. For e.g 12 vibratory channels refers to 12 vibratory grooves in the vibratory plate.

This vibratory effect plays the magic where the counting process starts automatically. A container or any filling jar can block the electromagnetic pathway that ensures filling material is available to cater to gummies.

Once the container is filled up to a desired quantity of gummies; the cylinder automatically opens and packed material is transferred to the conveyor. The photoelectricity eye tracks counting and filling hence allowing the next bottle/jar/container for the process. Similarly, if there is no bottle, no vibration, no counting, and filling.

7.What Are The Different Types Of Gummy Counters?

Basically, a gummy counter can be categorized based on their method of operation. We will see each of the types discussed below.

MANUAL GUMMY COUNTER

A manual gummy counter option is rarely used. This is suitable for small scale manufacturing of gummies or other products. They operate on behalf of labors working to input gummies into gummy counter and is totally dependent upon the workforce of humans. Therefore, it’s productivity is also associated with human speed and accounts for limited production capacity.

SEMI AUTOMATIC GUMMY COUNTER MACHINE

This machine is suitable for small to medium scale gummy manufacturing industries. As it has semi automatic functionality, it means that it can be operated by humans or by itself as well.

A semi automatic gummy counter can count gummies and other products at quite a moderate speed. The system is controlled through human machine Interface which ensures smooth operability.

AUTOMATIC GUMMY COUNTER MACHINE

An automatic gummy counter machine hardly requires any human workforce intervention to carry out the counting process. This equipment is operated by a Programmable Logic Control system which might require humans for entering settings and data for working parameters.

This machine works best to count the gummies at high speed to ensure greater productivity and therefore allows its use in large scale manufacturing industries.

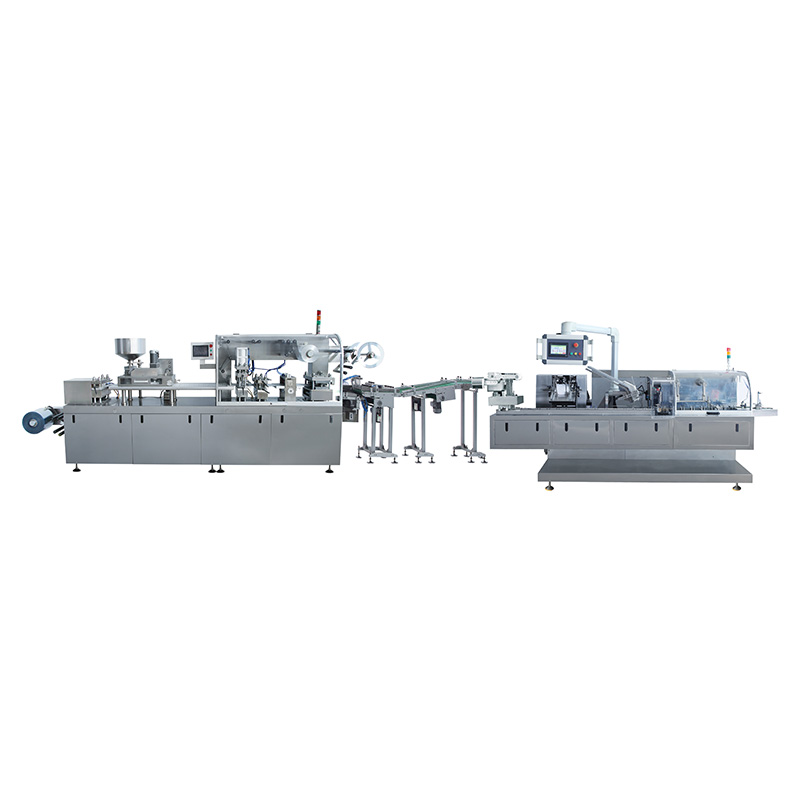

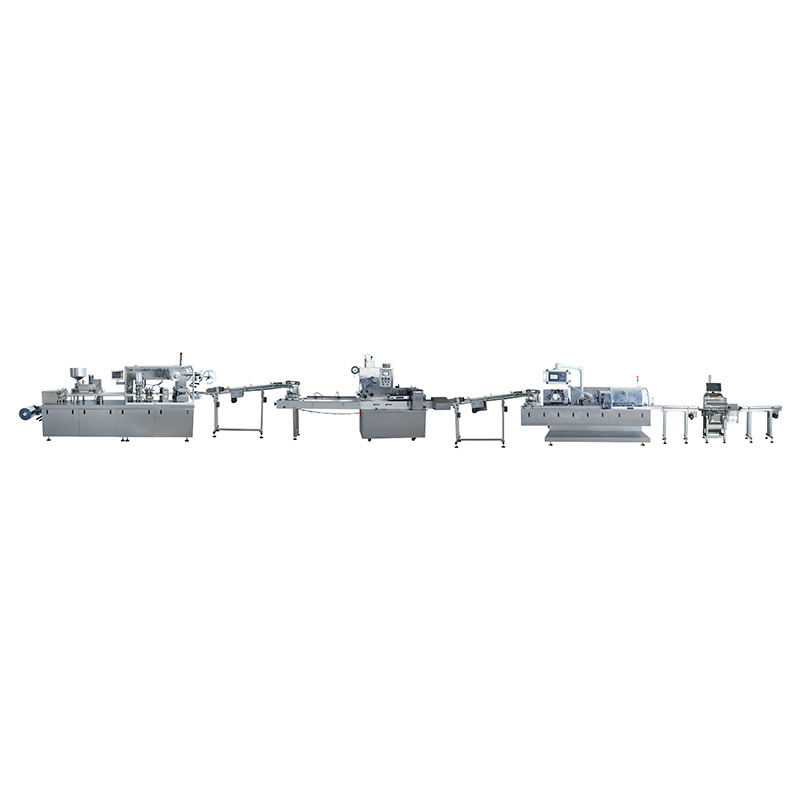

8.What Other Equipment Support the Working of A Gummy Counter?

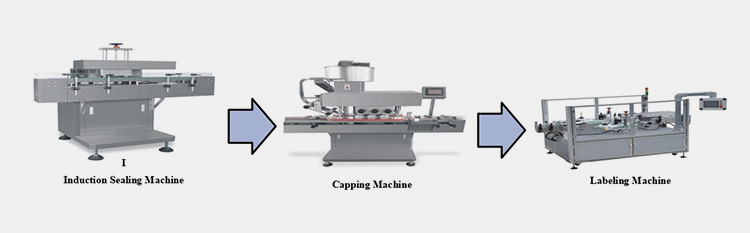

Induction Sealing Machine

To give an airtight storing environment to gummies, induction sealing machine is employed.

The induction Sealing machine starts by filling gummy candies and the lid is placed on top of the opening. The machine is turned on and the coil generates an electromagnetic field.

The conductive material in the lid is heated. This heat causes the material in the lid to melt. The melted material cools and solidifies, creating a tight, hermetic seal. The sealed gummy container is then ready for packaging and distribution.

Capping Machine

A capping machine is a great solution for securing gummy products. This is integrated with counting machine to smoothen the procedure.

The capping Machine works by first filling a hopper with your desired gummy mixture. The mixture is then fed into a forming machine. The gummies are then transported to the capping machine where they are automatically capped for distribution.

Labelling Machine

Labeling machines must add equipment which is an advanced technology. With an efficient design, this machine makes labeling your gummy candies in no time.

It works by printing out custom labels using an inkjet printer. The labels are then picked up and applied onto the gummy’s packaging using a special adhesive that is heat-activated.

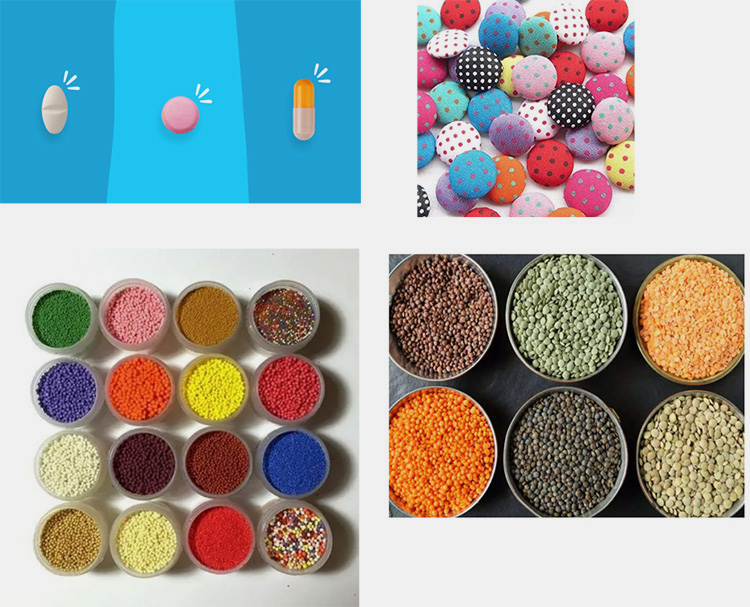

9.What Products Can Be Counted By The Gummy Counting Machine?

A gummy counting machine is the most effective and modern equipment used for counting various products such as:

- Candies

- Capsules

- Tablets

- Pills

- Cosmetic beads

- Textile fancy buttons and beads

- Pulses

- Coffee beans

10.What Feature Gummy Counter Offers?

The gummy counter is a compact and mandatory packaging solution. Discussed below are the list of amazing features it offers:

Sturdiness

To reduce cross contamination, fast counting, and effective dispensing, all parts of gummy counter unit that come in contact with the product and main body should be made up of industrial grade stainless steel.

Regulatory Certification

Since some of the target industries of packaging machines are highly regulated fields like pharmaceuticals. Gummy counter is complied with a high regulations set by local and international regulatory authorities.

Advanced Electronics

Gummy Counter is equipped with highly advanced electronic features like photoelectric alarm that can notify user of any irregularity during operations. In some machines not only, the alarms are triggered but also the operation is brought to complete halt if the irregularity is not timely addressed in order to protect the machine.

Accuracy And Precision

Gummy counter is usually equipped with servo motors and advance electronic features that guarantee accuracy and precision throughout production.

Safety Features

Gummy counter features with safety alarm that is triggered to notify user of the technical trouble; hence ensuring you about appropriate safety throughout operations.

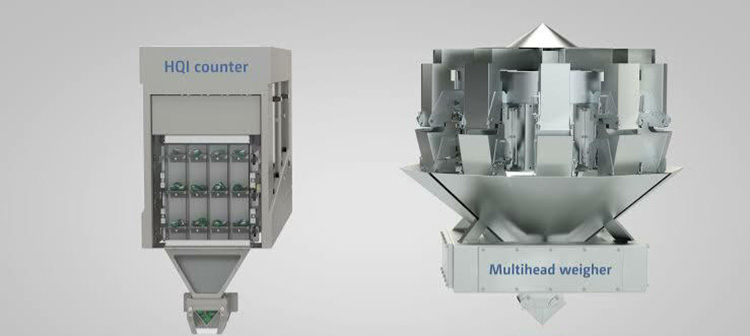

11.Gummies Counter Vs Gummy Weigher

For any industry efficient packaging, quantity measurement and quality assurance comes important for good manufacturing practices. Therefore it is a strategic decision to be made by the manufacturers to choose counting or weighing for their product’s filling.

A Gummies Counter is a machine that counts the number of gummies accurately that are supposed to be filled in a certain gummy package. A Gummies packet filled after counting will indicate to the consumer a certain number of gummies in single packaging.

A gummy counting system can be declared as the most cost effective and reliable method rather than today’s modern method of weighing and filling. Instead of a gummy weigher choosing a gummy counter can guarantee significant profits and customer satisfaction.

A Gummies Weigher is a machine that fills the packets of gummies according to the prefixed quantity of weight set into the computer system.

A Gummies packet filled after weighing will indicate the approximate weight of the gummies that may be deviated due to any mechanical or human error.

Packing by weight may result in the product’s deviation from mentioned quantity resulting in overcounting or undercounting. Both of these are not beneficial to the manufacturers and customers respectively.

12.What Is the Difference Between Semi-Automatic, And Automatic Gummy Counters?

| Semi-Automatic Gummy Counter

|

Automatic Gummy Counter

|

|

| Results | Lesser chances of errors | 100% precise and accurate |

| Machine size | Occupies little space | The machine size is larger, thus requiring a good space to install |

| Price | Cost-effective, more expensive than manual gummy counter | The machine requires a high budget for the purchase |

| User Friendly | A major portion of production is performed by the machine itself | A touch screen system promising ease of performance. The machine ensures 100% self-generated outcomes |

| Labor Cost | The machine requires less number of operators | Require one operator to initiate the process |

| Speed | Counts in hundreds to thousands/minute | Counts in thousands/minutes |

| Production Scale | The machine is ideal for medium to high production fields. | The machine is suggested for medium to high production. |

13.What are the Problems and Troubleshooting of the Gummies Counter?

| PROBLEM | CAUSE | SOLUTION |

| GUMMY BLOCKING |

The main reason for this problem is operating gummy manufacturing at high operability speed which results in the jamming of candies in the machine. | This can be solved by controlling vibration from the feeding system. |

| COUNTING FLAWS |

There may arise a problem in the number of gummies being counted due to setting up incorrect counting duration. | By adjusting photoelectric optical sensors to millisecond units, counting flaws can be corrected. Replace the counting detector. |

| INCORRECT SENSOR UNIT |

If the dust is accumulated on sensory devices or if it is damaged, errors may be represented via a counting system. | To overcome this problem, you must ensure the cleaning of the sensory system or replace the damaged sensor unit. |

| OVERCOUNTING OF GUMMIES | This happens when a fragment of the gummy's leftover detector glass or dust particles is there. | We recommend scrutinizing and wiping the detector screen and remaining machine parts regularly after each batch. |

| UNDER COUNTING GUMMIES | Improper handling or overrunning of the machine may result in a counting error. Moreover, the machine counts one item instead two. | We recommend running the machine at a moderate speed to avoid counting interruptions. |

| INACCURATE GUMMIES PACKAGING | A loose screw of appendages may modulate discharging direction. | A screw tightening is required. |

| DISPLAY MALFUNCTIONING | Improper sensor plug-in. | Re-do Installation and check the connection wire and re-calibrate the system. |

| VIBRATING NOISE | A loosened vibratory tray made a noise. | A vibratory tray must be adjusted, and screws tightening should be re-done. |

Moreover, it is recommended to clear dust, and debris, especially from those parts that are in contact with the product. Apply lubricant to moving parts (conveyor, vibratory channel), machine’s calibration, tightening of loose screws, and replacement of wear and tear components must not be ignored for efficient performance. The following steps will minimize the major problems with the gummy counter.

14.What are the Most Significant Aspects to Address While Purchasing A Gummy Counter?

Selecting a gummy counter is a vital and complex decision. This is not just from a speed point of view but productivity as well. The most important points to recognize are as followed:

The gummy counter must demonstrate accuracy for various shapes and textures.

The machine must show greater speed, great features, and functions. For this, the multichannel gummy counter is recommended.

The gummy counter must manage a great production capacity with no room for error.

Find a manufacturer who offers a great counting solution in an economical way.

A gummy counter must be user-friendly and designed to lessen possible wear & tear.

Conclusion

Whether pharmaceutical, food, nutraceutical, or chemical industry; you can’t ignore the significance of the gummy counter. This is an economical answer to achieve fast, accurate, and safe dispensing in various production sectors. AIPAK Pharmaceutical Promises for Reliable Gummy Production Line That Can Successfully Accomplish Your Business Goals And Skyrocket the Brand. Please Contact Us for More Information And Product Purchases. Our Team Is Here to Serve You Now.

Don't forget to share this post!

Cartoning Machine Related Posts

Cartoning Machine Related Products

Cartoning Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide, tips and trends sent straightly to your box? Sign up for AIPAK’s monthly newsletter, we’re free for your consultation and offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine