Capsule Filling Machine:the Complete Buying Guide in 2022

Nowadays,capsules are more and more common in the daily life.For example,capsule medicines are necessary for many people.In other words,the demand for capsules is expanding .Maybe you are familiar with capsules.However,do you realize about the capsule filling machines?Do you know how to choose a proper capsule filling machine?

Therefore,this article is to give you complete information about capsule filling machines.To help you have a basic knowledge about capsule filling machines,the points of the introduction of capsule filling machines are as follows:

1. What is a capsule filling machine?

Aipak NJP-1200D capsule filling machine

Simply speaking,capsule filling machine is a practical device which can fill multiple materials into capsules accurately and efficiently.Moreover,using a capsule filling machine,you can fill capsules of multiple shapes and sizes.

At the same time,capsule filling machines can finish the operations such as positioning, detaching, filling and locking of the capsules automatically so that it improves the production efficiency.

2.What are the features of capsule filling machines?

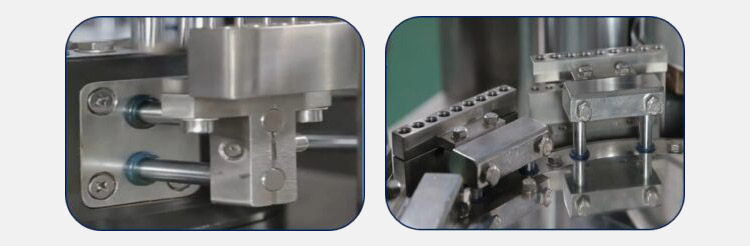

To begin with,capsule filling machine has a beautiful appearance and a high-level sense design,it’s easy and convenient to operate.

In addition,the parts of capsule filling machine are very convenient to disassemble and clean,and the model of the mold can be changed so that it can meet different level of production ability demand.

Another feature is that capsule filling machine can eliminate the defective capsules, recycle the drug in the defective capsules, which can largely improve economic benefits.

The most important is that capsule filling machine is confirm to GMP,it’s recognized by people from all over the world.

3.How will you benefit from using capsule filling machines?

In fact,if you use capsule filling machines,there are many benefits that you can get,which include:

Capsule filling machines are labor-saving

For instance,in traditional industries,workers are the subjects of production,this mode often needs to consume huge manpower and material resources,and it will spend you long hours finishing the production task.But this problem is totally resolved while using capsule filling machines because you do not need to hire many workers.

Therefore,by using capsule filling machines,you can save the investment of labor and take the cost into other aspects.

Capsule filling machines can improve production speed.

During the working process of capsule filling machines,a large amount of empty capsules are placed on the board.It is obvious that the speed of using capsule filling machines is much faster than filling capsules by hand.

Capsule filling machines can avoid damage and loss.

Actually,before the working process,the various parameters of capsule filling machines are well-setting. The actions of capsule filling machines are also sensitive and accurate,which allows them to fill materials into capsules precisely so that they can avoid damage and loss.

Capsule filling machines are easy to operate.

To be honest,most of the capsule filling machines in the market are smart enough to finish the working process automatically or semi-automatically,which doesn’t need too much manual intervention.Overall,you can operate a capsule filling machine easily.

4.What are the applications of capsule filling machines?

As well as known,the applications of capsule filling machines are very common in many industries such as pharmaceutical,food,beverage and cosmetic.

Pharmaceutical Industry

As a matter of fact,Capsule filling machines are widely used in pharmaceutical industry because capsule pills occupy a large proportion in medicine field.By filling the medicine powder into capsules,it not only protects the drug properties from being destroyed, but also protects the digestive organs of human bodies.

What’s more,capsule pills are easy to swallow and to store.Another advantage of capsule pills is that they can cover the bitter taste of drugs,which makes more people adapt to eat pills.

Food Industry

In today’s era,people’s living standard is getting higher and higher,their requirements for food are no longer just satiety.Instead of the taste of food,they pay more attention to the nutritional value of food.

For example,dietary fiber capsules can meet the demand for nutritional value.The dietary fiber can not be absorbed by the human body, but it has great benefits for human health, so capsule filling machines play a good part in such a food process industry.

Beverage Industry

On the contrary to the traditional beverage packaging industry,there are many capsule beverages in the market,now.For instance,capsule coffee is very popular among working people.Maybe you will come up with a question,why people prefer drinking capsule beverages?

Well,as you can see,capsule beverages are very portable.They are the best choices for you when you Go outdoors or go to travel.Where is the demand,where is the market,as a result,capsule filling machines are applied widely in beverage production field.

Cosmetic Industry

It’s not difficult to find that there are some capsule shaped skincare products,the filling materials of these capsules are always powder and oil.Generally,the effect of these skincare products is anti-aging,which means that the fillers of them are quite nourishing.Therefore,the usage of capsules can keep the fillers fresh and extend their shelf life.

5.What are the classifications of capsule filling machines?

According to the source of productivity,capsule filling machines can be divided into three types:fully-automatically capsule filling machines,semi-automatically capsule filling machines and manual capsule filling machines.

Fully-automatically capsule filling machines

The fully-automatically capsule filling machines can finish all the operation steps by themselves without any manual intervention.Namely,this type of capsule filling machines can save your cost in time and money,and it is also durable.

For this reason,the fully-automatically capsule filling machines adapt to large-scale capsule filling production

Semi-automatically capsule filling machines

The semi-automatically capsule filling machines,just as the name implies,they need some parts of manual operations.They usually have a simple design of their devices,which makes them easier to use.This type of capsule filling machines are sanitary in their using process.

So,the semi-automatically capsule filling machines are always used in medium-scale capsule filling production.

Manual capsule filling machines

In addition to the two types capsule filling machines which have been noted,there is also a type of manual capsule filling machine.During the working process,you don’t need to provide power to the machine, you can just operate it with your hand.

Because this type of capsule filling machines depend more on human labor,they have a low efficiency so that they only adapt to small-scale capsule filling production.

6.What kinds of fillers can capsule filling machines fill ?

As is known that there are two types of capsules:hard capsules and soft capsules,according to the different types of capsules,the fillers are different,too.The most common fillers of capsules in the market can be divided into three categories:powder,granules and liquid.

Powder is often filled into hard capsules.The most common applications of it are pharmaceutical industry and chemical industry.

Granules

Just as powder,granules fillers are also used widely in hard capsules,they are always applied in pharmaceutical industry.

Liquid

Different from the other two types of fillers,liquid is applied in soft capsules,such as cosmetic industry and food industry.

7.What are the main components of capsule filling machines?

To have a detailed and complete realization of capsule filling machines,you should know the structure and the main components of them.The constituent parts of capsule filling machines include:

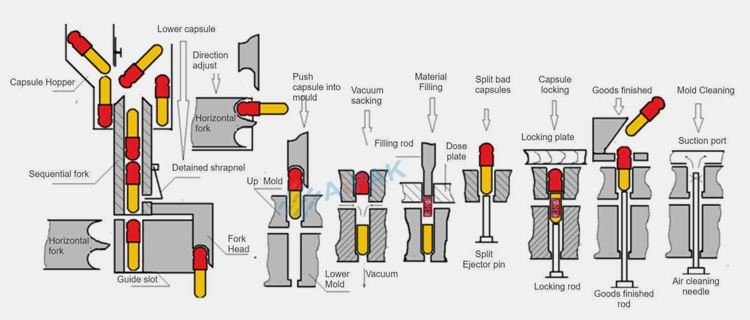

Capsule Hopper and Capsule Sensor

The capsule hopper is a storage space of empty capsules,when the machine is powered on,empty capsules are filled into the capsule hopper.

Certainly,the capsule sensor is an assistant of the capsule hopper to control the amount of empty capsules.

Capsule Feeding Unit

The function of capsule feeding unit is to adjust the amount of empty capsules which are filled into the capsule hopper.

Powder Hopper

The function of the powder hopper is similar to the capsule hopper,it is a storage space of the filling materials,but the difference is that it can also plays a role in mixing the filling materials.

Closed Dosage Device

Closed dosage device can control the accurate amount of filling materials which are filled into the powder hopper.

Closed Rotary Turret

Closed rotary turret is totally closed so that it can avoid the entering of dust or other environmental elements.There are many new types capsule filling machines adopt this device.

Mechanical Drive System

This part is at the most important status of capsule filling machines,it provides motivation to the whole machine.It is made of motor,gear and convey.

Lubrication System

As the name shows,this system is to lubricate the moving parts while the machine is working,which reduces the friction and makes the machine work more smoothly.This unit can reduce the possibility of downtime,then the working time of the machine is longer.

Vacuum Capsule Separating Mechanism

The role of vacuum capsule separating mechanism is to separate the capsule caps and capsule shells.

Safety Door

When the capsule filling machine is working,the safety door is in closed condition.Its function is that it can protect the machine from sudden attacks.

PLC and Touch Screen Control System

You can adjust all the operation parameters during the working process of the capsule filling machine by this system,in other words,it acts as the brain of the machine.

Automatic Feeding Device for Empty Capsule

With this part,the machines can feed empty capsules automatically.

Vacuum Feeder

Vacuum feeder can feed powder automatically,and the dosage is accurate.

8.What is the working principles of capsule filling machines?

So far, you have a summary realization about the structure of capsule filling machines,whereas,do you know their working principle?Don’t worry,then it will be introduced to you.

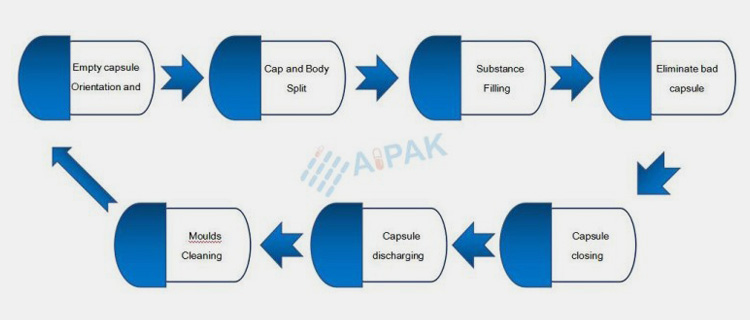

In general,the operating process the of capsule filling machine depends on the rotation of the turntable.During the short pause of the rotation,a series operations on the capsules are done quickly.

When the capsule filling machine is turning on,the capsules in the capsule hopper will vertically enter the delivering forks of the dispensing device one by one.Afterwards,vacuum capsule separating mechanism takes the capsules into the molds and separates the capsule caps and the capsule shells.

The next part is the filling of the powder,the filling material is pushed into the capsules,then the capsules are locked,which means the filling process is finished.After that,the molds are cleaned,at the same time,the next cycle begins.

To sum up,the basic working principle of capsule filling machine is as above.

9.How does a capsule filling machine work?

Totally speaking,there are five main working steps of capsule filling machines:the arrangement of empty capsules,the separation of empty capsules,the powder filling operation,the disposal of defective products and the locking operation of capsules.

Firstly,put the empty capsules on the finishing plate orderly,ensure the capsule caps are on the top and the capsule shells are on the bottom.

Secondly,after the arrangement of empty capsules,the capsule caps and capsule shells will be separated.

Thirdly,the filling materials are filled into the capsule shells.

Fourthly,expel the empty capsules which are not successfully separated.

Finally,cover the capsule caps on the capsule shells and then lock the capsules.Until this step,the filling process is basically finished.

10.Is it possible to fill a capsule without capsule filling machines?

It’s evident that you can fill a capsule without a capsule filling machine,but only if you do it on a small scale production.If you need a large-scale production,there are some disadvantages without using a capsule filling machine.

On the one hand,you should cost more time or money to do this thing if you don’t use capsule filling machines.You need to fill materials into capsules by your hand,maybe you need to hire some workers,which increases the investment.

On the other hand,you can’t guarantee the quality of the finished products,in terms of precision and measurement,it is absolutely no comparison between manual production and machine production.

Therefore,personally speaking,in the long run,it’s better to use capsule filling machines during the production.

11.What are the cautions of using capsule filling machines?

Apart from the understanding of the working principle and working process of capsule filling machines,the cautions of capsule filling machines are equally important to you.

A case in point,due to the vibration of capsule filling machines,the screws of each parts may be loosen,you should check and tighten them termly.

Besides,you should put the capsule filling machine in the place which is not only kept from direct sunlight but also far away form high temperature,and you shouldn’t put heavy things on it.

What’s more,You have to ensure the fuselage of the capsule filling machine is contact with the floor during the working process,and don’t forget to cut off the power supply after using capsule filling machines,which can avoid security risks.

The final caution is that you should clean the remained powder of the molds everyday to keep the machine sanitary.Pay attention, don’t flush the capsule filling machine directly with water.

Above all,these cautions can help you protect your capsule filling machines,it is suggested that you take a memory of them and comply with them.

12.What are the operation specifications of capsule filling machine?

Besides the cautions of using capsule filling machines,there are also some operation specifications of the machine,they are as follows:

At first is the preparation before the operation,you should check all the components of capsule filling machine to ensure they can be operated normally.In a brief,before the operation,you should adjust the components into a good condition.

The next one is the operation step,turn on the power,press the automatic feed switch, press the vacuum switch, and then press the start button,meanwhile the machine is starting working.

And then is the change of the mold,there are three parts of the mold of capsule filling machine:filling, module, distribution,all the molds can be changed freely.

At the end of the working process,you should stop the powder supply at the first,then press the stop button and shut down the vacuum pump,clean the table surface, and finally turn off the power.

And don’t forget that when you finish using capsule filling machine,you should clean up the whole machine and the work site for next use.

13.How to maintain an out-of-order capsule filling machine?

For the purpose of extending the service life of capsule filling machines,you should do a good maintaining,it is essential for you to clean the parts of the machines regularly.

Although capsule filling machines are efficient and professional,there are also some possibilities of out-of-order.The reason why capsule filling machines can be out-of-order is various,I’ll show you the situations and solutions one by one.

When the vibration effect doesn’t reach your ideal condition,you can adjust the voltage.

When the reed screw is loose,you should tighten it.

When the capsule shells are arranged in the working board,if the mouth is higher or lower,you should adjust the height of the dislocation plate and guide rail.

When the capsule shells fall down too much,maybe the reason is that the vibration isn’t adjusted properly,you should adjust the vibration.The other reason is that the size of capsule shells is substandard,you should choose eligible capsule shells.

When the capsules are stuck on the board and cannot fall down,you should change the capsule shells or you should adjust the position of dislocation plate and table plate holes.

When the mold cannot be reset in the track, and the guide rail rear end compression spring or the capsule variants is stuck. You should reinstall the spring or push rod ,and push the capsules down with a stick.

When the guide plate of the mold is worn,which results in the low capsule fitting rate,you should change a new mold.

In a word,these are general problems when using capsule filling machines.If there are other problems,you can repair the machines according to the real situations.

Conclusion

In conclusion,the capsule filling machine is a ultra important machine of many industries because it can improve the speed of capsule production.hope that you can have a primary understanding of capsule filling machines after looking through this article.If you still have some confusions,you can contact us at any time.

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine