Softgel Making Machine: The Complete Buying Guide In 2025

At present, many health products or drugs are made in the form of softgel, which is convenient for customers to use. With the rise of softgel, softgel making machines have gradually appeared on the market. Why is this machine favored by many people? Do you know very little about this machine?

Well, let’s explore the complete buying guide of softgel making machine. This article will lead you to understand the definition, advantages, working principles, and other aspects of softgel making machines. Let’s take a look together.

1.What is the Softgel Making Machine?

To begin with, are you familiar with softgel? It is a preparation that contains drugs in a soft material, usually in liquid or semi-solid form. To be honest, you must have eaten this capsule before.

Softgel making machine refers to a equipment that produce this kind of softgel. A complete softgel production line includes many processes, can provide customers with multiple choices, and can produce many types of soft capsules. The final softgels have the characteristics of precise size and small differences in weight.

2.What is the Strengths of the Softgel Making Machine?

Why are sofgel making machines widely used? How many strengths can this machine bring to you?

(1)Improving accuracy

With the development of technology, such as servo motors, sensors, etc, softgel making machines can accurately control the precision of each softgel, ensuring consistency in the size and scale of the softgels..

(2)Keeping uniformity

Keeping Uniformity - Sourced: Aligen

The softgel making machine can be equipped with specific molds according to the size and shape of the customer’s softgels, producing the products required by the customer. And it can be equipped with suitable machines according to the customer's production needs.

(3)Reducing waste

With the continuous development of softgel making machines, many machines are equipped with recycling systems that can recycle waste materials from the production process, reducing resource waste and improving the environment.

3.Which Industry Can Softgel Making MachineApply?

Are the vitamins you are using made from softgel? Are the beauty products you are taking also made of softgel? Currently, many industries are using softgel making machines. Let’s take a look at which industries there are.

(1)Health Products Industry

Softgel Vitamins - Sourced: Greenfield Nutritions

To be honest, the health product industry is the primary sector where softgel making machines are most extensively utilized. Softgels have the characteristics of easy ingestion and rapid absorption, and many health products are in this form. For example, the vitamins, melatonin, minerals, etc. we eat in our daily life are made by this machine.

(2)Pharmaceutical industry

Softgel Drug - Sourced: Precious Pharmacy

Have you ever taken medication in the form of softgels? Many drugs can be encapsulated in softgel to prevent oxidation when exposed to damp heat and instability. Additionally, softgel helps mask their unpleasant odors. The most common softgel medications include drugs that are inserted into the anus and vagina.

(3)Beauty industry

Skin Correcting Softgel - Sourced: JDBM Cosmetics

Some skin care products, such as lotion, will take the form of softgel, which is convenient to carry and use, and can also ensure that the product is not volatile or deteriorating. There are also some oral softgel that help with absorption and improve skin condition.

4.What Size and Shapes of Softgel can Softgel Making Machine Produce?

How many shapes of softgels have you seen? Do you know that there are different sizes of softgels?

(1)Round softgel

Round Softgel Size

The drug distribution of round softgel is relatively uniform, and the molding mold design is simple with relatively low cost. The specific dimensions are shown in the above figure.

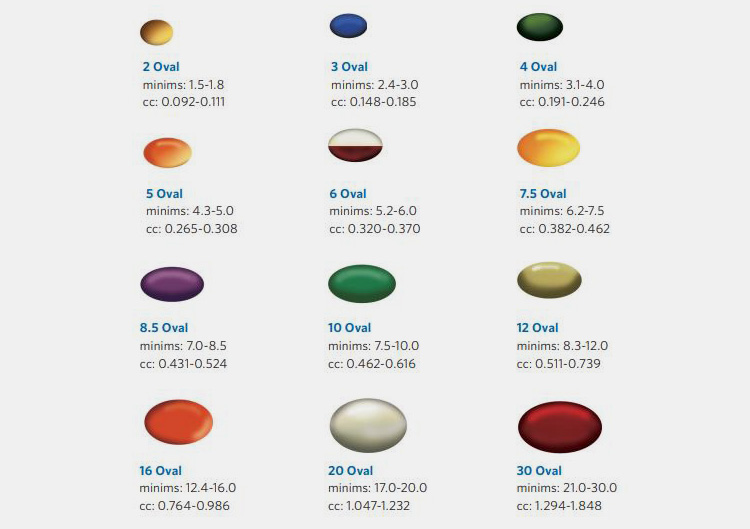

(2)Oval softgel

Oval Softgel Size

To tell the truth, oval softgels are the most common shape. and the vitamins, fish oil, and liquid calcium tablets we often eat have this shape, which is convenient to swallow for customers.

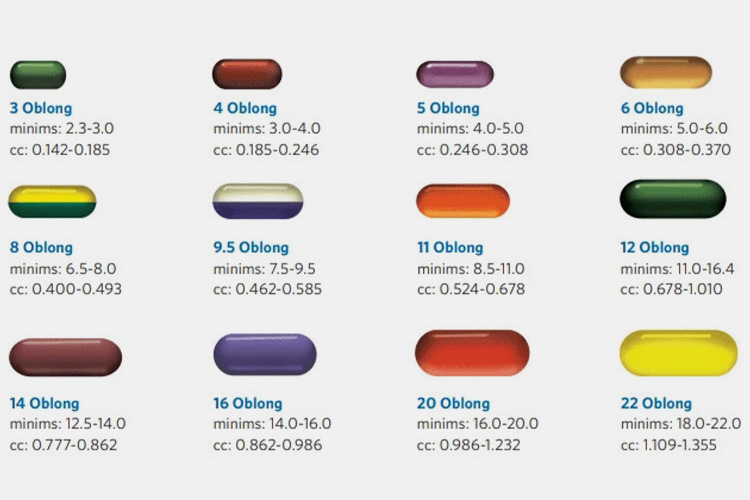

(3)Rectangular or oblong softgel

Oblong Softgel Size

Rectangular or oblong softgel are also very common, which have the widest range of applications. And this shape of softgel can accommodate more materials. The specific dimensions are shown in the above figure.

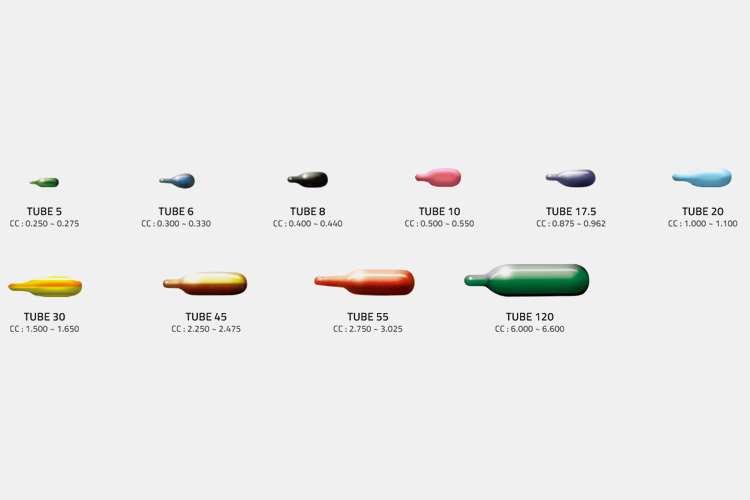

(4)Tube softgel

Tube Softgel

Compared to the three shapes of soft capsules mentioned above, this shape is relatively rare. There are also manufacturers that can produce this type of soft capsule, which can also feature various colors.

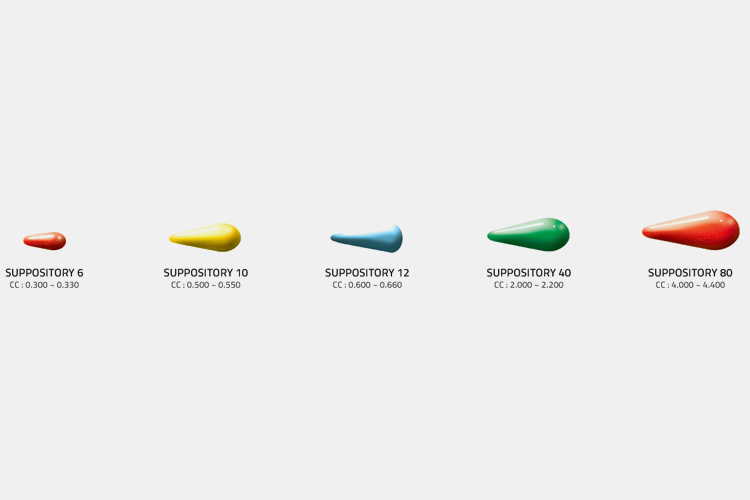

(5)Suppository Softgel

This shape of softgels often used for the production of rectal and vaginal administration. It is designed according to the human body, making it convenient for drugs to enter the body and helping patients absorb drugs quickly.

In addition, softgels have other shapes, such as animal shapes, which are more playful and cute. The products produced are mainly suitable for children, and can be customized according to real needs.

5.What are the Key Components of Softgel Making Machine?

A typical softgel making machine consists of five main systems. Each system has different accessories, as detailed below.

(1)Gelatin melting system

Gelatin Melting System - Sourced: Sinagel

Gelatin melting tank: This device is usually composed of 304 and is equipped with a scraper for stirring inside. It is also can be made of 316. This device has three layers, mainly for insulation and heat prevention.

Linear condenser: The melted gelatin has a high temperature, and this component can be cooled by pouring the gelatin into the main unit.

Water circling vacuum pump: There will be many bubbles during the gluing process, and this component undergoes vacuum degassing operation.

(2)Mixing system

Dosage Tank - Sourced: Ginhong

Dosage Tank: This component is used to mix the required solution, suspension, etc. in a certain proportion. This component uses an eccentric shaft for mixing and also has three layers to prevent scalding.

Colloid Mill: Some materials are difficult to mix thoroughly due to their large particles. This component is designed to grind some semi-solid or other materials for easier proportioning.

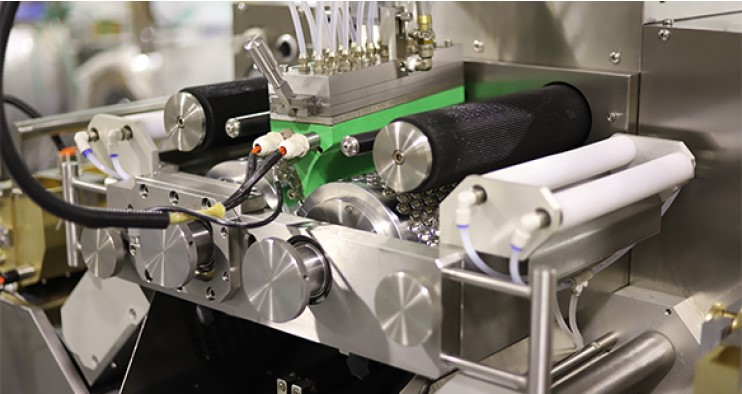

(3)Softgel system

Mold: This component is generally made of aluminum and is related to the size and shape of the final product. It can be customized according to your needs.

Mold

Electric control box: This component is made of stainless steel and contains switches, circuit breakers, etc. It is the power plant of the entire machine.

Cooling-water machine: It use circulating clean water to cool the thin layer of gelatin by continuously rotating.

(4)Drying system

Drying System - Sourced: CPHI Online

Tumble dryer: After the softgel pressing is completed, the tumble dryer dries the softgels to remove moisture and extend their shelf life. You can choose the number of sections equipped with a tumble dryer according to your own preferences.

Drying tray: This part is similar to a cart, which is used to place the completed softgels for air drying. It can also be used to drag and drop soft capsules into drying equipment.

(5)Recycling system

Centrifuge: This part can be customized according to requirements, mainly to save damaged softgels and optimize the environment. It crushing scrapped materials into 2cm rubber blocks.

Recycling machine: This component mainly dries the crushed rubber blocks and then reprocesses them.

6.What are the Working Principle of Softgel Making Machine?

Do you really want to know how the softgel making machine operates? Let’s take a look together.

Working Principle of Softgel Making Machine

(1)Gelatin preparation stage

The required gelatin, water, and plasticizer need to be placed in a gelatin melting tank in proportion for hot stirring. Form qualified adhesive solution through melting, vacuuming and other procedures.The temperature of the adhesive solution is often maintained between 50°C -60°C. You need to pay attention to the temperature of the gelatin melting tank to avoid burns.

(2)Prepare materials

Grinding the semi-solid material using a colloid mill and pour it into a mixing tank, and mixing the required solution, suspension, etc. in a certain proportion in the ingredient bucket, which is the liquid in the soft capsule.

(3)Softgel filling

The prepared medicine is loaded into the hopper, and the glue is transported to the machine through a rubber hose. The rubber and medicine are pressed into soft capsules through a mold.

(4)Drying

The compressed softgels are transported to the tumble dryer for drying and shaping. This process usually takes eight hours. After the drying is completed, the softgels are placed in a drying tray to continue drying.

(5)Inspection

To screen the dried softgels, a softgel sorting machine and inspection machine can be used to screen out softgels that do not meet quality standards, such as uneven surfaces and inconsistent sizes.

7.How Many Different Types of Softgel Making Machine?

Have you ever seen a softgel making machine? Generally speaking, this machine can be classified into two types based on their scale.

(1)Small scale softgel making machine

Aipak SEM-50 Softgel Making Machine

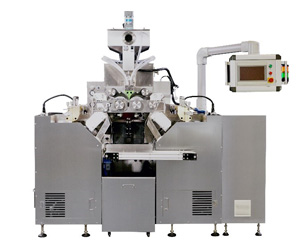

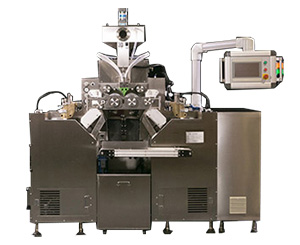

This type of machine has a relatively small footprint, with a production capacity of approximately 2,000 grains per hour. And it is mainly used in laboratories or small companies. This machine is relatively small in scale, but it has complete functions and can also achieve precise filling.

(2)Large scale softgel making machine

Aipak SEM-250B Softgel Making Machine

This type of machine has a large footprint and high production efficiency, with an output of approximately 6,000-8,000 sofetgel per hour. It is primarily utilized by large enterprises. The machine is fully functional and can achieve precise filling while maintaining high efficiency.

8.What Quality Standards Does the Softgel Making MachineFollow?

As a large machine, the softgel making machine produces products that are ultimately intended for human consumption and are related to people's health and life. This machine strictly adheres to quality standards for execution.

(1)cGMP

cGMP - Sourced: GOL Solution

cCMP is a rule set by the US Food and Drug Administration, which requires softgel making machines to maintain the best dust removal capability, the materials used must also be approved, and the machine must be safe.

(2)CE

CE - Sourced: IQS International

CE is a safety certification mark issued by the European Union. Machines that have passed this certification can protect consumers’ health, ensure product safety during use, and comply with environmental standards. Only machines that have passed CE certification can enter the European market, so softgel making machines strictly comply with CE certification.

(3)FDA

FDA - Sourced: iStock

The FDA has a wide scope of involvement and has put forward requirements for medical devices, strictly controlling harmful substances to ensure that products do not harm public health. Softgel making machines must strictly comply with quality system standards and undergo FDA review.

9.What Auxiliary Equipment Is Included With a Softgel MakingMachine?

In order to improve the entire softgel production line and provide customers with safe and high-quality products, the soft capsule machine can also be equipped with the following equipment.

(1)Softgel sorting machine

Softgel Sorting Machine - Sourced: theuspe

This machine can strictly control the quality of products. Although the precision of softgel making machines is gradually increasing, there are inevitably some defective products. To further ensure the quality of the softgels, you can equip them with a softgel sorting machine that can sort out softgels of different sizes.

(2)Softgel inspection machine

Softgel Inspection Machine - Sourced: Exlon Technologies

This machine can also control the quality of the product. This machine is equipped with vibration devices, mirrors, etc. Some softgels may have uneven surfaces, and a softgel inspection machine can inspect the surface of these soft capsules.

(3)Softgel Pulverizer

Softgel Pulverizer - Sourced: CapPlus Technologies

This equipment will produce unqualified soft capsules for recycling. This machine can separate the rubber and the materials inside, and process these separated items again, which can greatly reduce resource waste and minimize the company's losses.

10.What is the Difference between Softgel Making Machineand Standard Capsule Filling Machine?

Have you ever seen a regular capsule filling machine? What is the difference between the soft capsule machine and it? Let’s reveal the answer together.

(1)Filling materials

The materials used in these two machines are different. The materials that softgel making machines can use include liquids such as oil, gelatin, etc., while standard capsule filling machine are suitable for a variety of materials, including powders, pellets, and other materials.

(2)Filling methods

Besides, the two machines adopt diverse filling methods. The softgel making machine uses two rotating shafts to seal gelatin without a capsule shell. While, the conventional one opens the capsule shell, fills the material, and finally closes the capsule.

11.Should the Softgel Making MachineBe Equipped With a Fully Integrated Tumble Dryer or An Independent Tumble Dryer?

Whether this machine is equipped with a fully integrated or an independent tumble dryer depends on your choice. Generally speaking, the operation of the entire softgel making machine will be equipped with a tumble dryer.

Tumble Dryer - Sourced: FDP Specialties Group

If you want to equip an independent tumble dryer, it is also possible, but you need to be able to connect it with your other equipment to form a complete softgel production line. By choosing fully integrated tumble dryer, you don’t have to worry about the equipment of the machine, making it more convenient.

12.What Other Drying Options Can You Use In Softgel MakingProgress Besides the Tumble Dryer?

Tumble dryer is the most common drying system during the production of softgel, but there are also other alternative solutions available. If you have any needs, you can take a look at the following two options.

Option 1: Soft capsule drying tunnel

This device can also be customized based on your need. The purpose of this device is to dry the moisture in the softgels, to provide you with a comprehensive final product.

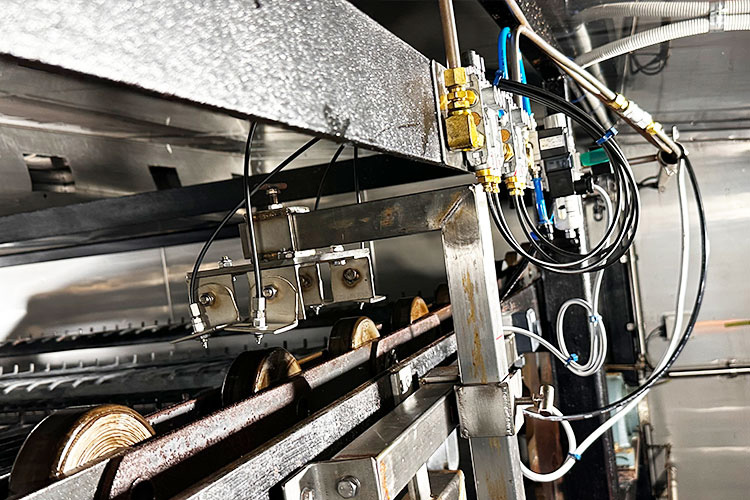

Option 2: In-line drying system for softgels

This system also can remove moisture from softgels. Besides, it can reduce the use of other devices, which makes it more efficient.

13.How Can You Polish Softgel?

Do you want to make the softgel more perfect? You can use the machine to polish softgel. To make the surface of the sofgel smoother and cleaner, a softgel polishing machine can be used.

Softgel Polishing Machine - Sourced: CapPlus Technologies

The operation of this machine is very simple, and all parts that come into contact with softgel are made of stainless steel. At the same time, the machine adopts a negative pressure waste removal device, which is pollution-free to the environment.

14.Are There Suitable Conditions for Sofetgel Process?

In order to achieve smooth production of softgels, it is necessary to strictly monitor the entire process of softgel production, so some sensors can be equipped for monitoring.

(1)Maintaining a certain temperature

Maintaining a Certain Temperature - Sourced: Freepik

When the machine is running, the temperature should not be too high or too low, and should be kept within a certain range. The temperature inside the gelatin melting tank should be maintained between 50°-60° degrees Celsius.

(2)Maintaining a certain level of humidity

Maintaining a Certain Level Of Humidity - Sourced: iStock

During the operation of the machine, the relative humidity of various components should be maintained within a certain range, generally between 30% and 35%.

(3)Controlling microorganisms and pollution

Soft capsules are related to human health. During machine operation, it is important to avoid contamination such as dust and other debris, as well as the influence of microorganisms.

15.How Does the Softgel Making MachineControl the Uniformity of Sofetgel?

It is very important to maintain the uniformity of softgels, which is related to the quality of the product. Do you know how this machine ensures the uniformity of softgels after continuous development and improved equipment?

(1)Calibrating micro pump

During the softgel production stage, you need to set the parameters of the micro pump. Inspecting and calibrating the micro pump to achieve precise filling.

(2)Checking whether each system is worn out

Checking Whether Each System Is Worn Out - Sourced: westend61

The wear and tear of the machine will affect the efficiency of filling. You need to check whether the mold system, valves, etc. are worn and need to replace them in a timely manner. In addition, you also need to inspect the entire soft capsule packaging equipment.

(3)Equipped with servo motor

Servo Motor - Sourced: moog

Compared to ordinary motors, servo motors are more stable and achieve more precise control. Therefore, many systems in the softgel production line are equipped with servo motors to achieve consistency in softgel production.

16.How to Control the Mold Synchronization of Softgel Making Machine?

The synchronization of molds is related to the consistency of the final softgel products. Do you know how to control the mold synchronization mechanism of this machine? There are two ways to choose from.

(1)Manual adjustment

Manual adjustment - Sourced: ACRA Machinery

If you don’t mind the trouble, you can use some small tools to make mechanical adjustments yourself and align the mold to achieve it. This method will be time-consuming and require a lot of manpower.

(2)Equipped with an automatic mold synchronization system

If you find it troublesome, you can choose a machine with an automatic mold synchronization system when purchasing, which reduces manpower and is more convenient. The benefits of adding this system far outweigh its costs.

If the molds are not aligned, the machine may not function properly. In addition, it is also possible to produce irregularly shaped softgels. Therefore, automatic mold synchronization is critical.

17.What Should be Considered When You Selecting a Softgel Making Machine?

When choosing a sofgel making machine, you must not blindly choose. In order to quickly understand the equipment, you need to consider the following points.

(1)Your production requirements

Different models of machines are required for different production capacity. You can estimate your own production capacity, such as 3,000 pieces per hour, so that the manufacturer can help you locate which machines.

(2)The shape and size of the softgel

Different Shape of Softgel

The different shapes and sizes of softgels have been introduced in the previous section. The machine molds equipped for different products are also different. Therefore, you need to provide the product you need, so that we can help you choose the appropriate mold.

(3)Workshop space

The entire softgel production line has five major systems and occupies a large area. You need to clarify how much space your factory has. The appropriate spatial location is necessary for the next purchase.

(4)Choosing experienced suppliers

Choosing Experienced Suppliers - Sourced: AuditComply

Choosing an experienced supplier can ensure that you receive the best softgel making machines and services. You can check the supplier’s website, visit the factory, and view customer feedback to evaluate the its strength. You can also check the ranking of the company in the softgel making machine and its reputation through the Internet.

18.How to Solve the Common Issues of Softgel Making Machine?

When using a soft rubber machine, if there is a problem, first refer to the following solutions for the problem.

Common Issues - Sourced: Sensum

(1)Uneven or cracked rubber

This issue will affect the overall product quality. You need to check if there are any debris in the mold and clean it up in a timely manner. In addition, you also need to check if the mold is worn out, and if it is worn out, it needs to be replaced in a timely manner.

(2)Inaccurate capacity

If the capacity of the softgels is inconsistent, it will affect the appearance and quality of the final product, making it difficult to deliver to the end customers. Therefore, in the face of such a problem, you need to check if there is air in the liquid, re mix the ingredients, replace the seals, etc.

(3)Material leakage

Material leakage may be caused by the viscosity of the adhesive, or it may be due to the blower not drying the surface temperature of the adhesive. You need to use a sensor to detect the temperature of the spray body.

19.The New Technologies in the Modern Softgel Making Machine.

With the development of the times and the diversification of people’s needs, manufacturers of softgel making machines are also increasing their research and development efforts, constantly introducing new technologies.

(1)Fully interlocked system

Some gelatin capsules may experience issues such as cracking or the entry of other foreign objects during the packaging process. Nowadays, many softgel making machines use fully interlocked systems to ensure the integrity and safety of gelatin capsules.

(2)Advanced gelatin saving technologies

In order to reduce resource waste and save gelatin, current softgel making machines are equipped with a modified spreader box system, greatly improving the situation.

(3)Easy to replace mold system

Due to the need for many factories to produce softels of different shapes and sizes, different types of molds are required. At present, the softgel making machine adopts an easily replaceable mold system, which is convenient for operators to adjust.

(4)Specialized lubrication system

Specialized Lubrication System - Sourced: JSG Industrial Systems

Previously, softgel making machines basically required manual maintenance, adding lubricating oil, and improving the filling efficiency of the machine. Now, equipping with a specialized lubrication system, the machine can automatically lubricate, reducing manual time and costs.

Conclusion

The application of softgel making machines is becoming increasingly widespread, and the demand is also growing. After reading this article, do you have a better understanding of softgel making machines? If you have any further needs to know about this machine, feel free to contact AIPAK at any time.

Don't forget to share this post!

Softgel Encapsulation Machine Related Posts

Softgel Encapsulation Machine Related Products

Softgel Encapsulation Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine