Gummy Packaging Equipment: The Complete FAQ Guide In 2025

Scrolling down to get the best gummy packaging equipment for your production? Are you interested in utilizing premade packages or designing your own? It is fully okay to have such strong concern regarding your gummy packaging, but do you have grip over the area of gummy packaging? Like what are the packaging requirements for various types of gummies? What is the labeling consideration, or the factors you should look for before purchasing gummy packaging equipment?

There are different aspects of gummy packaging equipment, and you should be familiar with all of them. Packaging is the way you get your products recognized around the world. It paves way for enhancing the charm of gummies. Therefore, you must be cautious about making your gummy packaging more attractive, safe and hygienic. This FAQ guide will assist you in this regard by displaying various aspects of gummy packaging equipment. Be sure to not miss any of them!

1.What Is Gummy?

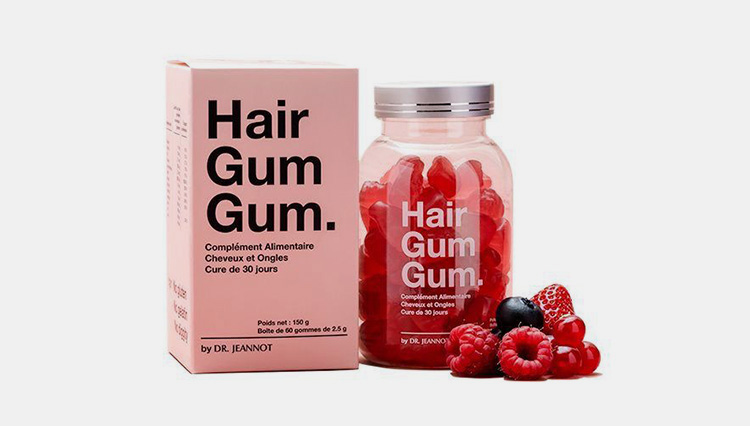

Gummy is gelatin based chewable candy which comes under the category of confectionary. It is made up of several ingredients including gelatin or pectin as a thickening agent, vitamins, sugar, colors and flavors. Due to its sugar rich juicy taste, it is becoming the most popular element among children and adults. Now, its presence can be traced outside food and confectionary industries due to the extension of its demand.

Pharmaceutical and nutraceutical industries are doing their best to provide their customers with medication through enjoyable means. This has eventually resulted in the production of gummy vitamins and supplements. After combining different vitamins, minerals and protein in form of gummy, an important step packaging becomes obligatory to retain the originality of the content. Hence, it is important to adopt safe methods for packing your gummies with quality material and giving them attractive look making and them more appealing to viewers.

2.Why Is The Gummy Become So Popular?

Gummy is becoming popular more and more every day. Gummies are delighted by many people who take them as snacks, supplements or adding into desserts. Following points would clearly display you the reasons behind popularity of gummy:

Delicious Taste

The most prominent reason which compel kids and adults to take gummies is the delicious taste which it possesses. It is favored both as confection and supplements, as people can choose gummies of their favorite flavors and get themselves enjoyed by chewing them.

New Alternative

Gummy is now used as an alternative to medicines in some extent due to sour taste and difficult swallowing. Gummies are in liquid form, thus can be easily absorbed in body than tablets which might take hours for dissolving. People have been amazed by the introduction of gummy vitamins for beauty and health leading them to take gummies for completing their nutritional health with immense pleasure.

Easy To Chew

Gummies are soft and easily chewable. Therefore, parents like to give their kids soft gummies which would not bother their teeth for crumbling hard candies. Furthermore, people who have trouble swallowing oversized tablets can chew gummy vitamins easily.

Alluring Appearance

Gummies come in beautiful shapes and colors which grab the attention of consumers. They cannot stop themselves from picking up the gummy bears, gummy flowers and gummy toys which can be eaten.

3.What Do You Mean By Gummy Packaging Equipment?

Gummy packaging equipment refers to the machine utilized for packing gummies, candies and jellies in individual bags or containers in order to maintain their color, taste and quality. It intelligently fills the exact volume of gummies in pouches or bottles by using multi-head weighers.

The structure of machine is made up of durable stainless steel and complying other safety regulations to fully assure that the gummies being packed are free of contamination and pollution. It enables you to pack the gummies in a perfect way while reducing time, labor and error. In addition, you can find different types of gummy packaging equipment with varying capacity, size and cost to acquire the crucial part of your gummy production.

4.Why Gummy Packaging Equipment Is Essential For Gummies?

Packaging is an important step for any type of production especially when it is related to food products. Hence, it cannot be overlooked due to the following reasons:

To Keep Integrity

The major purpose of packing gummies is to maintain their structure, shape and integrity by keeping them united under single pack, so they can be protected from damage.

Preserve Quality

To preserve the quality of gummies including taste, color and texture till they reach consumers, is an essential task. Therefore, several types of bags, pouches or containers are used for packaging gummies to reduce quality degradation which might caused by the direct contact with moisture, pollution and light.

Promote Easy Consumption

As there are numerous packaging alternatives available, including single gummy packs, stick packs, stand-up pouches, and bottles, people may easily buy their preferred gummy separately rather than purchasing whole carton.

Brand Promotion

Packaging is the most significant element which can help you in promoting your brand by giving unique identification and designing to your products. Resultantly, your customers will always be in search of your gummy packs.

5.How Can You Operate Gummy Packaging Equipment?

A gummy packaging equipment can be brought into operation through simple steps which can be understood by the following points:

Feeding Machine

The initial step of gummy packaging is feeding machine with bulk of gummies which are supposed to be packed in bags. Gummies are loaded in the collection tank which is attached to the main machine.

Bag Forming

In second step, the formation of bag occurs. The roller of printed film starts dispensing film for forming bags. The large circular metal rod is used for this purpose, over which film is dispensed. The film is sealed by back side and lower side.

Gummy Weighing

It is a crucial step which involves the measurement of gummies. Multi-head weighers are used to measure gummies. In start, gummies are delivered by hopper to the multi-head weighers which is followed by linear weighers and vibratory weighers. The exact dosage of gummy is then transferred to individual gummy holding devices.

Bag Filling

Here, the process of gummy filling happens when precise and fixed amount of gummy is delivered to the formed bags.

Bag Sealing

Finally, after the filling, sealing device come into action and hermetically seals the pouch through heat. The bag is separated from film through cutting and discharged by the output product conveyor.

6.What Are The Benefits Of Using A Gummy Packaging Equipment?

You can get lots of benefits by using a gummy packaging equipment including:

Fast Turnaround Time

Using a gummy packaging equipment better enable you to produce and pack your gummies in less time. It takes a very brief time to pack bulk gummies and increasing overall production.

Prolong Shelf Life

It can extend the shelf life of your gummies by keeping the optimal barrier layers between gummy and environmental effects.

Safety Assurance

The stainless steel body of the machine ensures safe and hygienic environment for gummies which are processed by it. The anti-acidic layers of the area in contact with gummies is free from bacterial presence.

Eco-friendly

Gummy packaging equipment ensures smooth running of packaging material and reduces the waste to lowest. It does not emit any harmful gas for sealing bags and the waste packaging material is simply transferred to recycle bin.

7.Describe The Major Components Of A Gummy Packaging Equipment?

Each type of gummy packaging equipment has its own components which may slightly vary from other types of machines. The main parts of a gummy packaging equipment are as follows:

Control System

Gummy packaging machine has a control panel that is used for giving your input to machine who will run the programs accordingly.

Collection Bin

It is the collection tank attached with the gummy packaging equipment through product transport unit. It provides the machine with gummies which have to be filled in packages.

Multi-head Weighers

As the name indicates, this part is composed of multi-head weighers which are used for accurate weighing of gummies. It is linked with a single hopper located above it. There are different types of weighers like multi-head weighers, linear filling weighers and vibratory weigher.

Counting Sensors

Counting sensor is a type of long passing channel which count the gummies by detecting. It is directly linked with the filling bags and thus allow accurate amount of gummy filling.

Dosing System

It consists of reclosable jaws holding an exact amount of gummies which is dispensed into bags or bottles.

Conveyor Belt

Conveyor belt is also known as transport unit which allows the quick movement of products during packaging.

Sealing System

During gummy packaging, sealing is the crucial part which is carried out by a sealing device. It consists of sealing jaws which are used to seal the opening of bags tightly through heat and cool it down.

Cutting Device

The filled and sealed bags are separated by the sharp cutting blades located in machine as the cutting device.

8.Explain The Various Types Of A Gummy Packaging Equipment?

There are different types of gummy packaging equipment used for the safe, beautiful and hygienic packaging of gummies. These include:

Vertical Form Fill & Seal Machine

Vertical form Fill and seal packaging machine is commonly used for the packaging of gummies. It forms vertical shape bags from small size to large one.

Components

consists of collection bin, a conveyor belt, multi-head weighers, pouch former, sealer, cutter, film roller, stainless steel body, casters and supporting stand.

Working Principles

The machine start processing when gummies are loaded in the collection bin. These gummies gradually falls into the compartments in conveyor belt. The conveyor belt take these gummies towards hopper, where gummies passed through different weighers and collected in closed jaws from upper side. The formation of bag occurs as the film start dispensing. After the sealing of bag from one side, the jaws holding gummies open and fill the pouch. The sealing, cutting and discharging finally leads to the end of process.

Automatic Jar/ Bottle Filling & Packaging Machine

Another type of packaging machine used for gummies is jar/ bottle filling and packaging machine. It can accurately fill the containers with exact amount of gummies effectively.

Components

The machine comprises bottle feeding turntable, hopper, multi-head weighers, collection tank, gummy transporting unit, conveyor belt, control unit, and bottle capping unit.

Working Principles

Empty bottles are placed in the bottle feeding turntable and gummies are loaded in the collection tank. After the machine get started, bottles begins moving towards filling station and the gummies are conveyed to hopper. The same process of passing gummies through series of weighers to make sure their quantity is reached to exact level. The dosage of gummy is then dispensed into bottle through gummy discharge chute. The bottles are filled one after another and taken by conveyor belt towards capping.

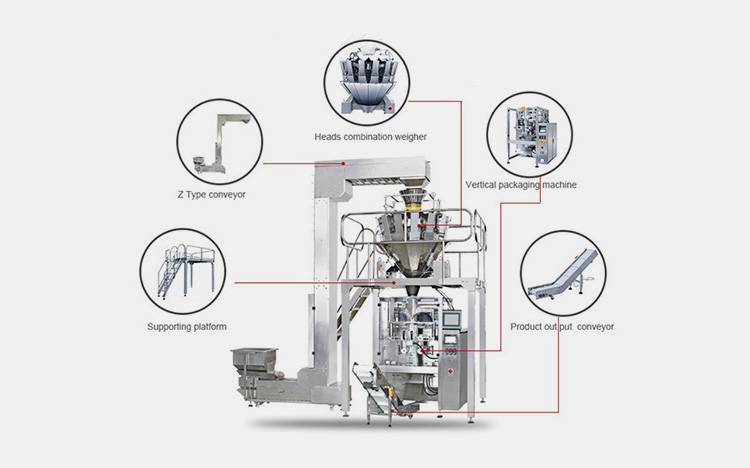

Premade Pouch Filling & Sealing Machine

Most of the gummies are packed in premade pouches for which this type of machine has been introduced. It measures the gummies intelligently and pack them into premade doypacks or stand-up pouches.

Components

The machine consists of control system, pouch feeder, gummy collection device, Z type conveyor, heads combination conveyor, supporting platform and pouch sealing device.

Working Principles

Gummies are first loaded into collection container. Along with that, premade pouches are placed in pouch feeder. The process starts when machine is turned on, the conveyor belt delivers bulk gummies to hopper located over multi-head weighers. Here the gummies are weighed and delivered to series of reclosable jaws which moves in rotary direction. On the other hand, the robotic arms pick up pouches, open them one by one which are filled by the dosing device after opening jaws. The filled pouches are sealed and discharged through conveyor belt.

9.Which Type Of Packaging Are Carried Out By A Gummy Packaging Equipment?

Due to the different kinds of gummy packaging equipment availability in market, you can use various packaging options for your gummies such as:

Bags

The most popular packaging type is bag which is made during the packaging process. Plastic and aluminum foil is commonly used as the packaging material in bags. These bags can be used for packing single gummy or number of gummies in each bag. However, the amount of gummies in bags are often lesser than other packaging.

Pouches

Another type of packaging is pouch which is more durable than bags. Premade doypack or stand-up pouches are usually used for the packaging of gummies which contains large number of gummies.

Bottles

Along with other packaging containers, bottle is the most notable. You may find plastic bottles or glass bottles filled with gummy vitamins or gummy supplements. These bottles are premade and filled by the gummy packaging equipment.

Cans

Cans are light weighted and hygienic containers made from aluminum or stainless steel. They are 100% recyclable and give your products charming outlook. Thus, most of the brands uses cans for their gummies to identify their production unique.

Cartons

Cartons are prepared from paper giving you cheap and reliable for packaging your gummies. The size and shape of cartons may vary, however, the attractive labeling make them more desirable to consumers.

10.Which Necessary Information Should Be Printed On The Packages Processed By A Gummy Packaging Equipment?

The packaging step is necessary because of the certain essential information which should be labeled over it such as:

Brand Name

The first thing your packaging should depict is the brand name of your production. It must be printed in the front side of packaging bag or container. This will help your customers to reach out their trustable supplier.

Nutritional Chart

Another important thing is the nutritional chart which comprises calories, fats, sugar and vitamins the gummies possess. It is helpful as most of the people prefer to know about the nutritional value of the goods they want to consume.

Expiry Date

Date of manufacturing and expiration is obligatory to mention over your packaging, as it would enable the users to take notice of the validity of gummies. Else wards, it may lead to serious side effects in case of taking expired gummies.

Batch No

Batch no consists of several letters, numerals and symbols which helps in tracing the manufactured goods.

Precautions

It is a matter of common observation, that people do have allergies or any other limitation on their health due to which they take care of diet. Here, it is important that the manufacturers should display necessary precautions and warnings to aware people about the possible reactions may cause due to allergies. This will ultimately assist the consumers to be cautious when taking their favorite gummies.

Ingredients

Different types of gummies contains different ingredients. For instance, gummies may be made from gelatin, but on the same hand, pectin and carrageenan are used as substitute to gelatin. Thus, the ingredients used in gummies should be labeled to enable the consumers with them.

Dosage

Gummies used for kids have lower dosage than that of used for adults or older people. So, the dosage for each day should be mentioned for the users ease.

11.What Is The Production Line For Gummy Packaging Equipment?

If you are engaged in the full-fledged business of gummy production, then you must be familiar with the production line for your gummy packaging equipment. The production line consists of following machines.

Gummy Making Machine

No doubt, gummy making machine is the inevitable part of gummy production line. It enables you to produce the desired number of gummies in different colors, taste and sizes. Gummy making machine consists of gelatin melting tank, gummy depositor and gummy cooling tunnel. After passing through these essential machines, gummies can be further processed for packaging.

Gummy Counting Machine

Gummy counting machine plays effective role in making your production more perfect by helping in counting gummies . It uses sensors to detect the numbering of gummies inside bottles.

Bottle Capping Machine

Gummies are also packed in glass and plastic bottles for which bottle capping machine would be requirement. When bottles arrive at capping machine through conveyor belt, it accurately places the bottle lids over them and start screwing for tightly sealing the bottles.

Palletizer

Your large production scale business may ask you to ship your products around the world. For the accomplishment of such task, you have to adopt the safe means in which palletizer would be inevitable. It helps you in making the integrity of your goods and loading them in stack form.

12.What Are The Uses Of A Gummy Packaging Equipment?

Gummy packaging equipment can be used in large number of areas including following:

Food Industry

The first area where presence of a gummy packaging equipment can be found is good industry. Due to the versatility of machine, it can be used for the packaging of beans, dry fruits and pulses etc.

Pet Food Industry

Pet food is packed in bags and containers to provide safe and contamination free environment. It is perfectly done by the gummy packaging equipment.

Pharmaceutical Industry

Gummies produced by healthcare and pharmaceutical industries are used for maintaining healthy lifestyle. They also need proper packaging to reach consumers in an unharmed way, for which a gummy packaging equipment is the requirement. Furthermore, or packaging pills, capsules and medicines help of this machine can be taken

Nutraceutical Industry

Gummy for beauty and health are now effectively produced by the nutraceutical industry. It eventually leads the industry to make use of gummy packaging equipment for secure delivery of produced gummies.

Confectionary Industry

Gummy packaging equipment can be utilized for packaging candies, gummies, chocolates, jellies and other confectionaries. That's why, the confectionary industry is constantly taking help of this device.

13.Which Determinants Should You Look For When Buying A Gummy Packaging Equipment?

Purchasing a right gummy packaging equipment is an overwhelming task, which needs proper consideration. Following determinants can help you in this regard:

Warranty Policy

If you are intending to purchase a gummy packaging equipment and invest a huge amount of your money, it is necessary to take the guarantee of the machine. For this, the most convenient and reliable method is checking the warranty policy which would ultimately provide you the safe side.

Feedback

To know the service of company, must go through the customer reviews and feedback about company. It can be proved a great source to know the service of the manufacturer.

Speed & Capacity

Check the speed and capacity of the machine you want to purchase. The more the machine will be automated, the efficient rate of packaging it would have.

Price

Another factor is to look towards your economical situation. If you are new to industry and having small scale business, it is better to choose semi-automatic or other precise machine having reasonable price. On the other hand, if the current status of your business is prosper you can definitely go for high quality automatic machine which may charge you more but would give exceptional results.

Customer Service

Buying a gummy packaging equipment is not a child play, you have invested the large amount of your pocket, thus you should look for the vendor which provides full customer support and timely response in case of any problem.

Conclusion

After going through the details given below, you may have cleared your concept how important role the gummy packaging equipment play in your manufacturing, that you should never try to take risk of avoiding its use. However, you should be concerned about the quality equipment and must consider the information provided above. If you want to know more or in search of a trustable and reliable supplier for gummy packaging equipment, we recommend you to consider AIPAK Pharma which has successful experience of over 15 years in providing advance technology for packaging.

Don't forget to share this post!

Gummy Making Machine Related Posts

Gummy Making Machine Related Products

Gummy Making Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine