Your Best Industrial Gummy Candy Depositor Machine Supplier

Servo Single&Double Head Depositing

Controlled Depositing Speed

Customized Gummy Molds

AIPAK Gummy Candy Depositor

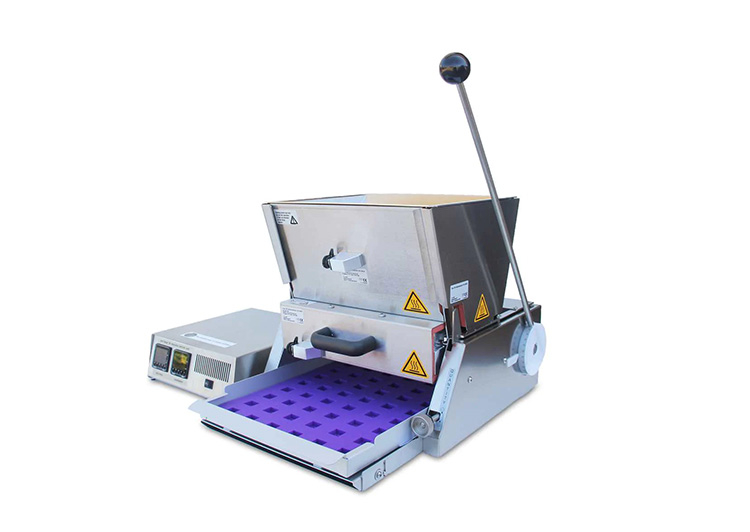

AIPAK gummy candy depositor is a small batch depositor machine used to pour syrup into different molds to produce different shapes’ gummy candy.Gummy candies of different sizes and shapes can be customized according to your need with single color,double color or gummy candy sandwich.It is suitable for small or medium-sized candy manufactures or scientific research units for product development.The gummy candy depositor occupies small space and easy to operate.Adopt PLC and touch screen,the gummy candy depositor is controlled by servo motor,its depositing volume and speed can be easily set on display.The whole gummy candy depositor machine is in simple structure and easy in installation and maintain.

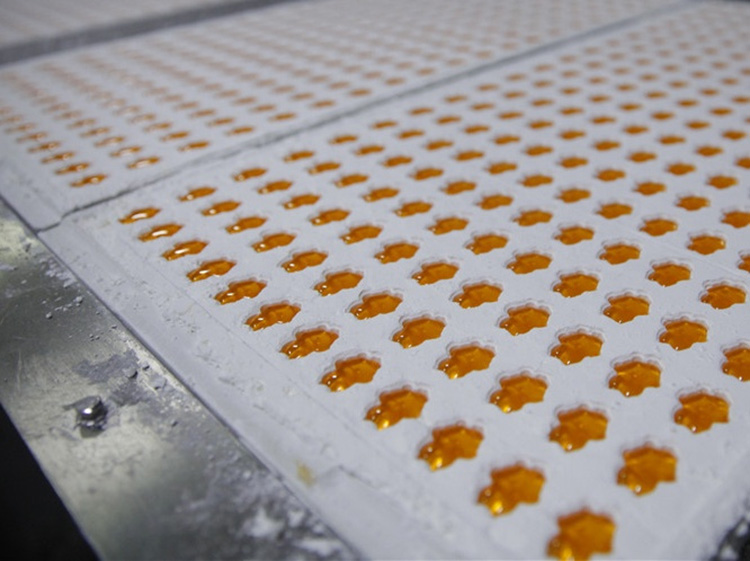

AIPAK Gummy Candy Depositor Sample Display

The Buyer's Guide

Gummy Candy Depositor: The Complete FAQ Guide In 2025

The gummy candy is always known as the most popular treat in the recent days. The gummy candies have been associated with new magical tastes and visual appealing shapes and colors which is the reason behind its day by day successful market value.

Interested in start up the gummy candy business? This is the right place to find all general queries that you are searching for. Our experts have carefully described the details about gummy candy depositor along with useful illustrations for you understanding. Let read now and comment us about how you find our efforts.

1.What is Gummy Candy? Why it is so popular?

The gummy candy is an enticing invention sprung in 1922 just in the backyard kitchen of German gummy candy maker Hans Riegel, a well-known owner of HARIBO. Do you know what ingredient is exactly played a magic? It was a ‘gum-Arabic’ that helped him in the making of chewy, elastic, and stretchable candy! Well, what you all know is, the gummy candy is absolutely delicious.

The particular reason behind its popularity is its shape. First, the maker invented gummy candy by creating it in the form of ‘bear’. This shape obtained a tremendous popularity among the folks. Moreover, the other variation were added and gained a fame among the children, youngster, and even old age people. However, the other reasons are:

| Colorful

|

No one can get bored when grabbing gummy candies as they’re available in various colors, bi-layer, tri-layers, and so on, that’s making them extremely vibrant. |

| Sweet

|

Due to various sugars and flavors making them extremely tasty that makes you happy when consuming. |

| Chewy

|

Due to presence of gelatin, gum-arabic, or pectin, the gummy candy are chewy in texture. This is an essential property of gummy candy. |

| Fun-Filled

|

The gummy candies are fun-filled treat offered to you in various unlimited shapes. Everyone loves to grab them. |

| Small & Compact

|

The regular gummy candies are not so big, they’re tiny and acceptable pack during picnic, road trips, offices, movie or celebration parties. |

| Healthy

|

They’re available as vegan and non-vegan. Both of these options are extremely healthy as it contains reducing sugar, starch, flavors, and sometime active ingredients such as vitamins, organic supplements making them a good options for health conscious people across the globe. |

2.What is Gummy Candy Depositor?

A Gummy Candy Depositor

The gummy candy depositor is an innovative invention to manufacture gummy candies of various shapes, colors, sizes, and capacities. The machine is capable of making uniform and accurate gummy pieces in a controlled manner. Overall, the produced product is able to stay longer with holding various nutritional ingredients and fruity flavors as freshly ripened.

The gummy candy depositor is an easy to operate machine helpful in running a programable operation with user safety and compliant to various international quality control certificates. If you’re running an industry and want to gain a good competitive market, then gummy candy depositor is the best solution to add into your production to achieve the large gummy candy output in an economical way.

3.What are the Advantages of Gummy Candy Depositor?

The gummy candy depositor is manufactured to assess various difficulties faced by consumers, so the new machines are manufactured by combating the previous problems and offering amazing benefits, some of which are discussed below:

Modular and Flexible Make up

The modular design of gummy candy depositor

The gummy candy depositor is designed with modular technology that helps you in the integration of the machine with other without tiresome ways. For example, the gummy candy depositor is linked to cooking unit, cooling tunnel, packaging units, and other without time consuming procedures. So now you can run the appropriate production line.

Excellent Automation

Excellent Automation gummy candy depositor

The gummy candy depositor is created in various ways offering several automation, and batch capacities, allowing greater automaticity with lesser human intervention with the machine. You just need to visualize the process without needing two or three technicians to run the process.

Extremely uniform Production

Extremely uniform Production- Gummy Cansy Depositor

The gummy candy depositor offering you the greatest advantages of producing large batches without variation hence you can carried out effective capacity rate.

No Tough Manual Labor

Ease of operating with low labor force

The machine is quite reliable and able to work with minimal labor requirements. You just need to place the depositor in front of filling nozzles and allow the machine to work then remove the mold respectively.

The gummy candy Depositor- Easy to Clean and Maintain

Gummy candy depositor is easy to clean and maintain unit

The machine is made up of stainless steel hence it is very easy to clean, and its maintenance is also flexible as machine parts doesn’t prone to stick the gummy particles and offering simpler repairing and have high strength plus longevity.

A Pocket Friendly Machine

A gummy candy depositor is a very cost economical machine that gives you high business by making quality products in a cost effective way.

Highly Customize Profile

The machine is able to offer various shapes, various colors, and flavors of gummy candies. Now you can make whatever shape you need or can run the system by customer’s demand efficiently.

4.What are the general Applications of Gummy Candy Depositor?

If you look into the functional applications of a gummy candy depositor , you will find enormous useful purposes it can be utilized for effectively in many industries.

Some of them are pharmaceutical, nutraceutical, food, cosmetics, veterinary and in making of some stationery items. You’ll have an insight on them further.

Pharmaceuticals

Delta 8 THC Gummies – Picture courtesy: Experience CBD

A gummy candy depositor is used by pharmaceutical company for producing gummies that are infused with THC or CBD. Medicinally filled pills or capsules can also be deposited by the role of gummy depositor as it is precise and accurate in dose delivery.

Nutraceuticals

Nutraceutical Gummies – Picture courtesy: Private Label Gummie

Nutraceutical industry has a great contribution to the use of gummy candy depositor as they formulate gummy candies that are filled with different vitamin supplements that propose to be for dietary deficiencies.

Food

Gummy Candies – Picture courtesy: NPR

Gummy candy depositor belongs to the food and confectionery industry as a huge sector involves producing soft and hard candies that are filled using this equipment.

Soft chewable candies like gummies, jelly beans,bubblegum and chocolate while hard candies like toffees and ganache are made using gummy depositor. Gummies can also be produced as a topping for different desserts and sweets.

COSMETICS

3D Printed Skin Supplements – Picture courtesy: Trend Hunter

When it comes to producing enticing cosmetic products that could be used to revitalize and look after your skin, hair, and healthy nails, gummies have transformed them all into eatable vitamins that work miraculously to enhance your beauty experience.

Cosmetic manufacturers have also formulated products that are gelatin based or vegan based such as gummy/jelly lipstick, gummy/jelly lip balm, gummy mask, and even gummy like soaps involving the use of a gummy candy depositor.

Veterinary

Flavored Gummies For Dogs- Picture courtesy: Dalmatian DIY

Veterinarians deduced that pet health is quite similar to human health, and so animals too require nutrients for healthy functioning. Veterinary industry has therefore opted a new way to introduce pet medicines in the form of gummies, having essential nutrients and even medicated ingredients inside those appealing gummy candies.

Another remarkable product is a gummy sponge which works if you place it on any surface to clean pet hair that is stuck at places in your house.

Stationery Items

Gummy Bears Paper Clips

Eye-catching and interesting stationery items are strangely also made up of gummies. Not really, although they resemble and have structural similarities to soft gummy candies. You might have come across jiggly gummy bear shaped pencil toppers, cute gummy shaped erasers, and even gummy like paperclips.

5.What Is Composition of Gummy Candy Depositor?

The Parts of Gummy Candy Depositor

A gummy candy depositor is a compact solution for manufacturing medium to large batch production. If you see the picture; the given labeling would help you to understand its superficial featured units and possible working. However, we have carefully described the roles and about them below.

Sensor

This is the most important and significant components helps in determining the temperature variation inside the system and allows it to maintain when it drops down. Without a regulator, it would be really hard to run the process with ideal outcomes. The machine ideal for making gummy candy without worrying about temperature fluctuations as it has held this responsibility to maintain consistency and quality of the product.

Hopper

The gummy candy depositor is equipped with a hollow bucket which is used to hold the gummy candy slurry for the depositing process. The gummy candy slurry is a prepared formulation therefore hopper allows constant and seamless flow of the formulation directly into the gummy candy depositor when required ensuring uniformity and ease of working.

Gummy Candy Nozzles

The gummy candy nozzles are a set of narrow tubes which help in the dropping down of gummy candy formulation directly into the depositor. The nozzles are the must have unit ensuring perfection and accuracy in the flow rate which is required for ideal shapes of gummy candies. The nozzle controlled operation helps regulate the over and under-flow of the formulation.

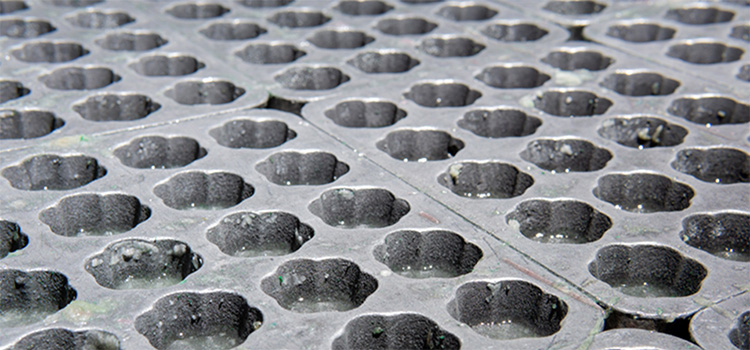

Molding Tray

This is the section where you can adjust the gummy candy depositing tray manually in order to take the desired concentration of the formulation into each cavity. The set of molding tray are available in various shapes that we’ve discussed later in this article.

Pedal Switch

As it name suggests, user have to press the unit by foot to operate or stop the machine anytime. The pedal switch use air pressures that converts electrical energy into the mechanical energy in the triggering the gummy candy nozzles to squeeze the calculated concentration of the gummy formulation.

Adjustable Tyres

The machine is quite flexible to move from one location to another by the help of adjustable rolling tyres. Now it is easy to integrate the gummy candy depositor with other units in no time as it is easy to move and work without any vibration.

Control Panel

This is the prime section that regulates the major settings such as the amount of gummy candy liquid, monitoring and controlling temperature, and nozzle control, as well as critical problems during troubleshooting, which is easily handled by the control panel. This is an enclosed box that hold various parameters and keys inside offering a safe system.

6.How Gummy Candy Depositor Does Work?

The working of gummy candy depositors is included in three basic sections.

Cooking Phase

The cooking phase gummy candy depositor

This is the first phase of gummy candy making process where various enlisted raw materials are subjected to a cooking unit and storing unit for melting and holding jobs. The basic raw materials include:

| Gelatin | Gelatin is the major ingredient which is the reason for behind smooth texture and chewy gummy candies consistency. The gelatin is mostly obtained from animal sources but to addition of additives like flavoring agents helps in the enhancing of taste and fruity smell when eating the gummies. Gelatin also has health benefits hence preferred by various manufacturers in the making of therapeutic gummies. |

| Pectin | This is a good replacement for animal-based gelatin which is mostly favored by people who are vegetarians. The pectin is obtained from the cell wall of citrus fruits and vegetables such as apple, orange, lemon, and others. |

| Reducing Sugar | The reducing sugar is also the main primary ingredient of gummy candies which include, glucose, sucrose, maltose, and other. Without sugars you cannot achieve the sweetness in gummy candies. |

| Color | The natural color is obtained from fruit and vegetable sources like mangoes, pine apple, oranges, lemon, berries strawberries etc., the colors are an important ingredient that brings vibrant and appealing appearance in the gummy candies. |

| Flavor | The flavoring agents help in the enhancing of fruity flavors when eating gummy candies improving enticing taste. The commonly used flavors are orange, lemon, pomegranate, mango, and others. There are some artificial flavorants also used in the gummy candies such as methyl anthranilate which are of course natural but passed through some synthetic procedure to form an active ingredient. |

| Syrup | A thick consistency in the gummy candy formulation is enhanced by the addition of corn syrup which is used to enhance the viscosity in the candies. |

Now all the ingredients are added into the cooking unit which is made up of an agitator, heating pipes, and a double jacketed closed system where raw material is cooked for around 10 to 12 minutes under the temperature of 108-110°C which is suitable for melting them. The prepared slurry is stored in a storage tank where the desirable temperature is observed around 60 to 70 °C.

Depositing Phase

The gummy candy depositor

The gummy candy formulation is transferred to the gummy candy hopper via connecting pipes or by manual technique. The hopper is mostly designed in a way that allows the warm temperature to the formulation so it won't condense or affect the consistency of the slurry. Now it is turned to place the mold manually. The machine allows the dropping of specific amounts of the gummy candy syrup into each depositing cavity. Once the depositing tray is filled, you can remove and place the new one.

Cooling Phase

Cooling Tunnel

Now the depositing molds are subjected to cool down for a certain temperature (0 to 10°C ) and a certain period of time (10 to 20 minutes). Once they acquire a shape, you can de-mold them and leave them for further drying to evaporate the moisture content.

7.What is the classification of Gummy Candy Depositor?

A gummy candy depositor can be classified according to its ability to function either on its own or requiring the involvement of an operator. This equipment can be found in specifications like, manual, semi-automatic, and automatic.

You’ll read their particularities below.

Manual Gummy Candy Depositor

Manual Gummy Depositor Machine – Picture Courtesy: FC Filtration

A manual gummy candy depositor is also called a bench top depositor, it is suitable to work for producing gummies at small scale industrial setups for home-based businesses or for homemade consumers. This machine can fill in gummy candies such as jellies, chocolates, and other candies into their mold cavity and form any shapes of gummies you want to achieve. However, the batch size production and working efficiency are smaller compared with other advanced types of depositor machines.

Semi-Automatic Gummy Candy Depositor

Semi-Automatic Gummy Candy Depositor- Picture Courtesy: Snack Food and Bakery

This is an advanced form of gummy depositor as it works semi automatically in the process of filling gummy mixture into molds, and an operator is required to feed instructions, change the depositing molds, and control the depositing step by using their foot.

A semi automatic gummy candy depositor is constructed of stainless steel and has easy operability due to a simple layout. It produces gummies, chocolates, and hard toffees as well but the batch production is on a minor scale compared with automatic depositors. Based on its size, it can easily be placed in a small to medium setup of industry and can be moved and adjusted conveniently.

Automatic Gummy Candy Depositor

Automatic Gummy Candy Depositor

An automatically functioning gummy depositor is the most advanced form of gummy candy depositor, as it has high production output and has heated panels and maximum efficiency pistons that work to deposit thousands of gummy pieces per hour.

It can handle the deposition of all types of gummy candies ranging from soft jellies to hard candies, chocolates, and caramel to medicinal gummies. Starting from the mixing process to demolding, the whole procedure is carried out smoothly on its own. An operator needs to control the PLC system to ensure reliable production.

8.What Auxiliary Equipment Are Associated with Gummy Candy Depositor?

The making gummy candy is not a one-man show, but it requires various other integrating and assisting machines and units to run a smooth operation. Some of the important auxiliary equipment are listed below.

The Gummy Candy Trays

The Gummy Candy Trays

The silicon made gummy candy trays play a significant role in the drying of gummy candies once demold from the demolding section. The trays are not too deep but designed with slated rows that helps in the movement of dry and warm air to evaporate the moisture content present in the gummy candies. The estimated moisture content in the gummy candy depositor should be around 18%. The various number of gummy candy trays are required for gummy candy manufacturing process.

Gummy Candy Tray Dollies

Gummy Candy Tray Dollies

These are transferring units used to carry gummy candy trays from the depositing, demolding, and cooling unit to the drying room. Once they are dried, these carts or dollies are helpful in transporting racks to the packaging unit. the gummy candy dollies are manufactured by food grade materials with high quality standards.

Gummy Candy Sand/Sugar/Oil Coating & Polishing Machine

Gummy Candy Sand/Sugar/Oil Coating & Polishing Machine

The gummy candy coating machine is used to pour a spray of either sugar, sand, or wax to enhance the texture, and taste, and polishing the overall appearance of the gummy candies. The machine is designed with a hollow movable tank or cylinder that revolves and allows the gummy candy bed to expose to the spray front to get overall and better coating.

Elevating Conveyor

An elevated conveyor

The gummy candy elevator is used to connect the continuous supply of gummy candies from the drying chamber/room to other important units such as the coater and polisher. You can easily transfer bulk of material using an elevator hence reducing the manual handling and cross-contamination.

9.What Various Shapes Gummy Candy Depositor Offers?

By involving the use of a gummy candy machine, there are a large number of unique and innovative varieties of gummies that can be designed. From the old and traditional gummy bears to many newly created shapes having 2D and 3D structures like gummy blocks and gummy burgers, you’ll see what different shapes a gummy candy machine can make for you!

Traditional Gummy Bears

Flavored Gummy Bears – Picture courtesy: The Candy Bar Toronto

Firstly introduced by Rigel, this shape of bear like gummy candy was designed inspired by dancing bears. They’re popular for it’s mini sized different flavored bear gummies which are enjoyed by consumers around the world.

Gummy Worms

Neon Gummy Worms- Picture courtesy: Marie’s Candies

Ever heard that you could eat sweet and delicious worms without nausea? Gummy worms are made for you in exciting flavors and neon colors. These worms also come in sour taste and are available in small and long sizes too.

Gummy Rings

Gummy neon rings – Picture courtesy: Jack’s Candy

Circular ring shapes that are made into gummies are available in flavors such as strawberry, apple, peach, etc. They come in both sweet and sour flavors and are present in colors similar to their flavors or have a neon multi flavored taste too.

Gummy Fruits

Gummy fruits- Picture courtesy: Handy Candy

Gummies are also available in the shapes of various fruits and are instilled with a similar fruity flavor in that shape. Gummy fruit shapes like strawberry, lemon, pineapple, banana, mango, orange, watermelon , and peach are commonly found infused with the same respective fruity flavors.

Gummy Lego Blocks

Edible Lego Gummies- Picture courtesy: Bored Panda

This 3D shaped gummy candies are a flavorful delight to add to your occasion if you’re hosting a Lego-themed party or kids may enjoy them for fun. Lego gummy blocks might be exciting for your kid if they’re fond of playing with blocks!

Gummy Shark

Gummy Blue Sharks – Picture courtesy: The Bulk Store

Afraid of sharks? Not anymore! Because these gummy shaped shark candies can now be savored into your mouth, offering sweet and juicy flavor to your taste buds. Gummy sharks come in blue and white colors or they may even be made into other color combinations offering exciting flavors.

Gummy Cupcakes

Gummy cupcakes – Picture courtesy: Baby Bliss

Gummy cupcakes are 3D shaped chewy treats that are interestingly made without the need for an oven and are an awesome snack to serve at any of your events. These cupcakes are made into appealing colors and have milky and fruity flavor added to them.

Gummy Alphabets

Gummy Alphabets

Alphabets can not only be read but eaten too! These gummy alphabets are manufactured in various colors and flavors and can be added to events such as preschool and vacation parties.

Gummy Strawberry

Gummy Strawberries – Picture courtesy: The Original Lolly Store

Gummy strawberries are candies that are shaped like strawberry fruit and possess the usual red and green color having the same taste as strawberry. They are favorites amongst kids and adults for their delicious taste.

Gummy Cola bottles

Gummy Cola Bottles -Picture courtesy: South Cove Foods LP

A mixture of candy and soda seems weird but not if you consume them in the form of cola bottle gummies. Bottle gummies are also one of the older shapes of gummies that are still found and enjoyed by many people.

Gummy Patches

Gummy sour patches- Picture courtesy: Nuts.com

Colorful and flavorful, small patches of gummy candies that are available in rainbow colors and individual colors, have sour and fruity taste in them. Strawberry gummy patches, blueberry gummy patches, and even cola patches of gummies are present.

Gummy Fast food

Gummy fastfood candies

Burgers, hotdogs, pizza and french fries can now all be devoured in sweet flavors as gummy candy makers have now transformed them into shapes! Gummy fastfood candies are 3D shaped mini flavorful sweets that seem too realistic.

10.What are the challenges and solutions of gummy candy depositor?

The gummy candy depositor meets with some technical challenges, discussed below are the points along with their solutions.

The flow of dissolved material is slow

The slow flow of formulation ingredients- Picture Courtesy: QHBake

This is the common problem where the rate of flow of gummy candy formulation is very slow. This could have occurred due to the high consistency of the gummy candy formulation. Due to this problem, the overall quality of the gummy candies could be affected. Moreover, the machine's internal system could be blocked to avoid excessive or appropriate flow of slurry.

Solution

To deal with this solution, the SIP and CIP method of cleaning the gummy candy system is employed. This system allows boiling water to run through the system to flush out the sticky and stubborn particles inside the circulatory system. Moreover, the machine should be reset and assessed with a test run prior to real time procedure.

The Stickiness of Particles on Gummy Candy Depositor

This is the common problem where gummy candy particles are stuck on the surface of the gummy candy depositor which eventually affects the quality of the gummy candies and causes cross-contamination.

Solution

This problem is solved by applying a simple trick. You need to add oil spray over the surface of the gummy candy depositor which is helpful in the easy and flexible demolding of the gummy candies. Also, the sprinkling of sugar or sand is also helpful on controlling this problem.

Conclusion

The gummy candies market is rising due to its greater acceptability among every age group people; that’s the reason it has shown total sales of $4.83 billion recorded in 2022 (IRI Report). AIPAK offers excellent gummy candy depositor equipment worldwide with high-profile consumer satisfaction. We’re here to provide you with turnkey solutions and various relevant product guidelines you are looking for. AIPAK is best known for its five-star after-sale customer services and machine training. Excited to know more? Contact us now for more information and machine purchase.

Gummy Candy Depositor Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951