Your Best Paddle Dryer Manufacturer

- Once-through Drying Technology

- Good Plug Flow

- Low Temperature Possible Due To Vacuum

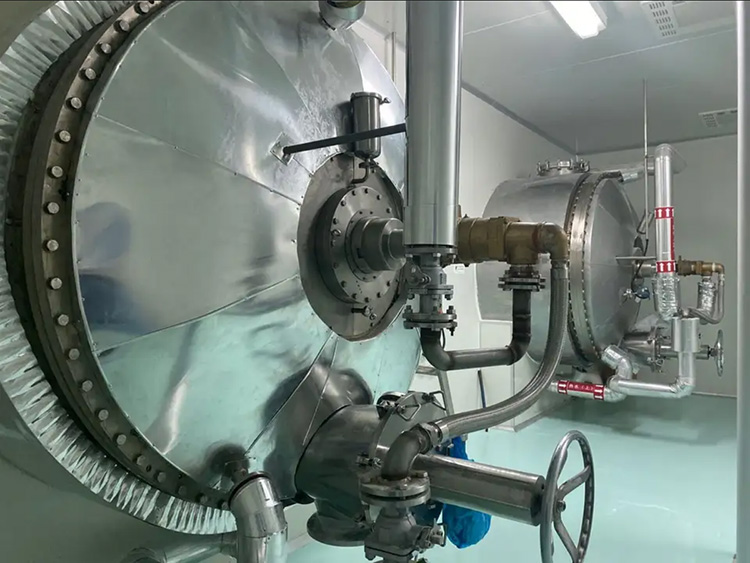

AIPAK Paddle Dryer

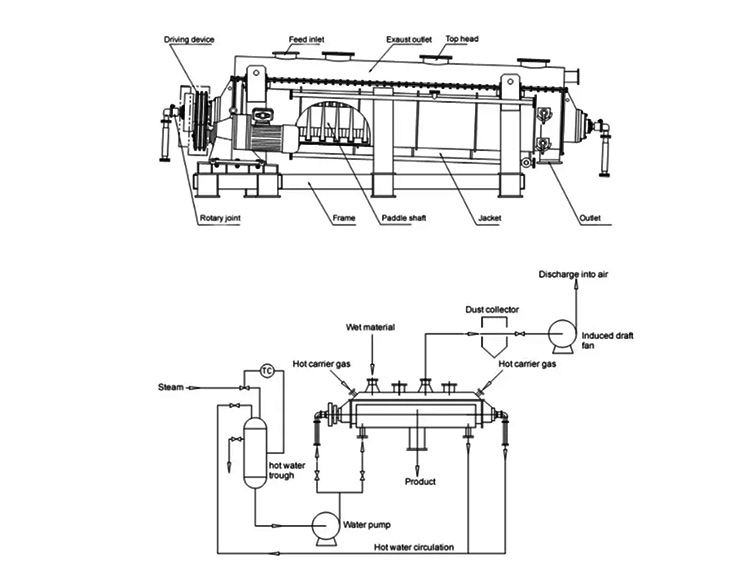

AIPAK Paddle Dryer is widely used in fields of food, agriculture products and by-products, dehydrated vegetable, Chinese herbal medicine, fish products, feed and chemical industry and are suitable for drying of flaked, striped, cube and granule materials.Paddle dryer is a low-speed stirring dryer set in the equipment to make the wet material under the agitation of the blade, fully contact with the heat carrier and the hot surface so as to achieve the purpose of drying, the structure is generally horizontal, biaxial or four-axis. Paddle dryer is divided into hot air type and conduction type. In the hot air type, the heat carrier (such as hot air) is in contact with the dried material and is dried. In the conductive type, the heat carrier is not in direct contact with the dried material, but the hot surface is in contact with the material.

Paddle Dryer Videos

The Buyer's Guide

Paddle Dryer: The Complete Buying Guide in 2025

Want to invest all in one dryer then chose paddle dryers.

The machine paddle dryer is versatile equipment, capable of drying, heating, and cooling. A paddle dryer can process pasty materials such as slurries, sludges, suspensions, and also granules, powders, and pastes. Above and beyond drying, it is used in agglomeration, granulation, alkalization, and sterilization.

If you want a paddle dryer for your products then read through this comprehensive guide to discover more about this handy machine.

Let’s start!

1.What is a Paddle Dryer?

A paddle dryer is an indirect heating dryer or heat transmission machine that uses heated paddles or blades to move wet slurries, granules, powders, sludges or paste in a container for heating and drying them.

The paddle dryer utilizes both heating as well as mechanical agitation to extract moisture from the feed materials. When paddles rotate wet feed in a paddle dryer, they expose them to a heating source which vaporizes the solvents from slurries.

The paddle dryer is a continuous machine and has one-step drying with no back mixing. It is used for drying materials with 50% moisture to minimal ppm values.

2.What is the Industrial Uses of Paddle Dryer?

From a commercial point, paddle dryer are wide-ranging benefits therefore paddle dryer is routinely employed in several applications including:

Pharmaceutical Industry

It is often employed pharmaceutical industry for drying and cooling different active pharmaceutical ingredients, slurries, de-aeration of liquids, etc. Moreover, for the formulation of drugs in the pharmaceutical industry these large-capacity processing machines are used.

Food Industry

Since, a paddle dryer is an appropriate means of processing different kinds of feed in various temperature zone thus it is widely used in the drying and handling of milk, sugars, flour, nuts, pulses, salt, corn kernel, rice, etc.

Their hygienic design and full vacuum capability make them a hit in the food industry.

Chemical Industry

The paddle dryer is gas-tight system having little to no presence of air and has high heat transfer capabilities consequently they are widely sought-out equipment in the chemical industry for processing compounds such as graphite, washing soda, sodium cyanate, dyes, pigments, additives, etc.

Petrochemical Industry

The application of a paddle dryer in the petroleum industry is essential since it is used in processing, heating, and drying polymer resins such as PP, PA, HPDE, LDPE, PET, PS, etc. Due to their high work capacities and one-pot processing paddle dryer are employed in the engineering of plastics.

Metal and Mineral Industry

A paddle dryer can perform heating and cooling in one machine and is an enclosed system therefore it is used in the metal and mineral industry for handling metal powders like lithium, iron, and potassium, as well as, minerals such as gypsum, limestone, etc.

Textile Industry

Yes, paddle dryer is also widely employed in the textile industry for the manufacturing of synthetic fibers like nylon, and acetate fiber. It is also used in the drying of textile feed, yarns, and other fabrics due to their uniform plug flow and easier extraction of end products.

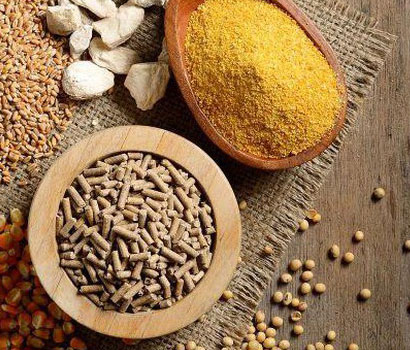

Feed Industry

A paddle dryer is efficient in treating feed sludges. The longer residence time along with 100°C temperatures make this system best for pasteurizing different feeds for instance food leftovers, digested manure, feed additives, bone-based feed, mud feed, etc.

Environmental Protection Industry

One of the most important industrial use of a paddle dryer is environmental protection. Several water treatment plants involve the treatment of digested sludge and drying of waste sludges by a paddle dryer reduces the water volume about 4-5 times thus making them easier to handle.

It is often used in the treatment of sugar industry waste, biogas residues, sewage slurries, paper sludge, coal ash, etc.

3.What are the Benefits of a Paddle Dryer?

The use of paddle drying for different purposes comes with a ton of benefits for production. Some of these advantages are listed below:

High Heat Transfer Coefficient

Wedge paddles enhance the surface area for drying purposes. It moves wet slurries and increases the contact of the heating source with materials. Thus, good mixing by paddles leads to a higher heat transfer coefficient.

Small Footprint

Paddle dryer has a small compact modular construction therefore it is easily installed in small spaces.

Processing of Heat Sensitive Materials

There is no direct interaction between the feed and heating medium thus it is routinely dry of thermosensitive suspensions and slurries. Moreover, a vacuum decreases pressure which cut down the need for high temperatures in the paddle dryer.

High Drying Efficiency

A paddle dryer has agitating blades which provide constant plug flow and do not have back-mixing. These two factors provide uniform residence time to every particle in the feed resulting in higher drying efficiency.

Safety

The drying operation occurs in a closed system therefore using a paddle dryer in production poses no risk to the workforce. There is no release of toxic fumes or chance of fire incidents using these systems.

Lower Energy Consumption

Paddle dryer is an energy-efficient system as compared to direct dryer. Low energy is required for processing materials in paddle dryer hence these machine lowers the operational expenses of production.

Excellent Solvent Recovery

The machine is gas-tight which averts the escape of solvents from the machines. Therefore, the paddle dryer has excellent solvent recovery by keeping the solvent content in exhaust vapor to a maximum.

These exhaust vapors are condensed for solvent recovery in condensing devices.

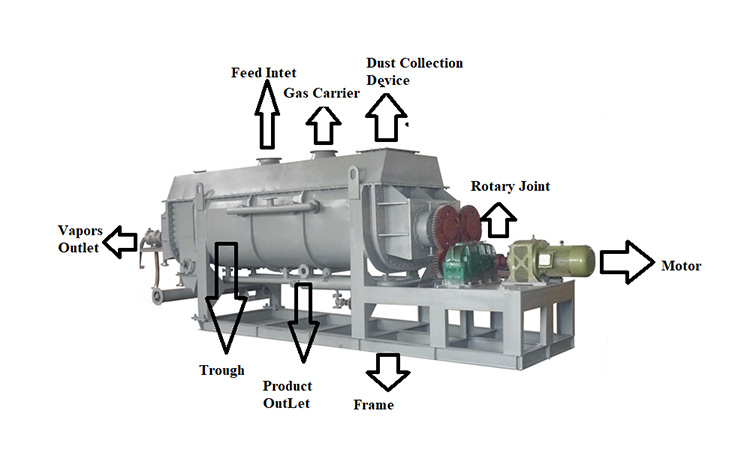

4.What are the Components of a Paddle Dryer?

Tubular Heating Jacket

These heated jackets are insulations that prevent heating loss. This outer covering of the paddle dryer is heated by heating systems and this part provides a uniform heating source to wet sludges in the machine.

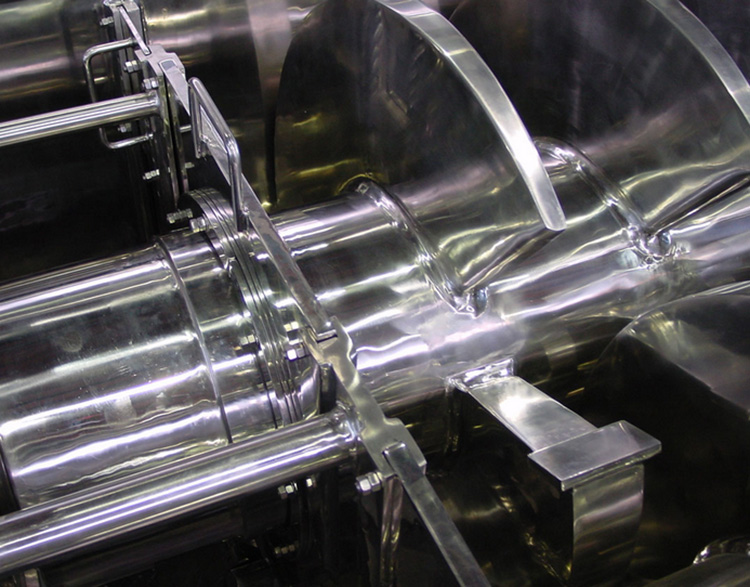

Hollow Shaft or Discs

This increases the surface area for heating. Small paddles are fixed on these hollow discs or shafts to uniformly mix substances.

Trough

This is the main mixing and drying vessel of the machine. The wet feed or powders are loaded in this trough for drying. This part is enclosed by the heated jacket.

Material Silo

These are large structures and store bulk quantities of sludges. Inlet pipes move slurries from the silo to the machine trough.

Paddle

The paddles are the crux of a paddle dryer. These important components generate high shear force in wet materials which is used for agitating them. This results in heat transfer from the heating source to sludges.

These heated paddles move and heat the products. They mix the slurries in a radial direction but not an axial direction- the direction of the discharge outlet. The typical design of the paddle is wedge-shape but they are also available in a plate or ribbon design.

Drive System

Gear motors or other drive systems provide mechanical energy for the agitation of paddles. These gear motors drive the working of pumps, heaters, separation units, etc.

Vacuum Systems

These devices process temperature-sensitive materials. They use a vacuum pump for decreasing the inside pressure which in turn reduces the boiling temperatures of solvents.

Heating Systems

These are heaters or burners that heat water, thermal oil, or gas. These materials are conveyed through pipes and are used for heating jackets, troughs, and paddles.

Solvent Recovery System

For the recovery of solvents, solvent recovery systems are installed in a paddle dryer. These components consist of a two-stage condenser, a separator unit, and a vacuum pump. Condensers convert the vapors back into liquid form.

A separator unit extracts the dust or other powder impurities from the water vapors.

Off-Gas Treatment System

These systems consist of a cyclone separator, a tube-like condenser, and two wet scrubbers. They are used for filtering contaminants from the exhaust gases before their release into the environment. The cyclone separator is used for removing powders from waste gases while the function of condensers and scrubbers is to dissolve impurities in condensed liquids for the safe disposal of discharge gases.

Discharge Systems

The discharge systems consist of an outlet pipe with an adjustable weir. The weirs regulate the exposure time of materials inside a paddle dryer. These weirs are employed for emptying vessels.

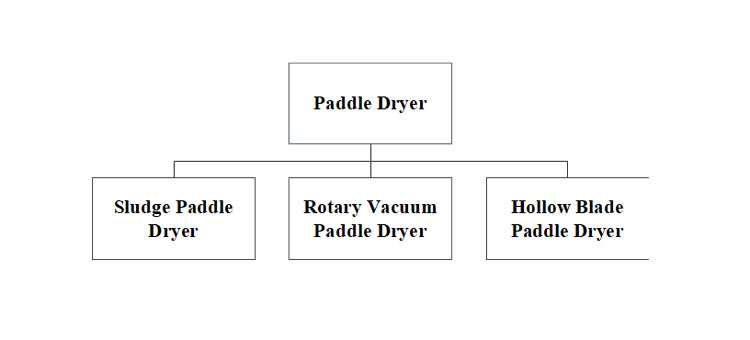

5.What are the Types of Paddle Dryer?

There are different types of paddle dryer available in the market. Different models of paddle dryer can handle different kinds of products. The types of paddle dryer are detailed below:

Sludge Paddle Dryer

These are the most widely used type of paddle dryer. They are used in the treatment of various sludges like municipal waste sludges, feed sludges, drilling mud sludges, etc. It is employed in the dewatering of sludges and consists of paddles, two to four shafts, condensers, off-gas treatment systems, and vacuum pumps.

Rotary Vacuum Paddle Dryer

As the name indicates, they’re equipped with a vacuum and are used in the drying of cement, fertilizers, food grains, etc. The feeder in these systems has a thermocouple which is used for monitoring the drying temperature.

By the use of a vacuum, a rotary vacuum paddle dryer maintains a low temperature for drying as well as vacuum distillation and thus is often used for processing heat-sensitive materials.

Hollow Blade Paddle Dryer

It is a horizontal mixing dryer and is often used for the smooth drying of materials. Hollow blade paddle dryer has hollow blades or paddles for indirect conductive heating. This kind of paddle dryer is mainly suited to process granular and powdery substances. Moreover, it is used for gentle drying and stirring of pastes

6.What is the Paddle Dryer Working Principle ?

A paddle dryer is an all-rounder machine with efficient working systems that are employed for the recovery of dry powders as well as solvents for wet cakes. Some important working drying steps of a paddle dryer are:

Preparation of Drying Medium

The operation of a paddle dryer starts with the entry of fresh air from the environment inside a tube-like heat exchanger. Instead of air, steam, as well as thermal oil, are also used for heating machines. Heat exchangers increase the temperature of the drying medium to the required level. Heated materials then enter jacket tubing.

Loading of Feed and Agitation

In the next step, the wet slurries with high moisture are loaded from a silo to a paddle dryer via an outlet pipe. Paddles stir and agitate the feed while hammers on paddles are designed to disintegrate feed into smaller pieces and also uniformly distribute heat to every particle in the feed.

Evaporation and Drying

Due to heat exchange, moisture evaporates from the wet cake and dry powders are formed. The solvent vapors are moved from an outlet to a condenser and the condensate is then collected inside a receiver.

Separation and Discharge

After complete drying, the dried powders are discharged from the drying chamber with the help of piston-driven discharging systems while air-carrying dispersed powder particles are moved to the cyclone separator for extraction of powders.

Wet scrubbers present below the paddle dryer spray water onto the gas with impurities which aid in the dissolution of impurities in water and this mixture settles inside the scrubber container. After treatment, fresh gas is discharged from the machine via an outlet.

7.In What Kind of Processes Paddle Dryer Used?

Paddle dryer is used in a variety of processes besides their original purpose-drying. Some common process applications of paddle dryers include:

Drying

It is the main use of a paddle dryer where it produces heated at high temperatures with steam or hot oil to dewater slurries, sludges, and feeds. This machine with its large coefficient of heat transfer removes moisture or solvents. After drying, small levels of about 10 ppm of moisture remain in feeds.

Furthermore, with the use of vacuum, paddle dryer is also used for vacuum drying.

Heating

Besides drying, high temperature is used in paddle dryer for cooking, braising, melting, and pasteurization of cakes, powders, and sludges. Moreover, with different temperature zones processing paddle dryer is a perfect match for melting metals, minerals, plastic resins, etc.

Cooling

The paddle dryer is equipped with water cooling systems that instantly lower the temperature of heated sludges. Moreover, thermal fluids for instance glycol having a temperature around 40°F are employed for removing heat from bulk feed in paddle dyers.

Reacting

Since the paddle dryer is capable of heating and cooling wet cakes thus, it is used for catalyzing and regulating chemical reactions like alkalization, solid-gas reactions, etc. With their precise temperature control and superior retention time, a paddle dryer is used in both exothermic and endothermic reactions.

Homogenization

The paddles and shafts in the machine carry out gentle agitation of wet feed which not only aids in even heat transfer but also facilitates in uniform and thorough mixing of various ingredients. Homogenization of ingredients in the paddle dryer can also be done in vacuum conditions.

Calcination

Paddle dryer is part of the calcination and, purification processes of different minerals. It uses thermal oil for low-temperature calcination around 700°F of ores.

Roasting

A paddle dryer is part of routine metallurgical processes and employed high temperatures for the processing of minerals. A paddle dryer is often used in oxidizing and volatile roasting for removing Sulphur and other volatile oxides from ores.

Crystallization

A paddle dryer is routinely employed in various industries for the crystallization of certain polymers. Its temperature control feature is ideal for forming crystals at the control rate.

Sterilization

In addition to drying, a paddle dryer is also used for sterilization of different manure feed, food waste feed, biomass, etc. It is utilized for the removal of microbes and additives from different feed sources with the application of high temperatures of about 70-80 °C.

De-aeration

A paddle dryer is also used for the deaeration of water streams, feeds, nutraceuticals, foodstuffs, etc. It aids in preventing oxidation and thermal shock of products and it also increases the shelf life of end products.

8.What Materials Are Dried in Paddle Dryer?

A paddle dryer is an ideal drying machine for processing several different kinds of materials such as:

Heat sensitive materials

Thermosensitive feeds and cakes are easily processed and dried using a paddle dryer as it is equipped with a vacuum which helps in lowering the boiling points of different solvents.

Lumpy Feed

With the use of paddles, the lumpy sludges are gently broken down into smaller particles which increases both the drying as well as mixing capability of materials.

Hygroscopic Materials

The paddle dryer is a perfect machine for the complete removal of moisture from hygroscopic materials. The machine uses high temperatures and longer residence time to dry feeds with high moisture absorption.

Materials With Low Melting Points

By employing different temperature zones and immediate heating and cooling, materials with low melting points are processed in a paddle dryer.

Dusty Materials

Yes, a paddle dryer with a fully closed system comprising dust collection or de-duster devices is employed for the drying of dusty materials.

9.What is the Heating Temperature in Paddle Dryer?

A paddle dryer is employed for processing different kinds of feeds like pharmaceuticals, metals, food, chemicals, etc. Usually, high temperatures are required for roosting, heating, and drying metallic ores. Hence, the heating temperature in the paddle dryer goes as high as 750°F or 400°C.

For cooling, the temperature in the paddle dryer is normally around 20°C.

10.How To Optimize the Process Efficiency of a Paddle Dryer?

As the performance of a paddle dryer is impacted by several factors consequently to optimize the process efficiency of this machine, the following process parameters should be adjusted:

Drying Temperature

It is the major factor that affects the drying efficiency of a paddle dyer. High drying temperature boosts the evaporation rate of solvents which in turn increases the drying rate. However, it is not recommended to dry temperature-sensitive feed at high temperatures because it may degrade.

Humidity

It is essential to maintain a low-humid environment in a paddle dryer. Humidity negatively impacts the drying efficiency of a paddle dryer. If the interior of a trough is concentrated in vapors, then drying slows down. It will take time to completely dry the materials.

Flow Rate of Sludge

If the flow rate of sludge is increased in a paddle dryer, then drying efficiency will be increased. Usually, it is best to fill the paddle dryer to full work capacity to achieve the best drying results.

Rotation of Paddles

When the rotational speed of the paddles is fast then the mixing capability of the paddle dryer is enhanced. Moreover, high rotational velocities are best suited for crushing and de-lumping sludge clamps.

Heating Systems Performance

These devices are an integral part of the paddle dryer. Without these systems, there will be no drying. Therefore, paddle dryer must has efficient, superior quality, and high-temperature heating unit. For high drying, machines must have a stable heating source to maintain a uniform flow of heat between equipment and sludge.

Machine Maintenance

The paddle dryer must maintain regularly for keeping the machine parts in excellent working condition. Because defective parts can reduce the working performance of a paddle dryer.

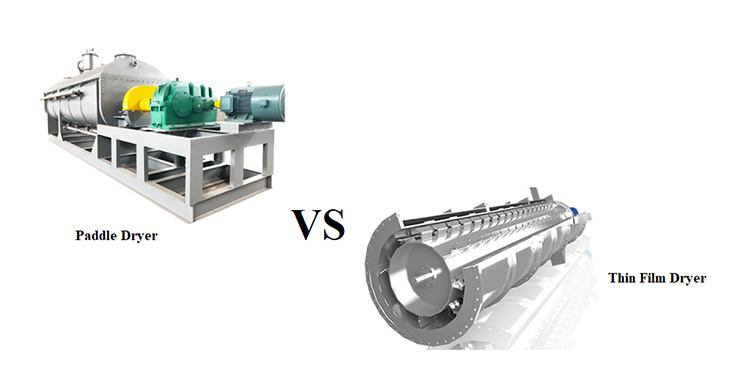

11.What are the Differences between a Paddle Dryer and a Thin Film Dryer?

Although both paddle dryer and thin film dryer are types of sludge dryers, there are some major differences between these two machines:

| Paddle Dryer | Thin Film Dryer |

| This uses a heated dual agitator or shafts for increasing the surface area for heat distribution. | The machine is comprised of single rotors with blades for generating thin films of slurries which aid in superior heat exchange without the need for rotor heating. |

| The machine is not automatically clean itself of slurries. | A thin film dryer can easily clean sludges. |

| A paddle dryer agitates materials at a low operational speed. | The thin film dryer operates at a high rotational speed. |

| The paddle dryer has high maintenance requirements. | The machine has low maintenance requirements. |

| There is a need for heating fluid in the paddle dryer. | Heating fluid is not required for heating a thin film dryer. |

| The machine is more thermal energy-intensive than a thin film dryer. | The machine consumes less thermal energy than a paddle dryer. |

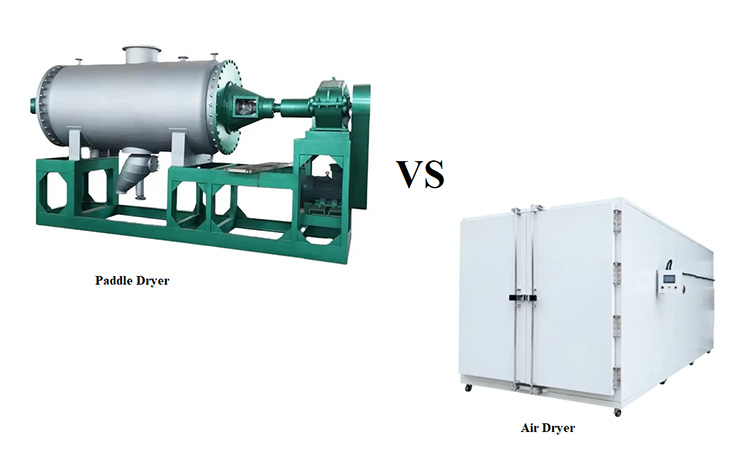

12.What are the Differences between Paddle Dryer and Air Dryer?

Both paddle dryer and air dryer is commonly used for drying different feeds and slurries. But there are some huge differences between both them including:

| Paddle Dryer | Air Dryer |

| They are made of troughs, shafts, paddles, heating systems, and solvent recovery systems. | They have a simple design and are comprised of heating systems, drying vessels, and condensers. |

| It consumes less energy and is capable of operating at low temperatures. | They require more energy and usually require high temperatures for running. |

| The machine has faster drying rates. | Air dryers take a long to dry products. |

| The paddle dryer is also capable of cooling, cooking, roasting, and crystallization. | It is used for drying purposes only. |

| They have a smaller footprint and take up less space. | These are usually large and hence need more space. |

| The machine produces a uniform and good quality dried products. | Since heating is not uniform in air dryers thus they produce inconsistently dried products. |

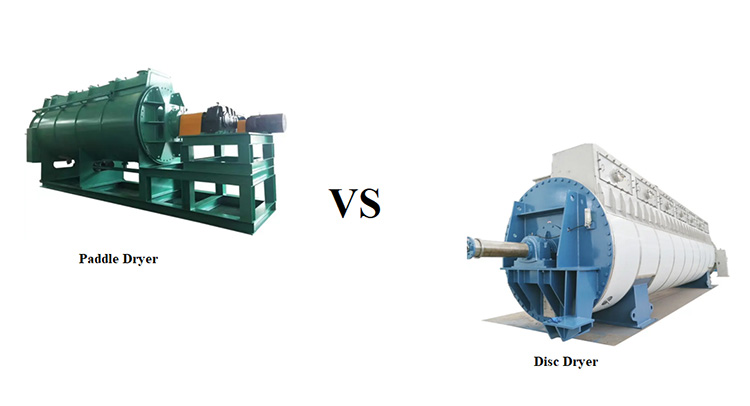

13.What Is the Difference Between A Paddle Dryer And A Disc Dryer?

Both machines are used for drying materials through a transfer of heat however there are huge differences between them are listed below:

| Paddle Dryer | Disc Dryer |

| It has a complex design with two or four shafts. | It has a simple construction and consists of a single shaft. |

| The shafts penetrate the sludge and are used for efficient stirring. | The shaft in the machine does not penetrate sludge but an impeller is used for stirring the sludge. |

| There is huge operational resistance in paddle dryer thus they consume more power than their disc dryer counterparts. | The running resistance in the disc dryer is relatively low therefore it consumes less power. |

| The machine is not suitable for highly viscous materials. | The machine is more suited to processing highly viscous materials. |

| It is a pressure machine which leads to wear and tear after some time. Furthermore, issues of steam or oil leakage arise in it with time. | The machine usually has a longer operational life. |

| Paddle dryer has a high running cost. | Disc dryer has a low operational expenses. |

14.How to Troubleshoot Common Problems in Paddle Dryer?

Several problems may arise during the operation of a paddle dryer. However, their troubleshooting requires simple remedies for instance,

| Problem | Cause | Remedy |

| Low Machine Output

|

Feeds are not loaded inside the machine to full capacity

The low rotational speed of paddles. Condense water comes back into the paddle dryer Leakage in jacket or trough Vapors remain in the paddle dryer

|

Fill the machine to full working capacity.

Increase the spindle speed of blades or paddles. Check the exhaust pipe Repair the cracks in the machine. Increase the volume of outgoing gases as well as inspect exhaust fans for defects. |

| High Moisture Content in Products

|

The retention time of sludge is low

A high volume of feed Low heating temperature Sludge is too wet |

Increase the retention time of sludge

Decrease the volume of feed Increase heating temperature Adjust the humidity of the feedstock |

| Lower Discharge of Material

|

The poor inclination of a machine | Adjust the inclination of the machine |

| Leakage in Rotary Joints

|

Defective or worn-out gasket seal | Repair or replace the gasket seal |

| Powder Adhesivity to Blades or Walls or Trough

|

High sludge volume

Poor heating of blades, jackets, and trough |

Decrease the sludge volume

Increase heating temperature for maintaining temperature to the required level |

| Failure in Paddle Rotation

|

Damage in motors

Worn-out or defective rotary joints |

Repair the damaged motors

Repair or install new rotary joints |

Conclusion

A paddle dryer is all-purpose equipment and is completely capable of performing drying, heating, cooling, roasting, cooking, crystallization, and many more. The paddles and shafts are the main components used for stirring, mixing, and heat transfer. Investing in paddle dryer brings a lot of benefits since they are cost-cutting devices with low energy consumption. Want to learn about these handy devices? Please contact our experts now.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586