Challenges And Opportunities Of Syrup Filling Machine

The syrup filling machine is a filling equipment specially designed for easy-to-pull syrup bottles, which is suitable for pharmaceutical factories, health care products companies, chemical industry and other institutions.

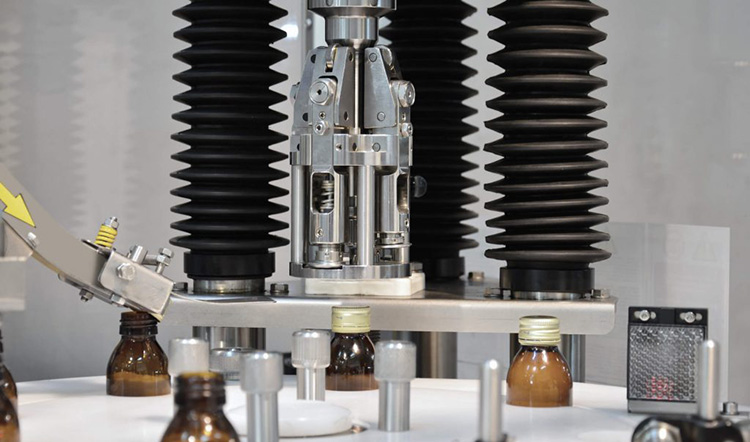

The working principle of the syrup filling machine is to use the motor to transmit the power to the worm gear shaft of the reducer through the pulley, and then the worm gear shaft passes through the gears to transmit the power to the dial shaft, the filling part and the capping head.

The filling part, the capping head and each dial move synchronously, and the filling of the syrup is completed by transmitting the power to the bottle feeding dial device through the bevel gear. The whole filling process has the advantages of reasonable design, simple structure and convenient operation, etc.

It is understood that syrup has the advantages of small dosage, fast absorption, stable quality, convenient carrying and taking, and easy storage.

In recent years, with the increase of the pharmaceutical industry and the growth of the domestic economy, China's oral drug industry has made long-term progress. It has made certain breakthroughs in terms of production technology and market size.

The syrup filling machines’ market demand is increasing and the scale of its market is expanding. Then the corresponding syrup filling machine will also usher in a new development opportunity.

Facing with new opportunities, companies need to be bold and innovative, strengthen scientific and technological research and development, and strive to produce syrup filling machine products that meet market demand.

The syrup filling machine is a filling equipment specifically designed for the new type of syrup easy-pull bottle. The design is acceptable, the structure is straightforward, the operation is useful, and it is equipped with a mechanical bottle-shortage stop filling device.

Nowadays, with the continuous progress of technology, the technology of syrup filling machine has also made great progress, especially the transformation of the manufacturing industry, which is primarily characterized by the deep integration and innovation of a new generation of information technology, is poised for development.

New technologies, new formats, new models are constantly emerging, and the filling machine companies are also accelerating the pace of transformation, establishing a development system that adapts to new changes, and striving to develop syrup filling machine products that meet new market demands to benefit more people.

It is reported that with the rapid development of intelligent manufacturing technology, intelligent automatic syrup filling machines have become a new favorite in the market.

Especially for children's syrup, it has higher requirements on dosage forms and other aspects, which requires companies to produce syrup filling machine products with higher precision and smaller errors to better apply to children's oral.

And intelligent automatic syrup filling machine or will rely on intelligent operation to better meet the children's syrup filling.

Some filling machine company personnel said that making products with higher filling accuracy and smaller errors is a requirement put forward by many pharmaceutical companies and health care product companies.

At present, with the continuous development of automation and intelligent technology, new exploration paths have been opened.

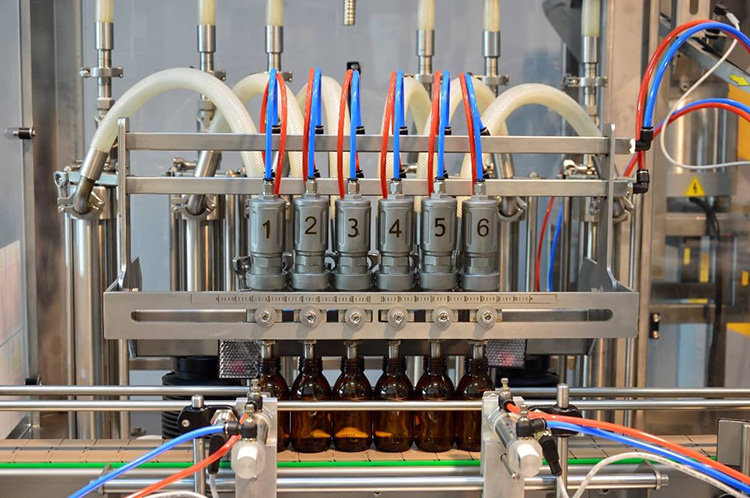

It is reported that automatic syrup filling machine is improved and designed on the basis of the original product, and some additional functions have been added to make the product more simple and convenient in terms of operation, precision error, equipment cleaning, maintenance, etc.

Bottles of different specifications can adjust the filling volume arbitrarily, and can be equipped with an automatic assembly line. In the filling of syrups such as children, intelligent automation equipment has high precision and will have greater advantages.

Automation is spreading throughout various industries, and the syrup filling machine equipment has also undergone earth-shaking changes.

Compared with the previous liquid filling machine equipment, its operation is simpler, and the one-key operation of the filling machine is completed, and the filling efficiency of syrup is significantly improved.

With the rapid growth of syrup preparations, the syrup filling machine industry is also developing in full swing. According to industry professionals, among the many filling machines, the brand image of the syrup filling machine attracts more attention, and it is also the most competitive in the industry.

There is no doubt that China's syrup filling products still lack independent intellectual property rights, and there are few original products and low technical content. There is no special filling machine major in domestic universities to provide professional talents for this industry. These existing problems are directly restricting the syrup filling machine’s development.

In addition, there are also syrup filling machine oral manufacturers that have made breakthroughs in technical bottlenecks.

For example, they have developed high-speed liquid filling production lines, widely used PLC systems, and both front and rear equipment have photoelectric sensors, which can effectively prohibit bottles from squeezing and breaking bottles.

It has the advantages of stable production, high yield, convenient operation and maintenance, and low operating costs.

Despite this, China's filling machine companies are still carrying out technological innovation and strive to achieve greater breakthroughs.

At present, there are at least hundreds of syrup filling machines on the market. For you, how to choose a suitable syrup filling machine is the key to ensuring good filling.

Some customers have said that the syrup filling machine imported from Germany is of high standard and high quality, but the price is very expensive, which is a big burden for companies with limited budgets.

In contrast, the price of domestic syrup filling machines is relatively affordable, but the performance in terms of automation and filling accuracy is lacking, which also means that domestic syrup filling machines have a large market space in the future.

The syrup filling machine manufacturers can gain more favor in the market by making continuous breakthroughs, improving the stability and quality of equipment, and improving the cost performance of products.

In general, with the continuous expansion of domestic market demand and the continuous emergence of new filling technologies, syrup filling machine companies must also continue to accelerate the pace of transformation, establish a development that adapts to new changes, and develop new products that meet new market needs.

Research and develop syrup filling machines that meet the new needs of the market, so as to benefit more pharmaceutical factories and health care product companies, and promote the rapid development of the syrup filling machine industry as a whole.

Don't forget to share this post!

Syrup Filling Machine Related Posts

Syrup Filling Machine Related Products

Syrup Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine