Cartoning Machine For Tray:The Complete FAQ Guide In 2025

Are you looking for a cartoning machine for tray packaging system for your various bottles, jars, octagonal aseptic packaging and cups? What kind of efficient equipment can provide you with unique cartoning tray packaging while saving you time and money?

Are you looking for a professional post that can answer all your questions about cartoning machine for tray? If yes, then you would better to go through this post about the cartoning machine for tray. It will offer you the most professional knowledge about this type solution for your different products application. Let us have a try now!

1.What Is Cartoning Machine For Tray?

AIPAK Cartoning Machine For Tray

The cartoning machine for tray is widely applied in pharmaceutical, food and cosmetic industries. It can automatically load products such as tubes, blisters, bottles and vials into cartons. The cartoner for tray can fold, insert and seal cartons efficiently and accurately while ensuring that your products are safely packaged.

The cartoning process is automated and can reduce your need for labor and increase your production speed. It can handle a variety of carton sizes and is flexible to meet your different packaging needs.

2.What Are The Different Trays Mostly Packed With Cartoning Machine?

The cartoning machine is an efficient and versatile packaging equipment. It can quickly process various tray packaging products such as food, medicine, daily necessities, etc. The different trays are:

Blister Trays

Blister Trays-sourced: wendaotrade

The blister tray is a type of blister packaging that can fix different products, such as vials, injections, bottles, tablet and capsule bottles, hamburgers, snacks, etc. After the blister tray packaging is completed, they are generally packed in hard plastic cartons or cardboard.

Thermoformed Trays

Thermoformed Trays-sourced: visipak

The thermoformed trays can meet the packaging requirements of various display parts, components or accessories. It is an ideal solution for all products in tray packaging. In addition to fixing the product well, this packaging method also facilitates the carton packaging of the thermoformed tray later.

Clamshell Trays

Clamshell Trays-sourced: clamshell-packaging

The clamshell tray is widely applied for packaging and securing different high-end items, including cell phones and cell phone cases, etc. It may come with a cover or another seal for your easy opening and using. This kind of tray can protect your products from outside tampering.

Paperboard Trays

Paperboard Trays-sourced: graphicpkg

The paperboard tray is a sustainable packaging solution for a variety of applications, such as food, dairy, ice cream, cheese, chilled and frozen food, etc. They are made from responsibly sourced recycled paper that can be composted at home.

3.What Are The Different Products Can Be Packed By Cartoning Machine For Tray?

Some of the products that can be packed by the cartoner:

Pharmaceutical Products

Pharmaceutical Products-sourced: cartonservice

Most of pharmaceutical products such as ampoule, vials, suppositories, injections, bottles, tubes, blister packs, seal trays, stick packs, sachets, tablets, capsules, soft-gels in tray, can be packed with the cartoning machine for your automatic operation and high production.

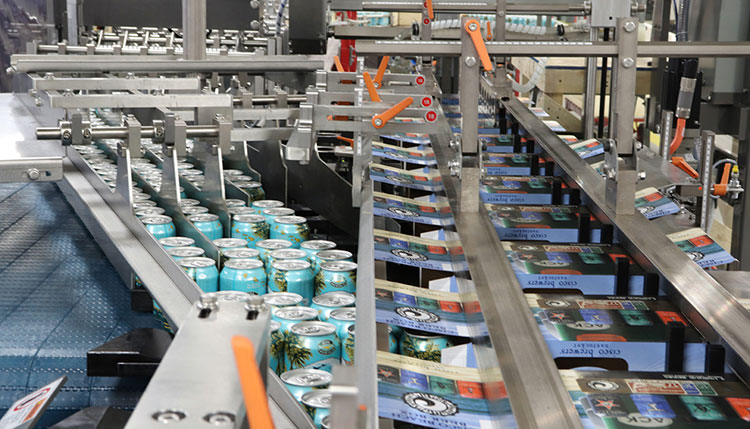

Food and Beverages

Food and Beverages-sourced: templepackaging

The snacks, jerky foods, dry foods, frozen vegetables and meats, cereals, tea and coffee, etc. can be packed into cartons with the cartoner machine. It can flexibly meet your needs of food and beverages packaging of different shapes, sizes and types, and meet the needs of different packaging bags and trays.

Cosmetics and Personal Cares

Cosmetics and Personal Cares-sourced: richpackaging

The cartoning machine for tray is also widely used in the field of cosmetics and personal cares products. Similar to tubes of creams, cosmetics boxes, shampoo bottles, soap bars, etc. In addition to the application of these products, it can also provide you with customized packaging solutions for special needs.

Electronics

Electronics-sourced: halfpricepackaging

By packaging electronic products in different blister, thermoformed and clamshell trays, and then loading them into cartons. This not only fixes the products in the box, but also allows for special displays, etc. These products include batteries, USB drives, earphones, headphones, small electronic devices, etc.

Hardware and Tools

Hardware and Tools-sourced: landpack

Various types of hard-wares and tools such as nuts and bolts assortments, drill bit sets, hand tools, etc. can be arranged and packed into different cartons for multiple application. It can fill a large number of products without changing parts, making your application more convenient.

Stationery and Office Supplies

Stationery and Office Supplies-sourced: customboxesshop

There are huge demands of carton packaging for stationery and office supplies, such as pens and pencils, notebooks, office supply assortments, etc. It is always a great way to keep your production costs down, and increase productivity.

Toys and Games

Toys and Games-sourced: sellmostmk

The board games, puzzle boxes, toy sets and action figures can all be packed into different cartons with clear printing and coding. This can bring you greatly improve your production efficiency with high quality.

Promotional Items

Promotional Items-sourced: pixartprinting

What's more you can carton packaging? The gift sets, promotional merchandise, subscription box items, all can be carton packed and sealed. It can also offer you automatic carton closing with good labeling.

4.Why You Need A Cartoning Machine For Tray?

Applying the cartoning machine for tray can help your business achieve leapfrog development. It helps you make your packaging process more efficient. The benefits are:

Cost-effective

Cost-effective-sourced: Monday

The cartoner can achieve fully automatic product packaging with almost no manual intervention. This can reduce personnel costs and production costs, increase output, and make your packaging process more efficient.

Error Reducing

Although it is not 100% error-free, the cartoner machine does significantly reduce the error rate caused by your employees working long hours. It also reduces and reduces repetitive motion strain injuries and health issues for manual boxing personnel.

Efficient Fast

Efficient Fast-sourced: koerber

There are different types of cartoning machines on the market for you to choose from. The appropriate machine can be adapted and processed according to your product type. By replacing inefficient manual product filling, the cartoning machine can greatly improve your production efficiency.

Customizable

Customizable-sourced: packmojo

Whatever your product type, shape and size are, the cartoning machine is able to adjust and adapt, handling different sizes and shapes of cartons with ease. The material used for boxing is ideal for printing, allowing you to print a variety of graphics and designs.

Sustainable

The cartons for your carton packaging are all made of the reusable and recyclable materials. These materials can greatly improve your environmental protection.

5.What Is The Working Principle Of Cartoning Machine For Tray?

The working principle of cartoning machine for tray may vary slightly depending on your product types, but its general principle is:

- Product feeding. You may manually or automatically feed your products from a production line or conveyor into the cartoning machine;

- Product positioning. Once the product is fed, sensors, vision systems and controls will ensure the correct orientation, position and integrity of the product and carton;

- Carton forming. The sensor detects the product and feeds it into the slot. The flat carton blank is picked up and then folded into shape;

- Product insertion. After the carton is folded into shape, a robot arm automatically picks up the product and places it into the carton;

- Leaflet insertion. After the product is inserted, a leaflet or instruction booklet is inserted into the carton;

- Carton sealing. The cartoning machine uses adhesives, fold-in flaps or other sealing methods to complete the carton;

- The completed carton is ejected from the machine onto a conveyor or packaging line for further processing or distribution.

6.What Are The Types Of Cartoning Machine For Tray?

Depending on your specific packaging requirements, there are many types of cartoning machines. Depending on how the product is placed in the carton, the cartoning machine can be vertical or horizontal type. Based on the type of automation, they are divided into fully automatic and semi-automatic.

Semi-automatic Cartoning Machine

Semi-automatic Cartoning Machine-sourced: shinebenmach

The semi-automatic cartoning machine is the perfect solution for complex retail cartons. Semi-automatic processes are more dependent on manual labor, which can complete the cartoning machine installation, simple setup, flexibility, and increased your quality control, and require manual supervision to complete.

Automatic Cartoning Machine

Automatic Cartoning Machine-sourced: serpapackaging

The automatic cartoning machine can automatically complete the carton forming, filling and sealing. The intermittent mode is slower and suitable for professional packaging of irregularly shaped products. The continuous mode is significantly faster and has no pauses, which is very suitable for simple packaging or regular solid products.

Vertical Cartoning Machine

Vertical Cartoning Machine-sourced: richpackaging

The vertical cartoning machine mainly inserts products and packaging cartons from the top of the machine. Generally, it is mainly of rotary type. This cartoning method is very suitable for cartoning of small bottles, cans and bottles. Such a short-term feeding system can well reduce the possibility of damage to materials and packaging boxes.

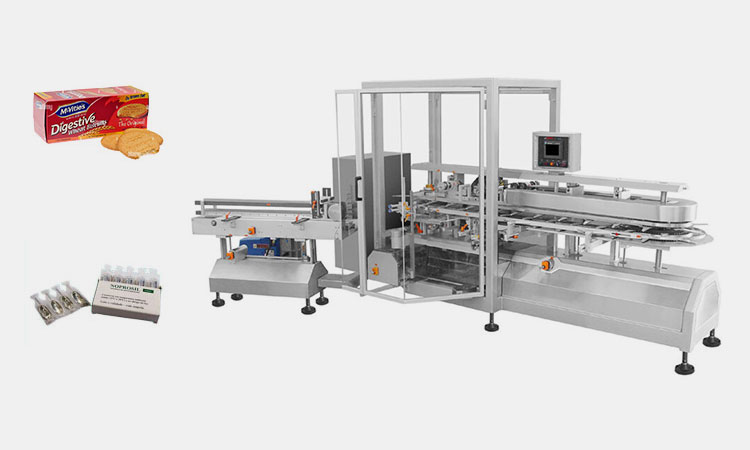

Horizontal Cartoning Machine

Horizontal Cartoning Machine-sourced: serpapackaging

The horizontal cartoning machine adopts a balcony design, and the packaged products and cartons are mainly inserted from the side of the equipment. This cartoning machine is suitable for industries that require high-speed batch packaging. And it is widely used in various products, including food, toys and daily necessities.

7.What Are The Main Parts Of Cartoning Machine For Tray?

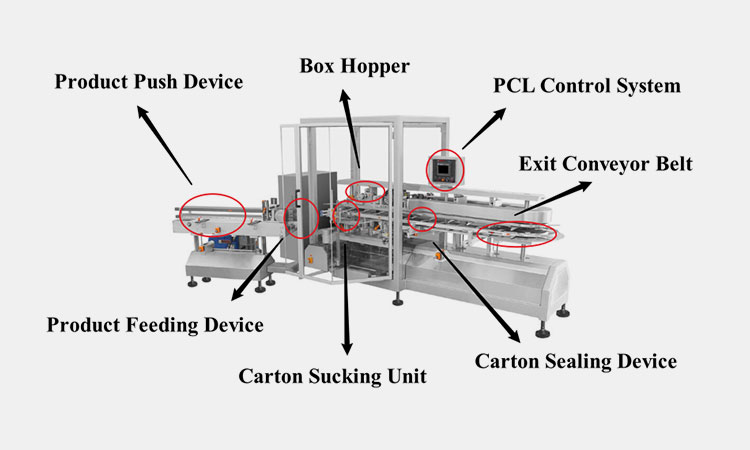

Main Parts Of Cartoning Machine For Tray-sourced: serpapackaging

There are seven main parts of the cartoning machine for tray:

Product Push Device

The product push device applies the infrared induction electric eye automatic detection and tracking system. Once the folds are detected, it will be pushed into the feeding system.

Box Hopper

The box hopper is mainly designed for the folds placing and arranging. After products have been loaded, the folds will be pushed and folded into box shape.

PLC Control System

The cartoning machine is equipped with a multi-language intelligent PLC control system that is easy for your to operate, program setting and make the adjustment.

Product Feeding Device

The product feeding device can easily open the box and fill the products into the box automatically. By using the pneumatic drive, the operation is fast and accurate with low failure rate.

Carton Sucking Unit

The box sucking unit mainly controls the carton folds when they are detected by the detecting switch after arriving at the paper-clipping chain. It will suck the folds, arranging and opening it for the products inserting in the next step.

Carton Sealing Device

The box sealing device is composed of two parts, including folding paddle and box carrying-out orbit. After products have been filled into the box, the machine automatically completes the box sealing.

Exit Conveyor Belt

The exit conveyor belt is an intermission running part for carrying out the filled and sealed cartons with chain running, and avoid the damage. It can be customized according to your box size and packaging requirements.

8.What Is The SOP Guide Of Cartoning Machine For Tray?

SOP Guide Of Cartoning Machine For Tray-sourced: corporatevision

The SOP guide of cartoning machine for tray explains the correct operation procedures of the equipment and forms good production practices for your application. It mainly includes:

Pre-running Checks

You need to check the cartoning machine for any visible damage, malfunction or defects. Make sure there is no residue or contamination before operating the machine. Inventory all necessary carton blanks, product units and power systems, and record all details.

Machine Set-Up

Set up the cartoning machine in the specified position according to the manufacturer's instructions. You would better load the carton blanks into the hopper and ensure that they are properly aligned and firmly fixed. Adjust the carton size, product unit position, etc. according to the product specifications and batches.

Cartoning Process

It is appropriate to feed products to be packaged into the feeding system, ensure their proper position and closely monitor the cartoning process. Closely monitor the carton packaging process and record the cartoning time, machine settings and standard procedures.

Post-Cartoning Checks

After the products are loaded, you need to stop the machine for inspection. Visually check whether the carton packaging is complete and the label is correct. Broken or any defective cartons should be further evaluated or handled.

Cleaning and Maintenance

Clean the cartoning machine and related equipment according to the cleaning procedures. And then perform the routine maintenance and lubrication of parts according to the manufacturer's recommendations to ensure continued performance of the machine.

Documentation

Properly record and archive all relevant records of the cartoning machine, including pre-operation inspection, machine settings, cartoning parameters, and post-cartoning inspections. This will facilitate later reference and regulatory inspections.

9.What Are The Upstream and Downstream Equipment With Cartoning Machine For Tray?

If you want to expand production or update equipment, adding new upstream and downstream equipment is very important. There are various types of upstream and downstream equipment that you can apply.

Upstream Equipment:

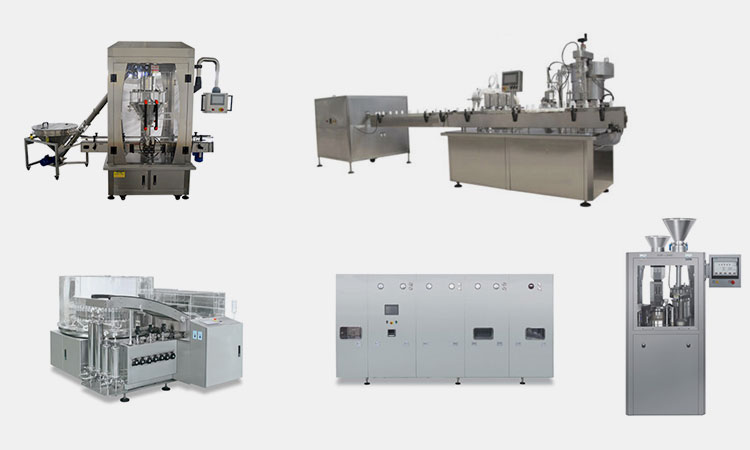

Filling Machines

AIPAK Filling Machines

The filling machines refer to all types of fillers that can fulfill your requirements for different products and materials filling and packaging. It including liquid filling machine, powder filling machine, capsule filling machine, granule filling machine, bottle filling machine, suppository filling machine, vial filling machine, etc.

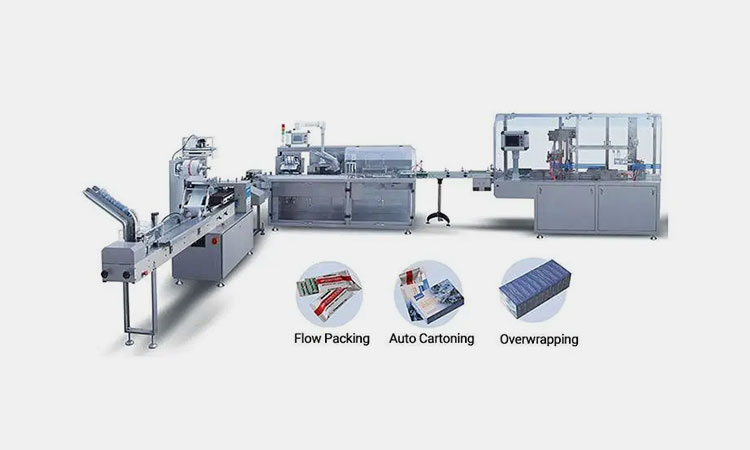

Packaging Machines

AIPAK Packaging Machines

There are plenty of packaging machines for your products packaging and sealing, including flow wrap machine, horizontal packaging machine, form fill seal machine, sachet machine, doypack machine, stick packing machine, blister packaging machine, premade pouch filling machine, etc.

Tray Sealers

ALLPACK Tray Sealers

Tray sealers, also known as tray lidding machine or top sealers, are widely applied for packaging and sealing meats, poultry, fish, fruits, vegetables and other types of products, such as cosmetics and pharmaceuticals. It main works by adding the plastic film lids to trays of varying materials, sizes, and depths.

Downstream Equipment:

Labeling Machine

AIPAK Carton Labeling Machine

The labeling machine is primarily responsible for attaching labels to products or packages for different application. It can help your box and carton with good and clear labeling after packaging.

Coding Equipment

ALLPACK Coding Equipment

The coding equipment can add you with printing information on products, such as expiration dates, lot numbers, barcodes, and logos, etc. This is a good downstream equipment for your products with good durability, ease of use, and maintenance requirements.

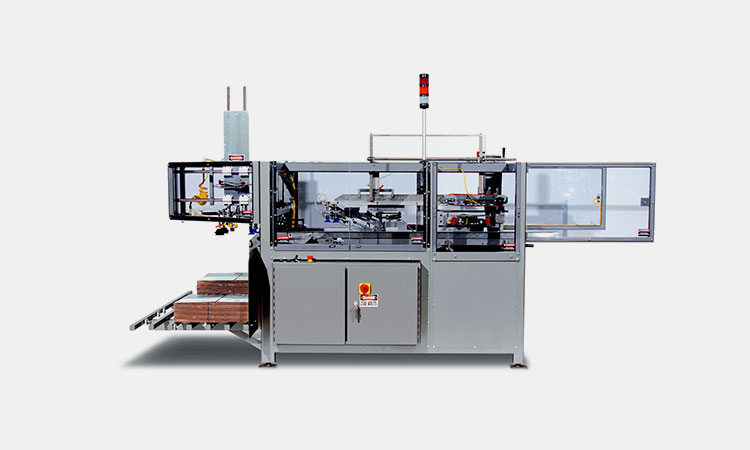

Case Erectors

Case Erectors-sourced: victorypackaging

It is important to automatically form, fold, and seal your corrugated cardboard boxes into cases after labeling and coding. It can offer you products with good stability and security.

10.What Are The Common Challenges and Troubleshooting With Cartoning Machine For Tray?

Although cartoning machines are efficient and widely used, they also face challenges during their use. They are:

Carton Jams

Carton Jams-sourced: shinebenmach

The folds tend to get stuck in the feeding system if they are not arranged correctly. You need to gently remove the stuck cartons, and make sure they are aligned and then clean the carton guides. Finally, restart the machine.

Carton Misalignment

Carton Misalignment-sourced: shinebenmach

You need to check whether the cartons are loaded into the machine correctly and in the correct direction. At the same time, you may check whether the carton guides, sensors and conveyors are working properly, and make sure that the carton size matches the machine settings.

Sealing Defects

Sealing Defects-sourced: herma

If the carton is not sealed well, you need to check whether the adhesive has failed or the adhesive parts have been worn. At the same time, you would better repair problems such as dried glue and clogged nozzles.

Electrical Problems

Electrical Problems-sourced: coynecollege

If the machine is down due to electrical problems, you need to check whether the wires are loose, the fuses are blown, or the circuit breakers are tripped. At the same time. Check whether the electrical components such as motors, sensors and switches are damaged or worn.

11.Factors to Consider When Choosing A Cartoning Machine For Tray?

When choosing a cartoning machine for tray, you can consider the following factors:

Production Capacity

Production Capacity-sourced: bwintegratedsystems

You need to consider the speed and output capacity required for your production line to meet your expected production volume and production efficiency.

Carton Size

Different machines have different capacities to accommodate and handle cartons. By determining your own carton size and configuration range, you can choose a suitable cartoning machine to meet your different types of cartoning packaging.

Product Compatibility

Product Compatibility-sourced: zeepackaging

Different cartoning machines have different capacities to handle different products. You need to determine the specific shape, size and material of the product you need to handle, such as tubes, bottles, vials or blister packs.

Carton Sealing

Carton Sealing-sourced: halfpricepackaging

The key to choosing a suitable cartoning machine for yourself is to choose the right carton sealing method, such as adhesive sealing, fold-in lid or other sealing options.

Automation and Integration

Automation and Integration-sourced: stingpack

Automation and integration capabilities are also an important criterion for evaluating the quality of the machine. It can improve the automation level and integration capabilities of your existing production line, and can improve the production efficiency and capacity of your cartoning machine.

Quality and Reliability

The higher the quality, durability and reliability of your machine, the better your productivity and results will be.

Conclusion:

The cartoning machine for tray is a great way to reduce your production costs and increase productivity. It can flexibly meet your various carton packaging needs. If you are considering buying a cartoning machine, or you want to learn more about it, please contact us now!

Don't forget to share this post!

Cartoner Related Posts

Cartoner Related Products

Cartoner Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours