Cartoner Equipment: The Complete FAQ Guide In 2025

Product processing is long and strict. When the products is made, you haven’t finish the whole manufacturing work. To make the real qualified and nice products, you should make the packaging from cartoner equipment for them. Only with this, can your products get into the market and sold out.

Cartoner equipment is the most frequently used packaging machine as it made carton packaging which is widely welcomed for its lightness, cheap price, easy-printing and so such advantages. You may need a cartoner machine as you have the carton packaging need. But how much do you know about cartoner equipment?

What industries can it serve? Can it make various shapes of carton? How many types of cartoner equipment are there? Which one suits you most? How to choose the most suitable cartoner equipment? What you should care in operating cartoner equipment? If you have these questions, go ahead to this complete FAQ guide in 2024.

1. What Is Cartoner Equipment?

Cartoner Equipment-Sourced:sedpharma

Cartoner equipment, also called as cartoning machine or cartoner, is widely used to play the secondary packaging of forming cartons to various products. It’s indispensable for storing and transporting requirements of product in current market.

Cartoner equipment can fold, erect, fill, seal cartons and can do the extra work like printing. It can adjust to suits various size and type and can finish the carton packaging work all by the single machine. It improve the working efficiency and prove the product quality greatly.

2.What Industry Does Cartoner Equipment Serve?

Cartoner equipment can serve industries with carton packaging needs. And most industries have this need for various reasons. Here are some typical industries.

Food and beverage industry

Food and drink like, biscuits, bread, juice, sugar and such products should be protected from light, dust or collision. The transporting and storing road is unpredictable, and products need careful protection of carton. Besides, the colorful painting and attractive information can also attract customers and improve sales.

Pharmaceutical industry

Medicine Cartons-Sourced:cafecodiac

Cartoner equipment plays the essential role in pharmaceutical industry. The high standard of pharmaceutical products like blister, vials and injection have the extra requires in hygiene and protection. Its packaging line can prove the hygiene and the different types of carton can give a nice fix and protection for products.

Beauty industry

Cosmetic Cartons-Sourced:pakfactory

You should give your cream, lipstick, essence and any beauty products with appealing and beautiful carton from cartoner equipment which reflect the beauty principle of product. Besides, the special light-shading ability of carton can prove the quality of products.

Health supplement industry

Health Supplement Cartons-Sourced:unleashwellness

Health supplement is booming and you can see vitamins, minerals, botanical and such products on market with appealing cartons. Cartoner equipment can highlight the selling point on market and attract people’s attention to lead them for the right choose. The protective carton packaging can also assure the integrity of medicines.

Stationary industry

Stationary Carton-Sourced:charmdecor

Stationary industry has a broad product field, scissors, books, pens, pencils, knives and so on. Small or big, they should get a well package from cartoner equipment to make the convenient transportation and also protect customers when choosing them as some of them is sharp.

3.What Types Of Carton Can Cartoner Equipment Handle?

Cartoner equipment can handle various folding carton types for different packaging need. The features like practicality, cheap price, space saving and high quality made it welcomed in most industries.You may find the most common types as follow.

Straight tuck carton

Straight Tuck Carton-Sourced:ibexpackaging

Straight tuck carton is one of the most frequently used carton type. It is made by a sheet of paperboard of cardboard. It has two flappers in its bottom and top parts and the two flappers are in the same directions.

Reverse tuck carton

Reverse Tuck Carton-Sourced:packm

Reverse tuck carton is just like straight tuck carton. It has top and bottom sides open with four other sides wrapped. The difference lies on the two reverse dimension flappers. It designed to better product protection.

Lock bottom carton

Lock Bottom Carton-Sourced:multifoldfinishing

Lock bottom carton, also called as 123 bottom carton, is particularly designed to heavy product packaging. It has the bottom parts pushed to each other and make stable holding.

Hanger carton

Hanger Carton-Sourced: rosboutique

Hanger carton is the normal carton appearance with a little hook on its top side. It is used to make products for displaying on shelves. With a combination of protection and displaying, it is widely welcomed. But it can’t take heavy products.

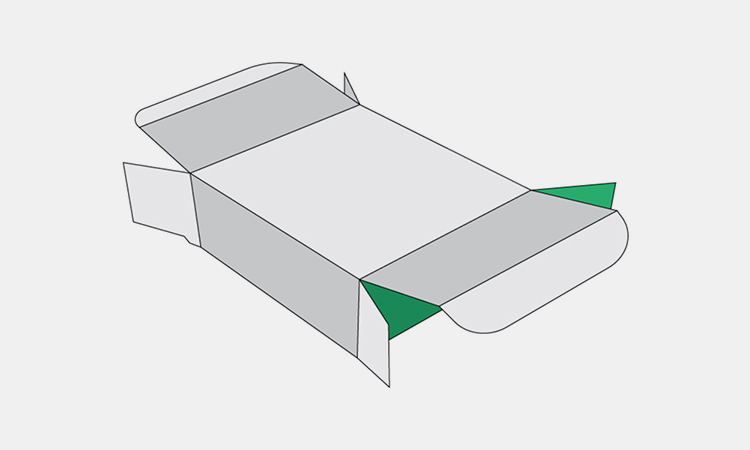

Seal end carton

Seal End Carton-Sourced:thepackagingboxes

Seal end carton has one flappers on its top side and its bottom side sealed. It may not that convenient in product getting, but it is sturdy enough to hold heavy products or get the long and dense filling process, like bare products.

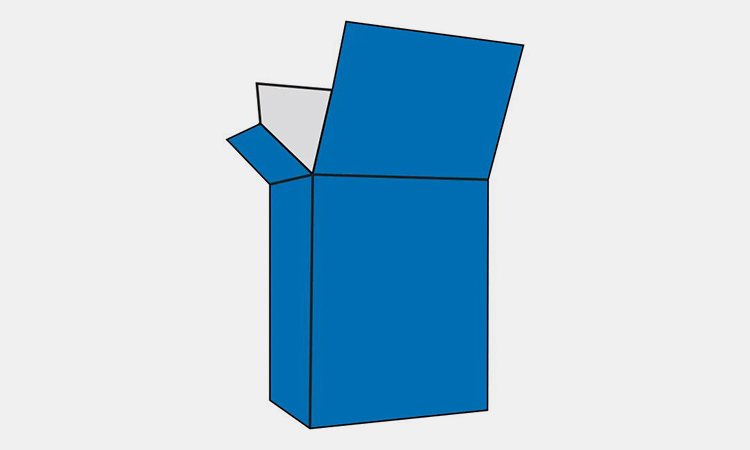

Tuck top carton

Tuck Top Carton-Sourced:imperialpaper

Tuck top carton is made by two sheets of board which stick into each other and made a solid structure. It’s strong and durable enough for heavy products. It’s also convenient to open and close. The so many advantaged made it greatly welcomed in market.

4.What Benefits Can You Get From Cartoner Equipment?

You can get a lot benefits from cartoner equipment.

Saving of money and time

Saving Of Money And Time-Sourced:freedom

Cartoner equipment makes highly efficient packaging compared with labor packaging way. The precise work saves extra energy in packaging and picking out unqualified carton. It looks save little, but in a long run, you can save so much money and time which is valueless in manufacturing.

High quality production

High Quality Cartons-Sourced:packmojo

The products you get from cartoner equipment are produced with precise measurement and unified standard. You have no need to worry about the carton quality as the cartoner equipment can give you the absolutely nice one.

Versatility

Versatility Of Cartoner-Sourced:packagingstrategies

Cartoner equipment can package cartons of various shape and type. You have no need to change packaging machine for your new series. Just a little adjust, it can run and make the expected carton for you.

Safety assurance

Safety Assurance-Sourced:freeredar

While handling some heavy, hard or sharp products, your labor may get hurt. But the cartoning equipment can control the whole packaging process no matter what product it is. Its mechanical hand is stronger and can protect your labor from damage.

5. Are There Any Drawbacks Of CartonerEquipment?

Cartoner equipment helps a lot in improving efficiency, but there also exists drawbacks.

Low flexibility

Low Flexibility-Sourced:kflexpack

Cartoner equipment is heavy and fragile. Once it is fixed in a place of your factory, it’s hard to remove or change. The flexibility is thus not that outstanding.

High cost

High Cost-Sourced:fortnightly

To get your suitable cartoner equipment, you should pay a lot at begin. The design, transporting, debug of machine are all added the cost.

High demand on labor

High Demand On Labor-Sourced:freepik

The operation of cartoner equipment is easy but professional. You should get your labor trained or hire professional labors. This is an extra cost of your cartoning process.

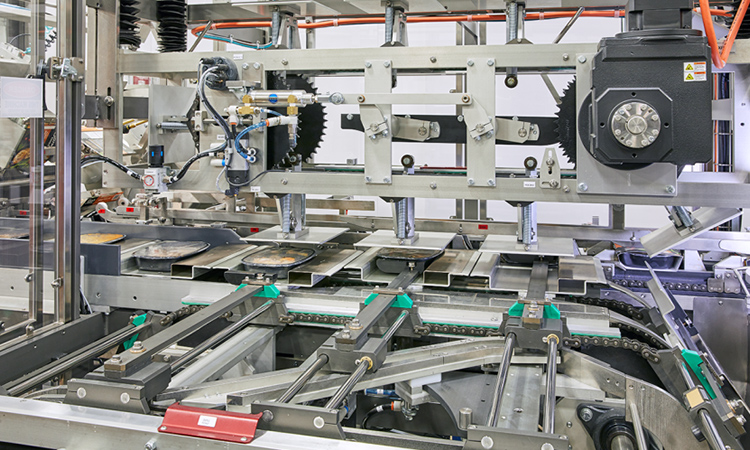

6. The Cartoning ProcessOf Cartoner Equipment

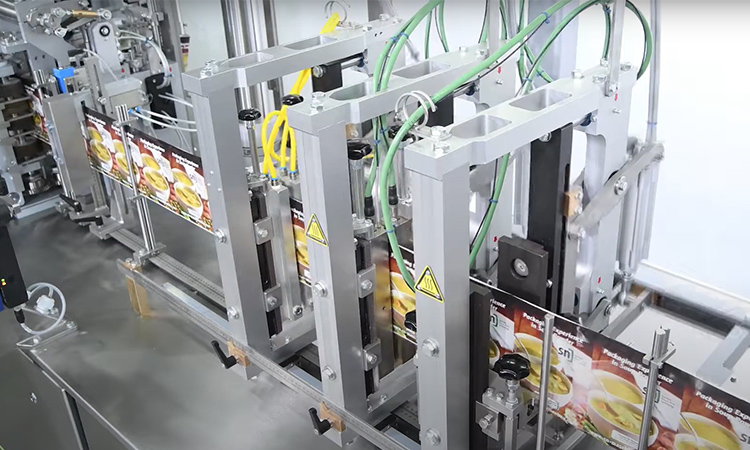

Working Cartoner Equipment

Cartoner equipment has various types according to its automation level, loading way and motion manner, but its cartoning process doesn’t change a lot.

- Products get into the cartoner equipment from the loading place and transformed by conveyor belt to wait for the cartoning.

- The sheet of board is folded by mechanical hand to the formed carton and left a side open to fill the waiting products in.

- Carton, after having products and other instructions or brochures filled, get it one last side sealed.

- After products are packaged well in carton, they should also experience a printing process and have the necessary information printed on it.

- The well-packaged carton than end the cartoning process and get out of the cartoner equipment by carton chute.

7. What Are The Main ComponentsOf Cartoner Equipment?

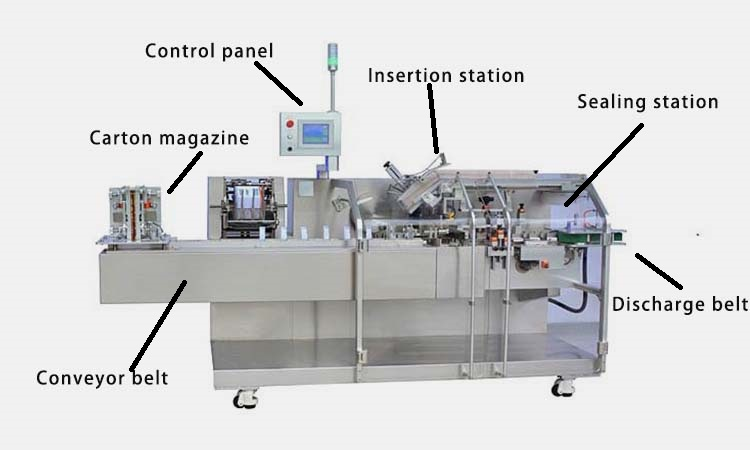

The Main Componets Of Cartoner Equipment-Sourced:trendsdirectindustry

Cartoner equipment has different types, but similar main components.

Control panel

Control Panel-Sourced:pcmachinery

Control panel takes in charge of the working of the whole cartoning process. You can get on the cartoning panel like carton number, size, type, printing information and so on. It’s just like the brain of cartoner equipment and decides the whole working of it.

Conveyor belt

Conveyor Belt-Sourced:massmanautomation

Conveyor belt links every process of cartoner equipment and does the transporting system of the machine. Without its, the cartoning work can’t be made.

Carton magazine

Carton Magazine-Sourced:shinebenmach

Carton magazine holds piles of board sheets and makes the preparation to send them to the carton folding process.

Insertion station

Cartoner Insertion system-Sourced:shinebenmach

Insertion station gets products and other things like instruments and brochures into the carton.

Carton sealing system

Carton Sealing System-Sourced:shinebenmach

Carton sealing system sealed the carton with all things filled.

Discharge Station

Discharge Station-Sourced:jornen

Discharge station is the last process of cartoner equipment, its role is to let products out machine and prevent the piling of well-packaged products.

8. What Are The DifferencesBetween Cartoner Equipment And Case Packing Equipment?

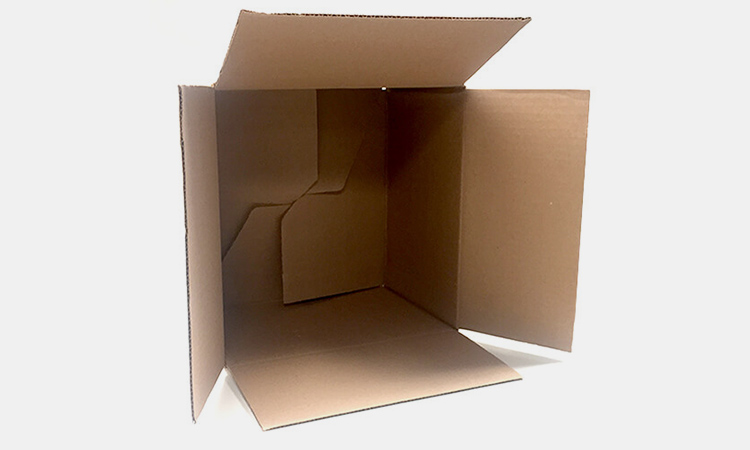

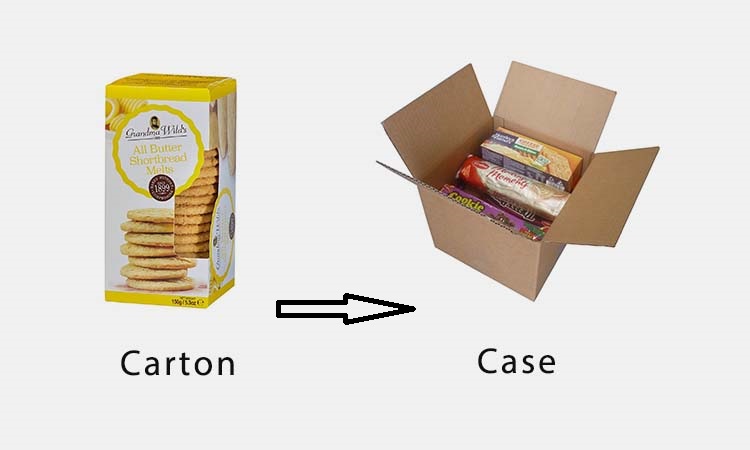

Cartoner equipment and case packing equipment, though share the same purpose of making packaging, are very different in its applying field, handling product size, material use and so on.

Applying Field

Carton And Case-Sourced:crimplevalleyfresh

Cartoner equipment and case packing equipment perform secondary and primary packaging respectively. Cartoner equipment makes packaged carton as retail setting which face market and customers, while casing packing equipment makes the larger carton to integrate the scattered and do distribution which benefits transport and store.

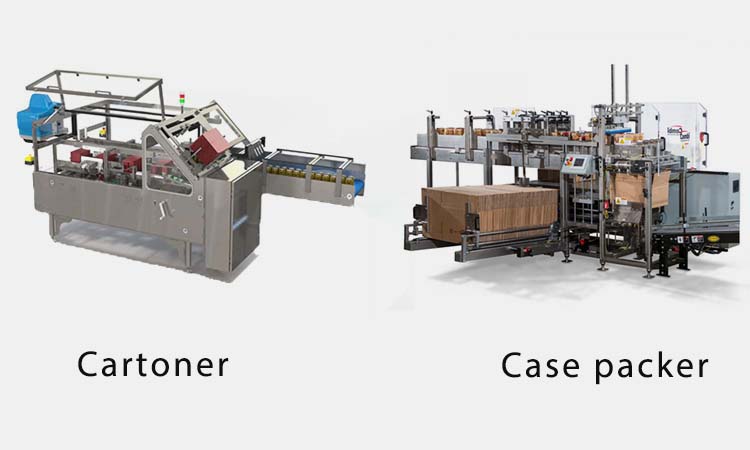

Other feature

- Packing size

Cartoner And Case Packer-Sourced:crownpack

Cartoner equipment deal with different size of products, but in all, it handled smaller products compared with case packer one. The later does the grouping and takes bulk of products.

- Material use

Carton And Case Material-Sourced:packagingformyproduct

Cartoner equipment makes cartons of various kinds of paperboard, like bleached sulfate paperboard, clay coated paperboard, kraft paperboard and so on. Case, in contrast, have the corrugated cardboard as the main material.

9. How To Maintaina Cartoner Equipment?

To prolong the live of cartoner equipment and let them benefit you in an all-around way, you should take a good maintenance for cartoner equipment. Here are some examples.

Regular examination and cleaning

Cartoner Examination-Sourced:makinate.

Regular examination and cleaning is an essential part in cartoner equipment maintenance. It can help you to find the hidden problems and prove the nice condition of the machine.

Daily inspection

Daily Inspection-Sourced:exapro

In the process of operation, you should inspect the cartoner equipment’s operation carefully. If there are any abnormal condition, it’s time to give it a further inspection.

Operation formalization

Carton Operation-Sourced:zhejiangleadtop

The standardized operation is more pleasing to cartoner equipment compared with the substandard and messy operation. It makes the smooth operation of cartoner equipment which is so good to machine.

Worn parts remove

Worn Parts Remove-Sourced:matco

There are parts worn in the process of cartoning. If you find the worn parts, you should replace it timely in case it affects the attached parts and make bigger worn for cartoner equipment.

10. What You Should Care In Operating Cartoner Equipment?

Cartoner equipment is easy to operate,but here are still some tips you’d better obey.

Instruction conforming

Cartoner Instruction-Sourced:haichinamc

The operation and maintenance of cartoner equipment should conform to the instructions. The substandard operation may leave you in the unexpected trouble.

Protective equipment

Protection-Sourced:communityconnection

In operation, you should let your workers wear safety gloves, protective clothing and relative protective objects. It can on one hand avoid the pollution of products with high hygiene standard and also prove the safety of workers when contacting with some harmful products.

No interruption for working machine

No Interruption-Sourced:clipartlibrary

If there is any mistakes or need to adjust products, material or panel, please switch off the machine. The interruption of working cartoner equipment may hurt you and make damage to machine.

Maintain according to standard

Standard-Sourced:allaboutlean

The maintaining schedule or lubricant should be conform to the standard. The unfitting one can hurt rather benefit your machine.

11. What You Should Care When SelectA Cartoner Equipment?

The right choice of a good cartoner equipment can benefit you a lot for your latter product manufacturing. Here are some tips for you to select your machines.

Speed

Speed-Sourced:jetspot

Cartoner equipment with higher speed makes greater production scale. You should select machines according to your production need and the future growth rate.

Product type

Product Type-Sourced: behance

What product you want package, can, ampoule or vial? Different machines show different packaging features, and you can get vertical cartoner which suits fragile products packaging and horizontal one which suits for multiple packaging.

Budget

Budget-Sourced:truesky

What is your budget of cartoner equipment. You can select your cartoner equipment in the sphere. The overspending can give you big burden.

Brand

Brand-Sourced:softmahal

You should search the cartoner equipment from big and reliable brand. They are the symbol of good quality and trustworthy after-sale service.

Automation and intelligence

Automation-Sourced:forbes

The higher level of automation and intelligence of cartoner equipment gives more convenience and efficiency for your product manufacturing.

Flexibility

Flexibility-Sourced:flaticon

The high flexibility of cartoner equipment means you can take it to deal with various size of carton. The money for change machine to suit different size is thus saved.

Easy operation

Easy Operation-Sourced:iconbunny

Where buying cartoner equipment, why not operate it actually. Choose the easy-operated one among the machines. You can save much money and energy in later labor training.

12.What Is The Future Trend Of Cartoner Equipment?

Cartoner equipment has a booming future. The suitable one will benefit your factory in a long run.

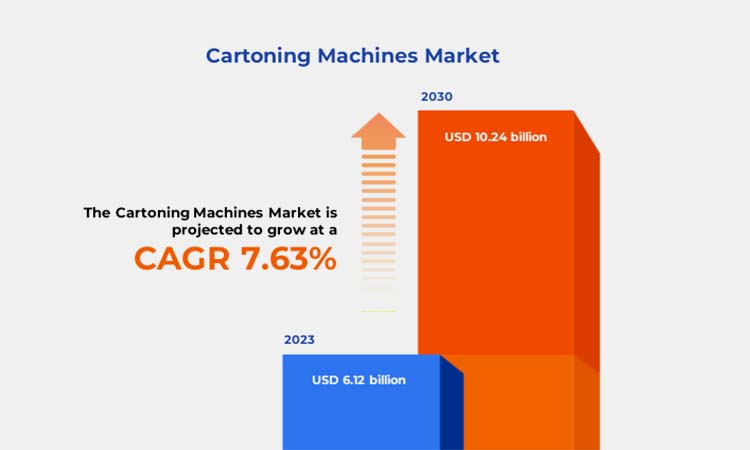

Future trend

Future Trend Of Cartoner Equipment-Sourced:360iresearch

The cartoner equipment has a market size of 6.12 billion USD. With a CARG 7.63%. it is expected to reach 10.24 billion USD. Cartoner equipment is obviously rising in an astonishing way. The dynamic market can also inject vitality and motivation for your company.

Future change

Cartoner equipment advanced itself to make more convenient packaging for your cartoning process.

- Intelligence

Intelligence-Sourced:educationalneuroscience

There is a trend of combing AI and cartoning equipment. These makes the cartoner more intelligent and humanized. These features will highlight greatly in the cartoning process.

- Automation

Automation-Sourced:globalsign

Now, robots are so common and you can see their figures in many field. It increases the automation of mechanization. The later trend of combing cartoner equipment with robot would endow great convenience to cartoning work.

- Sustainability

Sustainability-Sourced:wandsworthlifelonglearning

With the growing awareness of recycle and environment protection, cartoner equipment is tend to be more sustainable. It is designed to handle the recyclable material to improve energy efficiency and reduce waste.

Conclusion

The complete FAQ guide In 2024 of cartoner equipment lead you to have a comprehensive knowledge about cartoner equipment. And the knowledge can help you in its maintenance and operation. If you have any other questions about this machine or are confused in some parts of it, don’t hesitate to contact us.

Don't forget to share this post!

Cartoner Related Posts

Cartoner Related Products

Cartoner Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours