Capsule Strip Packing Machine: The Complete Buying Guide In 2025

Have you ever noticed the capsule strip pack for your various medicine? Are your surprised with the careful and creative design of this little pack? The hygienic and clear packaging way for capsule and tablet can make so much benefit and convenience for your daily life.

While you take them, do you have the relative questions? What you may benefit from capsule strip packaging machine? What are the disadvantage of capsule strip packaging machine? What industry can capsule strip packing machine be applied? Are there other packaging for capsule? To have a deep understanding of this machine, here come to check the buying guide!

1.What IsCapsule Strip Packaging Machine?

AIPAK Capsule Strip Packaging Machine

Capsule strip packaging machine is the machine which can make the efficient and qualified packaging of capsules, tablets, soft gelatin capsules. It can make the strip packaging for the products of medical, supplementary, chemical, food and so on. It can suits the products of various size and perform series of work from filling, packaging to cutting.

Capsule strip packaging machine can adopt plastic, aluminum or other material for the packaging. The products have the outstanding light-resisting and moisture-resisting ability. You may find its widely used in lab products, high required medicines, hospital dosage room and so on.

2.What Industry Can Capsule Strip Packing Machine Be Applied?

What industry can capsule strip packing machine be applied? There are so many places where this machine can make the nice work.

Pharmaceutical industry

Pharmaceutical Industry-Sourced:truepharmacia

Pharmaceutical industry is the place where capsule strip packing machine has the wide application. Besides capsules, pill, lozenga and tablets, you may also see the packaging of some machine parts or small equipment of pharmaceutical industry from this machine.

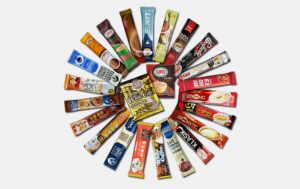

Food industry

Food Industry-Sourced:getsupp

There are various food which can be packed by capsule strip packing machine. You may use capsule strip packing machine for the various candy packaging. And you can also apply it for the packaging of chewing gums, compressed biscuits and so on.

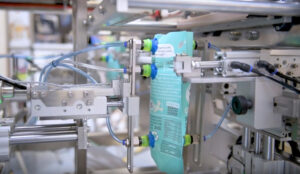

Electronic industry

Electronic Industry-Sourced:saintyco

Capsule strip packing machine can also be used in electronic industry. You may find the application of packaging battery, wire, cable, memory cards and so on. This machine gives the great settling of various electronic products.

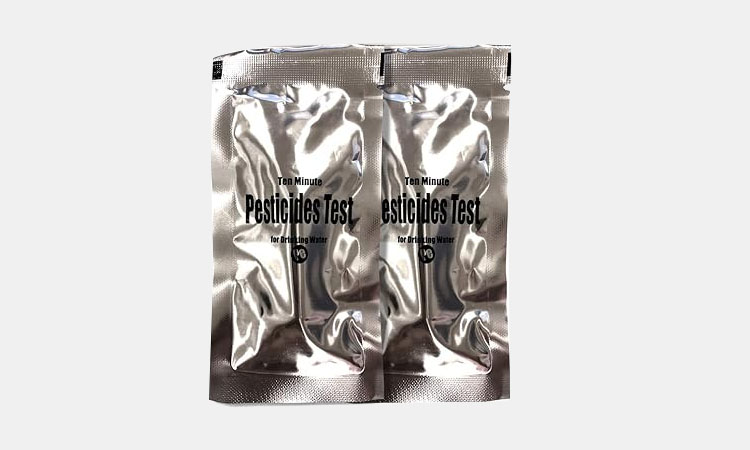

Agricultural industry

Agricultural Industry-Sourced:desertcart

For agricultural industry, there are the need of making the capsule strip packaging. For seeds and some pesticide, the capsule strip packaging can give the better protection in transporting and storing.

Chemical industry

Chemical Industry-Sourced:gztopone

There are various chemical products like mosquitoes’ repellent tablets, camphor and so on which can be better saved and conveyed by capsule strip packing machine. And there are also other chemical products which can be packaged by this machine.

3.What Types of Products Are Suitable For Capsule Strip Packing?

What types of products are suitable for strip packing? Here are the products which are frequently packaged by this machine.

Capsules

Capsules-Sourced:istockphoto

Capsules are the types of medical products which are suitable for the capsule strip packing. You may find the frequent adopting of this packing way in various capsules or pills. It can prove the sanitary and safe of medicine taking.

Effervescent tablets

Effervescent Tablets-Sourced:romaco

Tablets or effervescent tablets are the products which adopts the capsule strip packing frequently. This packing way can benefit taking of medicines and also prove the safety of medicine as it gives the great protection.

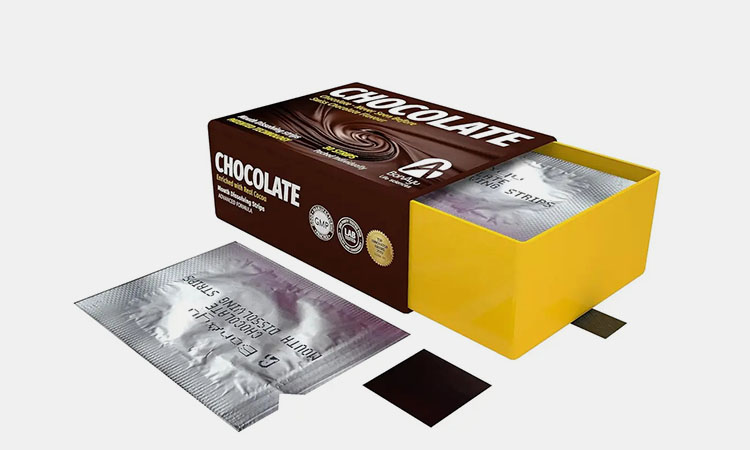

Candy

Candy-Sourced:candyboulevardusa

Capsule strip packing machine can also be applied frequently in candy packing. For chocolate balls, fruit candy and so on, capsule strip packing makes the nice work in proving products quality and so on.

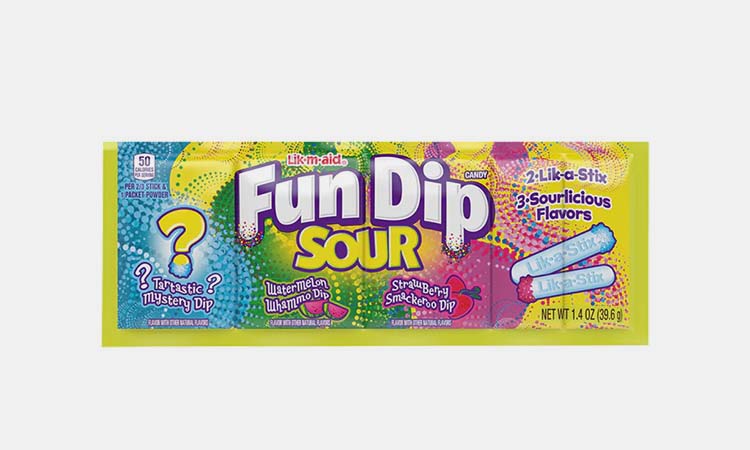

Chewing gums

Chewing Gums-Sourced:freepik

Chewing gums are the welcomed snack. And with the help of capsule strip packing machine, it can has moisture and air prevented. This packaging can prove products quality and also make the attractive appearance.

Lozenga

Lozenga-Sourced:cngrandmachinery

Lozenga is also packed in capsule strip packing machine frequently. Lozenga may get melted or damaged in the fragile packing. And for this reason, you should adopt capsule strip packing machine for the reliable packing.

Batteries

Batterie-Sourced:romaco

Batteries are a kind of electronic products. For the relative products like cables, memory cards and so on, you can also adopt capsule stick packing machine for the great packing.

Electronic components

Electronic Components-Sourced: livewiredirect

There are also various components for pharmaceutical industry or mechanical applying. To make the reliable protecting of electronic components, capsule strip packing is the great choice.

4.Are There Other Packaging For Capsule?

Are there other packaging for capsules? Of course there are. And here are the common packaging for capsules.

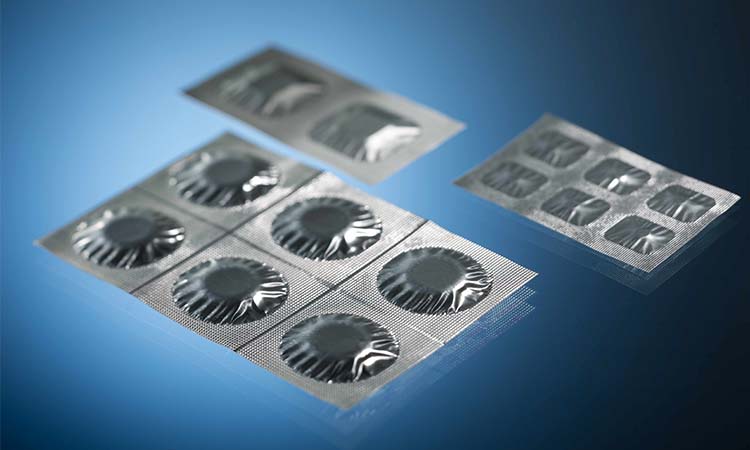

Blister packaging

Blister Packaging-Sourced:sedpharma

Blister packaging is the common packaging way for capsule packaging. Blister packaging is usually plastic or aluminum. And there are the according cavity on it. The cavity can give the great settling and protecting of capsules and the sealing is airtight to protect capsules.

Bottle packaging

Bottle Packaging-Sourced:roetell

Bottle packaging is also the packaging way for capsule packaging. For the medicines with large dosage or pills, bottle packaging is the time saving and cost saving way. You may see its widely use of capsules in supplementary industry.

Sachet packaging

Sachet Packaging-Sourced:spackmachine

Sachet packaging is the great way to make the nutrition pack for capsules. Here are the various sachet packing and you may also have your own design on size, appearance and shape on its designing.

5.What You May Benefit From Capsule Strip Packaging Machine?

What your may benefit from capsule strip packaging machine? Here are several advantages of capsule strip packaging machine which may benefit you.

Great protection

Great Protection-Sourced:threatresearch

Capsule strip packaging machine makes the protective packaging for the various products. The airtight pack can prove the active ingredients and also prevent the pollution of medical products of other dust, light and so on.

Tamper proof

Tamper Proof-Sourced:iprints

The special shape of capsule strip packaging machine can help protect your profits as it protects the original products. The capsule strip packaging machine can ensure the quality and genuine of products.

Prescription complying

Prescription Complying-Sourced:renuerx

The capsule strip packaging machine makes the individual settling of each capsules or tablets. For patients, the taking will be easier and more convenient. It can also make the more accurate medicine taking dosage.

Durable packaging

Durable Packaging-Sourced:shutterstock

The capsule strip packing machine is durable and its products are also durable. The strong and durable packaging can help protect the products in their transportation and storing.

User friendly

User Friendly-Sourced:webhosting

The capsule strip packaging machine produced the medicines which are user friendly. The unit dosage packaging makes the medicine taking and dividing easy. For many patients, this packaging makes the medicine taking more clear and easy.

Longer shelf life

Longer Shelf Life-Sourced:sunflower58554

The capsule strip packaging makes better protection of products and can thus extend the shelf life of your products. And the longer shelf life saves the frequent purchase of customers which in some way saves their life.

Appealing appearance

Appealing Appearance-Sourced:antaipacking

The capsule strip packaging has the appealing appearance. The compact designing and attractive cover can always attract customers and inform the important message to customers.

6.What Are The Disadvantage Of Capsule Strip Packaging Machine?

No products are perfect. What are the disadvantages of capsule strip packaging machine?

Contamination

Contamination-Sourced:vilasengineeringworks

Strip packing machine requires the higher technique and more careful packaging as there is the risk of strip packaging perforating or leaking. And the contamination may begin from there. The improving of quality control can help refuse the contamination.

Slower speed

Slower Speed-Sourced:vectorstock

Strip packing machine has the complex manufacturing process and slower speed compared with other packing way. The higher request on accuracy may cost you more in time and energy.

More complex and sensitive manufacturing process

More Complex And Sensitive Manufacturing Process-Sourced:rotadyne

The manufacturing process of capsule strip packaging machine is complex. And there may exist risk of products damage. The complex and intricate process of sealing rollers need pay extra attention for the pack with no wrinkles and perforation.

7.What Are The Material Used In Capsule Strip Pack Manufacturing?

There are various capsule strip pack. And do you know their difference in material applying? Here are the material used frequently in capsule strip pack manufacturing.

Paper

Paper-Sourced:romaco

Paper is the kind of material which is degradable and eco-friendly. The paper used for capsule strip paper manufacturing should be strong and durable for the nice containing and protecting of various products.

Foil

Foil-Sourced:rsfoils

Foil is kind of material used frequently for capsule strip packaging. Aluminum has the strong ability to defeat moisture and microbes. And for light-reflecting, it has also the great ability.

Plastic

Plastic-Sourced:cngrandmachinery

Plastic material is widely used in various packaging. And for capsule strip packaging, it also makes the nice work. There are various plastic material like polyethylene, regenerated cellulose, polyvinyl chloride, polyvinylidene chloride and so on. Different plastic material has different feature for different packaging.

Heat sealing material

Heat Sealing Material-Sourced:sigmaaldrich

Heat sealing material is widely used in strip sealing and packaging. It helps a lot in saving manufacturing’s strength in heat sealing. And the majority of heat sealing material are plastic and you may find the some board materials or rubber material for heat sealing.

8.What Are The Main Types Of Capsule Strip Packaging Machine?

You may be confused about the various types of capsule strip packaging machine on market. And here are the main types of capsule strip packaging machine which divided according to automation level and configuration.

Automation level

Semi automatic capsule strip packing machine

Semi Automatic Capsule Strip Packing Machine-Sourced:indiamart

Semi automatic capsule strip packing machine can perform a series of work in heating, sealing, cutting and packaging. With semi automatic capsule strip packing machine, you can have your labor cost reduced greatly as the quantity of sealing, temperature and speed can be set well.

Automatic capsule strip packing machine

AIPAK Automatic Capsule Strip Packing Machine

Automatic capsule strip packing machine has higher level of automation compared with semi automatic capsule strip packing machine. It is more efficient and accurate which is suitable for the large scale production. The simple operation can make the large production.

9.What Are The Main Parts Of Capsule Strip Packaging Machine?

What are the main parts of capsule strip packaging machine? Here you may check the main parts of automatic capsule strip packaging machine.

PLC control system

AIPAK PLC Control System

PLC control system is the way which you may control the machine. It can help you get in the important information and panel of your production. And for the beginning and stopping of machine, it is the only way.

Driving unit

AIPAK Driving Unit

Driving unit is the important part which is composed by drive motor, ball-lead screws, conveyor belt and so on. With no participation of this part, the capsule strip packing machine cannot make the smooth job.

Vibrating unit

AIPAK Vibrating Unit

Vibrating unit is the part where your products get in to the feeding system and get on the packaging process. It helps the begin of the whole packaging process.

Feeding unit

AIPAK Feeding Unit

Feeding unit has the hopper shape which helps transfer the products from one container to another container. The counting unit in it can count the products before packing. The right number of each products in some way show your products quality and so on.

Cutting unit

AIPAK Cutting Unit

Cutting unit can help make the precise cutting according to your procedure setting. The smooth and accurate cutting in some way shows the manufacturer’s ability. Perforation system of cutting unit makes also the irreplaceable work in capsule strip packaging process. It can uncoil, cut and shape the well made products which proves the nice appearance of your products.

Detecting and ejection system

AIPAK Detecting And Ejection System

Detecting and ejection system is also the special design of AIPAK capsule strip packing machine. This system helps detect and eject the unqualified parts of the products. It saved your energy of quality control and also proves your products quality.

Aluminum foil installing roller

AIPAK Well Performed Roller

There are roller printing with ribbon and aluminum foil installing roller for AIPAK capsule strip packing machine. It is made with the high qualified stainless steel and can make the series of excellent capsule strip pack.

Conveyor

AIPAK Conveyor

Conveyor is the last process of capsule strip packing machine. It leads the discharging of the well done capsule strip pack. Conveyor avoids the congestion of products in capsule strip packaging machine and is the last part of capsule strip packaging machine.

Eye marking system

AIPAK Eye Marking System

Eye marking system is the important part of capsule strip packing machine. It can help the dividing and cutting for the capsule strip pack with right position and so on. It is optional but useful.

10.What Is The Working Principle Of Capsule Strip Packaging Machine?

How does capsule strip packing machine work? What is the working principle of capsule strip packaging machine?

The Working Principle Of Capsule Strip Packaging Machine

Products filling

Products filling is the begin of the whole packaging process. You should connect the products and the hopper for the smooth and consistent products providing and filling.

Products conveying

After products are filled, the conveying part then makes the great job in conveying the products to next process. And in products conveying, you can have your products vibrated and separated for later packaging.

Products aligning

For further work, capsule strip packing machine helps align products with your sealing material. The set panel will help align your products with right number and place.

Products filling and sealing

After your products prepared and aligned well, it is time to fill and seal them all. The sealing roller cavity will help the two parts stick together. And this process is made by heating or pressure.

Package cutting

The cutter of capsule strip packing machine will then make the automatic trimming for the well packaged products. The products then can be even, clear and clean for further selling.

11.Strip Pack VSBlister Pack, What Are The Differences?

Besides strip pack, there are the blister pack which is also famous for capsule packaging. Do you know the differences between strip pack and blister pack.

Strip Pack VS Blister Pack-Sourced:istockphoto

| Difference | Strip pack | Blister pack |

| Forming technique | Strip pack usually apply heat forming for pack making. | There is thermoforming and cold forming technique for blister pack. |

| Packaging material | Strip packing has most soft alu foil as the packaging material. They are mostly soft aluminum foil packaging. | Blister machine can deal with aluminum packing and aluminum plastic packing. They are mostly hard aluminum foil packaging. |

| Products variety | Strip packing machine has wider variety and can take the capsules with various size and shape. | Blister packing machine has the more restricted products variety. |

| Machine size | Strip packing machine has smaller size compared with blister packing machine. | Blister packing machine has bigger size compared with strip packing machine. |

| Operating speed | Strip packing machine provides the fast packaging results. | The blister packing machine is slower in making the products. |

| Air proportion | Strip pack has less air compared with blister pack. | Blister pack has more air in cavity compared with strip pack. |

| Taking difficulty | The strip packing machine is more difficult in getting capsules. | You can cost less energy in taking capsules from blister pack. |

| Taking manner | For strip pack, you would better to tear the pack and get your capsules. | You should push or peel blister pack to get your capsule. |

| Suitable people | Strip pack is not suitable for the elder, weak patients or people with hand problem. | Blister pack is more easy to open and is more suitable for children and elder. |

| Protecting ability | Strip pack has the stronger protective ability. | Blister pack is less protective compared with strip pack. |

12.What You Should Consider For The Purchase Of Capsule Strip Packing Machine?

Do you want a qualified capsule strip packing machine? You would better to consider the below tips for the purchase of capsule strip packing machine.

Budget

Budget-Sourced:allbusiness

Budget is the factor you should take serious consideration while choosing the capsule strip packing machine. You should consider the machine and make the purchase with your budget.

Machine type

AIPAK Machine type

Machine type is also the factor you should consider seriously. Automation or semi automation, which is your needed one. You should get your machine type according to your need.

Production ability

Production Ability-Sourced:saintyco

How about your production scale? The large production should be equipped with the capsule strip packing machine with high speed and large production ability. Or the restricted production scale will hurt you.

Compatibility

Compatibility-Sourced: nsrd

The high level of compatibility is the factor you should consider for your machine purchase. The compatibility of machine for products and material can improve your efficiency in many way.

Regulatory compliance

Regulatory Compliance-Sourced:sweetprocess

You should also choose the machine which conform to the local regulatory compliance. The products which cannot comply with the local regulatory compliance may be restricted and priceless.

13.What Are The Common Trouble Of Capsule Strip Packing Machine?

The capsule strip packing machine cannot always operate smoothly. Here are the common trouble of capsule strip packing machine.

Unqualified sealing

Unqualified Sealing-Sourced:istockphoto

Capsule strip packing machine is easy to get little bubble in pack or have the lifted edges. For this condition, you should check the contacting condition of sealing voltage and sealing material. And you should also prove the steady of the voltage.

Wrong film place

Wrong Film Place-Sourced:saintyco

The wrong film place may obstruct the capsule strip packaging process. And for this condition, you should place the film at the spindle and make the right webbing. If your film can still not work well, you should replace or repair the film or the relative tracking system.

Irregular cutting

Irregular Cutting-Sourced:saintytec

Irregular cutting may lead the unsuitable and uneven capsule pack style and may lead the bad reputation for your products. For this condition, you should ensure the sharp blades and also ensure the right position of the blades. Only in the nice condition, can they work well.

No power

No power-Sourced:thedailystar

Without power, the machine cannot work. To make smooth manufacturing, you should check the power condition. Power cable, power condition and so on should all be checked well.

14.How To Maintain Capsule Strip Packing Machine?

Capsule strip packing machine is the big and intricate machine. How to maintain it and prolong the lifespan of it? Here are some advice for you.

Regular cleaning and checking

Regular Cleaning And Checking-Sourced:fieldinsight

You should make the regular cleaning and checking of your capsule strip packing machine. For the dust and some particles of machine, you should replace and assure the nice condition of it.

Worn parts removing

Worn Parts Removing-Sourced:mbaction

For the worn or broken parts, you should make the detailed recording and make the timely replacing. The leaving of worn parts in machine may lead the frequent problem of machine. In reserve, you may get the efficient work from machine with great parts.

Oil replacing

Oil Replacing-Sourced:idrivesafely

It is essential to replace oil in gearbox. The timely replacing can in some way prove the smooth operation of machine. Oil replacing is the important part for your capsule strip machine maintaining.

Genuine parts applying

Genuine Parts Applying-Sourced:createvista

You would better to adopt the genuine parts of reliable capsule strip packing machine manufacturer. The choosing of the genuine parts can prove the great working condition and smooth manufacturing process.

15.What Quality Standard a Qualified Capsule Strip Packing Machine Should Have?

A qualified capsule strip packing machine should have some quality standard to prove its high quality and great efficiency.

cGMP

cGMP-Sourced:convergencetraining

cGMP standard is the important qualification standard which takes the essential place in pharmaceutical industry. For the smooth and reliable manufacturing, cGMP standard makes clear request on machine material, technique, design, efficiency and so on. It is the prove of great quality.

FDA

FDA-Sourced:kffhealthnews

FDA has the full name of food and drug administration. It is the important administration of USA which makes the strict request on safety, efficacy and security of machines. If you want your machine and products have great sale on USA, you should pay attention to this standard.

ISO

ISO-Sourced:blog-qhse

ISO is the international organization for standardization. There is the standard which is accepted by over 160 countries. In international market, this qualification means the great quality and ability for most countries.

16.What Is The NFDSystem Of Capsule Strip Packing Machine?

NFD System-Sourced:sitcom

Have you ever heard of the NFD system of capsule strip packing machine? NFD system is the important system of capsule strip packing machine which help detect the quality of your well done capsule strip. For any missing or unqualified capsule strip, it can give the quick and efficient response.

You may activate the system which presents in automatic capsule strip packing machine. It is mostly consist of PLC and HMI unit. For the speed of your automatic capsule strip packing machine, the capsule strip packing machine can still make the great packaging speed.

17.What Are The Top 5 Capsule Strip Packing Machine Manufacturer On World?

If you are interested in the capsule strip packing machine, you may be interested at the various manufacturer of capsule strip packing machine on world. Here are the top 5 capsule strip packing machine manufacturer on world.\

Romaco

Romaco Capsule Strip Packing Machine

Romaco is the leading pharmaceutical machine manufacturer in world. Its machines have high quality and can suit the products of cosmetic, food, supplementary, pharmaceutical industry and so on. The high quality and technique of machine makes it leading in world in machine quality and efficiency.

Marchesini Group

Marchesini Group Capsule Strip Packing Machine

Marchesini group is one of the well known machine manufacturer. This manufacturer is able to design and produce a variety of machines. The rich experience and great focus of this group has made many benefits for people all over the world. You may get your dreamed machine with high quality here.

AIPAK

AIPAK Capsule Strip Packing Machine

AIPAK is the young and energetic capsule strip packing machine manufacturer. You may get your one-stand machine purchase here. As the professor of pharmaceutical industry, you may get the machine with great assurance here. And the after sale service and consulting service can also help improve the use experience.

Cam Packaging

Cam Packaging Capsule Strip Packing Machine

Cam packaging is the old brand pharmaceutical machine manufacturer on world. Since 1949, it devoted its large energy in machine investigating and developing. It is able to produce the production line for cosmetic, pharmaceutical, food and so on. Its worldwide technical assistance can provide you the timely response and help.

TOYO machine

TOYO Machine Capsule Strip Packing Machine

TOYO machine is the Japan pharmaceutical machine manufacturer. With over 30 years experience in machine investigating, the machine can make the smooth, long lasting and qualified work for many industries. It has the administration in many countries and can make the reliable and large production work.

18.What AIPAK Strip Packing Machine Can Benefit You?

Here are so many great machine manufacturer on world. And the AIPAK strip packing machine is highly recommended. You may check the reasons.

Humanized design

AIPAK Vibrating Feeder

The vibrating feeder is the great show of humanized design of AIPAK strip packing machine. It can make the even and reliable vibrating for your products coming into the strip packaging process. It also helps separate the sticky products and makes the preparation for the further aligning and packaging.

Precise cutting and filling

AIPAK Precise Cutting Part

AIPAK strip packing machine has the precise cutting and filling part which prove the pretty and even capsule strip pack. You may have your type and size of capsule strip pack designed and set from panel.

Reliable consulting and after sale service

Reliable Consulting And After Sale Service-Sourced:successive

AIPAK is the manufacturer which provides the careful consulting and after sale service for your various condition and request. With rich experience and great technique, it can always give you the reliable and efficient plan.

Easy operation and high qualified rate

Easy Operation And High Qualified Rate-Sourced:gorilladesk

AIPAK capsule strip packing machine is the complex machine but the operation comes from the touch screen. And the whole process is easy. The nice combination of machine part and system and the great machine design makes the products of high quality. For the perforation, wrinkle or any problem which happened frequently in capsule strip packing, AIPAK can make the great avoid.

Conclusion

Capsule strip packing machine is the useful and efficient machine for pharmaceutical, chemical, cosmetic, food and many industries. The complete buying guide in 2024 of capsule strip packing machine shows you the deep knowledge about this machine. If you have any question or problem about this machine, contact us now!

Don't forget to share this post!

Strip Packing Machine Related Posts

Strip Packing Machine Related Products

Strip Packing Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours