Capsule Inspection Machine: The Complete Buying Guide In 2025

Since their introduction in the 19th century capsules have now become 2nd most commonly used oral dosage form in the world. Although the manufacturing and filling technology has improved since then, producing defect-free capsules is still a far-fetched idea.

Owing to the fact that large quantities of capsules are produced daily there will always be some kind of defects in capsules; some are critical affecting purpose of final product while others are minor influencing quality and integrity of the brand.

Pharmaceutical companies are now investing more and more in to systems that detect and remove such imperfection. One such equipment that is employed worldwide is Capsule Inspection Machine. To answer your questions related to this equipment bringing to you Capsule Inspection Machine: The Complete Buying Guide in 2022.

Without further ado let’s delve deeper!

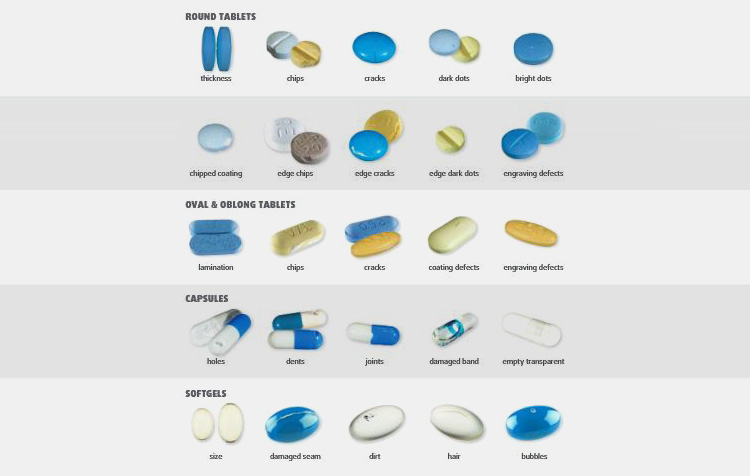

1.What are most common capsule defects?

Although capsules are quite easy to manufacture however, while working with capsules sometimes you may face problems. As a manufacturer the most common capsule defects that you should know are;

Length

A variation in length usually occurs due to a number of reasons such as increased moisture content, broken or missing knife, overfilling of capsules or failure of locking mechanism.

Holes

Holes in capsules may from due to incorrect machine parameters leading to stripper jaws malfunction.

Dents

Dents are usually formed due to improper machine and filling parameters. A dent may form because of machine applying excessive pressure or due to overfilling of capsules or because of high moisture content.

Damaged Joints

This occurs due to blunt cutter or knife.

Damaged bands

This problem occurs due to inappropriate machine speed, temperature, band thickness and poor band.

Empty shells

This problem occurs mostly in machines that are not equipped with safeguard features allowing unchecked empty capsules to come out of production lines.

Misprints

A number of reasons for misprints include improper drying and viscosity of ink, irregular ink flow and uneven pressure.

Color differences

Occur due to improper storage conditions that may lead to change in pH, moisture content, microbial growth or exposure to light and heat.

Telescoping

Misalignment of cap and body due to variations in capsule sizes, distortion of capsules and wear / tear of machine may lead to telescoping of capsules.

Cracking

This problem occurs mainly due to improper storage conditions, and improper alignment of both segments of capsules.

2.What is capsule inspection machine?

Due to any reason such as improper machine parameters or decreased efficiency of machine or the fact that no operation is 100% fault free; defected capsules can be produced during production. The most orthodox method is to visually inspect capsules for damage; however, this proves to be difficult when you have to inspect large production batches which is carried out by employing capsule inspection machine.

Capsule inspection machine an equipment utilized in major pharmaceutical industry to prevent defective product leaving production facility is available in both semi-automatic and automatic versions. These machines are employed at lab scale level as well as full-fledged capsule production and can be attached to capsule manufacturing unit to make a complete production line.

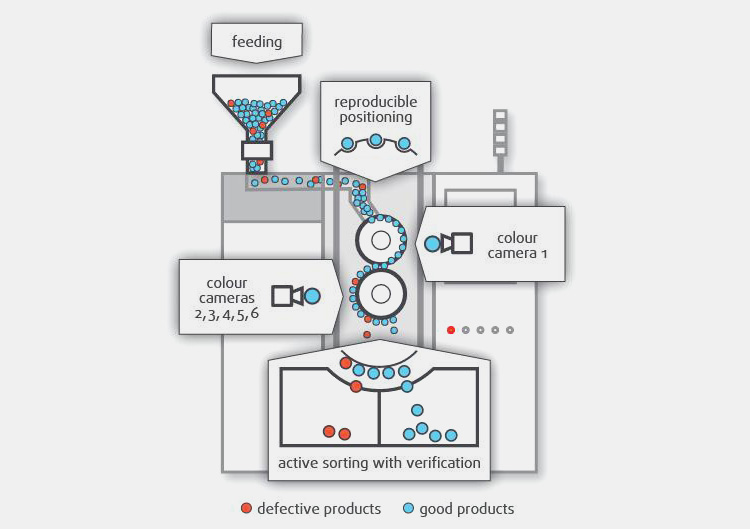

High tech features in automatic version, advanced electronics, multiple cameras, versatility in operations, integrated hardware and software ensures rejection of all faulty capsules. Moreover, these machines meet all the regulatory requirements of both local and international bodies making it to be most sought piece of equipment after capsule manufacturing unit.

A brief discussion about its make, components, specifications, troubleshooting is given below, read further if you want to know more about this machine.

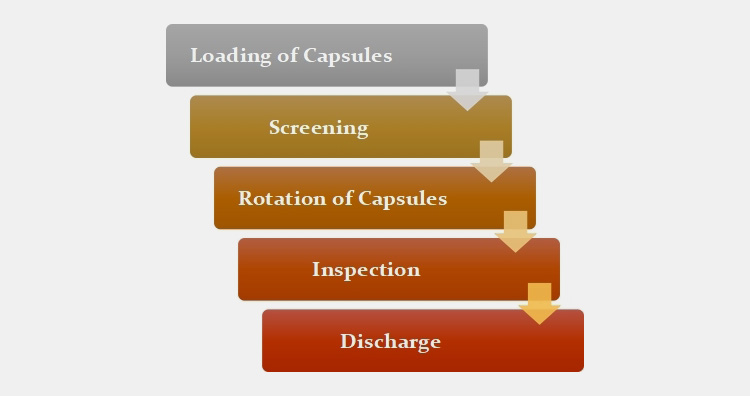

3.What is the working principle of capsule inspection machine?

The principle mechanism of capsule inspection machine is precise and regulated by PLC units. Learning the function of various parts allow the technician to resolve underlying problems in case of system breakdown.

Details of every step in working of capsule inspection machine are described below:

Feeding of Capsules

The capsules are automatically loaded inside the hopper by means of lift system or are poured manually by head. The capsules from hopper move to vibratory chute.

Screening

Perforated screen present in vibratory chute filter dust and chipped tablets.

Rotation of Capsules

Capsules go one by one vertically through vibratory chute and afterwards, the capsule moves horizontally towards rotation rollers that are employed for continuous rotation of the capsules.

Inspection

It is the main process of capsule inspection machine. Adjustable mirror and illuminating lamps are used for manual inspection of defected capsules from all sides.

In technologically advance machines, cameras capture images of capsules. These images go through special software for identification of flawed capsules such as cracked capsules, spotted capsules, etc.

Discharging

The information fed by image processing software allows separation for good quality capsules from faulty ones. Defected capsules are collected in rejection device while fine ones are moved to product barrel for packaging.

4.Advantages and technical specifications of capsule inspection machine?

These useful equipments have way more advantages for businesses than manual inspection as these automations speed up process and are highly accurate.

Some of important benefits of capsule inspection machine are detailed below:

| High Quality Inspection | Capsule inspection machine provide state-of-the-art assessment of capsule with 100% accuracy and precision. They are furnished with camera and LED optical illumination that perform 3D surface scanning of capsules bringing meticulousness to inspection of capsules. |

| User Friendly Operation | Ease of parameter selection on intelligent graphical interface assists in smooth operation and also reduces need of operators. Furthermore, parts are effortlessly dissembled within 10 minutes for cleaning and maintenance. |

| Flexibility | These machines easily detect imperfections of capsules. They can inspect capsules of various color, transparent capsules and can examine artifacts in capsules having size up to 40μm. |

| Minimal Contamination Risk | Handling and inspection of capsules by hands pose a risk of contamination. But in capsule inspection machines, capsules are examined using cameras that minimize the chance of contamination. |

| High Inspection Rate | By using advance technology such as 3D surface detection with cameras and LEDs, these innovations are process 500,000-600,000 capsule of capsules per hour. |

| Safety

|

Manual inspection of capsule is a repetitive and tiresome job that causes ocular strain and present severe health risk. But employing capsule inspection machines in manufacturing lines relive labors of this demanding job. |

Technical Specification

These help to identify the machines that you are interested to buy are well-matched with your productions. Some technical specifications of capsule inspection machine are:

| Capacity | 120,000-600,000 capsule per hour |

| Hard Gelatin Capsule Sizes | 0-5 |

| Inspection Precision | Can detect defect of 40μm |

| Hopper | 25-40 L |

| Roller Speed Regulator | 0.4 KW |

| Voltage | 220V/400V ± 10% |

| Temperature | 10-30°C |

| Humidity | 30-70% |

| Compressed Air | 0.6 MPa |

5.Can capsule inspection machine be employed for dosage forms other than capsules?

These instruments are quite versatile, practical and are highly popular in wide ranging industry like food, chemical, veterinary, and cosmetic industries.

In pharmaceutical industries, these are not only used for inspecting hard gel capsules but also

- Round tablets

- Oval or oblong tablets

- Coated tablets

- Softgel capsules

6.Difference between semi-automatic and fully automatic capsule inspection machine?

Semi-automatic and fully automatic capsule inspection machine are the types of capsule inspection machine based on automation. These equipments have same working principle but differ in design style and human supervision.

Some differences in both types are penned below:

| Semi-Automatic Capsule Inspection Machine | Fully Automatic Capsule Inspection Machine |

|

|

| In these machines, capsules are inspected by human operators manually when they are moving on conveyors. | The capsules are examined via camera and image processing software. |

| Mirror, foot switches and lamps are used to identify defective capsules in these machines. | 2D or 3D cameras and halogen lamps are employed for examining capsules in these equipments. |

| It costs more time during inspection as manual labor process capsule slowly. | It saves a lot of time owing to presence of modern hardware and software for capsule inspection. |

| There is more chance of error in detection of flawed capsules in these machines since humans are bound to make mistakes. | The detection in these automations is highly precise due to high sophisticated technology that has 100% error free detection. |

| These are less expensive but have more production expenses due to labor wages and product wastage. | These are pricier but lower your production cost as it does not need human assistance and also product wastage is reduced. |

| There is a high risk of contamination due to manual handling of capsules. | No contamination is possible as capsules are processed in vacuumed system. |

| It consumes less power. | It requires more power for running. |

7.What are different parts of a standard capsule inspection machine?

Standard capsule inspection machine consists of advance technology and modern component for thorough examination of capsules.

Below are details of some important parts of these innovations.

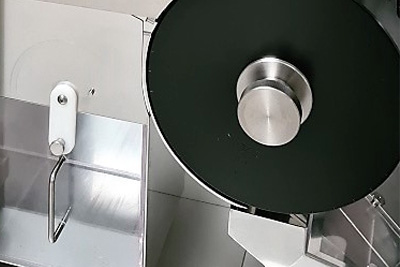

| Hopper

These components are used for loading or feeding of capsules. The size of hopper usually depends upon production capacity. |

|

| Vibration Chute

It is equipped with screens for eliminating dust or chipped capsule fragment before inspection. The vibrations in this part facilitate the removal of debris. |

|

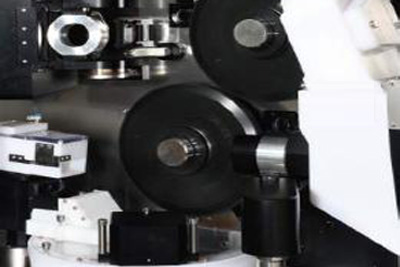

| Rollers

These are used for rotation of capsules. There are two types of roller: rectifier and transfer roller. They transfer capsule to inspection unit. |

|

| Mirror

These are used to inspecting the items from opposite side. |

|

| Inspection Unit

In inspection unit, errors in overall appearance of capsules are detected. |

|

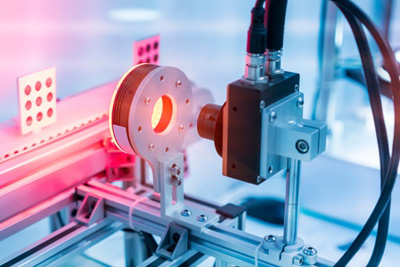

| Camera

Machines are equipped with 2D or 3D cameras for capturing images of capsules from every side. |

|

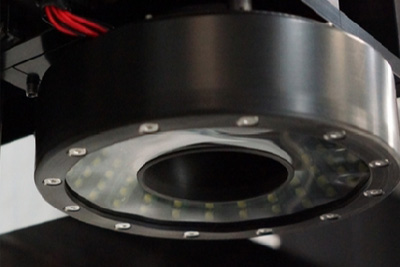

| Illuminator

Halogen lamps or LED lights are used to light up capsules for better detection. |

|

| Rejection Unit

This is a kind of collecting bin where faulty capsules are collected. |

|

| Discharge Chute

This is utilized for the removal of good capsule from the machine. |

|

| Intuitive HMI

This touch screen display is used for programming operational data and to adjust mechanical settings. |

|

| Image Processing Box

This is the part where images captured from cameras are analyzed. The software detects the visual anomalies in the appearance of capsules. |

|

| Vacuum Pumps

Vacuum systems aid in processing of capsules. With the help of compressed air, these pumps are employed for eliminating defective capsules. |

|

8.Features of a standard capsule inspection machine?

Standard capsule inspection machine is an important part of pharmaceutical industries and can perform detection of defective capsules with minimal error rate.

Some key features of these machines are penned below:

- The contact parts and external casing of these machines are made of stainless steel.

- GMP and CE certified and sleek design.

- Standard capsule inspection machine have different feeding option for processing different capsules.

- The conveying belts present in these machines are long-lasting and are easily cleaned.

- Hoppers are equipped with screens for collection of fragments and small bits.

- Capsules are continuously rotated in 360° for inspection of products.

- High density polymer materials are used for manufacturing inspection rollers.

- No chance of cross-contamination due to tool-less changeover.

- Optical strain is decreased because of installed lamps above and below the conveyors. These illuminating lamps aid in inspection of defective capsules.

- Vacuum system is used to remove faulty capsules from the machines.

- These machines are furnished with external vacuum cleaning system that decreases level of noise.

9.How to operate and clean capsule inspection machine?

For operation and cleaning of these automations you simply have to program parameters on machine interface.

Detail guideline for operating and cleaning capsule inspection machine is given below:

Operation

First program parameters are entered using HMI.

Capsules are loaded in hopper after which they are moved to supply drum and ultimately to rectifier roller.

Then the capsules move to inversion roller which carries them to inspection chute.

In inspection chute 3D camera and illuminating lamps scan and captures images of the capsules about 200 times. After that inspection chute stops and images are processed according to adjusted parameters on HMI.

Based on information formed by image processing software, the capsules are assigned two categories good and faulty ones.

Faulty capsules are transported to rejection chute and good ones are collected in collecting barrel.

Cleaning

It is necessary to clean capsule inspection machine after working for operational life of these equipments. Some cleaning hacks are:

Remove roller assembly and transport unit. Clean them with lint free cloth.

Wipe down the exterior, inside of hopper, and vibratory chute with the help of wet cloth.

Clean these parts with dry cloth and compressed air.

10.Troubleshooting some common machine problems.

Error free production of capsule is now achievable with high tech capsule producing units. However, these productions units are not absolute. Faults or defects may arise in your machine anytime anywhere. A tweak here and there will deal efficiently with such problems saving long downtimes and much higher repair costs.

Some tip of resolving major issues in capsule inspection machines are detailed below:

| Problem | Cause | Solution |

| Freezing of Machine During Operation | Bearing are not lubricated | Properly grease the moving parts |

| Accumulation of dust or powder in mobile joint | Properly clean the main especially nuts and screws | |

| Vibrator in gear box | Misalignment of motor load | Realign the motor load |

| Loose belts in gear box | Tighten the belts in gear box | |

| Worn out nut and screws in gear box | Replace old bearings in gear box | |

| Capsules Falls into Dust Collecting Unit | Unfasten discharge unit and feeder | Properly fasten all parts |

| Slipping of conveyors belts | Poor installed belt lagging | Properly install pulley lagging |

| Low temperature of the environmental | Use low temperature resistant belts | |

| Reduce capsule flow from hopper | Accumulation of capsule debris in hopper | Properly clean the hopper |

| Unclear images | Lens of camera is unclear | Clear the lens |

| Not enough illuminating light | Correct the illumination source |

11.Can you customize your machine?

Capsule inspection machines have varying design styles and production capacities. You can customize your machine to lower initial investment, reduce maintenance time, and to increase your operational output.

Some tips for optimizing these automations are:

Consider Space Availability

Space can be an issue in some small business and has an impact on footprint of capsule inspection machine. If you are buying large scale inspection automation, always make sure these do not clutter your operational area and cause production incidents.

Estimate Production Capacity

How much output capacity you need usually, depends upon the size and automation of equipments. By estimating output capacity, you will purchase capsule inspection machines that are compatible with your production needs and save your initial capital.

Illuminator

The use of high power illuminator will amplify and enhance the quality of image and thus your detection. Generally, LED lights, halogen lamps or electronic choke tube light are used as illuminator.

Number of Cameras

Increased number of cameras takes more images that result in more punctilious and thorough image analysis and inspection of capsules. Decide on number of cameras suitable for your capsule inspection machine before purchase.

Conveyors Belts

The speed on prefect conveyors should be on par with capsule movement and image capture. Furthermore, the belts should be durable, chemical resistant and must not emit contaminants upon wear and tear.

Horsepower

Verify the horsepower of capsule inspection machine before purchase as the power consumption of machine should be well-suited to voltage delivered to your production setup.

Conclusion

Purchase of capsule inspection machine is right decision of your business. Since these equipments possess highly advanced components that increases your manufacturing capacity and lower your production cost. By using this automation, you will get 100% results within specified time. Aipak is number one pharmaceutical solution provider,we are here to assist you 24/7. Contact us if you require further assistance.

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours