See Capsule Filler: The Ultimate Buying Guide in 2025

Have you been facing difficulties filling capsules?

Now, imagine you don’t fill the capsule properly and according to the given standards.

Capsule filler is one of the most vital machines in the pharmaceutical industry and it is widely accepted too.

There are very bright chances that capsule filler will give a boost to your business.

In this guide, I will explain to you each aspect of the business, starting from a brief introduction, the benefits, parts, working principles, different quality standards, different types of the machine, and even the troubleshoots.

Let’s not wait anymore and read this guide to boom your business.

1. What is Capsule Filler?

AIPAK Automatic Capsule Filler

AIPAK Capsule Filler is a machine that is widely used in the pharmaceutical industry for filling empty hard gelatin capsules with powder and granules. According to their work operation, these fillers are available in manual, semi-automatic, and automatic capsule filling operations.

With the help of Capsule Filler, you can achieve greater work rate efficiency and accuracy in your production.

If you handle your business with the help of filler then it will be easy for you to get quick production rather than doing it with the help of tray filler.

2.What are the Types of the Formulation When you Fill a Capsule?

Formulation of the capsules can be done with several different formulation materials like powder, granules, semisolids, beads, and mini tablets.

The formulation is done on two types of capsules hard gelatin capsules and soft gelatin capsules.

Hard Gelatine Capsule Formulation

Hard Gelatin Capsule

Formulation of hard gelatin capsules is done by getting the gelatin from animals' bones and skin. The collagen present in the connective tissues of the animals is used for the formulation of these capsules.

Furthermore, there are two basic types of these capsules defined on the basis of the collagen present in them.

- Acid hydrolysis of pork skin.

- Acid hydrolysis of bones.

These two capsule types are based on the difference of the isoelectric point present in them.

During the formulation of the hard gelatin capsule, there are some chemical properties that need to be kept in mind during the formulation to increase the quality.

- Bloom strength.

- Viscosity

Bloom Strength

A bloom gelometer is used to measure the strength & weight in grams that is required to depress a standard plunger a fixed distance in the surface of a 6.66 percent w/v under the standard condition.

The suitable strength that a capsule must-have during the formulation is from 150 to 280 called the bloom strength.

AIPAK NJP-1200D Capsule Filling Machine

Viscosity

The viscosity of the capsule tells about the thickness of the capsule and how much it is capable of holding the material inside without getting any damage.

Gelatin Capsule Formulation

Different substances are used for the formulation of hard gelatin capsules which promotes the release of drug constituents from the hard gelatin capsule these includes.

- Active Ingredients

- Fillers

- Glidents

- Lubricants

- Disintegrants

- Surfactants

- Hydrophilic Agents

- Protectives

- Anti Dusting Agents

Soft Gelatin Capsule Formulation

Soft Gelatin Capsules- Photo Credit: Slideshare

Formulation of this capsule is mainly involved liquid & emulsion can not be filled because water will be released that will affect the shell.

Made up of more plasticized gelatin film as compared to the hard gelatin capsule. They are basically filled with liquid dosage and need to be swallowed as a whole.

Soft gelatin capsules are more flexible as compared to hard ones & consist of a single unit after sealing.

These capsules are filled with the liquid solution or suspension of the drug in liquid form that will not solubilize the gelatin shell.

Soft Gelatin Capsules are available in different shapes like oval, round, oblong & tubular.

3. How many Capsules Sizes are there?

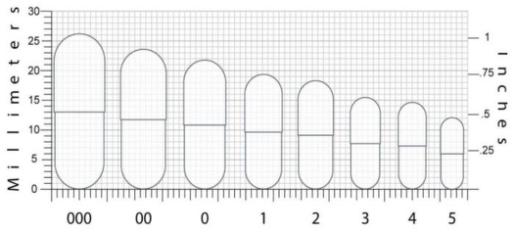

Different Size of capsules

There is some basic and general size of capsules that are available in the market and used for filing different kinds of material.

The size of the capsule lies between 000 to 5 and some other sizes of capsules are also present. The following figure will tell you about the size and diameter of different size capsules.

|

Size

|

Volume (ml)

|

Locked Length (mm)

|

External Diameter (mm)

|

||

|

000 |

1.36

|

26.14

|

9.91

|

||

| 00 | 0.95 | 23.3 | 8.53 | ||

| 0E

|

0.7

|

23.1

|

7.65

|

||

| 0 | 0.67 | 21.7 | 7.65 | ||

| 1 | 0.48 | 19.4 | 6.91 | ||

| 2 | 0.37 | 18 | 6.35 | ||

| 3 | 0.27 | 15.9 | 5.82 | ||

| 4 | 0.20 | 14.3 | 5.31 | ||

| 5 | 0.13 | 11.1 | 4.91 | ||

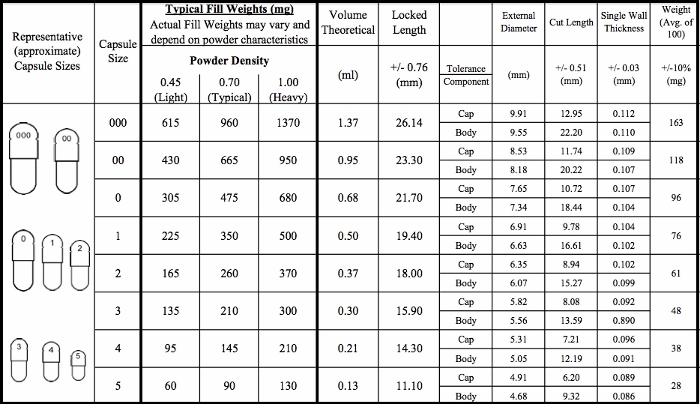

4. What is Capsules Fill Weight?

Filled Capsules- Photo Credits: NorthAmericaherbs

The filling capacity of the capsules depends on their size and diameter. Small size capsules will be filled with less amount of filling material having less weight as compared to the large size capsules that are filled with more material having greater weight.

There are three different filled weight classes of the capsules according to their size. You will know about the filling weight of the capsule with the help of this given figure.

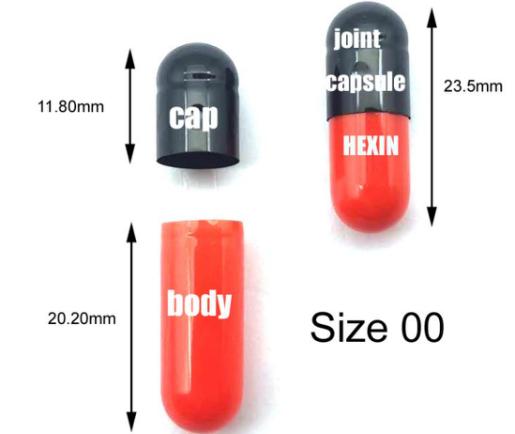

Cap Head & Body with size- Photo Credits: Pharma tech

|

Size |

Typical fill weights (mg)

Powder characteristics may change the actual weight dependency. Powder Density

|

Average weight of 100

|

||

| # | 0.45

( light ) |

0.70

(typical) |

1.00

(heavy) |

+/-10%

(mg) |

| 000 | 615 | 960 | 1350 | 163 |

| 00 | 430 | 665 | 950 | 118 |

| 0E | 380 | 550 | 820 | 100 |

| 0 | 305 | 475 | 680 | 96 |

| 1 | 225 | 350 | 500 | 76 |

| 2 | 165 | 260 | 370 | 61 |

| 3 | 135 | 210 | 300 | 48 |

| 4 | 95 | 145 | 210 | 38 |

| 5 | 65 | 90 | 130 | 28 |

5. What is Micro dosing in Capsule Filling Process?

Micro Filled Capsules in big capsules- Picture Credits: Capsule

Micro dosing in the capsule filling process is a technique in which capsules are filled with an accurate amount of dosage and this is done with the help of an automatic Capsule Filling Drum.

In the early 2010s the first pharmaceutical expert Bosch from Germany introduces the micro-dosing system with the help of an Automatic Capsule Drum filler that controls the volume of the capsule dosage.

Capsules having two pieces body and head are filled with more efficiency and accuracy with the help of Automatic Capsule Filling Machine in 2012.

Since that time we are providing quality testing on every filler for getting perfect micro-dosing in the capsule filling process & different sorts of machines are used to make the micro-dosing perfect.

Micro dosing is one of the key factors for getting early opportunities in the market & your production will grow faster and quicker.

This technique is very helpful in getting the perfect amount of filling material in the capsules and also helps to reduce the filling time.

Micro dosing of different products is different because some of the products have a high rate of density and some have a lighter density in addition to this FDA suggests that the products having proteins must have < 30 nanomoles during the capsule filling process.

Micro dosing consists of small powder particles & other granules that are used for filling different kinds of hard gelatin capsules.

The dosage of the medicine that is going to be filled in the capsules is kept in micrograms lower and equals 100.

6. What Affects Efficiency of Capsule Filling Process?

Some of the factors are present in the capsule filling process that may affect the efficiency and accuracy of the capsule filling.

Speed

The production speed of the Automatic Capsule Filling Machine can affect the efficiency of the capsule filling process.

As you know the phrase “time is money“. So, if you can save your time with greater speed of the capsule filling process then you will get more efficient production.

If the machine that you are using is quick and faster in capsule filling then less production cost will be required to fulfill your requirements for the production line.

At the same speed if the Capsule Filler can work on different products then your manufacturing cost will also decrease because you can work on different types of materials using the same equipment.

Greater the production speed less will be the required time for the capsule filling and you will reach the market demands accordingly.

The average speed of a good Automatic Capsule Filling Machine is 3000 capsules per hour with greater efficiency.

Yield

This is also one of the main and major factors that can affect the efficiency of the Capsule Filling Process. The greater the yield of the Automatic Capsule Filling Machine without including the empty capsules that are not filled properly the greater will be the efficiency in the capsule filling process.

Material that is used for filling is one of the main components in the yield of the machine because some of the products require more filling time and will cost you to utilize some other types of equipment as well to reach the filling level.

You can get more savings by working on the yields and improve the work efficiency of the Automatic Capsule Filling Machine. A machine with better yielding can help you to decrease the production time and you will require less labor for working on it.

Yield is such a major key point in your production that if you can make a small improvement in it then you will see a great financial impact on your production line.

When any of the firms are working to improve the efficiency of their production line in the first step they work to improve the yield of the production line for achieving the efficient work rate.

Downtime

If your production line had halted/stopped because of some technical or troubleshooting issues then it will affect the efficiency of the capsule filling.

Try to decrease the downtime of your Capsule Filling Machine because the greater the downtime greater the problems will reach you to stop the working and your machine may not work properly at its ideal state.

Always use the “fit for formulation” approach to reducing the downtime of your production line. It will help you to have less downtime and in the beginning, it will also help you from getting any trouble during the capsule filling process.

More than 30 study cases tell about the efficiency of the capsule filling process is mainly depend on these three areas that need to be covered while working with the Capsule Filling Machine.

If you can improve these three areas in your production line then you will get more efficient and accurate production.

7. What is the Purpose of Filling Capsules?

AIPAK NJP-7500C Fully Automatic Capsule Filler

Capsule filling is used for many purposes here are some of the main purposes that are kept in mind for filling the capsules with different kinds of dosage.

Here is the list of some purposes of Filling Capsules using the Capsule Filling Machine.

- A medicine or a dosage when not easy to compact into the tablets then capsule filling is used for this purpose.

- The capsule is easy to swallow as compared to larger size tablets.

- Different types of materials can be filled inside the capsule by mixing with some other materials like oil liquid, powder & granules.

- Medicine can be stored for a longer time.

- Make the medicine germ-free.

- When the drug/dosage required some other materials to be mixed with it for making the perfect absorption aid for the human body.

- Medicine may not get wasted during the replacement time from one place to another.

- Medicine present in the capsules reacts more rapidly as compared to the tablets.

- Drug absorption became more effective.

- Tasteless medicine or you can say that a person can easily swallow without getting any taste of the medicine.

- Capsules are not easy to be split into two halves or they are not able to crush like tablets.

8. What are the Benefits of the Capsule Fillers?

Accurate Filled Capsules- Photo Credit: Pharmaworld

Automatic Capsule Filling Machine is very beneficial in the pharmaceutical industry for filling capsules.

- An accurate amount of filling material can be achieved with the help of a Capsule Filler.

- Less amount dosage will be wasted during the filling process.

- In less time you will get more production as compared to the manual filling process.

- Capsule filler is designed and developed according to the quality standards so, that your labor can work safely.

- Precise dosage can be achieved with the help of an Automatic Capsule Filler.

- The fast & quick production rate of the Capsule Filler will help you to meet the customer requirements with the given time.

- You can achieve greater work efficiency by using this machine.

- PLC control system in the Capsule Filler makes it easy to operate.

- It is easy for you to maintain the machine if any type of problem occurs.

- You can easily adjust every type of settings to get the required products according to your needs.

- Safety of your product & labor is to make sure while working with the machine.

- Automatic Capsule Filler is very reliable and flexible to use with greater production efficiency.

- Your production demand will be increased if you provide quality and accuracy in your production & this can only be done with the help of an Automatic Capsule Filler.

- The flow of the filling liquid can be controlled by the 3-dimensional control system present in the Automatic Capsule Filler.

- You can get 35,000 filled capsule pieces per hour with this machine.

- If you want to replace any damaged part in the machine you can easily do it just by reading the manual.

- Different sizes of capsules from 000 to 5 can be filled with the Automatic Capsule Filler.

- As you know labor is very expensive in terms of operating the special equipment but a fully Automatic Capsule Filling Machine can reduce your labor cost. You will be required less labor to operate the machine.

- The investment you made on this machine will be very large but it will be very beneficial in a longer run.

- Touch screen present in the machine will make it easy to operate for your labor & provide you assistance about what is happening at that specific time.

- Capsule Filler is made up of stainless steel so, it will be rare to get any kind of stain attached to the body & machine get rusted.

- Quality material is used for making the machine that makes sure that the machine is very stable for every kind of production like, powder, granules & pellets filling in the capsules.

9. What are the Disadvantages of the Capsule Filler?

Automatic Capsule Filler provides some rare disadvantages. Here are some disadvantages of the Capsule Filler.

AIPAK NJP-800C Capsule filler

- As you know if you go for the full automation in the machine it will be much expensive for you to buy a Fully Automatic Capsule Filling Machine.

- It will be difficult for you to invest thousands of dollars to buy the machine but your investment will not get wasted it will be best for the long run.

- If some of its components get damaged it will be expensive for you to buy that specific component and replace it.

- If you compare the flexibility of the fully automatic capsule filler with the manual capsule filler then automatic capsule filler is less flexible.

10. What are the Different Types of Devices Machines for Filling Capsules?

According to the work operation and filling capacity there are different kinds of Capsule Filling Machines are available with different prices & working principle.

Basically, the division of Capsule Filling Machine is done into three different classes according to their working.

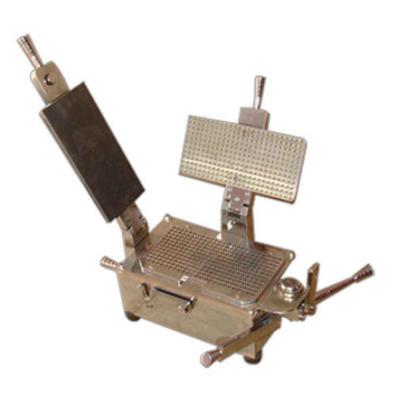

Manual Capsule Filling Machine

Manual Capsule Filler

Manually you can operate the machine as by its name manual capsule filler. It is designed & developed with the stainless steel material inside and outside as well so that when your labor works with the machine it will remain stain-free.

Manual capsule filler will require more labor to handle and operate for your production line.

It can fill different size capsules from 000 to 5 and you can also interchange some of its parts for better working.

All the working operations are performed manually by a person but it will give you efficient production because all of its working parts are designed according to the standard quality.

It is much cheaper in terms of other automatic capsule fillers but lies in a different range of pricing according to the quality.

It is very comfortable and stable in filling capsules of different sizes with powder, granules & pellets.

Semi-Automatic Capsule Filling Machine

AIPAK Semi Automatic Capsule Filler

The automation level in the semi-automatic capsule filler is higher if you compare it with the manual capsule filler & provides more flexibility in production.

The stainless steel body of the machine makes it secure to operate the machine & you can get better products with a better yielding rate.

Semi-automatic capsule filler works faster & quicker when compared with manual capsule filler because the four auger speed system present in it makes it more effective in terms of production speed.

You can fill different types of materials like pellets & powder at the same rate of speed.

It is not that complicated to work with your labor can easily operate the machine & you will also require fewer labors to operate the machine. When the filling is done the conveyor tray moves the capsules towards the polishing line & they also get sorted automatically.

If some of the capsules are not filled properly or remain empty then the ejector system in the semi-automatic machine will remove the capsules and send them again for the filling process.

Semi-Automatic Capsule Filling Machine is very reliable in filling different sizes of capsules with different kinds of filling material.

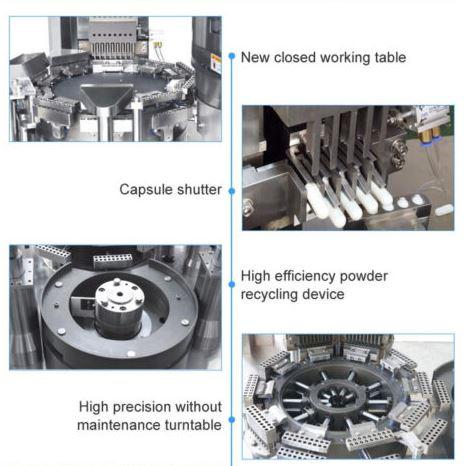

Fully Automatic Capsule Filling Machine

AIPAK NJP-2500C Fully Automatic Capsule Filler

If you go for the next generation automation level then you might need to invest more to get perfect equipment with a full automation level.

A fully Automatic Capsule Filler can work on its own from the start to the end without any human effort required. When you compare this machine with the other two then it is on the top level in terms of accuracy and efficiency in your filling production.

A multi-sensor system in this machine will tell you about every kind of problem if it occurs during or after the capsule filling process. The reliability and flexibility of this machine are very high and provides you every kind of operation with just a touch.

In less time you will get maximum production & more customers will reach you if you give them perfect production in terms of accurate filling

Automatic Capsule Filler can fill up to 45,000 capsules per hour depending upon the type and speed of the machine. You can fill multi types of materials in different sizes of capsules from 000 to 5 & many others.

Pellets and granules can be filled at the same speed as the powder does. A greater amount of production rate can be achieved with the help of this machine. The vacuum system in the machine works to separate the body and head of the capsule without giving any damage.

Dust suction tube helps to remove any kind of dust that enters the machine & try to harm the components of the machine.

11. What are the Parts of Capsule Fillers?

An Automatic Capsule Filler is based on different working parts that help the machine to work effectively and accurately.

Some of the major components of the Automatic Capsule Filler are listed below.

Screw Feeding & Powder Hopper

Screw Feeding Unit

Different design of the machines works with different parts as well these are the two parts of the to feed the material that is going to be filled in the capsules.

The screw feeder & hopper works in terms of mixing the material before leaving it towards the filling tube. Sensors present in the screw feeding detect the quantity of the filling material.

Capsule Feeding System

This part of the Automatic Capsule Filler is present at the top of it that helps to feed the capsules for filling. The feeding unit works based on rotary motion and performs constant rotary movement to feed the capsules.

Perfect size capsules with a certain size can be passed through it and it will remove the damaged capsules. When the damaged capsules are removed then they will pass through the feeding unit then they are further moved towards the main hopper.

Capsule Hopper/Holder

Capsule Hopper in AIPAK Capsule Filler

A capsule hopper is used to hold the capsules that are going to be filled. A container made with stainless steel metal is used to hold these intended capsules on which you are going to do the filling & you can avail them in different shapes and sizes.

Another component is also present with the capsule hopper called level sensor that tells about the empty capsules and works to hold these capsules at a certain level.

Dosage Filling Tube

When it comes to the empty gelatin capsule filling this tube fills the capsules with an accurate amount of powder, granules, or pellets. The sensor present in this part of the machine determines that either the capsules are filled accurately or not.

According to the size & working of the machine, it may consist of one or two filling/dosing tubes present in it.

Closed Rotary Turret

Before starting the capsule filling it is making sure that the rotary turret of the capsule filler is well closed to make the production dust-free and the versatility of the product remains perfect.

Filled capsules without the head are moved from one component towards the other inside the rotary turret and filled capsules are made secure in such a way that the filling dosage not get wasted.

Vacuum Unit

The vacuum part present within Fully Auto Capsule Filler works in many different ways for operation the machine components and also assist the components in filling the capsules.

Capsule hopper and feeding tube these two parts are connected with each other with the help of a vacuum system. Separation of the capsules is also done with the help of a vacuum unit.

In terms of cleaning the machine, a vacuum unit is very helpful to clean the different parts of the capsule filler after every cycle.

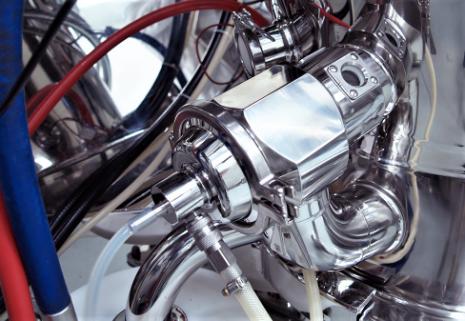

Mechanical Drive Unit

Mechanical Motor- Photo Credit: Zehanlee

Every moving component of the capsule filler depends on this component of the machine it provides every type of operation for different working parts of the machine.

The design of the Automatic Capsule Filler tells about the motion of the machine that is it going to be rotary, oscillatory, or linear. This part of the machine is based on different motors that set up the other system to move like conveyor unit & moving gears. PLC touch screen control system in the Automatic Capsule Filler is used to operate this part of the machine.

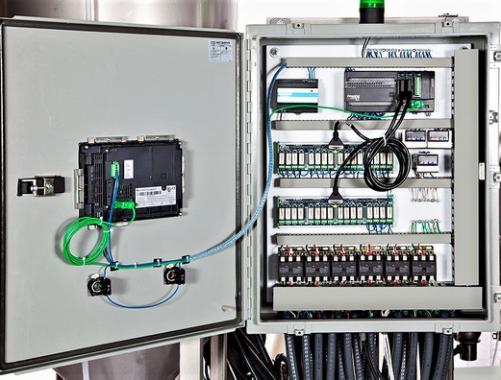

PLC Control System

Inside of PLC Control System-Photo Credit:xnhanglee

A fully digitalize touch screen of the Automatic Capsule Filling Machine makes it easier to operate & user-friendly. It is easy for your labor to command every type of operation with greater reliability and ease.

HMI interface provides easy assistant by providing the touch screen control panel. You can easily control the filling speed and amount of dosage with the help of a PLC control unit.

This part of the machine will help you to save labor costs by providing an easy guide for operating the machine.

The automation level of your machine will tell you about the PLC control unit that how many persons will be required to operate this machine-like semi-automatic capsule filler will require more labor in terms of operating some specific tasks.

Capsule Polisher & Sorter

A shining look can be achieved with the help of a capsule polisher that will give a shiny look to your product to attract more customers. A capsule sorter is also present along with the capsule polisher that helps in sorting the empty and damaged capsules.

If some of the capsules are not filled accurately then they will be ejected and move into the trash bin for further processing.

Empty Capsule Loader

Capsule Loading Unit

A device or a part of Automatic Capsule Filler that is used to load the empty capsules in the conveyor chamber for the filling process.

You can easily manage all the operations about the empty capsules like when to stop them and when to start loading with the help of this user-friendly part of the machine.

The size and design of the Automatic Capsule Filler will tell about the quantity of the empty capsule loading system present in the machine.

Safety Doors

Open Safety Doors of Capsule Filler-Photo Credit: Pharma Test

Interlock safety doors are made up of glass that ensures the safety of your labor to not get in touch with the working components of the capsule filler during capsule filling.

When any of your labor or person unlock these doors machine will stop working for the safety of that person and your production

Automatic Lubrication System

One of the major factors to get quick production is by providing the necessary lubrication to the machine. This system in the machine holds the lubricants and lubricates each of the moving parts of the machine including dosing discs, plug injectors, etc.

This part of the machine will also tell you about the lubrication level that is required for the smooth working of your Automatic Capsule Filler.

Metal/Foreign Particle Detector

The basic working of this part in the Automatic Capsule Filler is to detect any sort of foreign particle that enters into the machine with filling material or some other way.

An alarm system present in the machine will stop the operation if any kind of metal particle or other foreign particle is detected.

12. What is the Working Principle of Capsule Fillers?

Every machine has its working principle according to its design and size. But the basic working of the Automatic Capsule Filling Machine is as follows.

A fully Automatic Capsule Filler can work in form of loading the capsules, separating them, and then lock them when the filling is done.

Step-1

Rectification & Separation Of Capsules

Rectifiers for Capsule Filling Machine

This is the beginning of the capsule filling process in which capsules are held in the delivery plate. At the bottom of this plate, some springs are present that help the plate to make the vibratory motion so, that the capsules can go through the circular tube one by one.

The capsule can enter the circulatory pipe with the cap head on top of the body on the top and the cap heads down like in a vertical shape pipe.

The too and fro motion of the delivery chamber sorts the capsules to enter the tube for further rectification.

When capsules are rectified then the vertical fork present in the Automatic Capsule Filler will make the rotation on the capsule to make the head of the capsule upward for further processing.

Vertical rotation on the capsules is done with the help of measuring the diameter of the capsule from the center.

Step-2

Cap & Body Separation Of Capsule

Separate Cap Head & Body of Capsule

The capsule tray that holds the capsules moved towards the separation unit. The vacuum unit divides the air vacuum into the upper and lower surface of the capsule tray then the capsule is raised upward and the air suction present in the capsule tray holds the capsule.

The vacuum unit divides the capsule into two parts by separating the head of the capsule towards the upper capsule tray and the body will remain in the lower capsule tray for further processing.

When the separation of capsules is done then they will be sent towards their respective units.

Step-3

Filling Unit

In Automatic Capsule Filling Machine the filling unit works in terms of filling the capsule with greater accuracy and efficiency. The dosing tube that holds the dosing material fills the capsules up to the right level.

According to the working of the machine the dosing in the capsules can be done in many different ways like vacuum filling, tamping filling, cylinder dosage filling & dosator filling.

Tamping Filling

In this filling process, a punching bag is used to compress the filling powder into the capsules for getting an efficient filling. First, the dosing tube opens the mouth & fills the capsules. When the filling is done the tamping unit compresses the filled material so, that the dosage not get wasted when the capsule is moved from one place to another.

This technique will provide an accurate amount of filling & the chances of getting any kind of problem during the capsule filling will be minimum.

Dosator Filling

The intermittent dosator method of filling the capsules is very direct. The dosing tube directly moves into the hopper that holds the empty capsule and fills the capsules up to the right amount.

The punch present in the dosater will press the dosage into the capsule & then the dosing tube rotates at 180 degrees for pressing the plug that holds the powder.

Cylinder Filling

The main hopper in the capsule filler has two moveable pistons under it that help in up, down & left, right movements of the dosage tube to fill the capsules without wasting any dosage.

A cylinder is used to hold the filling material on the upper level of the empty capsule and by making the movement right, left & up, down the dosage came down in the tube for filling.

Vacuum Filling

In this filling process, a vacuum-based system is used to fill the accurate amount of filling in the capsule. The dosing disc fills the capsules by coming down into the capsule hopper that holds the empty capsule.

When the filling is done the vacuum-based punch compress the dosage into the capsule and very light air pressure is applied to the medication. This method is very reliable with every type of filling material.

Step-4

Rejection Of Capsules

When capsules are filled and moved further there might be some capsules that remain empty because of some error during the filling. These empty capsules are rejected by the rejection unit.

Capsules may not get separated from the body and head that might be the reason for the capsules to remain empty.

Empty capsules when rejected they fall into the collection bags.

Step-5

Capsule Locking

Locked Capsules-Photo Credits: Amair & Co

The capsule tray that holds the head and body of the filled capsule then makes a rotation towards the locking unit. When the lower and upper axis of the capsule tray overlap with each other than the pin present in the locking system lock the cap head and body of the capsule.

In this way, the locking of the capsule is done to make your product safe and secure. The locking tray plays a very vital role in the safety of your production.

Step-6

Capsule Ejecting

Just like the capsule rejection, the ejection unit in the Automatic Capsule Filling Machine is used to eject the filled capsule and this is done with the help of a pin.

Locked capsules are moved towards the packaging line in this way a complete capsule filling process takes place in the Automatic Capsule Filling Machine.

Step-7

Cleaning

After the ejection of the filled capsules is done and the remaining production is done then the auto cleaning system present in the Automatic Capsule Filler cleans all the dosage and other parts of the machine.

Cleaning is done on every single part of the machine for the quickness and smoothness of the capsule fillers working. The above-mentioned steps describe the whole working principle of the Automatic Capsule Filler.

You can get a high production rate with the help of this machine. It is capable of filling 15k-45k capsules per hour depending upon the working and type of machine.

13. What Quality Standard you must Ensure While Filling Capsules?

Every machine that a firm is going to manufacture must fulfill some of the quality standards that are defined by the European and other unions.

Production and practices made on Automatic Capsule Filler must fulfill these quality standards that are written below.

CGMP

FDA set this standardization in which the product material that is going to be used for developing the Automatic Capsule Filling Machine. FDA must approve the material that a firm going to use in making the Capsule Filler.

With the help of this standardization, it makes sure that the quality raw material must be used for the production of this machine. Quality material will definitely increase the life of your Automatic Capsule Filling Machine.

CCC

Inside of the Capsule Filler, the raw material must be of good quality so, you can get quality production without getting damaged on your product.

The production rate and work accuracy of your machine are based on this standard quality if the raw material used in the production of capsule filler is of good quality then you can get great work experience.

ISO

Before starting manufacturing of the Automatic Capsule filler customers' demand will be asked first what needs to implement on the machine during the manufacturing.

According to your product, all the requirements are fulfilled with the help of this standardization so, that you can get perfect quality by working with this machine.

Customer needs and SOPS are kept in mind during the production of this machine to achieve better quality and efficient work rate.

CE

Every machine is designed and developed in many different ways and Automatic Capsule Filling Machine is one of them. Different kinds of practices are made on the machine before delivering it to the customer.

With the help of this standardization, you will know about how safe and secure it is for you to use the machine in any type of environment & your labor can safely operate the machine by knowing some basic knowledge & precautions from the manual.

EN

Economical parameters of Capsule Filler are defined in this standardization and these rules are defined by the European Union for the steel machinery production.

At this point, you will know some basic idea that how much you need to invest in the machine. A rough idea can be generated about the investment that needs to be done on the product.

ROHS

Some of the materials are restricted that will not be used during the production of Automatic Capsule Filler because they are very reactive & safety of your production and labor is to make sure by putting a restriction on reactionary substances like led and mercury.

The dosage that you are going to fill in the capsules may react with the walls on the inner container if it is made up of led or mercury this often happens because of some electrical problem so, that is why it is necessary to make your production line safe & secure.

ASTM

One of the general and globally used standardization that helps to perform different types of practices on the Automatic Capsule Filling Machine before delivering it to the customers.

The machine must have been made error-free and small production will be gained beforehand it over to the customer in which every sort of error is cleared and dealt with.

14. What is Softgel Capsule Filling Machine?

Soft Gelatin Capsul- Photo Credit: Pharma tech

Soft gel or Soft Gelatin Capsule Filling Machine is a type of filler that fills the liquid in the soft gel capsules with accuracy & efficiency.

Many of us use to eat or swallow soft gel dosage in our daily life that helps our body in many different ways these soft gel capsules are made with the Soft gel Capsule Filling Machine.

It is very useful in the pharmaceutical industry providing many useful applications. The machine works through an electromechanical way in which capsules are filled with a semi-liquid or liquid material and made airtight.

AIPAK NJP-3800C Fully Automatic Capsule Filler

It is not that easy to fill these sensitive capsules with an accurate amount of filling material & get efficient production but this machine is designed especially for this kind of sensitive production line. You can get quality production with this machine as the technology grows faster so, more advanced level machines are present in the market for you to get perfect production.

Different types of soft gel capsules can be filled with this machine-like soft gel capsules are available in the form of a tube or the form of an egg in small size. It is very capable with every type of production.

This machine is very beneficial in terms of providing medicine dosage in the form of liquid & every type of production in the form of liquid can be achieved with the Soft gel Capsule Filling Machine.

Soft gel capsules are very digestive when compared with hard gelatin capsules because it is easy for a human body to digest liquid quickly & comprehensively. Soft gel Capsule Filler is very impressive in terms of getting accurate production without any wastage of filling material.

15. How do Softgel Encapsulation Equipment compare to Standard Capsule Fillers?

As you all know in the medical field there are two main basic kinds of gelatin-made capsules that you can avail of for filling purposes & these two types are Soft Gelatin Capsule & Hard Gelatin Capsule.

There is a huge difference between these two capsule types one is hard in terms of its body and structure but the other is made of soft gelatin having a soft surface layer in which the filling is done.

The automatic capsule filler that is utilized for filling the filling of hard gelatin-made capsules is called standard capsule filler because it is very known to everyone.

And the other type of capsule is called a soft empty gelatin capsule and is often filled with a Soft gel Capsule Filling Machine.

Soft gel Capsule Filler

Soft gelatin Capsules-Photo Credit: zehanlee

Auto-soft gel filler is specifically developed for sensitive & soft capsules made with gelatin they are filled with liquid or any other semi-liquid material. Empty soft gelatin capsules will only get filled with this machine because of their sensitive structure and body.

Soft gel capsule filler is only capable of filling oil, liquid, or any type of substance in the disposition of liquid in the capsules. It will not allow you to fill powder, granules, & pellets in the capsules.

You may counter some minor sorts of problems or errors during the process of filling because it is not that precise as compared to the Standard Capsule Filling Machine.

Working with a Soft-gel capsule filling machine will give you more reliability in terms of liquid encapsulation in the empty soft gelatin made capsules as this filler can work only on soft gel capsules so, that is the reason it is the so-called Soft gel Capsule Filler.

Standard Capsule Filler

The standard capsule filler is fully designed and developed according to the customer requirements that can fulfill every type of your need according to your production line.

It may be expensive for you to buy the standard equipment for filling capsules but it will be very beneficial for you in the future to achieving a greater production rate with an accurate filling level.

In standard capsule fillers, the chances of getting any kind of error during the filling purpose are very low as compared to the other fillers. Most of the people you know demand quality instead of quantity for this purpose a standard capsule filler is very impressive for providing quality as well as quantity. Standard Capsule Filler is often used for filling different kinds of products & it can work with different types of production line because of its advanced manufacturing level & greater work efficiency.

16. How do you Fill Softgel Capsules?

There are lots of different ways of filling soft gel capsules they are often filled with the help of a Soft gel Capsule Filling Machine.

A soft gel Capsule Filling Machine is used to fill the empty soft gel capsule shells with an accurate amount of liquid without any trouble. The formation of the filling material is done in the soft gel melting chamber that holds the filling material.

When the liquid is melted perfectly up to the specific level then moved into the box that spread the liquid and colds down the soft gelatin to make a shell for filling purposes.

A perfect amount of dosage is delivered into two pockets of the die that holds the soft gel capsule shell the filling nozzle present at the end of a filling pump goes inside these two pockets and fills the empty shell up to the given level and goes out. Then the two pockets of the die when filled they are closed with the help of a wedge that is used for filling purposes.

In this way, the capsule is filled and closed in such a way that no material goes out from it after the filling.

When the shell is made then it is filled with the help of a pin that is attached to the rotary system that rotates the capsule after the filling to make it seal pack so, that no liquid gets out from the soft gel capsule.

That is how the empty Soft gel capsule is filled.

17.How does Hard Gelatin Capsule Filler compare to Softgel Encapsulation Machine?

The standard capsule filler is fully designed and developed according to the customer requirements that can fulfill every type of your need according to your production line.

It may be expensive for you to buy the standard equipment for filling capsules but it will be very beneficial for you in the future to achieving a greater production rate with an accurate filling level.

In standard capsule fillers, the chances of getting any kind of error during the filling purpose are very low as compared to the other fillers. Most of the people you know demand quality instead of quantity for this purpose a standard capsule filler is very impressive for providing quality as well as quantity. Standard Capsule Filler is often used for filling different kinds of products & it can work with different types of production line because of its advanced manufacturing level & greater work efficiency.

Soft gel Capsule Filler

Soft gel Capsule Filler can only fill liquid substances in the empty soft gelatin capsules that are very sensitive as compared to hard gelatin capsules. Soft gel Capsule Filler needs more time to work with the formation of the capsule but on the other hand, Hard Gelatin Capsule Filler will require less period for the formation of a capsule.

Soft gel Capsule Filler often made the capsule by itself Hard Gelatin Capsule Filler can work on the pre-made hard capsule.

Soft gel Capsule Filler holds the liquid for filling the soft gelatin capsules & can work with different types & sizes of soft gelatin capsules.

Hard Gelatin Capsule Filling Machine

AIPAK NJP-7500C Automatic Capsule Filler

Hard gelatin capsules are filled with the Capsule Filling Machine that is also called a standard filler. Every type of powder dosage can be filled in the capsules with the help of this machine.

This machine is very suitable for different kinds of hard products like granules, pellets, & powder.

You can rely on this machine for getting accurate filling & efficient work rate because it is specially designed according to the quality standards. It will not enable you to fill any kind of liquid material in the capsules that is why it is called the standard capsule filler.

The main difference between a soft gel capsule filler & a standard capsule filler is that the soft gel capsule filler can only fill liquid in the soft gelatin capsules & on the other hand the standard capsule filler can fill different types of materials in the capsules like powder, pellets & granules.

18. How does Semi-Automatic Capsule Filler compare to Fully Automatic Capsule Filling Machine?

Fully Automatic Capsule Filler and Semi-Automatic Capsule Filler can be compared with one another on the basis of their working difference & some other terms as well.

Fully Auto-Capsule Filling Machine

AIPAK NJP-200C Automatic Capsule Filler

The fully auto capsule filler is designed up to some extreme automation level. This fully auto capsule filler is very efficient & can operate from the beginning towards end product of the filler without requiring any human effort you will only interact with the machine to control operations by using a PLC control system.

This machine can load the capsules automatically onto the conveyor to send them for further process of filling & sorting of the empty gelatin capsules can also done automatically in this machine.

If some damaged or useless capsules are present in the conveyor chamber the sensor system present in the auto capsule filler will deal automatically to remove the unnecessary capsules from the dosing chamber & move them into the junk bin.

You will require only one or two-person to work with the fully auto-capsule filling machine since most of its working is done automatically so, it will be very beneficial in terms of saving your labor cost.

A fully auto-capsule filler will give you accurate & efficient filling with a minor rate of error. It can fill some type of capsules at the same speed.

The vacuum system present in the machine will clean each working component of capsule filler without any human effort required.

Semi-Auto Capsule Filler

AIPAK Semi-Automatic Capsule Filling Machine

This capsule filling machine is not fully automatic you will require some effort to do some specific operations on this machine. You will require more labor to operate this machine as compared to a fully Automatic Capsule Filling Machine.

It is mainly used for small production lines because of its low-speed working rate & labor cost as compared to fully automatic capsule filler. Some parts of this machine will require some human effort to work on them like the loading of the capsules in the chamber can be done by the person operating the machine.

Semi-Automatic Capsule Filling Machine is very precise in filling some specific amount of capsules. When the capsules are filled then they are moved towards the polishing unit and this is done automatically in the Semi-Automatic Capsule Filling Machine with the help of conveyor belts.

This machine is very demanding in terms of precision filling in the capsules. Semi-Automatic Capsule Filling Machine can help you control the filling weight and how much you want to put inside with capsule.

Different sizes of capsules can be filled in this machine just by controlling the amount of filling material & weight.

19. What are the Ingredients of Capsules?

Every product is made up of some unique elements that fulfill the product design and quality and capsules are also made with some special ingredients for their long life and safety.

Here is the list of some ingredients that are used for making the capsules.

Ingredients for Soft Gelatin Capsules

- The outer surface of the soft gel capsules is made with Gelatin Water.

- Gelatin

- Plasticizer made of Gelatin Water.

- Flavor in the form of aromas.

- Liquid on any type inside (oil, water, etc).

- Agents for Suspension.

- Lecithin

- Soybean

- Yellow wax.

Ingredients for Hard Gelatin Capsules

- Hard Gelatin shell outside surface.

- Plasticizers in hard form.

- Opacifying Agents.

- Preservatives

- Hard material inside (powder, granules, pellets)

20. What is Delayed-Release Capsules?

A specially prepared capsule that is used for different purposes of medication to lower the acidity in your stomach to recover your body from any kind of harmful disease like diarrhea or bone fracture.

These capsules are prepared in such a way that they can work slowly but perfectly to overcome any kind of disease by doing a bypass on your stomach towards the small intestine so, that the nutrients coming inside your body can be easily digested.

The digestion in your body made slower with the help of Delayed-Release Capsules because when you are ill you are not able to move and your stomach will be filled with acidity in this way the acidity in your stomach is released with these capsules and the digestion in your body made continuous with a slower rate.

These capsules help your body to work against the stomach problems that occur during your recovery.PPI (proton pump inhibitor) base medication is used in these capsules to work for your body.

21. Which Capsule Filler is Suitable for Liquid and Sticky Powders?

AIPAK NJP-260 Automatic Capsule Filler

You can always decide what is required for your production line to fulfill the customer's need and decide what type of Capsule Filler you need according to your filling product.

Your filling material can guide you to find the best capsule filling machine. A sticky powder is also a form of semi-liquid containing some other solvents in the liquid.

As you know the liquid can be filled inside the soft gelatin capsules so a Soft gel Capsule Filling Machine will be the best choice in terms of filling the liquid and other sticky powder in the form of semi-liquid.

Soft gel is very reliable with every kind of liquid filling & other semi-liquid materials can also be filled with this machine. Basically, liquid filling in the capsules is done when the human body needs a very large amount of vitamins and proper dieting is required.

Soft gel Capsule Filling Machine is very suitable in terms of filling liquid and sticky powder into empty soft gelatin capsules.

22. Can you use one Type of Capsule Filler for all Capsule Sizes?

Capsule Filler Filling Size and Weight-Photo Credit:capsulesupplies

Different machines are designed for filling different sizes of capsules but in the modern world with advanced technology, you can fulfill all your demands by selecting the best machine.

Fully Automatic Capsule Filling Machine & Semi-Automatic Capsule Filling Machine they can work with different size of capsules. You will not need any other side equipment to work with different sizes of capsules.

A fully Automatic Capsule Filling Machine can be adjusted according to the size of the capsule and you can fill the capsules at the same speed. It may be expensive for your to buy this type of machine but it will be very beneficial for you in terms of working with different capsule sizing.

The size of the capsules lies between 000 to 5. Capsules that lie in between 000 to 0 are considered as the largest and the capsule started from 1 and goes up to 5 they are considered smaller in size.

This machine can fill every size of the capsule with the same speed & accurate filling level. Different kinds of dosage like powder, pellets, and granules can also be filled with this machine.

23. Which Support Equipment do you Need for Capsule Filling Industry?

Some other types of equipment may be required for a Capsule Filling Industry & you might need some help from these types of equipment to make a complete production line.

Capsule Loading Unit

This equipment is used to lift the empty gelatin capsules and load them into the chamber for filling purposes. Loading of the capsules from the pack towards the machine is done with the help of this equipment.

Capsule Filler

When capsules are loaded then capsule filler does the process of filling empty gelatin capsules with different types of materials.

Polishing Machine

When capsules are filled up to the right amount of filling material then they are sent towards the polishing unit and this is done with the help of a lifting pump that sends the capsules onto the conveyor belts for the polishing unit.

The Polishing Unit made the capsules clean by doing the cleaning process & make the outer surface of the capsules brighter and shiny.

Packing Unit

AIPAK Blister Packaging Machine

When the capsules are fully prepared then the packing is done in different shoppers and boxes to make your production safe & travel-free.

This is the last equipment in your production line that is used for making the secure so, that the material inside the capsules not get wasted during the traveling or capsules not get damaged.

24. Why should you buy AIPAK Capsule Fillers?

AIPAK provides you best quality Capsule Filling Machine in terms of greater productivity and efficient filling of capsules. If you want your production line to remain good for a longer run then it will be the best option for you to have AIPAK Capsule Filler.

Here are some major and key points that AIPAK provides you in their Capsule Fillers.

- Designed according to the standard rates.

- Well maintained & best body structure to fit in any type of production line.

- Accurate & efficient filling of capsules can be done with AIPAK Capsule Filler.

- Best in terms of filling different sizes of capsules range from 000 to 5.

- Every type of filling material can be easily handled.

- The stainless steel body of the machine makes it more attractive and stain-free.

- Easy to operate in any type of environment.

- Security of your labor & your production is to make sure when they work with the filler.

- Available in different sizes according to your requirements.

- User friendly & quick in production rate.

- The higher production rate in less time so, that can reach the market demands.

- PLC control systems present in the AIPAK Capsule Filler make it easy for your labor to work with.

- You can easily fix every type of error because the digital screen can tell you about the type of error.

- Some of the capsule fillers are very expensive when it comes to their maintenance but AIPAK Capsule Filler is very easy to maintain a person with some basic knowledge can maintain the machine.

- The automatic Cleaning system in the machine assists the machine in cleaning different parts of it after when each cycle is passed.

- Cleaning the machine is very easy you can open and fix every part easily just by reading the manual.

- Some of the machines required some other equipment to fulfill their work rate but AIPAK will need less equipment to make a complete production line.

- Sorting & polishing of capsules can be done automatically in the AIPAK Capsule Filler.

- You will need only some basic knowledge to work with this machine.

- During the filling process, there will be a minor rate of getting any problem & capsules getting damage.

- You can easily troubleshoot any type that may encounter during the filling process.

- As the AIPAK provides you fully Automatic Capsule Filling Machine so, you will need less labor to operate the machine.

- It is very reliable & best in terms of getting perfect production.

- AIPAK Capsule Filler is very consistent in terms of giving you accurate production.

- With the higher demands of the industry, it will give you a high production rate & will help you achieve more production in future.

25. How do you Troubleshoot Capsule Filler?

There might be some errors and problems that can occur during working with the Automatic Capsule Filling Machine.

1. Capsule not Entering in Hopper

Sometimes when a capsule is not sorted likewise the other capsules it may not enter the hopper unit for the further filling process. Magazine that holds the capsule might have some other foreign particles inside of it.

Solution

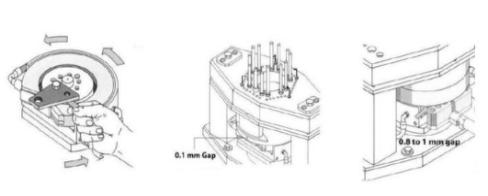

Gap settings between different parts of machine- Photo Credit: Bushan gike

A baffle plate present in the machine might not be set properly so, you just need to set it at its desired position so, that the capsule can enter the hopper and the magazine can easily load the capsule for filling.

2. Capsule Getting Damaged

The rectifier block/unit present in the machine may be not set to its desired location or not placed on the specific working position which is why the capsule might get damage while passing through the conveyor.

Solution

Just simply see the rectifier unit and place it on to its desired position so, that when the filling process is started bush head can hold the cap head properly and the capsule body and head remain perfect in shape.

3. Variation Changes in Weight of Capsule

During the filling of the capsule, you might encounter that your machine is not giving you accurate filling material in every capsule. Weight class in capsules might be different.

Solution

This might happen because of gap difference between the feeding disc & wiper unit is incorrect always set both of these parts at the gap of 0.1mm.

And another measurement that needs to be set is the body bush gap and bush head that need to be set between 0.2mm to 0.4mm.

4. Missing Cap Heads

Missing cap head of capsule- Photo Credit: tab caps & co

First, the cap head and body are separated before the filling process then the filling is done inside the capsule body and cap heads are attached with the body again. But some of the capsules may not have cap heads on them.

Solution

Vacuum pressure present inside the dosing tube removes the cap heads then places them on the body of the capsule. When the pressure is higher cap heads may not set properly on the body of the capsule so, you need to maintain the vacuum pressure at a moderate level to troubleshoot this problem.

26.How do you Clean the Capsule Filler?

If you want your machine to work for a longer run & help you in the future for getting greater production then you must need to clean your Capsule Filling Machine based on its working cycle.

Cleaning Process

A person cleaning the production line- Photo Credit: clean & co

In a Fully Automatic Capsule Filling Machine a vacuum system is used to do the cleaning of inner parts of the machine to make them stain-free and protect them from getting rusted.

The vacuum system present in the machine makes it easy for you to do the cleaning inside of the machine & you will not need to open and then fix the inner parts of the machine.

On the other hand, the outer surface of the machine needs to be clean regularly to make it attractive & remain perfect in shape and provide a better look.

Use a fiber piece of cloth and wet it with some hot water to remove the outer stains present on the body of the machine & after that use a dry fiber piece of cloth to dry the water present on the surface of the machine to make it stain free.

Try to avoid electrical parts of the machine during the cleaning process because if some of the electrical parts get damaged or become wet then the machine can give some sort of electric shock that can damage your product & labor as well.

Cleaning of a capsule filler can also be done with the help of detergent-based water because some of the stains are hard to remove but with the help of detergent water, you can easily remove these stains.

A person that is going to do the cleaning must have some basic and general information about all the parts of the machine so, that cleaning can be done easily and precisely.

Capsule Filling Machine Related Products

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours