Capsule Counting And Filling Machine: The Complete Buying Guide In 2025

Have you ever wondered the packing of your capsules while taking them out of bottle? You may wonder the number and hygiene of your packaged capsule? Do they cut the capsules? Do they pack them by hand? How to assure your medical products’ sanitary and your profits? You can just relax with the help of capsule counting and filling machine.

What is capsule counting and filling machine? What types of medicine can they handle? How does this machine work? Can this machine be applied to other industry? How to choose your suitable capsule counting and filling machine? Here you may find the answers! Come on and check!

1.What Is Capsule Counting And Filling Machine?

AIPAK Capsule Counting And Filling Machine

Capsule is the medical form which is widely used in our daily life and pharmaceutical industry. The capsule type varied. The hard capsule, soft gelatin capsules and various pills for sachet, bottle or other container packaging all have a great sale on market.

The packaging machine used to count and fill various types of products is capsule counting and filling machine. It can make the accurate counting and efficient packaging for many industries. The whole process is sanitary and low waste. You may also apply capsule counting and filling machine for other use.

2.What Products Can Capsule Counting And Filling Machine Handle?

There are various types of products for the capsule counting and filling machine to have the great handling. Here are the common product type.

Tablets

Tablets-Sourced:stockadobe

For the various size and shape tablets, capsule counting and filling machine can always give the nice work. There are round, oval, rectangular tablets for supplementing or caring. And you may also find the difference in coating or scoring. The capsule counting and filling machine can pack tablets with high accuracy and efficiency.

Hard capsules

Hard Capsules-Sourced:pharma-trends

The hard capsules have also various size and color. The capsule counting and filling machine can avoid the pollution or invasion of dust and damp in the process of packing. It can also help count and pack the empty one as well as the filled one.

Soft gelatin capsules

Soft gelatin capsules-Sourced:cphi-online

Soft gelatin capsules have also various shape and size. It can be as small as water droplets. But the capsule counting and filling machine can all give the precise counting. With liquid or suspension filled in soft gelatin capsules, the delicate and soft capsules can be handled by capsule counting and filling machine.

Pills with special shape

Pills With Special Shape-Sourced:goodrx

There are also pills with special shape. For the children medicines, the cute animal shape medical products is great welcomed. You should have no worry about the various shape of gummy of pill as capsule counting and filling machine can give the accurate handling.

Gummy

Gummy-Sourced:bellatrx

Gummy is also the representative medical products in pharmaceutical industry. The great taste made it welcomed in many places. The capsule counting and filling machine can pack the sticky gummy in bottle. The sticky products are counted with high accuracy.

Seed

Seed-Sourced:eoitushy

For seed and grain of agricultural industry, capsule counting and filling machine is essential. It makes the outstanding work in making the accurate counting for the bottling of seed and grain. And for seed or grain, the accurate number is sometimes essential in market.

Nuts

Nuts-Sourced:shutterstock

Nuts are the welcomed food in market. To make the nice packaging, you should make sure the even number of nuts in your pack. The capsule counting and filling machine can thus count the right number of nuts in each pack and make the nice package for your products.

Candy

Candy-Sourced:gadpiparty

There are various kinds of candy. Gummy, chocolate beans, chewing gums, fruit candy and so much sugar type can all be packed with high sanitary and accuracy. The precise number of candy in each pack shows the nice quality of your products.

Laundry Pods

Laundry Pods-Sourced:7sgood

Laundry pods which is the great helper in our cloth cleaning also need the help of counting and filling. This machine improves the efficiency in counting and filling the various shapes of laundry pods.

3.What Container Can Capsule Counting And Filling MachineFit?

Have you ever wondered the container for capsule counting and filling machine? There is little restrict on the container type and you may find the below containers for the frequent applying.

Bottle

Medical Bottle-Sourced:shutterstock

There are various types of bottle and you may find the round rectangle, square, oval, flat and so on. The material of different bottle is also varies and you may find the glass and plastic as the common type. the capsule counting and filling machine can fit most bottle type.

Jar

Medical Jar-Sourced:guardianmedicalusa

Jar is also the container which is used in capsule filling for supplementary products and many other medical products. There are glass jar, plastic jar, metal jar and even ceramic jar. You can just adopt the fitting channel for the filling and then get the great counting and packaging work.

4.CanCapsule Counting And Filling Machine Be Applied To Other Industry?

Capsule counting and filling machine is the reliable machines which make the outstanding work for pharmaceutical industry. And you can also use capsule counting and filling machine for other industry.

Food industry

Food Industry-Sourced:jysyfzsh

Food industry has the great need in food counting and filling. You may see the wide application of capsule counting and filling machine in sugar, chocolate, cake, strawberry and so on. For food industry, the capsule counting and filling machine can prove the efficiency and sanitary of the high qualified food products.

Cosmetic industry

Cosmetic Industry-Sourced:cosmeticsnow

Cosmetic industry has also the need of product counting and filling.Facial mask paper, capsule essence, second polish essence and so many cosmetic products all require the careful counting and packaging of capsule counting and filling machine.

Supplementary industry

Supplementary Industry-Sourced:trackmind

There are various capsule, soft gel, pills, gummy and tablets for supplementary use. The supplementary products have the high request on sanitary and accuracy, and the capsule counting and filling machine can make the great work for supplementary products and nutrition products packaging.

Agricultural industry

Agricultural Industry-Sourced:shutterstock

There are various agricultural products in agricultural industry. You may see the various seed, fertilizer and other agricultural products of agricultural industry. For the packaging, the machine should make the accurate and efficient work.

Chemical industry

Chemical Industry-Sourced:wsj

There are various chemical products in chemical industry. And you may find laundry pods, soups, disinfectants and many other chemical products which are all suitable for the counting and filling of the capsule counting and filling machine.

5.What You Can Benefit From Capsule Counting And Filling Machine?

What you can benefit from capsule counting and filling machine? Here are so many advantages of capsule counting and filling machine.

High efficiency

High Efficiency-Sourced:motorsatwork

Capsule counting and filling machine can make the efficient and high speed counting and filling work. The consistent working can suit the large production and save your most time and energy.

Accurate filling

Accurate Filling-Sourced:ampnutra

Capsule counting and filling machine can make the accurate filling. For various types of products, this machine can all make the accurate filling. You may have the extra time saved in counting and reducing errors.

Easy operating

Easy Operating-Sourced:flaticon

The capsule counting and filling machine is controlled by the single panel. From the touch screen you may give the various direct instructions from it. The operating of capsule counting and filling machine is easy.

Sanitary prove

Sanitary Prove-Sourced:ALLPAK

The capsule counting and filling machine reduce the adding of human labor in the whole processing. In the stainless steel environment, the chance of dust and damp pollution is reduced greatly. The sanitary of your capsule counting and filling machine can be better proved.

Easy maintaining

Easy Maintaining-Sourced:fleetroot

The capsule counting and filling machine is a complex and fragile machine. The maintaining of it is not that difficult. You have little worry about the destroy in the maintaining process.

Cost effective

Cost Effective-Sourced:cflowapps

The purchase of capsule counting and filling machine is a big cost. But in a long ran, it is a great deal. This machine saves your much energy and time in large production. And the high quality from this machine can also prove the great sale of your products.

Wide application

Wide Application-Sourced:colourstudies

The capsule counting and filling machine has a wide application. You may apply it to other products packaging besides the capsule. You may use it to count food, cosmetic products, supplementary products and so on.

6.What Are The Type Of Capsule Counting And Filling Machine?

The capsule counting and filling machine has various type. Here is the types of capsule counting and filling machine which is divided according to automation level and channel.

According to automation level

Manual capsule counting and filling machine

Manual Capsule Counting And Filling Machine-Sourced:ipharmachine

Manual capsule counting and filling machine is machine which made the capsule counting and filling work by labor hand. The efficiency and accuracy are in large scale decided by the operator. It is of course easy to operate and practical. But the low efficiency and accuracy makes it restricted in only small production.

Semi automatic capsule counting and filling machine

ALLPAK Semi Automatic Capsule Counting And Filling Machine

Semi automatic capsule counting and filling machine can improve the efficiency of capsule filling and packaging greatly. The basic operation requires the work of people and then makes the consistent processing. The higher automation level makes higher efficiency.

Automatic capsule counting and filling machine

AIPAK Automatic Capsule Counting And Filling Machine

Automatic capsule counting and filling machine makes the counting and filling work with high automation level and little adding of human labor. The work of this type of machine is easy and all things happened with the essential number set. It makes the highest automation and efficiency. Its excellent work save your time, improve your efficiency and precise.

According to model

8 channel

8 Channel-Sourced:rqpfmm

The channel of each automatic capsule counting and filling machine is also different. The 8 channel automatic capsule counting and filling machine is the representative one. It can makes the capsule counting and packaging with 8 channel’s consistent work.

16 channel

16 Channel-Sourced:herunmachinery

If you are not satisfied with the production scale of 8 channel automatic capsule counting and filling machine, you may also seek the 16 channel automatic capsule counting and filling machine for help.

24 channel

24 channel-Sourced:njmpackaging

The channel of automatic capsule counting and filling machine can also extend its channel and makes to 24 channel, 32 channel and even 40 channel. The number of channel depends on your production need. And you can make the flexible combining and extending of it.

7.What AreThe Main Parts Of Capsule Counting And Filling Machine?

The capsule counting and filling machine is the machine which is composed of various parts. And the lacking of one parts will lead the malpractice of the machine. Here are the main parts of capsule counting and filling machine.

Touch screen

AIPAK Touch Screen

Touch screen is one of the most important component in capsule counting and filling machine. Touch screen is the connection of your direction and the machine. Here you may also monitor and control the machine in the whole operating process.

Hopper

AIPAK Hopper

Hopper is the beginning of the whole capsule counting and filling process. It contains the capsules and links the capsule source to the capsule counting and feeding system. It makes sure the consistent feeding and processing of capsule counting and filling system.

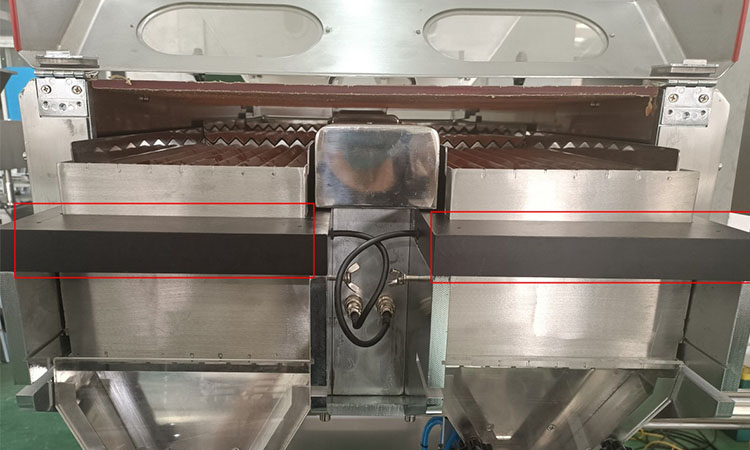

Conveyor belt

AIPAK Conveyor Belt

Conveyor belt is the place where the many capsules come to the counting places. And this process is essential as the vibrator in the process separates the capsules, pills and tablets which make the later sensor more accurate.

Vacuum dust collection

AIPAK Vacuum Dust Collection

Vacuum dust collection is the place where the dust is collected. In the transporting and vibrating way, there may always dust stick in the capsules. For the better and safer capsule filling and packaging work, vacuum dust collector is a great helper.

Dust cap

Dust Cap-Sourced:nkpharmamachinery

Dust cap is also the important part for the whole capsule counting and filling process. It is set above the conveyor belt to prevent the invasion of dust, damp and other dirty products in the conveying process.

Counting sensor

AIPAK Counting Sensor

Counting sensor is the place where the number of capsules gets in. The sensor will make clear the number of capsules. And when it comes to the set number, the whole capsules then get out to the bottle.

Feeding funnel

AIPAK Feeding Funnel

After the counting of capsules by counting sensor, the feeding funnel then get the whole capsules and feed them for the below bottle. It can change the size, height and shape to meet the various types of bottle.

Bottling system

AIPAK Bottling System

After the feeding of one bottle, there is the new bottle come in. And the consistent work comes from the bottling system. It makes the timely and consistent feeding of new bottle for the capsule counting and feeding system.

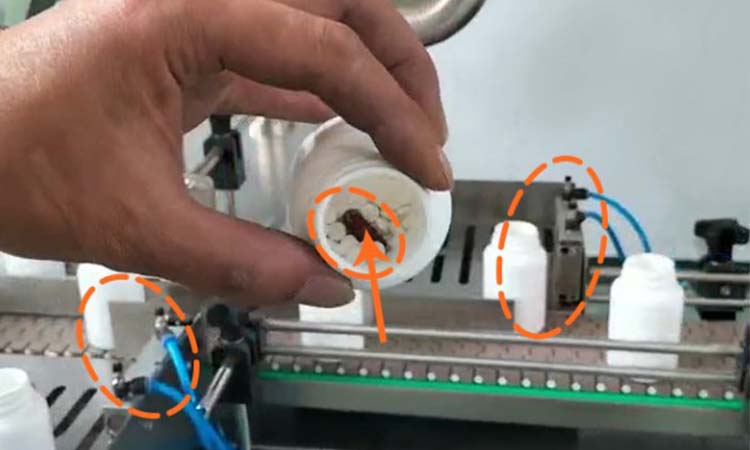

Detection system

AIPAK Detection System

Detection system is the reliable system which pick the unqualified capsules out. The automatic detection system may detect the defected material. This parts can prove the quality of the whole processing.

8.What Is The Working ProcessOf Capsule Counting And Filling Machine?

The working process of capsule counting and filling machine is not complex and here is the simple working process of capsule counting and filling machine.

The Working Process Of Capsule Counting And Filling Machine

Preparation for material and machine

Before the working of capsule counting and filling machine, you should make the comprehensive preparation. After cleaning the machine, you should set the right panel in touch screen. Besides, you should also make sure the right connection of tray, enough feeding of capsule, suitable height of hopper and so on.

Feeding capsules

While machine began, the consistent capsules then get conveyed by conveyor belt to the counting part. In the conveying process, the dust detector will get off the dust in the process and vibrator will separate them apart for the more smoother counting. It will then dropped to the hopper for capsule counting and so on.

Counting capsules

The capsules then get into the capsule counting process. The counting sensor counts dropped capsule with laser and inspect the quality of each capsules. After the accumulating of the right number of suitable capsules, the large set of capsules then dropped into .

Filling capsules

The well counted capsules then feed into the bottle, sachet or other container which is waiting below the feeding tunnel in the certain position. The counting sensor and filling part are connected. After the filling of the specified number of capsule, the container then ran away.

9.What Machine Can Corporate With Capsule Counting And Filling Machine?

Have you even wondered the way to maintain the best efficiency of capsule counting and filling machine work? Yeah! Here is the capsule counting and filling line.

Bottle unscrambler

AIPAK Bottle Unscrambler

Bottle unscrambler is the machine which arrange the bulk of messy bottles. It is the important preparation for the smooth capsule counting and filling work. The missing of it requires the great work and time.

Desiccant inserter

ALLPAK Desiccant Inserter

Capsules and many products are easy to get moist, to make sure the quality and prolong the shelf life. It is essential to put desiccant in the bottle or sachet. And the desiccant inserter is the reliable machine which ensures the inserting of desiccant in every bottle.

Capsule counting and filling machine

AIPAK Capsule Counting And Filling Machine

Capsule counting and filling machine is the machine which makes the reliable and efficient work in counting and filling the various capsules. It is the center of the whole manufacturing process.

Capping machine

AIPAK Capping Machine

Capping machine is the machine which makes the outstanding work in covering the various lid for the filled bottle. You can match it to fit the various cap size and shape for the relative bottle.

Induction sealing machine

AIPAK Induction Sealing Machine

After the covering of lid by capping machine, there should be further protecting of the packaged products. Induction sealing machine apply the electromagnetic induction to make a hermetic seal between cap and bottle. This process can prove the hygiene of machine better. It makes the airtight environment and protect medical products greatly.

Labeling machine

AIPAK Labeling Machine

The qualified products cannot leak the adding of various label. Labeling machine is the machine which sticks the label for bottle. There are various labeling type and the relative labeling machine also varied. The work of labeling machine is stable and efficient.

10.How To Get The Best Capsule Counting And Filling Machine?

The capsule counting and filling machine makes such excellent work in so many industries. And here is the comprehensive guide for you to get the best capsule counting and filling machine.

Cost

Cost-Sourced:freshbooks

Cost is the first thing you should consider for the capsule counting and filling machine choose. The price of your machine should conform to your budget. You should take great concern on the machine price as well as the price of the later transporting, installing and so on.

Compatibility

Compatibility-Sourced:marthadebayle

You should also take great concern in the compatibility of your capsule counting and filling machine. How about the compatibility with other machine? How about the compatibility with the various medical products?

Production capacity

Production Capacity-Sourced:janicebastanicoaching

Production capacity is also your big concern on capsule counting and filling machine purchase. The production capacity of machine should conform to your business’s production scale and the future developing.

Regulatory compliance

Regulatory Compliance-Sourced:lexisnexis

The pharmaceutical packaging has high standard and you should make sure the complying of your product standard to the regulatory compliance. You should make clear the regulatory compliance for the further purchase.

Machine performance

Machine Performance-Sourced:freepik

Machine performance relates to the machine quality and machine efficiency. The machine performance should be inspected with great care. The type, production scale and so on should all taken into consideration.

Maintaining difficulty

Maintaining Difficulty-Sourced:shutterstock

As capsule counting and filling machine is a complicated machine, the maintaining of it should be taken with great care. The difficult maintaining will cost you a lot energy and money in later working.

Manufacturer brand

Manufacturer Brand-Sourced:elegantthemes

The large and reliable capsule counting and filling machine manufacturer is able to provide machine with higher quality and better after sale service. For your smooth manufacturing work, you should get your machine from manufacturer brand.

11.What Are The Common ProblemAnd Solution For Capsule Counting And Filling Machine?

There may be problems in the working of capsule counting and filling machine. For the problem, you should have no worry, here is the common problems and the solution.

Problem And Solution-Sourced:copyengineer

| Problem | Solution |

| Capsule jamming | The high speed operation of capsule counting and filling machine is the key factor for the jamming of capsules. You should adjust the vibrating speed of vibrator and feeding track. |

| Inconsistent bottle | The inconsistent conveying of bottle may lead the leaking of capsule and inaccurate filling. For this condition, you should renew the relative information and adjust the railing spacing. |

| Spilling capsules | The spilling capsule of bottle comes from the the unsuitable space between feeding dropper mouth and bottle. |

| Bottle trips | The tripe of bottle in the opening of bottle holder may come from the delay opening of bottle holder. |

| Wrong counting number | If you found the capsule number of your container. You should first get to check the sensor system and find the potential problem in it. |

| Sudden alarm | There may be sudden alarm of capsule counting and filling machine while in the process. There may be various reasons. The lacking of bottle may lead the sudden alarm. The white bottle may produce powerful light and induce the alarm. Last, you should check the sensibility of sensor to give the more precise alarm sensing. |

12.How To MaintainYour Capsule Counting And Filling Machine?

Capsule counting and filling machine is a complex and fragile machine. And for the maintaining, you should take the below steps into serious consideration.

Make the regular cleaning

Make The Regular Cleaning-Sourced:the-cleaning-company

The cleaning of capsule counting and filling machine should be regular. You should make the deep and regular cleaning after using. After the shutting of the whole system, you would better to dismantle the small parts for the deeper cleaning. For the cleaning tool, the mild and soft is the most recommended.

Replace the worn parts

Replace The Worn Parts-Sourced:reddit

For the worn parts which is found in the operating process, you should replace it in time. The sticking of worn parts in the whole process may lead more and more wear and tear. You should also lubricate them regularly for the better maintaining.

Follow the right operating procedures

Follow The Right Operating Procedures-Sourced:bolddesk

The right operating procedure is the prove for the nice condition of capsule counting and filling machine. You should follow the right operating procedures to make the nice products and maintain products well.

13.What Standard And Certification a Reliable Capsule Counting And Filling Machine Should Have?

The capsule counting and filling machine needs to pass several standard and certification to be real nice and qualified.

cGMP

cGMP-Sourced:golsolution

cGMP which is also named as current good manufacturing standard is the standard developed particularly for the great quality prove and supervision for pharmaceutical industry, biotechnological industry and so on.

URS

URS-Sourced:pharmaguddu

URS refers to user requirement specification. It makes the specific requirements on the designing of capsule counting and filling machine, inspecting and testing protocol of the capsule counting machine, quality standard procedures and responsibilities of different parties.

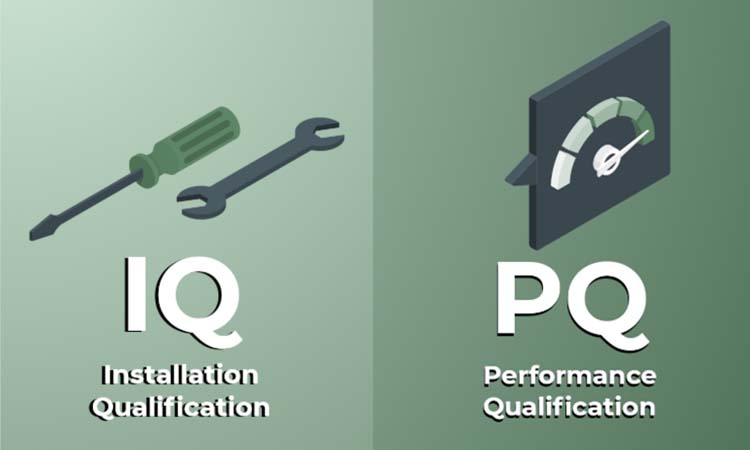

IQ and PQ

IQ And PQ-Sourced:spkaa

IQ and PQ protocol make the specific requirement on the installation qualification and performance qualification. It makes sure the later performance of your machine in factory and the right method for installing.

CE

CE-Sourced:authorisedrepcompliance

CE standard which referred to conformite europeenne is also the important standard which prove the machine quality and the products quality. The passing of CE makes the great application in European market.

FDA

FDA-Sourced:kffhealthnews

FDA refers to the food and drug administration which proves the quality of food and drug in many places. For pharmaceutical industry, it takes the rather important state and makes sure the quality of many places.

Material and structure

Material And Structure-Sourced:puvainsaat

For the reliable capsule counting and filling machine, here is the extra requirement on material and structure. The conveyor of this machine and construction frame should be of AISI 304. The other components of the capsule counting and filling machine should all pass CE standard.

14.Why You Choose AIPAK Capsule Counting And Filling Machine?

AIPAK is the renowned brand in pharmaceutical industry. Its capsule counting and filling machine enjoys great reputation in market.

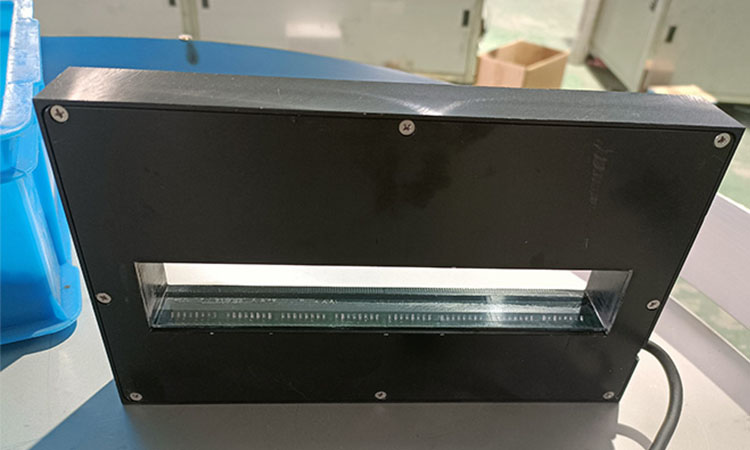

Scanning system

Scanning System-Sourced:AIPAK

The AIPAK capsule counting and filling machine is equipped with the infrared scanning system which may make sure the high accuracy of counting and make the high qualified filling work.

Dustproof design

Dustproof Design-Sourced:AIPAK

You should have no worry about the invasion of dust, moisture or other products in the counting and filling process. The dustproof design of AIPAK capsule counting and filling machine makes the nice work to maintain the nice condition of capsule products.

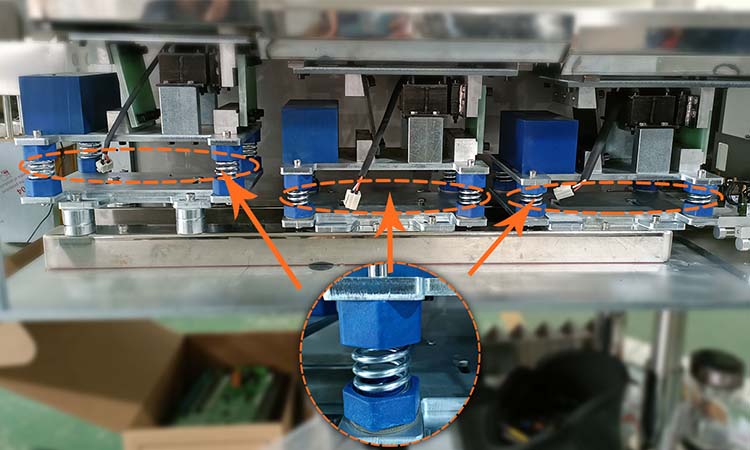

Three stage vibrator

Three Stage Vibrator-Sourced:AIPAK

The three stage vibrator of AIPAK capsule counting and filling machine makes the three stage road for the capsule transporting. It separates the capsules apart and makes the preparation for the later accurate counting.

Transparent operating window

Transparent Operating Window-Sourced:AIPAK

The transparent operating window of AIPAK capsule counting and filling machine can let you observe the processing of capsule transporting, counting and filling. This helps operator know the condition of machine operation and makes the timely reaction.

Low noise design

Low noise design-Sourced:AIPAK

There is low noise in the operation of AIPAK capsule counting and filling machine. The capsule counting and filling machine of other brand may make the loud noise and affect your operating.

Dust collection design

Dust collection design-Sourced:AIPAK

For the medical products and products with high standard on sanitary, AIPAK capsule counting and filling machine adopts the vacuum dust collection design to make the further and better protection of products.

New platform structure

New Platform Structure-Sourced:AIPAK

The stable new platform structure of AIPAK capsule counting and filling machine makes sure the smooth and steady condition of capsule counting and filling machine operation.

Bottling hopper

Bottling Hopper-Sourced:AIPAK

The bottling hopper AIPAK capsule counting and filling machine offers have different types to suits different bottle type. The sleeve bottling hopper makes no clogging and leaking in the counting and filling process.

Automatic detection system

Automatic detection system-Sourced:AIPAK

You may have your process of detecting the quality of your capsule products or other products. The automatic detection system of AIPAK capsule counting and filling machine saves your energy and makes the products of great quality.

Conclusion

Capsule counting and filling machine makes so much benefits for business of many industry. The choose of the reliable and great one can help you a lot in your business development. If you have any question or problem on capsule counting and filling machine, you should have no hesitate to contact us.

Don't forget to share this post!

Tablet Counting Machine Related Posts

Tablet Counting Machine Related Products

Tablet Counting Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours