Capsule Bottle Filling Machine: The Complete Buying Guide In 2025

Capsules have various package and you may see the packaging of capsules for pack, bottle and sachet. The capsule bottle filling machine is the excellent machine which makes the great packaging work for capsule bottle filling for pharmaceutical industry. For the capsule packaging, you may not miss this machine.

What are the types of the machine? What are the advantages of capsule bottle filling machine? Can they corporate with other machines for better application? Are there other filling machine for pharmaceutical industry? Here is your complete buying guide! Come on and check!

1.What Is Capsule Bottle Filling Machine?

AIPAK Capsule Bottle Filling Machine

Have you ever wondered the sanitary and accuracy of your capsules in medical bottle? Capsule bottle filling machine is the essential machine which makes the hygienic and efficient capsule counting and bottling. The great automation and high accuracy of capsule bottle filling machine make much benefits to pharmaceutical business.

The capsule bottle filling machine adopts the cutting edge technology and precise mechanism to make the series of work like counting and filling. The simple operation, compact structure and efficient work make it the irreplaceable machines for capsule, tablets, soft gelatin and so on.

2.Which Industry Needs Capsule Bottle Filling Machine?

Capsule bottle filling machine can be adopted to more than one places. And there are the industries which need capsule bottle filling machine.

Pharmaceutical industry

Pharmaceutical Industry-Sourced:meghmaniglobal

Pharmaceutical industry is of course the most common industry for capsule bottle filling machine. Besides capsules, you may also adopt capsule bottle filling machine for the filling of soft gelatin capsules, suppositories, pills and so on. The great work of this machine can help you a lot in quality control.

Food industry

Food Industry -Sourced:aboxshop

Food industry has the representative products like various candy, chocolate ball, nuts, gummy, chewing gums and so on. The many food products all need the capsule bottle filling machine for the filling. There is the high standard on food quality and the capsule bottle filling machine can all handle this.

Chemical industry

Chemical Industry-Sourced:dhgate

For chemical industry, capsule bottle filling machine is the great machine for improving the packaging efficiency and proving the high quality. If you pack the laundry beads by labor, the low efficiency with high error rate may lead the destroy of your brand reputation.

Supplementary industry

Supplementary Industry-Sourced:sks-bottle

Supplementary industry is the booming industry which has various products form. You may see the gummy, soft gelatin capsules and so on from supplementary industry. The various products form and bottle size can all be easily handled bu capsule bottle filling machine.

Cosmetic industry

Cosmetic Industry:Sourced:mxhaitao

For cosmetic industry, there is also the wide application of capsule bottle filling machine. Essence capsules are now the welcomed form for skin care. The capsule bottle filling machine can pack the essence with the great prove of hygienic station and accuracy.

3.What Products Can Capsule Bottle Filling Machine Pack?

The capsule bottle filling machine has a wide application and you may see the products it can pack in many places. And here are some products it can pack.

Tablets

Tablets-Sourced:freepik

Tables are the common medical form which is widely applied in pharmaceutical industry and food industry. And it is also one of the most common type for bottling. For tablets of various size and shape, capsule bottle filling machine can make the great handling.

Capsules

Capsules-Sourced:drugplastics

There are hard capsules and soft gelatin capsules for capsule bottle filling. Their shell which made of gelatin may be easy to get sticky while contacting moisture. And the great work of capsule bottle filling machine can make the efficient and clean work for them.

Candies

Candies-Sourced:restaurantware

Candies have various size, form and color. And for the various kinds of candy, capsule bottle filling machine can make the excellent work. You may see the bottling of precise number and great candy settling in bottle.

Nuts

Nuts-Sourced:istockphoto

Nuts are the popular and healthy snack in market. The round and hard products takes much efforts to achieve the qualified packaging. Capsule bottle filling machine takes the great work to make the nice packaging work.

Seeds

Seeds-Sourced:nativeseeds

Seeds are the common products in agricultural industry. The small size of seeds requires the careful counting and packaging of human being. For the capsule bottle filling machine, you may get the unbelievable packaging work.

Capsule essence

Capsule Essences-Sourced:55haitao

Capsule essences are the recommended cosmetic form which prove the cleaning and efficiency of essence. Capsule bottle filling machine can make the efficient and reliable packaging for capsule essence.

Laundry beads

Laundry Beads-Sourced:daraz

Laundry beads are the chemical products which benefit our laundry in many aspects. The capsule bottle filling machine may make the nice work in dealing with the laundry beads of various brand and size.

Chewing gums

Chewing Gums-Sourced:shutterstock

There is strict request on the number of chewing gums for packaging. The capsule bottle filling machine is the perfect machine which make the nice packaging and the precise counting for chewing gums.

Gummy

Gummy-Sourced:bellatrx

There may be some trouble in packaging gummy as the sticky gummy may prevent the fluent packaging. The capsule bottle filling machine can make a series of nice work to pack gummy with right number and great quality.

4.What Are The Container Suitable For Capsule Bottle Filling Machine?

Have you ever wondered the suitable bottle for capsule bottle filling machine pack? Here are the suitable containers for capsule bottle filling machine.

Bottle

Bottle-Sourced:grihoshaj

Bottle, glass or plastic, ceramic or wood, can all be applied for capsule bottle filling machine. The capsule bottle filling machine can fit the filling hopper size to deal with various bottle size and type.

Jar

Jar-Sourced:fellowproducts

Jars are the preferable container for the filling of candy, chocolate and many other products. They are mostly glasses and make the great job of displaying the products. The various size and material of jar can be handled well by capsule bottle filling machine.

Can

Can-Sourced:desertcart

Cans are the stable and durable container for products saving. You may find the wide application of can in food industry. Capsule counting and filling machine can make the great dealing of can.

5.What Are The Types OfCapsule Bottle Filling Machine?

There are various capsule bottle filling machine. And to divide them clearly, you may check the automation level and structure basis.

According to automation level

Manual capsule bottle filling machine

ALLPAK Manual Capsule Bottle Filling Machine

Manual capsule bottle filling machine needs your whole work to make the accurate filling and packaging. It takes small place in your bottle filling work. But the precise counting of capsules needs the high focus of your workers. It takes little cost but may take much efforts and energy.

Semi automatic capsule bottle filling machine

ALLPAK Semi Automatic Capsule Bottle Filling Machine

Semi automatic capsule bottle filling machine is the fragile and efficient capsule bottle filling machine which makes the high efficient bottle filling work. It has higher products capacity compared with manual one. But the smooth operation of this machine can not leave the adding of operator.

Automatic capsule bottle filling machine

AIPAK Automatic Capsule Bottle Filling Machine

Automatic capsule bottle filling machine is advanced machine which makes the efficient and precise bottle filling. This machine adopts the cutting edge technique and high qualified material to make speedy filling. It is suitable for the large production of large business. And its high automation needs little adding of labor.

According to structure basis

Vibratory capsule bottle filling machine

AIPAK Vibratory Capsule Bottle Filling Machine

Vibratory capsule bottle filling machine is the advanced capsule filling machine which can suitable for the large production of various products in bottle filling. It has the conveying belt which makes the consistent vibrating in transporting for the later accurate counting and filling.

Rotary capsule bottle filling machine

AIPAK Rotary Capsule Bottle Filling Machine

Rotary capsule bottle filling machine is the bottle filling machine which has a wide application in various industries. This advance machine has rotary plat rather the conveying belt for the capsule dividing and sorting. It takes smaller place and its accuracy can be also proved.

6.What Are The Main Parts Of Capsule Bottle Filling Machine?

The capsule bottle filling machine is composed of the precise and elegant small parts. Here are the main parts of automatic capsule bottle filling machine.

Touch screen

AIPAK Touch Screen

Touch screen of capsule bottle filling machine is the important part which connects the capsule bottle filling machine and operator. The touch screen has various form and it is the irreplaceable part for capsule bottle filling machine work.

Hopper

AIPAK Hopper

To make the smooth filling, you should connect your capsule bottle filling machine with capsules source. And the capsule hopper is the place which connect and store capsules for your capsule bottle filling.

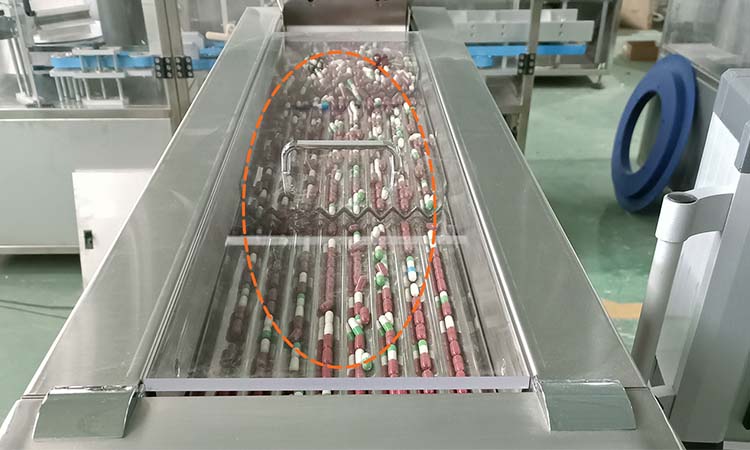

Vibrating conveyor belt

AIPAK Vibrating Conveyor Belt

Vibrating conveyor belt is the transporting road of your capsules to the scanning system. The vibrating conveyor belt is the great process which helps the separating of your capsules. It helps to improve the accuracy of counting.

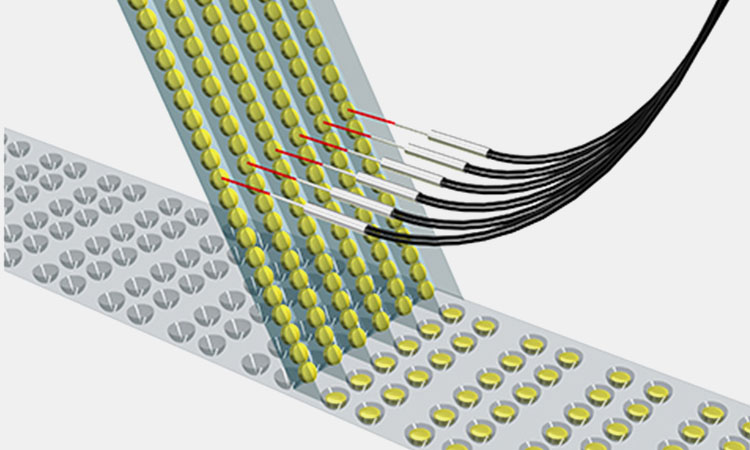

Scanning system

AIPAK Scanning System

Scanning system is the important counting parts of capsule bottle filling machine. The infrared scanning part can give the precise counting of capsules and other products. It is the basis of your qualified products.

Sleeve bottling hopper

AIPAK Sleeve Bottling Hopper

Sleeve bottling hopper is the excellent device which conveys the well counted capsules to the waiting bottle with high efficiency and accuracy. It has various type and size for the accurate filling of different bottles.

Bottle conveying device

AIPAK Bottle Conveying Device

Bottle conveying device is the place where make the consistent conveying of bottles. This process avoids the accumulating of bottle and makes large efforts to the smooth operating of bottle filling.

Dust collection system

AIPAK Dust Collection System

Dust collection system makes the important role in assuring the quality of capsules and other products. The transparent operating window, dust collection design and dustproof design can all prove the sanitary and quality of products.

7.How Does Capsule Bottle Filling Machine Work?

How does capsule bottle filling machine work? Here is the detailed working procedure of capsule bottle filling machine.

The Working Process Of Capsule Bottle Filling Machine

Machine preparation

For capsule bottle filling machine working smoothly, you should first make the nice preparation of your capsule bottle filling machine. Besides the connecting of sufficient capsule, you should adjust the relative panel to suit your machine feature. You should adjust the feeding hopper, conveying belt tray and so on.

Bottle placing

To make the smooth capsule bottling, you should make the timely transporting of bottle to take the capsules. And you should also place and adjust the relative machine for the smooth and rapid transferring of bottle.

Capsule transporting

Capsule transporting is the important process where the various capsules are transported by the conveying belt to the counting place. The vibrator system and three stages conveyor belt makes the great sorting of capsules and work for later counting.

Capsule counting

Capsule counting is the core process of the whole capsule bottle filling work. The sensing system count each capsules by infrared in the process of capsule falling off. Each interrupt of infrared by capsules will be counted by machine. When it comes to the final number from panel, it is time to let it out.

Bottle filling

For the well counted capsules, the capsule bottle filling machine will make the last process by bearing the falling capsules. The bottle conveyor belt is well programmed and has the speed set for the smooth bottle filling and bottle replacing.

8.What Machine Can Capsule Bottle Filling Machine Corporate With?

What machine can capsule bottle filling machine corporate with? Here is the recommended machines for you to consider.

Bottle unscrambler

AIPAK Bottle Unscrambler

Bottle unscrambler is the machine which helps arrange your bulks of bottles. It avoids the accumulating and twining of bottles and makes it arrange well for the capsule waiting.

Desiccant insert machine

AIPAK Desiccant Insert Machine

Desiccant is essential for many capsule package. It helps prevent the spoiling and damping of medical products. The desiccant insert machine is the machine which makes the efficient work in inserting desiccant in each bottle.

Capping machine

AIPAK Capping Machine

Have you ever wondered the after work of your bottle after filling. For the reliable capping, why you do not choose capping machine. The capping machine makes the great job of capping each bottle.

Induction sealing machine

AIPAK Induction Sealing Machine

Induction sealing machine is the machine which makes the further protection of your bottle. The further sealing by aluminum layer can better protect your capsule. This is the irreplaceable part for pharmaceutical products protecting.

Labeling machine

AIPAK Labeling Machine

Label is the show of your brand and products feature. The labeling machine is the machine used particularly for label sticking. It can stick various types of label and suits for the bottle of various types.

9.What Are The Advantages Of Capsule Bottle Filling Machine?

The capsule bottle filling machine has many advantages and here are the outstanding advantages of capsule bottle filling machine.

High efficiency and production scale

High Efficiency And Production Scale-Sourced:llumin

The capsule bottle filling machine is highly efficient and is able to make the large production of various capsules and products. It makes the great saving of your energy and time.

Accuracy

Accuracy-Source:documentmedia

Capsule bottle filling machine is the machine which can count capsules and other products with high accuracy. It cannot always be perfect but the higher accuracy rate can help you improve the products quality.

Hygiene prove

Hygiene Prove-Sourced:gemdentalexperts

For labor work, you cannot assure the sanitary of your packaged products. But the operation of capsule bottle filling machine can prove as the labor joining is so small and the layers of protection is strict. For products of pharmaceutical industry and products with high standard, the hygiene prove is must.

Low labor cost

Low Labor Cost-Sourced:flaticon

The smaller adding of capsule bottle filling machine means the less cost on labor. The low labor cost may be the great saving of your business. And the low labor cost can also mean the less labor mistake.

Strong compatibility

Strong Compatibility-Sourced:thezombieshuffle

The capsule bottle filling machine has strong compatibility. Besides the capsule bottling, it can also bottle the various medical products and products of other industry. Nuts, sugar, chocolate and even seeds can all be counted by this machine.

Easy to operate

Easy To Operate-Sourced:leadingwithtrust

The machine is intelligent, automatic and easy to operate. You may get in the various instructions on panel. It saved you much energy and saved the much efforts in learning and operating.

10.What You Should Pay Attention To In The Operating ProcessOf Capsule Bottle Filling Machine?

The capsule bottle filling machine is easy to operate, but here are still some parts you should pay attention to in its operating.

Clean and check before use

Clean And Check Before Use-Sourced:learnloft

Before the operating of capsule bottle filling machine, you should make the cleaning and check. Besides the regular cleaning and disinfecting of machine, you should also check the sticky capsules or tablets of machine from the former operation. For the nuts, parts and all connections you should all have the check. Remember to clean yourself before use.

Operate according to regulation

Operate According To Regulation-Sourced:econlib

There are strict operating direction for capsule bottle filling machine use. Your whole operating should all conform the direction. The wrong operation may lead the mistake of your machine and the failure of the qualified products manufacturing.

Keep a maintenance log

Keep a Maintenance Log-Sourced:simplyfleet

You should keep your maintenance log of machine. This can help to make the careful maintaining schedule and makes the trace if there is any problem in machine operating.

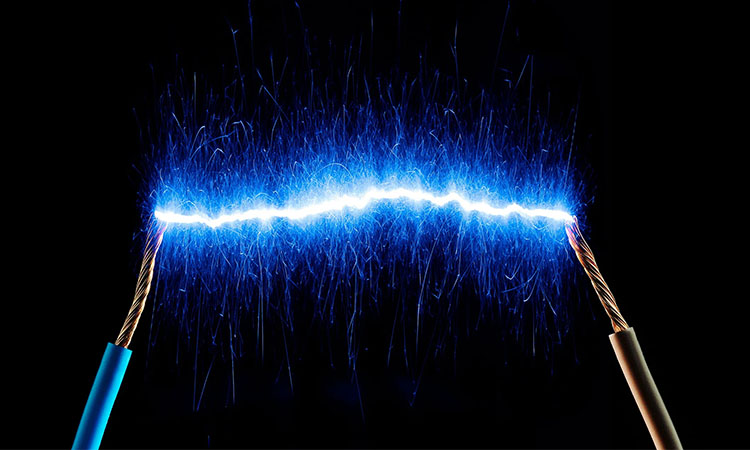

Correct power connection

Correct Power Connection-Sourced:sellleadsucceed

The wrong power connection may induce a series of mistakes in capsule bottle filling operating. You should make sure the right connection and great condition of capsule bottle fulling machine in the operation.

11.How To Maintain AccuracyOf Your Capsule Bottle Filling Machine?

If you want to maintain the high efficiency of your capsule bottle filling machine, you may not miss the following steps.

Set appropriate panel

Set Appropriate Panel-Sourced:mmsonline

You should set the appropriate panel according to your products type and feature on capsule bottle filling machine. The wrong and unsuitable setting may make mistake in the process.

Make the regular cleaning

Make The Regular Cleaning-Sourced:twogalsandabroomkc

The cleaning of capsule bottle filling machine should be regular and deep. The dust or granule may interrupt the accuracy of sensing part and lead the mistake in counting and filling.

Use it in suitable environment

Use It In Suitable Environment-Sourced:green

The unsuitable environment may also lead the mistakes of capsule bottle filling machine and even lead the shortening of lifespan of this machine. You should avoid the machine operating in high temperature, acid condition and humid condition.

Right operation

Right Operation-Sourced:shutterstock

The right operation is the base of the accurate result of your capsule bottle filling machine. You should not blame the the accuracy of your machine if your do not make the right setting or operating.

Appropriate oscillation frequency

Appropriate Oscillation Frequency-Sourced:leverageedu

The oscillation frequency is also the part you should not ignore in the accuracy of capsule bottle filling machine. There may be different oscillation frequency for different kinds of capsule, tablet and so on.

12.What You Should Consider For The Nice Capsule Bottle Filling MachinePurchase?

Capsule bottle filling machine makes so much important role in your business. The purchase of it should be taken great consideration.

Budget

Budget-Sourced:numbersknowhow

You should make clear your budget and then choose the suitable machine. There are capsule bottle filling machine of wide price range and you should get the one suitable for your company and budget.

Type

Type-Sourced:censius

The capsule bottle filling machine type is also the important factor for you to consider. You should take the accuracy, production scale, energy consuming, maintaining difficulty, machine material and other factors for the consideration. The choose of machine type is the probe of your business and company’s quality.

Regulatory compliance

Regulatory Compliance-Sourced:intellect

Regulatory compliance is also the point you cannot ignore. For the law and regulation of different country and state, there are always different request on medicine manufacturing and the violation of the law may lead the ruin of all your products.

Future developing

Future Developing-Sourced:depositphotos

The planning of your business also decides the purchase of your capsule bottle filling machine. You should consider your factory’s condition for the machine purchase. The capsule bottle filling machine should be versatile and makes nice compatibility with other products.

Brand

Brand-Sourced:paradigmmarketinganddesign

Brand is also the essential factor for you to consider. The big and reliable brand may offer your the capsule bottle filling machine with better quality, efficiency and after sale service. Your right can be better proved in this way.

13.Why You Choose AIPAKCapsule Bottle Filling Machine?

For the reliable brand, you should take AIPAK into serious consideration. With rich experience and high quality standard, here is the reasons for you to choose it.

Precise scanning

AIPAK Precise Scanning

AIPAK capsule bottle filling machine has the precise scanning system. The low error rate makes little problem in counting products. For various size and type, it can all make the precise scanning.

Strong dustproof

AIPAK Strong Dustproof

The strong and reliable dustproof of AIPAK capsule bottle filling machine makes sure the nice conveying condition of products. The prevention of dust and other contamination makes the better quality.

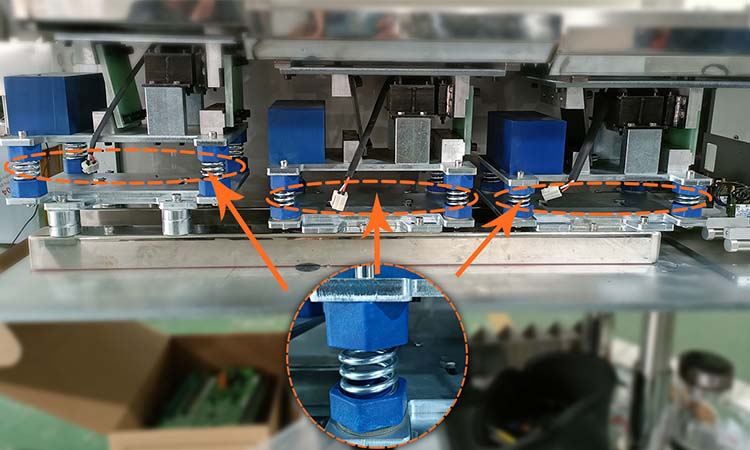

Reliable vibrator

AIPAK Reliable Vibrator

The vibrator has various frequency for the different types of products. It makes the stable and smooth transporting of capsules. The combination of scanning machine makes the high accuracy counting.

Visible operation

AIPAK Visible Operation

The operation of capsule bottle filling machine is visible. The special design of AIPAK capsule bottle filling machine makes the operation more reliable and efficient. And for any problems, you may find them quickly and make the relative reaction.

Humanized design

AIPAK Humanized Design

The low noise design and dust collection design of AIPAK capsule bottle filling machine is humanized. The operator may stand less interference and makes the better operation for products processing.

Stable structure

AIPAK Stable Structure

The stable structure of AIPAL capsule bottle filling machine separates the counting part and electrical control part. This design makes the smoother and more stable operation.

Adjustable bottle hopper

AIPAK Adjustable Bottle Hopper

The bottle hopper of AIPAL capsule bottle filling machine is adjustable. You may have bottle hopper changed according to different bottle type. The suitable bottle hopper has more precise filling.

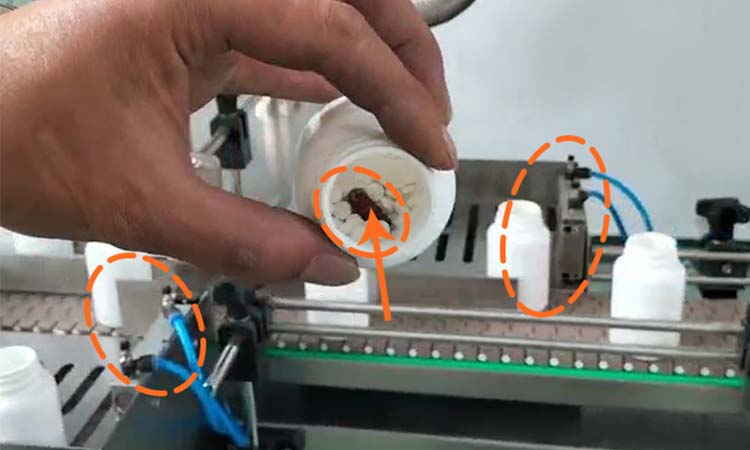

Automatic detection

AIPAK Automatic Detection

The special automatic detection system of AIPAK capsule bottle filling machine can detect the unqualified products automatically. It saved your further energy in picking out the unqualified one.

14.How To Deal With The Common Trouble Of Capsule Bottle Filling Machine

Capsule bottle filling machine cannot always operate smoothly. Here are the common problems of capsule bottle filling machine and the relative cause.

Trouble And Cause-Sourced:isixsigma

| Trouble | Cause |

| Loud noise | 1. No bottle on the relative position.

2. Sensing system inaccurate for the dust accumulating. 3. Apply white bottles and make lot of light reflection. 4. Center screw vibrates and cause noise. 5. The close contacting of vibrating tray with the discharging channel inlet. |

| Incorrect counting | 1. Low counting speed.

2. Fragments mixed in the process and interrupted counting. 3. Inaccurate feeding hopper makes the overlapping of products. 4. Low sensitivity of sensing system. 5. Strong natural light interrupt the counting. |

| Products spilling | 1. Incorrect hopper height leave gap between bottle and feeder.

2. Wrong bottle conveying speed. |

| Wrong bottle position | 1. Wrong bottle timings.

2. Conveyor system makes the wrong spacing. |

| Products jamming | The wrong speed of bottle conveying. |

15.What Quality Standard a Reliable Capsule Bottle Filling Machine Need?

You should conform to the relative quality standard for the capsule bottle filling machine manufacturing. Here are some representative quality standard.

cGMP

cGMP-Sourced:convergencetraining

cGMP is the standard which makes the requirements for the manufacturing practice, machine standard and quality. It is widely circulated in many country and location. It is the important standard for many products manufacturing.

CE

CE-Sourced:obelis

CE is the standard which makes sure the wide circulation of your machine in European area. It makes the strict quality standard for your machine and the products quality.

RoHS

RoHS-Sourced:sensiblemicro

RoHS is the standard which makes the standard for restricting the hazardous substances. It makes the restrict of manufacturing on environment. This standard helps make the nice environment and build human health.

FDA

FDA-Sourced:today.uconn

FDA is the known quality standard which has the full name as food and drug administration. This standard maintain people’s benefit by making the strict standard in product quality, safety and efficiency.

16.What Are The Common Technical SpecificationOf Capsule Bottle Filling Machine?

What are the technical support of capsule bottle filling machine? Here are some of the main technical parameter of AIPAK capsule bottle filling machine.

Technical Specification-Sourced:techspecs

| Bottle shape | Round, square bottle which is plastic, glasses and so on. |

| Products type | 00~5#capsule,soft capsule, Φ5.5~22 compressed tablet, special-shaped tablet, Sugarcoated tablet, Φ3~12pill |

| Production capability | 50-100 bottles per minute(It depends on the bottle size, filling quantity and the tablet size) |

| Power supply | AC220V 50Hz 0.6kw |

| Accurate rate | >99.5%(higher than the industrial standard ) |

| Air pressure | 0.6Mpa |

| Weight | 500 kg |

17.What Are The Developing Of Capsule Bottle Filling Machine?

What are the developing of capsule bottle filling machine? Here you may find its developing road.

Mechanical counting

Mechanical Counting-Sourced:123rf

Mechanical counting is the first generation of capsule bottle filling machine. It is more efficient compared with the manual manner. But for different types of size of products, it needs the frequent parts changing to make the nice work. For the small production, it is the reliable machine.

Photoelectric counting

Photoelectric Counting-Sourced:optex-fa

Photoelectric counting is the second capsule bottle filling machine generation. The infrared it applied in counting makes the great and accurate counting work. It is widely applied in many places and makes the long lasting counting work in the wide time sphere.

Electrostatic fields counting

Electrostatic Fields-Sourced:wired

Electrostatic fields counting is the cutting edge capsule bottle counting machine. The photoelectric detection is the core technology for the accurate capsule counting and filling. This tech has been into the application, but the strong position of the photoelectric counting has made the larger market.

18.Can You Take A Try Of Capsule Bottle Filling MachineBefore Purchase?

You can of course take a try of capsule bottle filling machine before purchase. And before the trying, you should consult the manufacturers. And here are the rough process of it.

Send inquiry and get contact

Send Inquiry And Get Contact-Sourced:getprospect

To try the machine, you should send an inquiry to the company and tell the materials you want to count. You should also check the loading volume, machine capacity and other information.

Send your sample

Send Your Sample-Sourced:particletechlabs

You should send your material or bottle sample to the manufacturer for the try. And you can also give the material information for manufacturer. They will help you find the similar information for you.

Try the machine

Try The Machine-Sourced:en.ac-illust

After the materials and machines are ready, the salesperson will confirm the trial operation. There will be the video for you which show the precise operation process.

Question solving

Question Solving-Sourced:depositphotos

If you have any questions about the machine, you can contact salesperson who will solve your problem and answer your questions.

Sample check

Sample Check-Sourced:vecteezy

If your want to check your sample in reality, you should contact the salesperson to get the sample. And you can also choose to check sample online. After the whole try of capsule bottle filling machine, you could then make your final purchase decision.

19.The World Top 5 Capsule Bottle Filling Machine

There are many capsule bottle filling machine manufacturers in world. And if you are still confused about the different type or brand, here are the top 5 capsule bottle filling machine, consider it seriously.

BellatRX

BellaRX Capsule Bottle Filling Machine-Sourced:Bellarx

BellaRX is the young and creative manufacturer for capsule bottle filling machine. With 20 years experience, it is leading in providing the packaging solution for packing, filling, capping, inspecting and so on. The great service, high flexibility and efficiency makes it welcomed for many business.

AIPAK

AIPAK Capsule Bottle Filling Machine

AIPAK is the manufacturer which provides the special service for pharmaceutical industry. It is the professor in providing the various pharmaceutical packaging solution. The high reliability and standard on machine manufacturing promote the production of the high qualified machines.

Unitedpharmatek

Unitedpharmatek Capsule Bottle Filling Machine-Sourced:unitedpharmatek

Unitedpharmatek is the old brand manufacturer which sticks to creation and profession. This company has rich experience in serving the various industry. Their machines are found in pharmaceutical, nutraceutical, cosmetic, food, and chemical industries. The high flexibility of this company attracts many customers.

Ascendpkg

Ascendpkg Capsule Bottle Filling Machine-Sourced:Ascendpkg

Ascendpkg began the manufacturing business 50 years ago. The machines it provide are intelligent and efficient which helps the improving of the operation performance and efficiency greatly.

CVC

CVC Capsule Bottle Filling Machine-Sourced:cvc

Established in 1979, CVC is the manufacturer which provides the pharmaceutical packaging machine like tablets counting machine, liquid filling machine, powder filling machine, bottle unscrambler, air washing machine, labeling machine, cotton inserter and so on. It is rather reliable as it gets the various international standard and regulatory certificate.

Conclusion

Capsule bottle filling machine is the great machine which can take your business much benefits. And the further knowing of it can help you a lot in its operation and purchase. If you have any problem on this machine, you should just relax to contact AIPAK now!

Don't forget to share this post!

Tablet Counting Machine Related Posts

Tablet Counting Machine Related Products

Tablet Counting Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine