Capsule Blister Packing Machine: The Complete Buying Guide In 2025

How do pharmaceutical businesses ensure the safety of their medications? How do they protect medications from the elements? How is medicine packaging tamper-proof and child-resistant? Capsules and other pills are packed in clear and secure packaging known as blister packaging. It is just not best for product aesthetics but also keeps them safe in the tamper-proof and child-resistant compartment.

This packaging requires ultimate equipment for its intricate and meticulous production and that job is accomplished with an innovative system named capsule blister packing machine. You’ve noticed a diverse series of capsule blister packing machines in the market. And that would’ve perplexed you.

But it’s okay. You’re exactly where you need to be. As, in this blog post “Capsule Blister Packing Machine: The Complete Buying Guide In 2024”, we’ve compiled every answer to your questions about a capsule blister packing machine. Let's get going!

1.What is meant by a capsule blister packing machine?

Capsule Blister Packing Machine

Imagine a pill packed in the blister. How this blister is formed? Well, a special device termed a capsule blister packing machine is mainly involved in the creation of blister packs (clear or opaque cavities for filling the products) by heating and molding different kinds of materials, such as PVC or aluminum.

This machine usually employs a formable web, such as thermoplastic to create heated molds and then loads the pharmaceutical products and other consumer items in these molded cavities. It heats the plastic polymers until they are malleable and then casts these web-like structures in molds to form a pocket base. This pocket exactly matches the contours of the product thus forming the safest cavity.

2.How does a capsule blister packing machine boost your business income?

Businesses are always seeking different ways to maximize their profit rates, so that’s why, they invest in machines to optimize profitability. These devices are a proven solution for enhancing production throughput and reliability. A capsule blister packing machine is no exception to this rule. Indeed! It improves your business income in different ways, including:

Enhancing Production Volume

Enhancing Production Volume- Picture Courtesy: Jornen Machinery

It is the first and foremost benefit due to which a capsule blister packing machine is the leading choice of machinery in every manufacturing area. It has refined and cutting-edge components that enable this machine to manufacture a large volume of blister packs in a relatively short span. It is on the must-have machine list of every pharmaceutical brand because it outputs an increased volume of packaged products.

Besides this, you can quickly changeover between batches, as it has conveniently adjustable settings and components. So, you can effortlessly reduce idle time in your facilities.

Say Yes to Product Protection

Say Yes to Product Protection

By packing products, a capsule blister packing machine offers absolute protection. It shields the pills and other products from weather elements, for instance, UV light, air, humidity, and high temperature by enclosing them in tight cavities. Furthermore, you can avoid both physical and biological contamination by blister-packing them.

In this way, this machine ensures product potency and prevents wastage. Every capsule reaches in intact form to the market and customers without damage in any way or form with the advanced product detection systems of this machine.

Branding and Customer Loyalty

Branding and Customer Loyalty

Branding isn’t about advertising your product but also about making the customers happy. So, yes, a capsule blister packing machine is an undeniable way to uplift brand image by packaging capsules in customized packaging. You can provide unmatched convenience to customers as each dosage is placed in a different compartment that helps patients track dosage more easily. There is no chance of forgetting or missing a dose.

This machine manufactures tamper-proof packaging and ensures capsules are not tampered with. This lays customer worries at rest, building a strong customer base and bolstering possibilities of repeated buying.

Cutting-Down Production Costs

Cutting-Down Production Costs- Picture Courtesy: Jornen Machinery

In these economically difficult times, cutting down operational costs provides a great deal of financial security to companies. Therefore, pharmaceutical brands rely on a capsule blister packing machine to conserve the use of packaging materials and minimize packaging waste. This saves firms from buying more and more packaging films.

Also, this instrument is built to run on low energy, which decreases your utility bills.

Processing a Broad Range of Products

Processing a Broad Range of Products

One of the major pros of a capsule blister packing machine is its ability to process a wide array of products. Thus, productions include diverse product types in their catalog and captivate customers from far and wide corners of the world.

You can easily alter the programming protocols of this equipment to create a custom-made blister packing. Thereby, you can create a unique product display to stand out among tough competitors and earn brownie points with your customers.

3.Do you know in what manufacturing sectors a capsule blister packing machine is used?

When you wonder about the uses of the capsule blister packing machine, the pharmaceutical industry comes first in mind. But do you know that the use of a capsule blister packing machine is not limited to the healthcare field? Subsequently, for your information, we are penning some useful applications of this equipment.

Pharmaceutical Industry

Blister Packaging- Picture Courtesy: SED Pharma

With the revolution in pharmaceutical packaging, a capsule blister packing machine is found in almost every type of pharmaceutical manufacturing. Indeed! Every kind of pill, capsule, suppository, ampoule, and vial is packed by this device to safely distribute them to the market without any contamination risk.

Medical Industry

Syringe Blister Packaging- Picture Courtesy: Jornen Machinery

Medical devices, for instance, diagnostic vials, test strips, syringes, needles, and catheters are e breakable and could be damaged if mishandled. Therefore, to keep them from breaking and uphold their safe use, you must have seen them in blister packaging. Surely! You can produce this packaging with a capsule blister packing machine in order to maintain the sterility and protection of medical instruments.

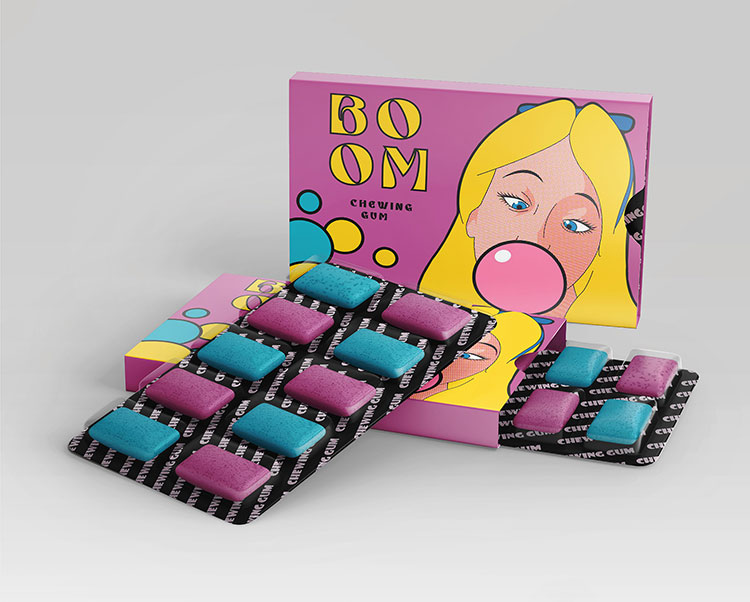

Food Industry

Gum Blister Packaging- Picture Courtesy: Behance

Visualize the utility of the capsule blister packing machine in the food industry! Yes, it is a foolproof approach to secure different kinds of confectioneries, such as mints, chocolates, candies, sweeteners, etc. in clear and sturdy blister packaging. Blister packs are meant to keep food items fresh and tempt customers into buying.

Cosmetic Industry

Cosmetic Capsule Blister Packaging- Picture Courtesy: Aenova Group

Cosmetic packaging has sure come a long way and today, there is a variety of cosmetic packaging for purchase. One of them being cosmetic blister packaging. You would’ve bought skin care products, cosmetic capsules, lipsticks, eyeshadows, and more in the blister packs. And it is only possible with the use of a capsule blister packing machine in the cosmetic industry.

Hardware Industry

Hardware Blister Packs- Picture Courtesy: Thermoforming Plastic Sheet

Hardware companies make use of a capsule blister packing machine to enclose and seal their products, such as screws, nuts, bolts, nails, and other small items. The blister packs are essential in restricting their movement and in turn, keeping them from scratching the packaging.

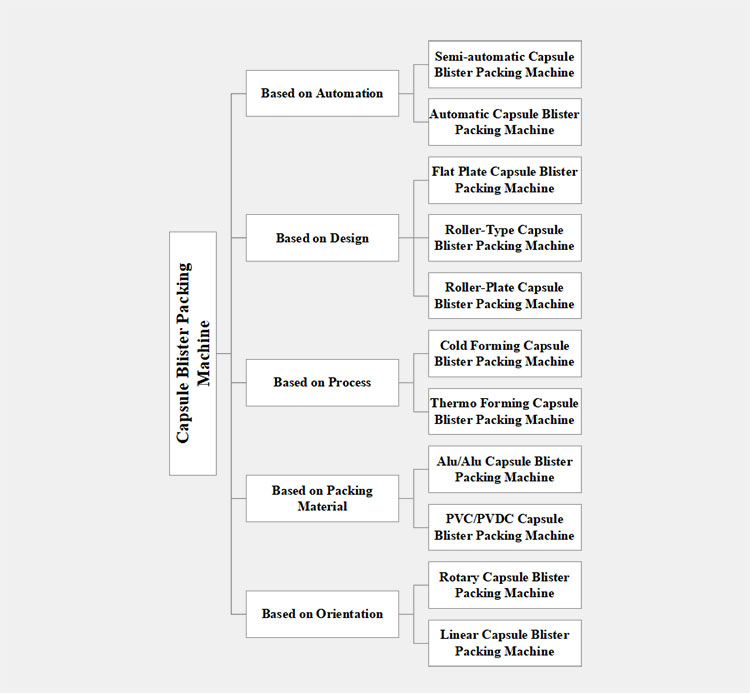

4.Enlist different types of a capsule blister packing machine.

With the revolution in types of machinery, every day you have a new version of a capsule blister packing machine arriving in the market. Causing difficulty in the selection process for the manufacturers like you. So, we’re accounting for the classification chart and its description of a capsule blister packing machine to enable you to make the perfect choice for your business:

Based on Automation

Semi-automatic Capsule Blister Packing Machine

Semi-automatic Capsule Blister Packing Machine

If you’re looking for a machine that has an ideal balance of both automatic processing and manual intervention, then a semi-automatic capsule blister packing machine is perfect for you. It needs human operators to place pre-cut plastic foils on the blister-forming station and deposit capsules in the hopper.

Other functions, for instance, blister formation, capsule filling, and heating are carried out automatically in this machine. Definitely, it is an effective way to enhance your production efficiency.

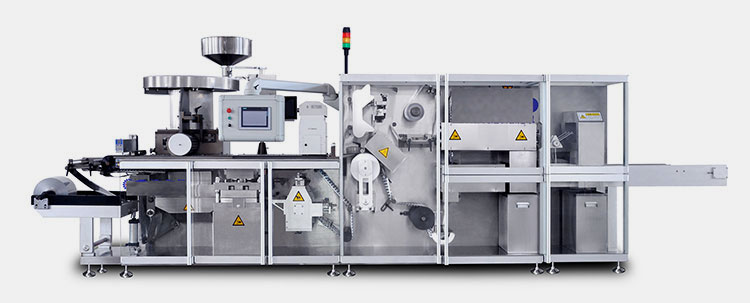

Automatic Capsule Blister Packing Machine

Capsule Blister Packing Machine

It is a highly advanced version of the capsule blister packing machine when the latter is categorized based on automation. Are you thinking about its advantages? Well, it is a must-have packaging unit in huge-scale processing units because it has automatic functioning and easily caters to the operational requirement of large-batch production.

With its automation at every step (loading, blister formation, filling, sealing, and cutting), it doesn’t require heavy human supervision, which saves labor expenses.

Based on Design

Flat Plate Capsule Blister Packing Machine

AIPAK Flat Plate Capsule Blister Packing Machine

As the name suggests, this instrument is comprised of a flat plate, used for both filling and sealing. It utilizes positive pressure or compressed air to place hot plastic film in the mold cavities and then a flat plate is pressed on the molding to form blisters. You can use this machine to create blisters of even thicknesses and large sizes.

It has the huge benefit of cost-effectivity and straightforward operation.

Roller-Type Capsule Blister Packing Machine

Roller-Type Capsule Blister Packing Machine

This type of capsule blister packing machine has a series of rollers to transfer film to the blister-forming station. This machine employs a negative pressure or vacuum system to introduce plastic sheets in the moldings. After capsule filing, the servo-driven rollers move the blister packs to the sealing unit. Here sealing step is carried out on these rollers. The finished blisters produced by a roller-type capsule blister packing machine are small-sized, have a thinner top, and have irregular stretch.

Roller-Plate Capsule Blister Packing Machine

Roller-Plate Capsule Blister Packing Machine- Picture Courtesy: Hoping Machinery

You’ve guessed it right! This machine combines the working of both flat-plate and roller-type capsule blister packing machines because it has both flat-plate and rollers. The flat plates are used for blister formation, whereas, the rollers are well-recognized because of their involvement in the sealing process.

Based on Process

Cold Forming Capsule Blister Packing Machine

AIPAK Cold Forming Capsule Blister Packing Machine

This machine is quite distinct from its counterpart. Because it doesn’t apply heat to form blisters. So, how does it perform its job? Simply, by using mechanical pressure. Two diverse types of molding- concave and convex- are used to press aluminum laminates and mold them into required shapes.

This machine offers a higher level of protection than its thermo-forming counterpart. However, it takes more time to create blister cavities and has a higher price tag.

Thermo Forming Capsule Blister Packing Machine

Thermo Forming Capsule Blister Packing Machine- Picture Courtesy: SED Pharma

By reading its name, you can foretell that this machine exploits heat in its operation. Plastic polymer films are softened using high temperatures and then shaped. You use aluminum foil as the back sealing material in this instrument.

It is employed for packaging less sensitive capsules that do not require extreme moisture, air, and light protection. The usage of thermos-forming capsule blister packing machines is widespread in the pharmaceutical sector because they offer faster blister production rates and are more affordable devices than their corresponding machines.

Based on Packing Material

Alu/Alu Capsule Blister Packing Machine

AIPAK Alu/Alu Capsule Blister Packing Machine

It is dissimilar to other capsule blister packing machines. Owing to its packaging material utility. It only utilizes aluminum foils for producing both blister and lidding materials. Also, it does not need heating elements to make blister pockets. This machine is highly renowned due to its superior moisture and light shielding effects.

It packs light-sensitive, thermos-sensitive, and other potent capsules that are degraded if packed in plastic blister packs. Hence, it is ideal for maximizing the protection and potency of these capsules over time.

PVC/PVDC Capsule Blister Packing Machine

PVC/PVDC Capsule Blister Packing Machine- Picture Courtesy: Hualian Pharmaceutical Machinery

This kind of capsule blister packing machine utilizes plastic films, for instance, PVC, PVDC, or PET in addition to aluminum foil. In this machine, the blister molds are formed from plastics whereas, aluminum or laminated materials serve as a lidding material. Since it is easier to mold plastic than aluminum, therefore, PVC/PVDC capsule blister packing machine is way quicker than the Alu/Alu capsule blister packing machine.

You can create lightweight and transparent blisters using this device.

Based on Orientation

Rotary Capsule Blister Packing Machine

AIPAK Rotary Capsule Blister Packing Machine

It is a high-speed capsule blister packing machine best known for its continuous and swift processing. It has a rotary configuration with cylindrical rollers or rotary molds to create, load, and seal blister packs. Typically, you can have a thermoforming blister packaging machine in a rotary orientation but cold-forming machines can be also customized with a rotary structure.

How does it have faster productivity? Since it simultaneously forms, fills, and seals, different blister packs at various stations, thus it is more efficient.

Linear Capsule Blister Packing Machine

AIPAK Linear Capsule Blister Packing Machine

This machine has a straightforward and horizontal configuration. Each station is present one after the other in this machine and the packaging film moves one station at a time. You can easily check and regulate each working step in this machine.

It has simple operativity and maintenance because you’ve easier access to all its parts.

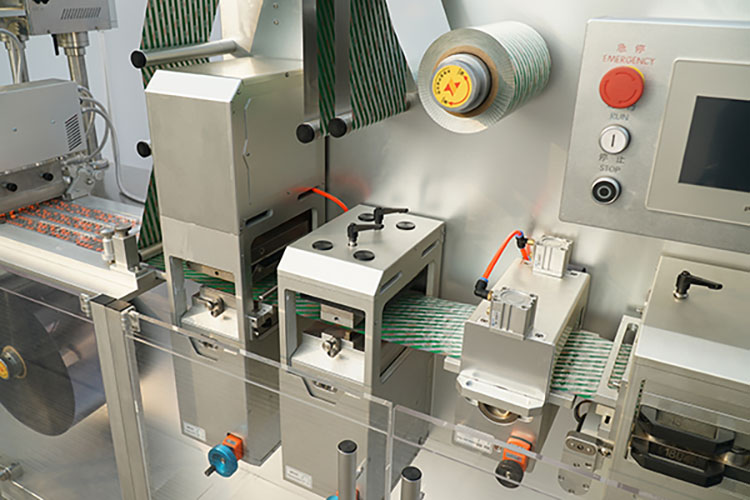

5.How to define the working principle of a capsule blister packing machine?

The working principle of a capsule blister packing machine is somewhat complicated and involves heating of packaging film and the formation of even blisters on melted film, which are ultimately filled with products. Finally, the filled blisters are sealed on the reverse side with aluminum or cardboard paper. Now, let’s discuss the details of the working steps of a capsule blister packing machine:

Unwinding

Unwinding- Picture Courtesy: Jornen Machinery

At the beginning of the operation, packaging film materials, such as plastic polymers and aluminum foils are loaded on an unwinder called a foil un-coiler. Usually, the bearing rollers present in a capsule blister packing machine hold the job of transferring the film to the forming station.

Blister Forming

Blister Formation- Picture Courtesy: Jornen Machinery

In this step, you’ll observe the pliability of the plastic film. This film is typically heated at high temperatures of about 110-130 °C with either radiant (using infrared rays) or conductive (direct heating source) heating methods. Once heated, now the film is ready to be molded into the desired shape. It is the central step in the working of the capsule blister packing machine.

There are various approaches to the blister-forming process:

In blister forming or negative pressure forming approach, pliant plastic film is drawn into mold vents by the vacuum suction. On the other hand, in blow molding or positive pressure formation, compressed air is flown from above to propel the plastic film into the plate mold for blister forming.

Whereas in the punch-assisted blow molding, the malleable film is hit by the punch-like device and afterward, compressed air is blown to force fit film within molds. In the cold stamping method, two convex and concave molds are used for cold-forming blisters without using any heat.

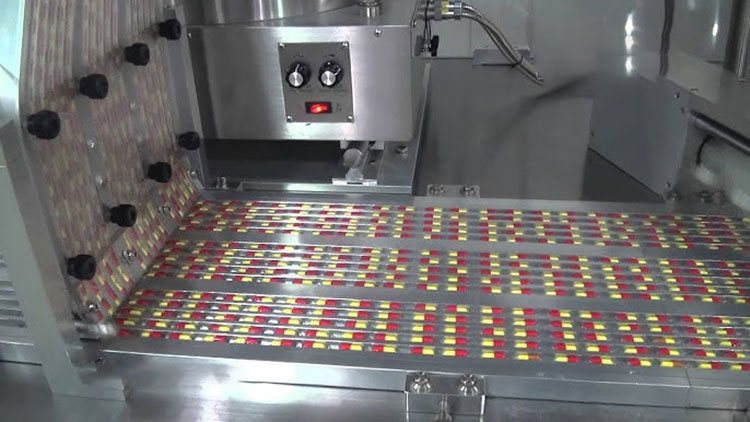

Capsule Placement

Capsule Placement- Picture Courtesy: Jornen Machinery

As soon as blisters are formed, the molded film is transferred to the filling station with the help of a driving device. The capsules are filled in the hopper and using a rotary or vibratory feeder, they are moved to filling devices. The filling mechanism consisting of the soft brushes is responsible for precisely depositing capsules into empty blisters.

Sealing

Sealing- Picture Courtesy: Jornen Machinery

After the completion of the capsule filling step, you’ll now see the filled blister film traveling toward the sealing station. At this unit, the substrate (normally aluminum foil in the case of capsule packaging) is heat-sealed on top of the blister by two diverse methods.

In the rolling type sealing method, the blister and aluminum foil are pressed between two rollers under the desired temperature and pressure for a short time to acquire a high-quality seal.

In the plate pressing method, a hot sealing plate and a bottom template are employed for pressing the blister and aluminum foil together. You would’ve noticed a texture or shape on the sealed aluminum foil, it is because of mesh texture or raised contours on the sealing plate or roller. It improves packaging appeal and increases sealing impact.

Trimming and Rejection

Trimming and Rejection- Picture Courtesy: Ascend Packaging System

You can observe that capsule blister packing is roughly completed after going through the sealing step. The sealed blister is carried out to the trimming station, where its corners are rounded. Moreover, a breakable short mark is pressed on the blister for easy splitting at the trimming station.

After trimming, the essential product information is printed on the blisters. And lastly, the poor-quality or defective blisters are rejected from the machine. Only qualified blisters are moved for cartoning packaging.

6.What is the structural framework of a capsule blister packing machine?

Hopefully, you would’ve understood the working of a capsule blister packing machine, now let’s discuss its structural framework consisting of different parts.

Parts of Capsule Blister Packaging Machine

| Film Unwinder | The plastic film or aluminum foil is first placed on the film unwinder. Its function is to uncoil the film and move it to the forming station. It is a part that prevents any tension issues in the film and transfers it smoothly and steadily to the next unit. |

| Forming Station | You must’ve thought about the part responsible for blister cavity formation. Well, this task is successfully handled by the forming station. The heating elements and mechanical parts aid in molding cavities in film sheets using heat or pressure, respectively. |

| Capsule Feeder | It is the main component that carries out the loading of capsules in the empty blister pockets. The capsule feeder deposits capsules at steady speeds. It is meant to make the whole procedure of capsule packaging smooth. |

| Hopper | It is a cylindrical part in which you load the capsules in bulk amounts. During the operation of the machine, it continuously directs capsules to the capsule feeder. The hopper part has in-built release systems that enable capsule movement in a regulated manner. |

| Touch Screen | You can think of a touch screen as the brain of the machine. It is equipped with a PLC control unit that is involved in the processing of commands and transmits the signals to various instrument components. You can program and set parameters for accurate working using this intelligent interface. |

| Heat Sealing Station | Blisters are securely sealed with aluminum foil. Which part performs this job? It is done by heat sealing devices that firmly bond the suitable lidding materials at the top of the blister. Using this component, you can keep the packed capsule in place. |

| Indentation Station | It is like a sculptor. Because it presses indentation to the blister pack for easy identification of a single blister pocket. Moreover, the indentation unit boosts the texture and appearance of the packaging. |

| Traction Station | You certainly would’ve seen a smooth stretch of blister pack. How is it done? A specialized device is present at the end of the equipment and properly stretches the film without causing any wrinkles, creases, or folds in the film. |

| Alarm Light | It acts as the safety inspector of the device. When any kind of malfunction is identified in the machine, the alarm light lights up and sounds an alarm to inform operators about the said machine's failure. |

| Waste Collection | You surely desire machines that generate less waste. Your wish is certainly granted by the waste collection device found in a capsule blister packing machine. It gathers unused or surplus film and foil materials after the blister pack cutting. You’ll obtain a clean workstation through this device. |

| Cutting Station | The job of the cutting station is to trim the corners of blister packs. In addition to this, you’ll acquire individual blister packs from a continuous stretch of blister sheets using this device. |

| Product Discharge | It is a rectangular chute located at one end of the machine and collects and discharges fully formed and cut blister packs from the machine into a collection bin. |

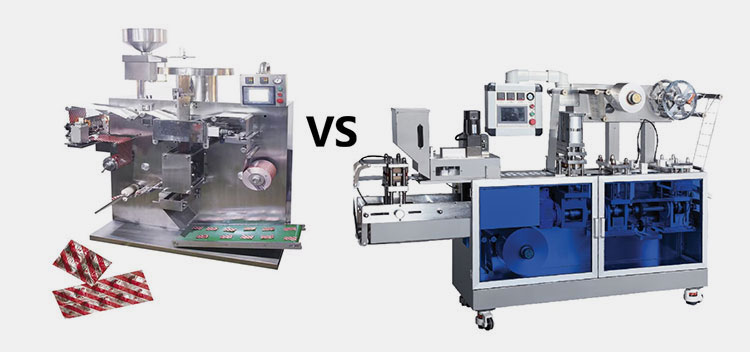

7.What are the differences between a capsule blister packing machine and a strip packing machine?

The strip packaging machine and capsule blister packing machine are two superheroes of the packaging era that help you bring promising solutions in terms of high production, safety, and compliance. Both machines possess some distinction in various ways. We have discussed them just right below:

Strip Packing Machine VS Capsule Blister Packing Machine

Type of machine

| Strip Packing Machine | Capsule Blister Packing Machine |

| Just understand the term strip, which means an uninterrupted sheet with a series of individual numbers of solid dosage forms. This machine is capable of flowing sealing materials, where your products are fixed and packed with the help of a heat-sealing system to form a unique packet. | Blister means a cavity, this machine forms a hollow cavity, where your capsules are accommodated safely and can be stored without harming their structure throughout various processing of shipping, storage, and marketing. A capsule blister packing machine uses materials polyvinyl chloride, polystyrene polypropylene, and aluminum for the formation of blister packing. |

Type of Packaging

| Strip Packing Machine | Capsule Blister Packing Machine |

| The machine generates a continuous process of placement of medication following a non-stop series. | This machine produces an individual pocket for the positioning of the medication. |

Level of Protection

| Strip Packing Machine | Capsule Blister Packing Machine |

| The machine offers you moderate protection in terms of physical and chemical environment. | This machine is highly protective in terms of providing safety to your medication, as it keeps the medicine in individual pockets that are capable of bearing shocks and maintains its quality and integrity for a longer time. |

Budget

| Strip Packing Machine | Capsule Blister Packing Machine |

| This machine is quite budget-friendly and can be affordable to you. If you’re running a small business or conscious about maintaining the budget, then it is a good option for you. | As compared to a strip packing machine, this is way more expensive, but it is hooked to many properties and benefits for small, moderate, and larger batches. |

8.How can you resolve various operational issues in a capsule blister packing machine?

A capsule blister packing machine is well-accepted in the manufacturing sector because of its optimized performance and precision in making blisters. However, you sometimes have an operational issue in your equipment that disturbs the nonstop flow of operations and decreases your packaging output.

As every problem has a silver lining, consequently, you can troubleshoot your machine without going for heavy repairs and replacements. We are writing some operational issues and their solution for you:

Blister Cavity Don’t Have Proper Shape

Blister Cavity Don’t Have Proper Shape- Picture Courtesy: MedicalExpo

Have you come across asymmetrical shapes or sizes of blister cavities? There could be diverse reasons for this, for instance, you might have set the wrong temperature inputs or your molding station is old and damaged. It is also due to irregular film tension.

Solution

To solve this problem, you should inspect the settings of temperature and alter them according to your protocols. You might need to change your molds and dies if they are significantly worn out. Don’t forget to check the alignment and working of rollers for even film tension.

Misalignment of Film Flow

Misalignment of Film Flow- Picture Courtesy: Jornen Machinery

Are there problems with your film feeding? Is it sagging or extremely tight? Well, different causes can contribute to this issue, like inadequate film tension or defects in the film driving system (rollers and unwinding disk).

Solution

You can solve this issue without any difficulty by altering the film tension so that you have consistency in the film feed. You mustn’t neglect to check film rollers for blockage, misalignment, or fault and rectify the issue with rollers. Cleaning and lubricating rollers and drive parts are the best ways to prevent obstruction or sagging of film in the first place.

Sealing is Weak or Unfinished

Sealing is Weak or Unfinished- Picture Courtesy: Jornen Machinery

Do you discover blisters with weak or unfinished sealing in your production? You must be worried about this problem, as it can result in the dropping of capsules from packaging.

Solution

It is recommended to input the correct temperature and pressure parameters on the control panel so that they’ll match the specification of sealing materials. You should inspect, clean, and, align the seal rollers on a routine basis to have flawless blister sealing. To have uniformity in seal quality, you should regularly calibrate sealing components.

Errors in Capsule Feeding

Errors in Capsule Feeding- Picture Courtesy: Jornen Machinery

Is capsule feeding in the blister not going to your expectations? There could be various factors attributed to this problem, for example, defective or damaged capsule feeding systems, errors in alignment of sensors, and, capsule jamming.

Solution

You must pay attention to the capsule feeding system. Align it. Replace the hopper or feeding chute if they have significant damage. You should clean the feed system on a daily basis to avert capsule jamming. Checking and calibrating sensors is a definite way to have proper identification and loading of capsules in blisters.

Conclusion

A capsule blister packing machine is one of the highly popular packaging units to generate safe, protective, sturdy, and durable blister packs in not only the pharmaceutical industry but also food, medical, and other industries. Its multi-stations (blister molding, filling, sealing, indenting, cutting) enable you to acquire error-free results. So, to elevate your packaging experience, you’re invited to explore the wide-ranging catalog of AIPAK. We’ve several years’ worth of experience in fabricating machines that will surely revolutionize your packaging flow.

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine