Capsule Automatic Filling Machine: The Complete Buying Guide In 2025

Capsule has entered our daily life, such as drugs, and health products. Do you know how capsules are formed? Capsule automatic filling machine plays a vital part in the whole production process of capsules.

A suitable capsule automatic filling machine can improve the production efficiency, save cost and has other benefits. To be honest, choosing a suitable machine is not a simple task.

If you want to know this kind of machine, please read this article, I will provide you a complete buying guide for capsule automatic filling machine.

1.What is Capsule Automatic Filling Machine?

Allpack Capsule Automatic Filling Machine

The capsule automatic filling machine is a device applied to fill materials into capsule shells. This machine involves lots of material, which has gained favor from many factories due to its various factors, and it does not require manual assistance to operate.

2.What are the Strengths of the Capsule Automatic Filling Machine?

Do you know why do so many factories introduce this kind of machines? The reason lies in its various strengths.

(1)Improving production efficiency

Improving Production Efficiency - Sourced: Universe Capsules

Production efficiency is the top priority for factories. With an automation system, this kind of equipment can significantly enhance its speed. Typically, such machines can filling between 2,500 and 7,500 capsules per minute.

(2)Enhancing accuracy

Accuracy is directly related products’ quality, but the ordinary filling machine may exhibit filling accuracy variations ranging from approximately ±5%. In contrast, automatic capsule filling machines are approximately ±2-3%.

(3)Safeguarding products’ safety

Safeguarding Products’ Safety - Sourced: South Central Public Health District

Safety of capsules is directly related to customers’ life and health. Most capsule automatic filling machines have an automatic cleaning system inside, which can prevent any dust or impurities from entering the middle of the capsule, thereby ensuring the quality and safety of the product.

(4)Saving materials

Ordinary capsule filling machines may cause material waste without high automation system. The capsule automatic filling machines can reduce the waste of material. Thereby it can reduce the cost of the factory.

(5)Easy to use

Modern equipment is equipped with a display screen, which can clearly display various parameters. You can follow the instructions to operate, which is simple and easy.

3.What are the Applied Industries of Capsule Automatic Filling Machine?

As you can see, many drugs, health products, and skincare products you take are in the form of capsules. Therefore, this capsule automatic filling machine has extensive applications in these areas.

(1)Pharmaceutical industry

Drug - Sourced: Mankind Pharma

Beyond all doubt, the most extensive application field of this equipment is the pharmaceutical industry. Many cold medicines, painkillers, and other medications we take are all in the form of capsules for better swallowing.

(2)Health care products industry

Health Product - Sourced: Prime Health

At present, some of the health care products we eat also come in capsule form. Health care product manufacturers add some nutrients, such as vitamins and traditional Chinese medicine, to empty capsules through capsule automatic filling machines.

(3)Cosmetic industry

Capsule For Cosmetics - Sourced: In-cosmetics Connect

Have you ever tried skincare products in the form of soft capsules? The cosmetics factories uses capsule automatic filling machines to produce a large number of oral soft capsules, which can improve the skin color and enhance the skin condition of customers.

4.How Many Types of Capsule Automatic Filling Machine and Their Differences?

The market offers a wide array of machines, often overwhelming in variety. Do you want to know how many types of this equipment are available? The answer is capsule fully automatic filling machine and capsule semi-automatic filling machine. What’s the difference between them?

Different Types of Capsule Automatic Filling Machine

| Capsule Fully Automatic Filling Machine | Capsule Semi-Automatic Filling Machine | |

| Efficiency | This kind of machines can operate for a long time and have higher work efficiency. | This kind of machines require manual intervention, which is lower than fully automated machines. |

| Applicable factory scale | The output is relatively low, but it can meet the needs of small-scale production. Therefore, it is suitable for large-scale factory use. | It is suitable for use in small and medium-sized factories. |

| Filling accuracy | It adopts precise control system and measuring system, with high filling accuracy. | It requires manual intervention, which may result in errors and affect the accuracy of canning. |

5.What Material Can be Packaged by Capsule Automatic Filling Machine?

What are the ingredients in the capsule you are eating? Do you want to know what materials the machine can package? Let’s explore them one by one.

(1)Powder

Powder- Sourced: Westend61

Many drugs are ground into powder, such as vitamins and herbs, and filled into capsules. Powder is the most common material in capsules and can be mixed with other materials for easy filling.

(2)Pellets

Pellets are also commonly used materials for capsules, often with very small sizes. Pellets are generally made from plant extracts, caffeine, etc.

(3)Liquid

Soft Capsules - Sourced: MPI

Soft capsules often contain liquids such as gelatin, glycerol, etc. This type of filling machinery is capable of filling liquids to create soft capsules.

6.What Capsule Size Can Capsule Automatic Filling Machine Handle?

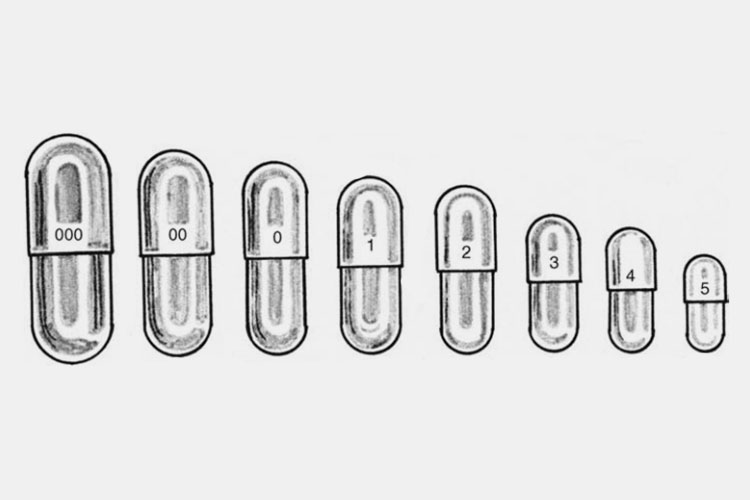

Do you know the capsule sizes of a typical capsule automatic filling machine? The answer is from #000 to #5, the detail date as follow. According to specific product differences, some machines may not be suitable for all sizes.

Capsule Size - Sourced: pharmacy180

The table below displays the detailed information of eight different sizes of capsules, including external diameter, length, capacity, and weight.

| Capsule size | External diameter (mm) | Length (mm) | Capacity (ml) | Weight (mg) |

| 000 | 9.91 | 26.14 | 1.37 | 163 |

| 00 | 8.53 | 23.30 | 0.91 | 118 |

| 0 | 7.64 | 21.70 | 0.68 | 95 |

| 1 | 6.91 | 19.40 | 0.50 | 75 |

| 2 | 6.35 | 18.00 | 0.37 | 60 |

| 3 | 5.82 | 15.90 | 0.30 | 47 |

| 4 | 5.31 | 14.30 | 0.21 | 38 |

| 5 | 4.91 | 11.10 | 0.13 | 28 |

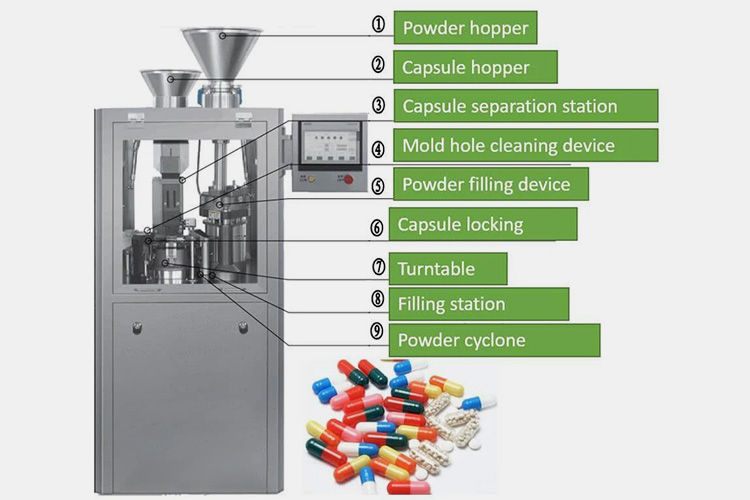

7.What are the Key Parts of Capsule Automatic Filling Machine?

As a large machine, this type of machine contains many components. Do you know how many parts a capsule automatic filling machine has? Do you know which specific parts they are? Well, let’s move to know its key parts.

Parts of the Capsule Automatic Filling Machine

Powder hopper

This part is used to store materials such as powder and pellets, usually made of stainless steel.

Capsule hopper

This component is used to store capsule shells and is generally made of stainless steel material.

Capsule separation station

Capsule Separation Station - Sourced: SaintyCo

This part separates the capsule cap and body through vacuum, making it easier to fill materials.

Mold hole cleaning device

This cleaning device is specifically designed for flushing mold holes. They usually use high-pressure water flow or chemical solvents to remove impurities from the mold holes, which have the characteristics of high efficiency, speed, and safety.

Touch screen

By setting parameters through this section, it is convenient for staff to operate and monitor the running status. You can adjust the operation function, set filling speed, capsule size and other parameters.

Filling device

This part serves the purpose of inserting materials into capsule shells.

Capsule lock

The device fixes the capsule cover and shell together to form a capsule.

Turntable

Turntable - Sourced: SaintyCo

The turntable has a rotating mechanism, good sealing, easy disassembly, and is used for transporting capsules.

Filling station

This part uses a tamping needle to quantify and fill powder, without the need to stop and adjust the filling amount, making it more convenient.

Power cyclone

This component separates the powder and uses the force of swirling to precipitate and separate the powder, thereby obtaining a higher purity of powder.

8.What is the Workflow of Capsule Automatic Filling Machine?

Have you seen the workflow of capsule automatic filling machine? How many stages do we need to go through? This kind of equipment will experience four stages:

| Step 1: Capsule and material delivery | Empty capsules and materials are respectively fed through their respective feeding ports. And it is guided by directional devices to reach the packaging room for the next round of work. |

| Step 2: Dividing the capsule into its cap and main body | For better filling, utilizing vacuum technology to divide the capsule into its cap and body. |

| Step 3: Filling material into capsule | In the filling process, materials such as powder and pellets are filled into the main body of the capsule. |

| Step 4: Locking | In the sealing process, the machine fixes the capsule cover and shell together to form a capsule. After sealing, the capsule is discharged from the capsule filling machine. |

9.What Quality StandardsShould the Capsule Automatic Filling Machine Follow?

In order to ensure the quality of the product, the capsule automatic filling machine needs to strictly comply with various rules and regulations.

(1)ISO 9001

ISO 9001 - Sourced: 3SC

The capsule automatic filling machine must strictly comply with ISO 9001 in all processes of production, safety, and debugging to ensure the safety of the entire product process.

(2)ISO 14001

ISO 14001 - Sourced: Glass and Glazing Federation

This is an environmental standard that stipulates that enterprises must reduce environmental pollution and strictly follow the standard during the production of capsule automatic filling machines, thus achieving green production.

(3)cGMP

When using a capsule automatic filling machine to produce capsules, strict adherence to cGMP is required. Once deviations occur, inspections should be conducted to ensure product quality.

10.How to SelectAn Appropriate Capsule Automatic Filling Machine?

Have you developed feelings for capsule automatic filling machine? Do you know how to choose an appropriate machine? Next, we will provide you with some things to consider when making a purchase.

(1)Clarifying your own requirements

Clarify Your Own Requirements - Sourced: Medium

The first step is that you need to clarify your own needs, as different specifications of capsule automatic filling machines have different functions. Selecting the suitable equipment according to your specific requirements, including the material and size of the capsules.

(2)Reasonably allocating budget

The prices of different machines is diverse, so you need to allocate your budget reasonably based on your own financial situation and try not to exceed it. You can carefully compare prices and choose products with reasonable prices.

(2)Brand

Brand - Sourced: Oyava

The prices of this equipment from different brands vary. When selecting capsule automatic filling machines, we should choose products with a certain reputation. Large brands have relatively better after-sales and service.

The capsule this device is a consumable machine. If you purchase a machine with poor quality, it is inevitable that there will be some minor problems in future production, and maintenance will be a significant expense.

(3)Visiting factory

Visiting Factory - Sourced: Istock

The price of capsule automatic filling machines is not cheap. As a large machine, when purchasing, you need to conduct on-site inspections to gain a deep understanding of the machine’s performance. Through on-site inspections, understand the production situation of the enterprise, and through actual machine operation, feel whether the machine is convenient to use and whether its functions are complete.

11.How to Maintain A Capsule Automatic Filling Machine?

Regular maintenance can protect the performance of the machine. Do you know how to maintain this kind of machines?

(1)Cleaning it regularly

If the capsule automatic filling machine is not cleaned for a long time, a lot of dust will appear, which will affect its filling efficiency. Capsules are related to people’s physical health. If capsules contain impurities or dust, it can affect the safety and quality of drugs or nutritional supplements.

After each use or after use, residual drugs on the machine and in the mold holes should be cleaned to keep the whole machine clean and hygienic.

(2)Lubricating all the moving parts

Lubricating All The Moving Parts - Sourced: Electrical Apparatus

As is well known, if the machine is not lubricated, the frictional resistance will increase, greatly reducing the efficiency of the machine. Therefore, relevant personnel need to regularly lubricate this kind of filling machine.

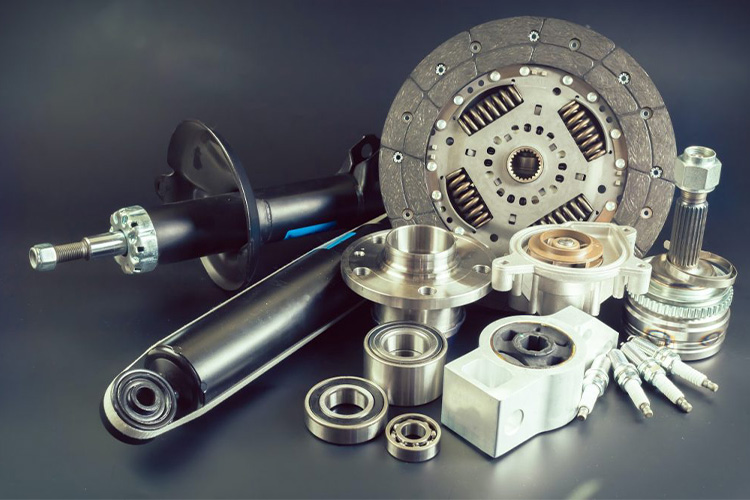

(3)Replacing worn-out parts

Replacing Worn-out Parts - Sourced: BJ Wreckers

Long term operation of the machine inevitably leads to some problems. Staff need to regularly inspect various components and replace damaged ones in a timely manner to avoid affecting the operation of the machine, thereby increasing time and labor costs.

12.How to Solve Common Issues of Capsule Automatic Filling Machine?

Long term use of machines inevitably leads to some problems. Do you know which ones? Do you want to know how to solve it?

Common Issues And Solutions - Sourced: MyClass - BIBF

| Common issues | Solutions |

| Material leakage | Check if the material inlet exceeds the recommended amount and try to reduce the material. |

| Incomplete capsule separation | Using tension measurement tools to set the separation pin tension. Adopting laser alignment tools for alignment check. |

| Inconsistent capsule weight | The main reason is that the control system has errors. Timely replacement of the control system can maintain consistent speed. |

| Capsule shell blockage | Capsules need to be kept within a certain temperature and humidity range, otherwise it will affect the state of the capsules, so strict environmental control should be implemented for capsule storage. |

13.The Future Development Trend of Capsule Automatic Filling Machine.

With the continuous advancement of technology, capsule automatic filling machines are also constantly being updated and upgraded, with increasingly comprehensive machine performance.

Multifunctional

With the strengthening of research and development efforts, capsule automatic filling machines in the future will have more functions. The detailed functions include the ability to achieve more efficient filling and the ability to simultaneously fill different materials.

Intelligent

Intelligent - Sourced: Search Engine Land

The development of technologies such as artificial intelligence promote that capsule automatic filling machines in the future more intelligent. The machine will automatically detect problems that exist during machine operation, propose solutions, and make automatic adjustments, greatly improving work efficiency and reducing time and labor costs.

Conclusion

Capsule automatic filling machines are used in lots of industries due to their unique advantages. Have you gained a better understanding of capsule automatic filling machines after reading this article? For any additional inquiries about this machine, you can contact Aipak at your convenience.

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine