Your Best Automatic Capping Machine

- Suitable For Multiple Industries

- Strong Compatibility

- No Bottle Or Cap ,No Work

- Fault Self-diagnosis Alarm

AIPAK Capping Machine

AIPAK capping machine can be used to fasten the caps / covers on bottles in pharmacy, cosmetics, foods, drinks and so on.It is a flexible and multifunctional capping machine, that can be used to fasten various caps / covers with screw inside.All AIPAK capping machines adopt advanced PLC with touch screen operation system, that is easy to operate, and simple adjust to applicable with different sizes caps. This machine can be used independently, and also can be assembled with various production lines.

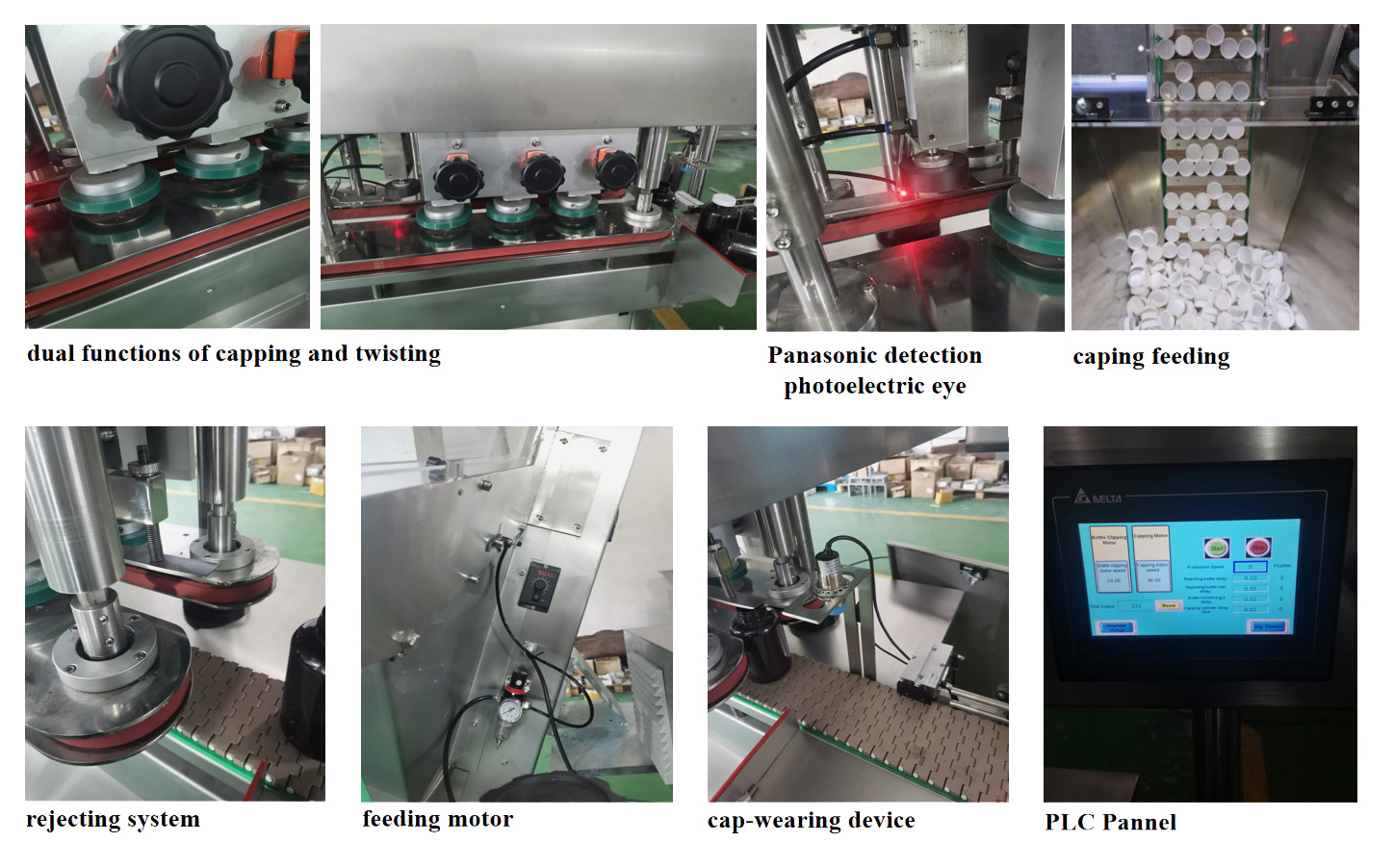

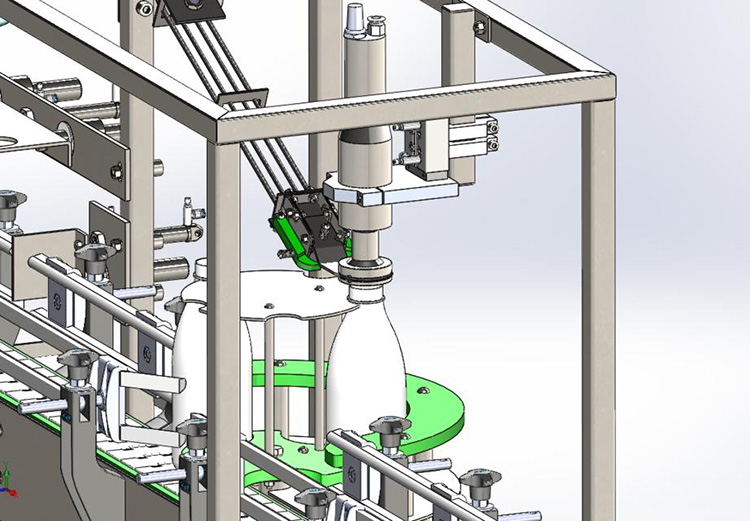

Main Structure Of Screw Capping Machine

Why choose AIPAK

Working with market leaders in the On-demand manufacturing industry, without the busyness and risk.

Consistently High Quality

Every parts applied in our machines are through precise R& D and design,all our machines must be inspected before delivery.All AIPAK machines are automatic that is easy to use and maintain.

Competitive Prices

In China, the competition between suppliers keeps the prices fair. Our fully optimized equipment helps us maintain a low price without sacrificing the quality and performance of your parts.

Broad Range of Capabilities

AIPAK advanced technologies mean we can offer hundreds of service to our customers.AIPAK expert team will propose the most suitable machines as customer budget and raw materials.

Higher Efficiency

AIPAK automatic machines that is economical to use ,will help you achieve your tasks within target time.All our machines feature many pre-fitted tools that lead to rapid tool changes.

Instant Quotes

We offer instant quotes based on your materials and budget without complicating the processes through long email chains. We calculate prices based on millions of orders we've previously processed.

Economy Lead Times

For your time-sensitive production line, AIPAK offers economic lead-time options. You can submit your order through our online quoting system,we will quote to you in less than 5 minutes.

The Buyer's Guide

Capping Machine: The Ultimate Buying Guide In 2025

Capping machines maintain the hygiene, safety of the products and prevent contamination of materials. In the modern age, capping machines are of prime importance as almost every container like bottles, tubes, the pouch is being capped. Capping machines has a major role in primary packaging. If you have your production, then you should invest in capping machines as it stops your product from spillage. Read this blog to learn about features, kinds, uses operations, and troubleshooting of capping machines.

1.What is a capping machine?

AIPAK capping machine

Capping machines secures the containers after being filled with the materials either liquid or solid like pills. These capping machines aid in the sealing of products and prevent the risk of contamination by environmental elements.

These machines ensure that products are safe during transportation and storage. These capping machines also reduce product leakage. These machines apply various kinds of caps to the containers from screw-type to child-resistant caps.

2.What are the technical features of capping machines?

- Capping machines have durable, heavy-duty construction made of stainless steel.

- These cappers can accommodate a wide range of caps and products just with the change of sealing head.

- Some machines also count and show the number of the container being capped.

- Capping machines have accurate and reproducible torque efficiency.

- Cappers are equipped with a PLC user-friendly interface that is easy to understand.

- These machines are designed with no container no cap detection system.

- If there is no cap present the machine will automatically stop.

- These machines have built-in safety features to avoid damage to the container and prevent the capper from getting jammed.

3.What are the industrial applications of capping machines?

The capping step has prime importance in the packaging industry. Many industries use capping machines to seal the containers. Some industries that use capping machines are listed below:

Pharmaceutical and Medical Industry

Pharmaceutical and medical manufacture various kinds of powders, antibiotics, syrups, syringes that are packaged in various kinds of vials, ampoules, and bottles. Capping machines are utilized to seal all these containers.

Food and Beverage Industry

Many kinds of products like jams, sauces, and kinds of ketchup are filled in jars. Similarly, many soft drinks and other beverages are packaged in bottles and cans. Capping machines have a significant part in the food and beverage industry to cap all these products.

Agricultural Industries

Many agricultural products like fertilizers and pesticides come in tightly sealed containers. These industries depend upon capping machines to make tamper-proof caps.

Cosmetic Industry

Capping machines are important in sealing the foundation and mascara bottles. These products come in firmly sealed bottles to prevent contamination.

Chemical Industry

Capping machines play a vital role in the sealing of chemicals in bottles. These machines are used to stop the spillage of chemicals.

4.What are the basic parts of capping machine?

Some important parts of capping machines are discussed below:

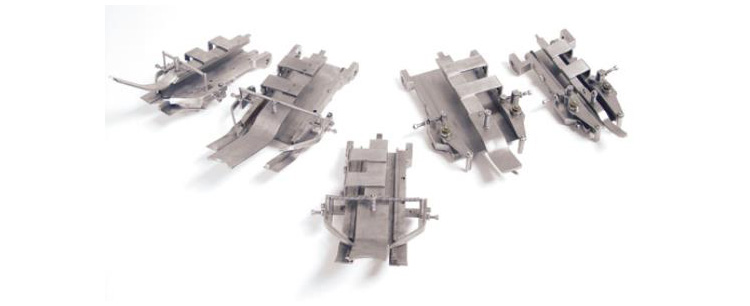

Ⅰ.Chuck or Inserters

These parts help in gripping the caps before fixing them on the containers. These parts come in various forms and sizes, usually depending on the type of capping machine and its function.

Ⅱ.Chute

Chute parts of the capping machines hold the caps in the proper place and fix the caps on every container that goes through the chuck or spindle. The chute can be made wider or narrow by the knob to accommodate caps of various sizes. Chute has several parts like

Stabilizing bars

These bars help in the stability of caps, and they go down the chute.

Finger and Tongue

Fingers and tongue secure the cap at the end of the chute. Fingers are the metallic bars located at either side of the cap to hold the cap in place. The tongue is laid at the top of the cap. These two parts work in combination to apply pressure for the proper placing of the cap on the container.

Ⅲ.Clutch Capping Heads

These parts assist the spindle capper to apply uniform torques on the caps. The clutch part is magnetic and holds the caps strongly for the application of torque. These capping heads fix the caps on the top of containers.

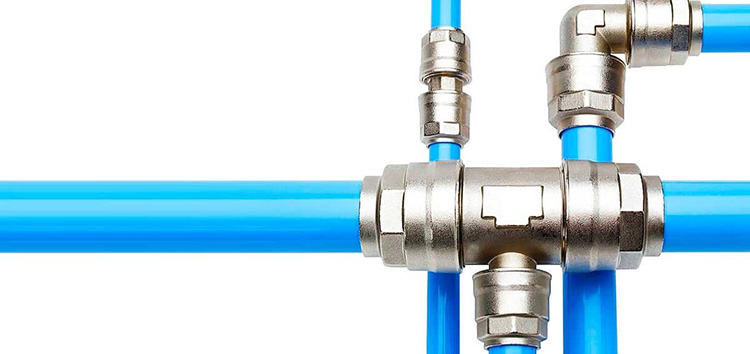

Ⅳ.Compressed Air Cylinders

These air cylinders assist in closing and twisting the caps. These parts also hold the caps in the capping machine.

Ⅴ.Cap Elevators

These are used to enhance the efficiency of the capping machine. The empty caps are placed inside the hopper of elevators. It is automatically activated when caps are needed to be restocked.

Ⅵ.Gear Boxes and Motors

These parts control the movements of the components of the machine. The speed of motors and gears is controlled by parameters on the control panel.

Ⅶ.Hopper

This part of the machine stores a huge amount of the hopper. If the hopper is at the top of the machine, then procuring a cap elevator reduces the need for a ladder to fill the hopper.

Ⅷ.Gripper Discs

These clamps hold the container in position and prevent it from rotating. These grippers increase the holding force of the machine and prevent misalignment.

Ⅸ.Cap Sorter

These parts of the machine sort the caps before they entered the transfer system or chute. The configuration of cap sorter depends upon the shape of caps. These are the brain of the capping machine and determine the running speed of the capper.

5.What is working principle of capping machine?

The working principle of capping machine based on two main steps:

- Cap Delivery

- Cap Sealing

Ⅰ.Cap Delivery

Two basic types of cap delivery systems are used for placing the caps on the containers: are a pick-off and, a pick & place approach.

Pick off Approach

In this technique, first, the cap goes down the chute and is picked by the container which is passing underneath the chute. This method is generally used to place aluminum skirted caps.

Pick and Place

In this method, the robotic arm takes the cap and sets it on the container. This method is used for a variety of caps and closures.

Ⅱ.Cap Sealing

After, placing the cap on the container, the capping head goes down to seal the cap. But precise action of capping head will depend upon the closure system.

If the capping machine is sealing aluminum skirt caps, then the capping head will apply pressure in a downward direction as the rollers cast aluminum in the bottleneck.

The capping head will apply downhill pressure and torque to hermetically seal pre-threaded plastic caps.

6.What are installation instructions for capping machines?

Installation Requirements

- A capping machine must be installed in the room having proper ventilation and lighting.

- The temperature should be about 5 -40°C.

- The capping machine should be placed on flat ground for installation.

- The pressure of compressed air should be about 0.4-0.6 MPa.

- The place where capping machines are installed should not have liquid spillage.

Mechanical Adjustment

The cap pressing belt must be adjusted according to the height of the containers and caps. If the cap press is at too much altitude, then the pressing function is not performed properly. If the pressing part is very low, then containers and caps are damaged.

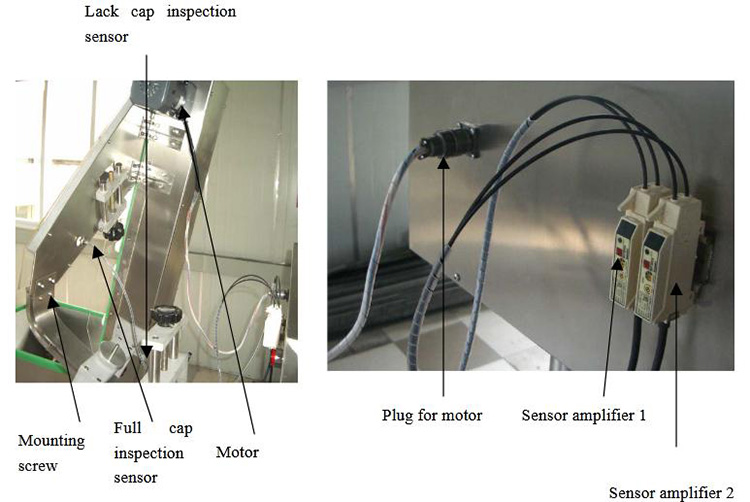

Ⅰ.Installation of Elevator and Sensor

- Fix the cap dropping part with the chute by the screw.

- Fix the motor plug to the right part of the control panel

- Adjust the full cap of the sensor to amplifier 1.

- Adjust the lack cap of the sensor to amplifier 2.

- Fix the height of the ladder-type chain so that chain is at the proper angle for feeding the cap on the top of the chain.

Ⅱ.Fixing the Chute

The cap dropping system is adjusted by losing the mounting screw and tightening the adjusting screw.

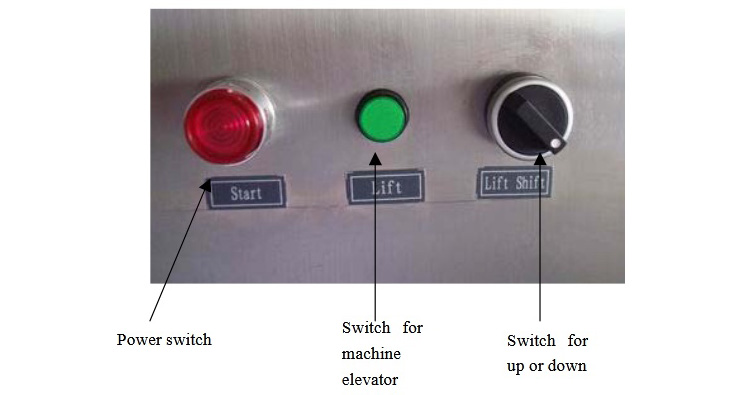

Ⅲ.Fixing the height of Main Body

The height of the main components of machines should be adjusted as one by elevator. Press the green button on the right side of the control panel till the main body is in the right position.

Ⅳ.Fixing the Bottle Fixing Structure

A fixing belt should be used to adjust the position of the bottle fixing part. This part should be elevated properly so that the pressing belt functions accurately.

7.Discuss the types of capping machines?

Capping machines are classified by means of:

- Level of Automation

- Types of Caps and Products

Ⅰ.Classification on the Basis Level of Automation

Manual or Handheld Machine

These machines are used in smaller production to ensure uniform and accurate capping. These machines are portable to allow capping at various locations in production. These machines are used for screw-type bottle closing of shampoos, soaps, beverages, etc.

Semi-Automatic Machines

Semi-automatic machines vary in size from small desktops to large-sized capping machines. These machines can be snap caps, screw caps, etc.

Semi-automatic machines need an operator to perform the machine operation. The working staff places the cap on the container then capping head tightens the caps. The speed of these machines depends upon the speed of the operator.

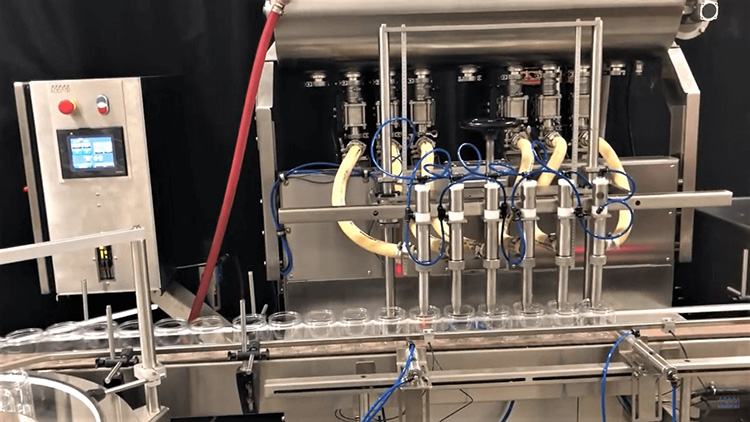

Automatic Capping Machines

AIPAK automatic capping machine

In automatic machines operator must run the equipment and then observe the working of the machines. All machine functions are performed mechanically.

In automatic machines, elevators and hoppers move the cap to the chute, which then secures the cap on the container. This boosts the machine's operation and output capacity.

Ⅱ.Classification based on Cap Types and Products

Chuck Cappers

Chuck capper uses threaded caps. In these machines, caps are rotated to fasten the caps on the bottles. In chuck cappers, the container is in motion. These machines use very high torque to fasten the caps on the containers.

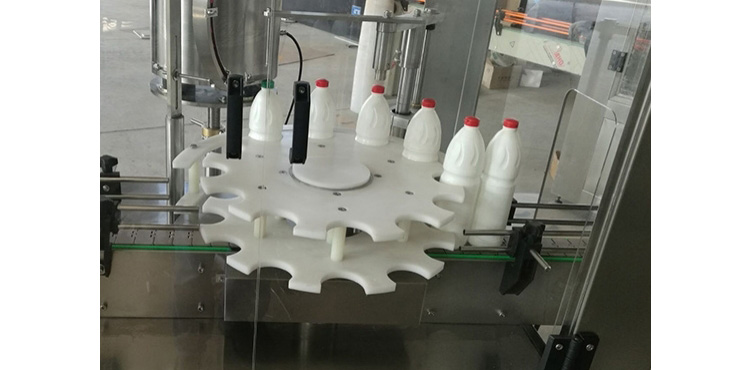

Snap Cappers

It is used for NEPCO application and uses little pressure to secure a snap-type cap on the containers. Caps hold on containers with the aid of friction. It is utilized to secure and snap the caps on milk jugs as these pass capping units.

Spindle Cappers

This machine is like a chuck capper but the container halts at the capping area while the cap is rotated on the container. The spinning disc will spin the cap. These machines can cap differently without changing the machine parts. These are appropriate for threaded caps.

Wheel Pluggers

These cappers press the caps such as corks into the container rather than placing the cap on the top of the container.

8.How to operate a capping machine?

Ⅰ.Before Starting Machine

- Check if the gear, conveyors, and railing are properly fastened. If not, then first affix these parts with screws.

- The power supply should be around 220V

Ⅱ.Capping Machine Operation

- First, place the bottles on the transport belt.

- Fix the size of the chute as per the size of the cap.

- Afterward, fix the placement of the railing and bottle space fixing wheel so that it is in uniformity with the diameter of the bottle.

- Next, fix the height of the bottle gripping belt according to the height of the bottle.

- Click the ‘ON’ button located in the operation menu to start the machine.

Ⅲ.Stopping the Machine

- Click the OFF button present in the operation menu of the machine to halt or shut down the machine.

- In case of an incident press an emergency, button, or switch off the power supply to immediately stop the machine operation.

9.What are the maintenance tips of capping machines?

Maintenance is of prime importance for the healthy and long operational life of any machine. Some maintenance hacks of capping machines are given below for superior mechanism.

Daily Maintenance

- You should daily clean the capping machine after its operation.

- You should prevent the capper from getting damaged.

- Do not attempt to temporarily repair the capping machine.

- Clean the compressed air connection daily.

- Remove the dust and debris from sensors regularly as it affects the machine operation.

- Rub the machine with a clean cloth without using water.

- Get rid of water in the vacuum holder after every shift.

Weekly Maintenance

- Inspect the fastening clamps of sensors

- Inspect the buttons and control system is in proper working

- Examine the electric cables connectors

- Lubricate all the working components of machines like rollers and capping heads weekly

- Use silicone oil to lubricate the surface of the capper

Monthly Maintenance

- Secure the bolts in every unit

- Eliminate the leakage in compressed air pipes

- Check the working conditions of protection devices.

10.How do capping machines boost your business?

Capping machines comes in several sizes and forms and have different output capacity. Whether capping machines are used in medium-sized production or in large production, these all have their own advantages. Some advantages are discussed below:

Product Quality

Human handling of materials can result in an error, and it is a tedious and monotonous process to place caps one by one on the containers. By doing capping by hand, people will become tired and cause misplacement of caps on bottles which will be expensive for the company.

Capping machines help in preventing these errors and saving your money.

Production Efficiency

Capping machines increase the speed of production. By using capping machines, you will have accurately sealed bottles that improve the rate of capping and boost your process efficiency.

Prevents Risk of Contamination

Capping machines prevent your products from being contaminated as most of these machines do not require human handling. These machines also stop the growth of microorganisms.

Versatile and Consistency

Capping machines are very flexible as they can handle a variety of caps. You can easily change between different kinds of containers and caps.

Capping machines give uniform output. The caps placed on the containers are not over-tightened or loose during a single event. These cappers apply the same force and pressure on every cap.

Health Safety

Manual capping can cause fatigue and injury to the working personnel as a result of continuous application of force for twisting especially when the same twisting motion is repeated for a long time.

Capping machines require little human intervention thus saving workers from injury.

Economical

Purchasing the capping machine is very beneficial for you in terms of cost. Acquiring capping machines can be costly but soon you will achieve more cost-effective results by capping machines. As manual labor can be expensive but by investing in these machines you will be free of this task.

11.What factors should be considered before buying capping machines?

If you are thinking about buying capping machines and you are facing some challenges in your objective due to the variety of capping machines available in the market, then some factors are enlisted that will make your decision easy.

Shapes of Caps

You want to look for the capping machine that has a cap sorter matching the shape of the cap. The height to width ratio of the cap limits the choice of the capping machine.

Flat caps are easily handled by any cap sorter but when the caps become taller than their width many caps sorter cannot process them.

Geometries of caps will determine whether you choose an inline capper or chuck capper.

Size of Caps

Choose a capping machine that can handle the size of cap you intend to place on the container. The size of the caps ranges from 5mm to 120 mm. large caps usually need vertical instruments and a cap tightener.

The size of caps also determines the cap sorters. Small caps need a vibratory sorter while the large-sized caps require a bulk elevator.

Closure Design

First, you need to determine the design of closure that fits the mouth of the container. Some capping machines like vertical chuck only deal with skirted caps. Vertical sorting sort plugs, stoppers, and corks.

Inline capping machines efficiently process these caps.

Floor Requirement

If you have small floor space, then choose compact benchtop machines. If you have large floor space, then go for large production machines.

Plant Environment

Select a capping machine that has necessary specifications like power, a quality requirement that will fit the environment of your plant. If you market corrosive chemicals, then select a machine that is within these harsh chemicals.

Production Requirement

If your production does not need high product output, then choose manual or semi-automatic capping machines. But if you run a production plant that requires high output capacity then select automatic capping machines.

A Competitive Manufacturer

Only a competitive manufacturing company can offer you a broad range of extensively featured machines. You must look for a good leading company that can understand your requirement, budget, production line, and support your market growth.

12.How to troubleshoot capping machines?

During every run, you encounter some problems. But now can troubleshoot them if you know what has gone wrong. Our expert tips and suggestions are given here to solve the issues that arise during the operation of capping machines.

Ⅰ.The gap between bottles is very small

This is a very common problem that the gap between two bottles is very little.

Cause

- A wheel that adjusts the bottle space is not functioning properly

- The wheel regulating the bottle space is fast

Remedy

- Shift the bottle space fixing wheel so that it is in the center of the conveyor.

- Decrease the velocity of the bottle space fixing wheel.

Ⅱ.Bottles Getting Trip

Sometimes bottles fall and cause liquid spillage.

Cause

- The speed of the conveyor and pressing belt is not in sync.

- The elevation of the bottle fix is not proper.

Remedy

- Fix and align the speed of the conveyor and press belt.

- Raise the elevation of the bottle fix structure.

Ⅲ.Caps are not placed on the Bottle Properly

The caps on the bottles are not adjusted and tightened properly.

Cause

The level of the cap drop unit is not accurate.

Remedy

Fix the position of the cap drop system.

Ⅳ.Missing or Crooked Caps

Sometimes the shape of caps is deformed, or the bottles are missing caps altogether.

Cause

- Caps are not present in bulk.

- Passage of caps is blocked.

- Elevation of belts and stabilizer is not proper.

Remedy

- Ensure that caps are present in bulk amounts in the machines.

- Remove the hindrance from the passage of bowl to cap drop unit.

- Adjust the elevation of belts and stabilizer bar.

Ⅴ.Freezing of Machine

Sometimes capping machines get frozen and do not function correctly.

Cause

- The fuse of the machine encountered an error.

- The emergency button is unintentionally pressed.

Remedy

- Replace the fuse.

- Reset the emergency lever.

Conclusion

Most industries need rapid solutions for formulating, filling, packaging procedures. A good capping machine not only secures your product, but also maximizes effectiveness, potency, and patient compliance. AIPAK Pharmaceutical Equipment offers a new approach i.e., automatic, user-friendly, cost-economical, and excellent featured machine that can enhance your production line with increased output. AIPAK understands the technological issues that every consumer suffers, hence presenting a capping solution to improve the manufacturing process. Want to make the purchase? Please click HERE to get Free Consultation and Buying support right now.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586