Bottling Line Machine: The Complete Buying Guide In 2025

How to choose the correct bottling line to treat your medication with professionally sound techniques?

No doubt the bottling line machine itself has a long and effective history in the various fields of manufacturing sciences that range from medicine to nutraceuticals, cosmetics to chemicals, and so much more.

Indeed, for larger industries, you can enjoy uninterrupted workflow simply by installing the bottling line machine.

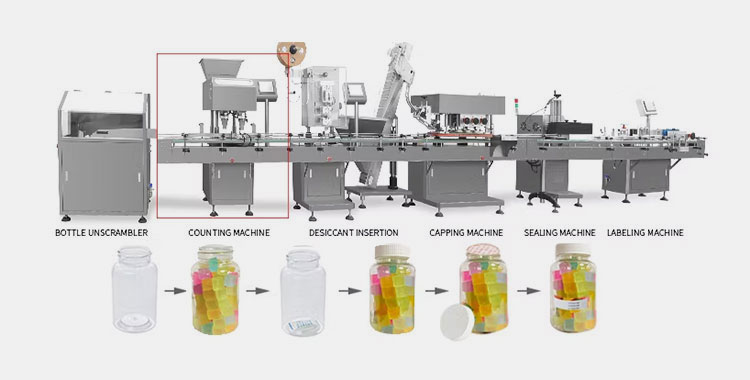

Today the bottling line machine is known as a very developed technique that is composed of several equipment that bring a single solution under one roof. Starting from bottle unscramblers to labeling machines, this robust and reliable set of solutions is quite popular nowadays because of its significant output.

In this extensive article what you are going to explore is all about the bottling line machine and its significance during the procedure of the packaging sector. Without further ado let's start this blog right now.

1.What do you understand about bottling line machine?

Bottling Line

The bottling line machine is simply an excellent series of innovative technologies that are merged into a properly integrated line of equipment to bring the bottling task efficiently.

This typically includes multiple categories of equipment that help you to ensure that whatever else steps come in the production line are carried out consistently and uninterruptedly. All units used in the bottling line are fully compliant with international regulatory requirements hence it is preferably used in a large spectrum of industrial platforms.

2.Where is the bottling line machine required?

There are the following types of industries where a bottling line machine must be used to accomplish necessary tasks. For example:

Healthcare and Pharmaceutical Industry

Healthcare and Pharmaceuticals

The bottling line is an essential task in various manufacturing sectors of the healthcare and pharmaceutical industries. You must be aware about how the correct medication can be crucial when it comes to a patient’s life. Therefore, the correct counting figure is very important, and it is significantly carried out by a bottling line machine.

Chemical Industry

Chemical Industry-Picture Courtesy: Orlando science centre

Accuracy and purity of chemicals are the fundamental principles of manufacturing in the chemical industry. Therefore, you will always need to set up a bottling line machine for counting and packaging of the items in its perspective materials. For example, chemical tablets, chlorinated discs, cleaners, pools, testing chemicals, etc.

Nutraceutical Industry

Nutraceutical Industry

The processing of natural products into nutritional supplements is always beneficial to your health. The nutraceutical industry is the sensitive sector of manufacturing products where a bottling line machine is required for counting and filling various ranges of products such as tablet, capsules, pills, etc.

Food Industry

Food Industry- Picture Courtesy: Chicken Stock Cubes

The most popular field of manufacturing offers you various products related to sweet, spicy, or saltish cuisine. For example, chocolates, candies, granules, dried fruits, chips crackers, and so on. They are entirely packed with desirable material with the utilization of a bottling line machine.

Medical Industry

Medical Industry: Picture Courtesy: Blood Glucose Tester

The utilization of a bottling line machine can ensure that your operational efficiency in the medical packaging items is carried out in a smooth workflow. This machine will guarantee that accurate and correct medical products are packed in each bottle appropriately.

Stationery Industry

Stationery Industry

The stationery industry is meant to produce and sell educational, office, research, hospital, art, etc supplies. The stationery products are perfectly counted and packed by utilization of a bottling line machine. For example, art-related items, brushes, erasers, sharpeners, pencils, and printing consumables, etc.,

3.How does a bottling line machine improve workflow?

A bottling line machine is always known to improve your workflow by simply maintaining the streamline of various steps associated with product counting. The particular benefits of bottling line machines are described below:

Providing You with Errorless Counting

No Counting Errors- Picture Courtesy: Pharma Specialist

A bottling line machine is a promising solution when it comes to counting your products and packaging them in the bottle. This way provides you with an error-less product count with reduced chances of human error. It not only increases the high trust of users in your brand but also the reliability of your products.

An Excellent Automation

Excellent Automation- Picture Courtesy: Health Tech World

The overall features and properties of the bottling line machine are met with tremendous automation therefore ideal for achieving awesome productivity without spending much time and labor. Whether it is a bottle unscrambler or other machines integrated with the line, many of them are available with advanced automation that treats your product with a high degree of care and automation.

Greater Production Speed

Greater Production Speed

The bottling line machine is absolutely an excellent way to attain high-speed output. Because this equipment is capable of handling medium to large and largest capacity that you have designed for your company.

The machine is significant to meet your demands to reach your market size and is capable of handling thousands of products counting in hourly rates ultimately giving a tremendous output.

Improved Safety and Reduced Chances of Cross-Contamination

Safe products- Picture Courtesy: SE Tylos

Without any doubt, you can ignore the level of safety and cross-contamination especially when you belong to an industry that is closely associated with your health and well-being.

A bottling line machine is highly good for dealing the products that are very close to your health. The construction of its body is based on safe materials, and its entire design is approved by CGMP compliance. Therefore, by considering these factors, you are assured that whatever good brand you are using is highly protective of your product and maintains quality assurance.

Capable of Integrating with Large Spectrum Machines

Bottling line machine

This is a friendly addition that is capable of connecting a broad spectrum of various units used for the filling and packaging procedure for the bottling line. The bottling line machine would be an exceptional unit ensuring the possible smooth and uninterrupted procedure that every manufacturer looked for.

4.What are the working steps of a bottling line machine?

In a general term, the bottling line machine is mainly based on the following working steps to form a complete production line. For example:

Organization of Random Bottles

Bottle Orientation

The bottling line machine process begins with the organization of empty and disoriented bottles. The correction of these bottles into an upright position must have to be taken to avoid unnecessary manual handling and the risk of errors. The first machine ensures the proper supply of the bottles in the required proper correction and position.

Counting & Filling

Bottle Counting and Filling

The second step is to count and fill the material into each bottle which is mainly ensuring that dispensing of the material is taken place by an advanced and specialized system that is incorporated with high-tech photoelectric sensors, and vibratory movement without any risk of cross-contamination and counting error.

Moisture Proof Pack or Desiccants

Desiccant pack- Picture Courtesy: Wisesorbent store

The design of the bottling line machine is also proposed in consideration of moisture content. This is well known to every manufacturer that moisture can kill the quality and potency of the substance. Therefore, various products especially related to healthcare and foods are carefully packed with desiccants after the filling is done to stabilize the integrity and potency of your goods.

Closure of Bottles

Bottle Closures

It’s time to close your bottle with the firm application of caps over each bottle. The purpose of this step is to offer a high degree of safety and security to the product present inside. The step is taken place in various ways such as screwing, snapping, pushing on, etc. followed by careful inspection by the machine with the help of advanced detectors.

Bottles Protective Sealing

Bottle Sealing

How your customers believe that the product’s originality is simply by observing the tampering-proof sealing provided by the manufacturer. This is mainly done by induction of electromagnetic radiation which is produced by the machine, and it also ensures that the inside product is safe from humidity and unwanted physical factors.

Branding and Product Information Labels

Labeling

The bottling line machine's final working process is to ensure that each bottle is treated with detailed information such as about the product, its manufacturing, batch number, expiry, and critical guidelines. Also, labeling plays an integral role in catching the user’s attention so aesthetically application of the labels over each bottle is taken place to finish the process.

5.How do you classify the bottling line machine?

The basic classification of bottling line machines is described below:

Classification Of Bottling Line Machine

Automatic Bottle Unscrambler

AIPAK Bottle Unscrambler Machine

The automatic bottle unscrambling machine is a highly automated solution for organizing the bottles without the involvement of technicians. This machine is mainly subjected to larger industrial production where complex and large quantities of bottle orientation are required in no time. Here, it is offering you auto-feeding, adjustment, and discharging of bottles in bulk.

Automatic Bottle Counting Machine

AIPAK Bottle Counting Machine

It is an automatic solution for the counting of materials to be filled in the bottle with almost zero involvement of humans. Amazing equipment that is capable of running production workflow by automatically feeding, sensing, counting, filling, and leaving the bottles from the system.

This machine is highly user-friendly as well as flexible to integrate with other machines of your production line. The unit is so smart in sensing and accurate counting of the product. In case of a faulty product, it directly sends the material to the rejection center. It can handle production capacity ranges from small to medium and large quantities. The high-speed machine is so ideal for running your manufacturing business efficiently.

Automatic Bottle Capping Machine

AIPAK Capping Machine

The automatic bottle capping machine is an important component of the bottling line where you again do not require much human involvement. The filled bottles must be secured from the outer environment and made presentable by applying the caps. Indeed, there are so many other important responsibilities behind a single cap such as avoiding spillage, easy to distribute, etc.

The machine detects the presence of bottles and the exact position of the allocating the caps. The grippers pick the cap, put and twist by applying strong torque to induce promising security of your product. The feeding, positioning, and securing of the caps ultimately improve the shelf life and quality of your product.

Automatic Induction Sealing Machine

AIPAK Induction Sealing Machine

A simple machine but occupied with excellent features that ensure your product is packed with tamper-evident properties. In case anyone distorts the seal, one can easily identify the tampering. So, the induction sealing machine is an automatic and modern solution.

The automatic feeding of bottles takes place in the machine where the application of seal, foiling, heating, cooling, and formation of strong induction seal takes place by advanced mechanism.

There are wide range of units, and designs are available in the market. Based on various needs, you can pick the machine of choice that can carry medium to high production capacities at a faster pace without worrying about human errors.

Automatic Bottle Labeling Machine

AIPAK Bottle Labeling Machine

This is a significant piece of equipment that allows an easy, correct, and quality application of the labels over the bottles and various other packaging materials.

The automatic feeding of the bottles takes place where the labels are applied by utilizing specified methods such as pressure, sensitivity, glue, cold press, etc. to stick on each bottle perfectly.

There are various series of classifications related to automatic bottle labeling machines available in the market where you can enjoy the particular machine based on your needs. The unit is capable of dealing broad range of labeling tasks with tremendous speed.

6.What are the components of a bottling line machine?

The composition of the bottling line machine includes several units that make an integrated set of machines to bring an amazing job for bottling. Yes, this is quite an affordable way to minimize your workflow labor expenditure simply by installing the following sets of machines altogether.

For your understanding, we will present each figure of the machine with major units and their specified functions. For example,

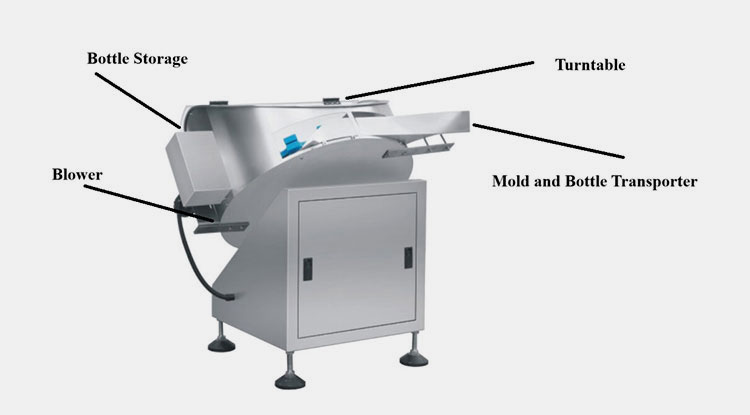

Bottle Unscrambler

AIPAK Bottle Unscrambler

| Bottle Storage | The empty and random sets of bottles are stored in the storage that facilitates the easy supply of the bottles toward the machine's main section. This is also known as a hopper. |

| Blower | The blower induces extremely powerful blowing action to improve the alignment of the bottles with the parallel action of the vacuum ensuring uninterrupted movement. |

| Turntable | The game changer of the machine where bottles blow and form a proper alignment with the action of the circular motion of the turntable. |

| Mold and Bottle Transporter | Each bottle fixes itself in the mold and the conveyor facilitates the easy transportation of properly positioned bottles towards the next section. |

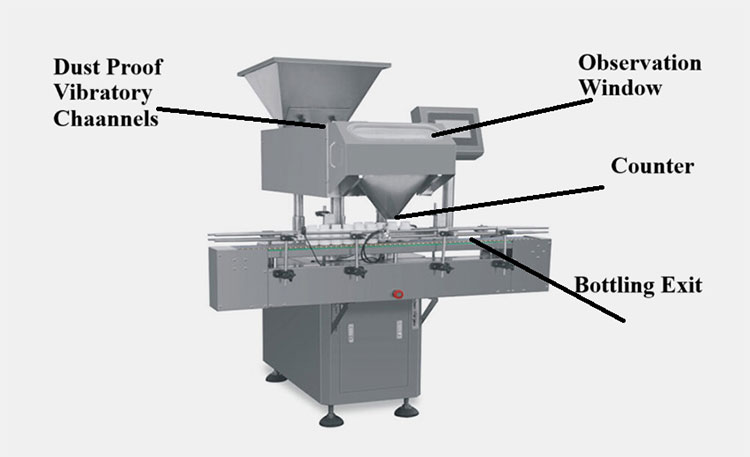

Bottle Counting Machine

Second, this machine is known as a bottling machine which is the main giant unit for the counting and filling of the bottles individually.

AIPAK Bottle Counting machine

| Dust Proof Vibratory Channels | The dust-proof vibratory channels ensure safe and secure movement of the product in each vibratory channel. |

| Observation Window | The transparent glass window allows you to enjoy visualizing the inside mechanism going on in the machine. |

| Counter | The individual product passes through the photoelectric detector and marked as counted and drops down into the bottle. |

| Bottling Exit | The filled bottles leave the machine via the transporting conveyor belt already fixed in the unit. |

Desiccant Inserter

Thirdly, in some cases you need to put desiccant as some products are more prone to absorb moisture therefore, many manufacturing companies install desiccant inserts.

Desiccant Inserter

| Feeding Supplier | The regular supply of desiccant inserter film strips is taken place by a feeding supplier which rotates and opens the strips during the operation. |

| Supporting Rollers | These rollers act as a guiding channel for the uninterrupted movement of the film strip and contribute properly aligned supply of the roll. |

| Jog Belt Assembly | This is also a supporting tool that helps in the consistent desiccant supply strip. |

| Sensor | The presence of the bottle inside the machine and the exact positioning of the desiccant pack are perfectly done with the help of sensors that detect the presence and absence of the required object. |

| Fix Guide | This section allows the support to desiccant film during cutting and inserting inside the bottle. |

| Cutting Knives | The sharp set of knives ensures a uniform and even cutting of the desiccant pack. |

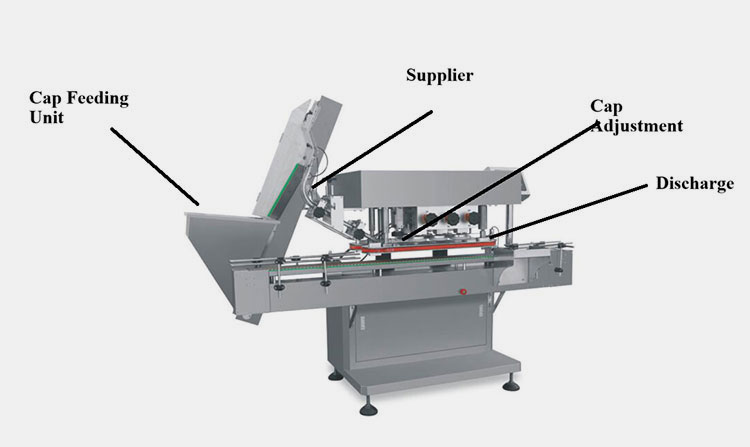

Capping Machine

Soon after counting and desiccant insertion, you will need a capping machine, and your bottles will be secured with tightly twisting caps around the bottleneck.

AIPAK Capping Machine

| Cap Feeding Unit | A large number of caps are fed into the machine’s hopper which is also known as a cap-feeding unit. |

| Supplier | This is a kind of elevator that supplies the movement of the cap from the downward to the upward side of the machine in order to facilitate the continuous supply of caps. |

| Cap Adjustment | The grippers pick the caps and position them over the bottleneck making it a powerful twist to fix the caps tightly. |

| Discharge | The finished products are discharged via a conveyor support system. |

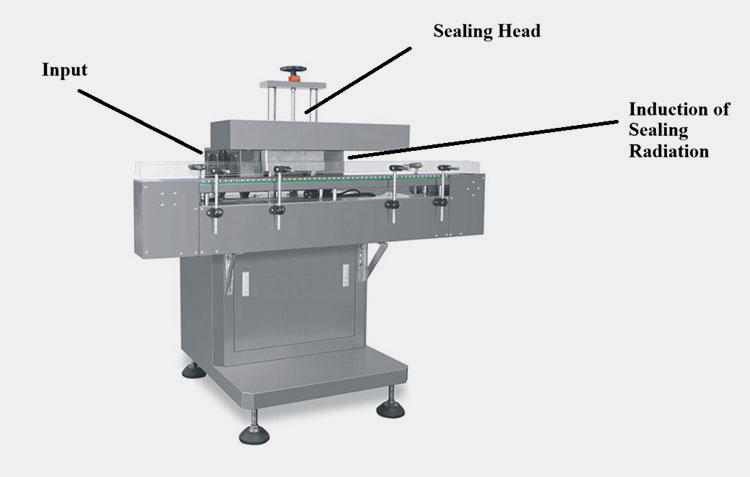

Bottle Induction Sealing Machine

The tamper-evident packaging is accompanied by an induction sealing machine.

AIPAK induction sealing machine

| Input | The capped bottles come to the machine by utilizing the input pathway. |

| Sealing Head | The bottles are subjected to induction sealing under the sealing head. |

| Induction Sealing Radiation | This section allows the emergence of electromagnetic radiation. |

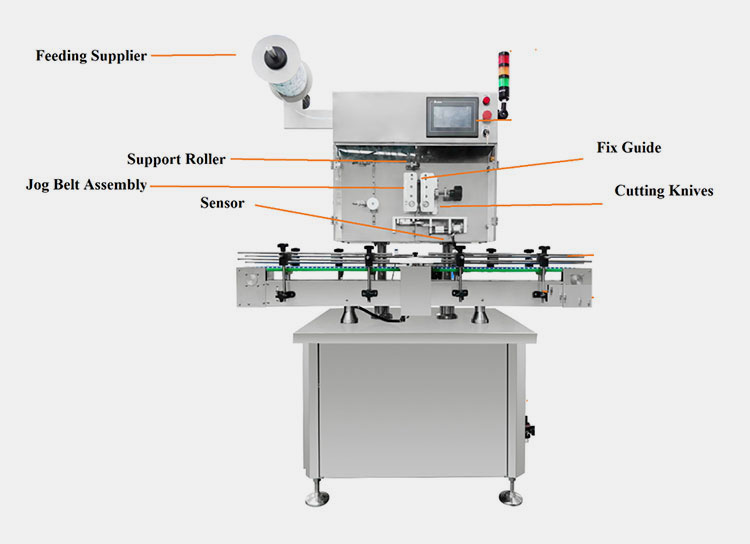

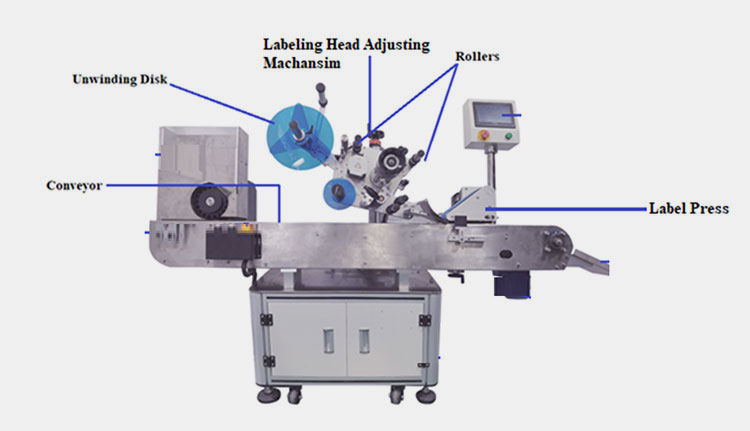

Bottle Labeling Machine

The bottle unscrambler machine is meant to provide a uniform supply of bottles for filling units.

Bottle Labeling Machine

| Unwinding disk | This section ensures the unwinding of the label roll. |

| Labeling head adjusting mechanism. | The set of spread channels ensures easy movement of the labeling material without the risk of jamming. |

| Roller | It also allows uninterrupted movement of the label. |

| Label press | It presses the applied label over the bottles to fix them properly. |

| Conveyor | The section facilitates the transportation of the bottle. |

7.What are the various types of bottling line?

The bottling line is a modern production system method that is implemented for various spectrum utilization and is of different types. For example:

Capsule Bottling Line

Capsule Bottling Line- Picture Courtesy: Roetell

The commonly used bottling line for counting and filling of capsules related products into their specified packaging materials followed by sealing and labeling to ensure that capsules are provided to you with extra care and quality.

Tablet Bottling Line

Tablet Bottling Line

The filling line is used for various shapes, sizes, and types of tablets and pills in their bottles ensuring the subtle workflow and integrity.

Gummy Bottling Line

Gummies- Picture Courtesy: ICE headshop

Medicinal and non-medicinal gummies are packed cautiously by utilizing the gummy bottling line machine. The construction and materials used in the bottling line for gummies are non-sticky and user-friendly, so one can use them without the risk of gummies clumping or related issues.

Softgel Bottling Line

Softgel Bottling Line

The various softgel products related to well-being, nutraceuticals, herbals, cosmetics, etc are packed and sealed by using the softgel bottling line machine. The unit promises to offer you an accurate quantity of softgel capsules in each bottle.

Powder Bottling Line

Powder Bottling Line

The specifically designed unit for powder-related products such as baby powder, medicinal powders, and formula milk or nutritional products is packed in bottles by using a powder bottling line machine. The unit is made up in a way that has an auger dispenser ensuring accurate filling of your product without risk for spillage or dust formation.

Liquid Bottling Line

Liquid Bottling Line

The various liquid-formulated products are packed in bottles by using a liquid bottling line which is designed in a way that specialized liquid flow dispensers are utilized depending on the viscosity of your formulation. For example, piston fillers, volumetric fillers, pressure fillers, etc the bottles and sealed by the involvement of another unit of the bottling line.

8.What kind of materials are filled by the bottling line machine?

The bottling line machine is an outstanding addition to the packaging world to cater to materials with various shapes, sizes, and categories. For example:

Various Shaped Medications

Oral Solid Medicines

The solid dosage oral medication should be packed with the utilization of a bottling line machine, and this is an important way that safely count and pack the tablets, capsules, pills, etc in an accurate manner. It is included with softgel, and hard gel capsules, various shapes and sizes tablets, and related products.

Frozen Items

Frozen Items- Picture Courtesy: The Taste of Germany

You might be surprised to know that the bottling line machine is an absolute solution for counting and packaging various frozen items such as nuggets, chicken zongzi, sausages, vegetable rolls, and related products inside their specified packing materials.

Laundry and Cleaning Items

Cleaners

You must have used laundry tablets and cleaning bars in different packaging materials. Yes, they are mainly packed accurately by using a bottling line machine. For example, bathing bombs, laundry beans, granules, etc.

Delicious Gummies

Gummies- Picture Courtesy: Lolly Mail

Various shapes, colors, and flavors of gummies are efficiently packed consistently by a bottling line machine without any risk of unhygienic mishaps or alteration of shapes during packing.

Chewable Items

Various Chewable Items

Various bubble gums, candies, toffees, and related items are also packed by application of a bottling line machine.

Coffee and Granules

Coffee Bottles

These are very small in shape and sizes; but a bottling line machine is considered as an ideal solution for the packaging of coffee, granules, and similar products by an adaptable method of the unit.

Spices and Dry Fruits

Spices and Dried Fruits- Picture Courtesy: Janta Sweet Home

The subtle and gentle vibration and high detection system of the bottling line machine allow the significant packaging of delicate products such as spices and dried fruits in proper packaging materials.

9.How to deal with problems with bottling line machine?

Sometimes due to problems in handling or maintenance, the bottling line machine may cause unwanted technical problems. Do you know how to deal with those problems? We have directed some suggestions just right below to treat the bottling line machine in case of trouble.

Error in accurate Bottle Counting

Inaccurate Number of Product

This is a pretty common technical problem where the machine is not signified with correct counting and results in repetitive wrong results.

Solution

In some cases, the hygroscopic substances as well as materials with sticky consistency lead to clump each other and cause double counting. However, it is recommended to check the right state of the filling material before subjecting the machine. Side by side, it is highly suggested that your bottling line machine should be maintained and calibrated in accordance with the regular schedule to avoid errors.

Bottle Falling

Bottles Falling

In some cases, it has been observed that bottles fall during the workflow.

Solution

The distance between the bottle and its conveyor pathway must be adjusted to allow proper and easy flow of bottles from one machine to another. Moreover, the speed of the unit should alter in a way that can facilitate a subtle workflow.

Poor Labeling on the Bottles

Labeling Problems- Picture Courtesy: Blue Label Packaging

You noticed irregular labeling application on the bottles that presents the poor quality of your brand.

Solution

The problem may be due to poor feeding of the label roll, or its assembly on its channels. Also, the issue may be occurred with label roll or the applied tension. Therefore, it is recommended that proper adjustments must be made prior starting the equipment. moreover, the label roll and its applicator must be corrected, and the machine must be in calibrated form.

Conclusion

In conclusion, the purpose of the bottling line machine is to offer you the equal distribution of product in each bottle. This means that the bottling line machine first provides you with an upright and positioned bottle for efficient counting and filling followed by required machines such as a desiccant inserter, capping, induction sealing, and labeling machine. You all need them to enjoy the smooth flow of the bottling line from scratch till its final packaging in a professional way. AIPAK is an excellent one-stop solution for finding and purchasing a tremendous series of bottling line machines. These world-class machines are specifically designed for your needs under an affordable budget. What are waiting for? Please contact us now for more information and procurement.

Don't forget to share this post!

Bottle Unscrambler Related Products

Bottle Unscrambler Related Posts

Bottle Unscrambler Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine