Bottle Packing Line: The Complete Buying Guide In 2025

Many products are packaged in bottles, such as pills, beverages, etc. Are you looking for a bottle packing line for your product? Whether you are in the pharmaceutical industry, food industry, or health product industry, bottle packing lines are involved.

With the development of enterprises, higher demands may require new solutions to prepare products for consumers. Using a complete packing line can achieve efficient, consistent, and reliable preparation. Do you want to know which machines are involved in bottle packing lines?

Next, let’s explore the complete buying guide for bottle packing line together.

1.What Is Bottle Packing Line?

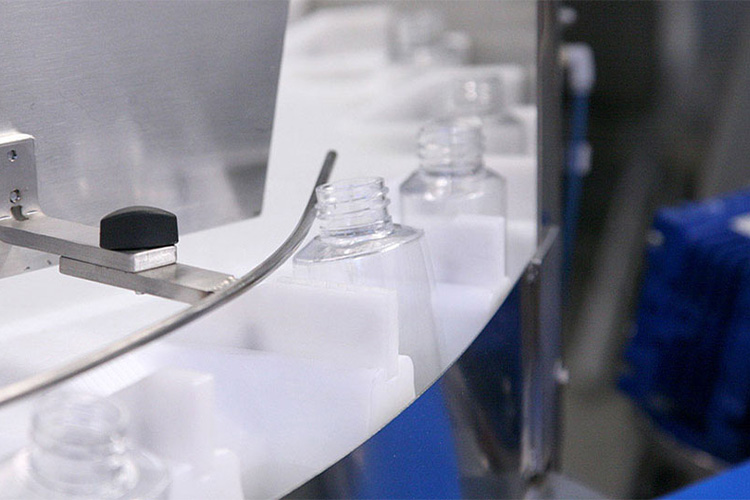

Bottle Packing Line

The bottling packing line is a production line consisting of multiple machines that perform different functions. Each machine can achieve seamless connection, greatly improving work efficiency.

The bottling packing line can be applied to different industries, and for granular products, it can achieve accurate counting to ensure that the quantity of each bottle of product is consistent.

2.What Can Bottle Packing Line Bring for You?

Why choose bottle packing line? Actually, it can bring many benefits to your business.

Improvingwork efficiency

The entire bottling packing line has been automated, and each machine can be seamlessly connected, greatly improving the production efficiency of products for pharmaceutical and other industries.

Easy to operate

With the continuous development of technology, almost all machines on the bottling line have adopted human-computer interaction interfaces, and operators can turn on the machine, adjust precision, capacity and other values through the touch screen.

Ensuring product quality

Ensuring Product Quality - Sourced: Yvea

Manual operation can easily cause pollution and affect water quality. The fully automatic bottling production line adopts a highly clean production environment, and all operations are carried out under sealed and sterile conditions. This effectively avoids pollution, ensures the safety of bottled products, and improves the overall quality of the products.

3.What Products Can You Package Through Bottling Packing Line?

What things do you see packaged in bottles in daily life? To be honest, many products can be packaged by bottle packing line.

Tablet

Tablet - Sourced: Devrom

To prevent the tablets from getting damp, different types of tablets such as round, square, etc. can be packaged in bottle lines, and accurate counting can be achieved.

Capsule

Capsule - Sourced: Devrom

Many capsules are packaged in bottles, and plastic bottles can provide good sealing performance to prevent the capsules from getting damp, oxidized, or contaminated by external factors, thereby extending their shelf life.

Soft capsule

Soft Capsule - Sourced: Ubuy Hong Kong

Soft capsules are widely used in health products, and bottles can protect soft capsules from external influences while also ensuring product stability. Soft capsules are often packaged in plastic bottles and are also easy to carry.

Drinks

Drinks - Sourced: Buffalo Wild Wings

For the convenience of carrying and pouring, many beverages are packaged in PET bottles, and the transparent material is also easy for consumers to observe.

Candy

Candy - Sourced: TricorBraun

Many candies are packaged in plastic and glass bottles, which not only seal the storage effect, but also prevent the candy from melting and oxidizing, allowing the candy to always present a very good taste and texture.

Gummy

Gummy - Sourced: Amazon

Gummy belongs to a type of fruit juice soft candy, some of which contain vitamins. After eating, it can supplement vitamins to a certain extent, which is beneficial to the body. Vitamin gummy usually has a good taste. Bottles are also one of the commonly used packaging for gummies.

Chocolate beans

Chocolate Beans - Sourced: The Online Sweet Shop

Chocolate beans are often packaged in transparent bottles, and colorful products can attract consumers’ attention, especially for children, which has strong appeal.

Grains

Grains - Sourced: Freepik

In order to maintain the dryness of grains and extend the shelf life of products, grains are also commonly packaged in bottles. Counting threads can achieve efficient and precise filling.

Chewing gum

Chewing Gum - Sourced: Jaya Grocer

Packaging chewing gum in bottles can reduce the loss of moisture and oxidation of chewing gum, maintain its fresh and tender taste, and enhance its durability In addition, chewing gum plastic bottles are environmentally friendly and recyclable, which is more in line with the consumption concept of modern consumers

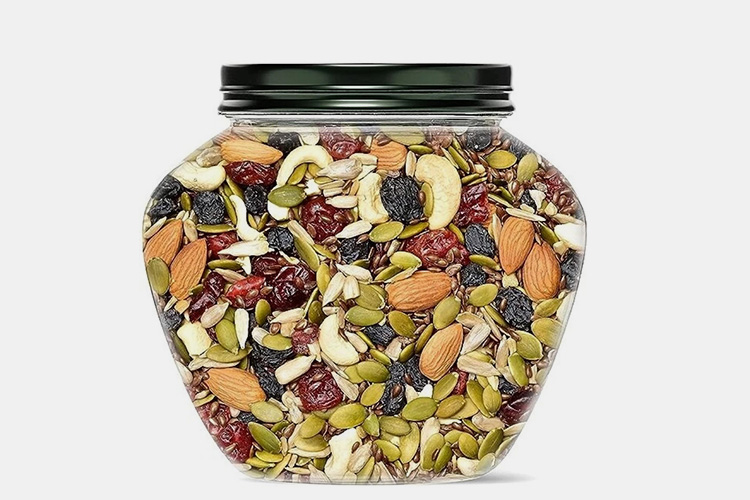

Nut

Nut - Sourced: Flipkart

Nuts are often sealed in glass or plastic bottles, with large storage capacity and no oxidation. The bottle packing line can achieve precise filling.

4.What Applied Industry for Bottle Packing Line?

Actually, many industries require bottling packing lines. Let’s take a look together.

Health products industry

Health Products Industry - Sourced: iHerb

Plastic bottles are usually lighter and more durable than glass bottles, making them easier to carry in daily life. In addition, the bottle cap design is also relatively convenient, which can be easily opened and closed, allowing users to conveniently take out and consume health product capsules.

Pharmaceutical industry

Pharmaceutical Industry - Sourced: The Guardian

Plastic bottles are widely used containers in pharmaceutical packaging, which have the advantages of lightweight, durability, and good sealing, and are suitable for various types of drug packaging. Some liquid medicines require glass bottle packaging, such as penicillin bottles.

Cosmetics industry

Cosmetics Industry - Sourced: Pixeden

Bottles can be used to hold products with high use frequency, such as face cream, essence, etc. The characteristics of cosmetics are a certain viscosity and the need for long-term storage. The bottle has strong barrier properties and can maintain the original characteristics of cosmetics for a long time without losing the effective ingredients.

5.What Types of Bottles Can be Used in the Bottling Packing Line?

The bottling line can use multiple types of bottles, and different materials of bottles can be selected according to the type of product.

Glass bottles

Glass Bottles - Sourced: Futurity

This kind of bottles do not release harmful substances, so they are relatively safe. Glass bottles are mainly suitable for storing skincare products, etc.

Glass bottles are more environmentally friendly than plastic bottles because they can be reused, are heat-resistant, resistant to acid and alkali corrosion, are not easily deformed or aged, can be used multiple times, and reduce garbage pollution.

Plastic bottle

Plastic Bottle - Sourced: Unicat - MSF

Plastic bottles can be used to hold beverages, medicines, etc. They have the characteristics of frost resistance and explosion prevention, and as a rubber material, their shrinkage performance and strength are also very good. Compared to glass bottles, plastic bottles are easier to store and transport without worrying about the risk of breakage.

6.What Is the Production Process of Bottling Packing Line?

Bottle packing line is complicated and delicate process, which involves many key steps.

Unscramble bottle and prepare material

Unscramble Bottle - Sourced: Sarg S.r.l.

You should prepare the bottles, such as glass bottles, plastic bottles, ampoules, rubber stoppers, aluminum caps, etc., and perform necessary cleaning and disinfection treatment. After preparing the bottles, bottle unscrambler can be used to arrange and organize them one by one for the next step of operation.

In addition, it is necessary to prepare the materials that need to be packaged, such as pills, mixed liquids, etc.

Filling

Filling - Sourced: Lenis Machines inc.

The cleaned bottles enter the filling process. Filling is the process of injecting medication or powder into a bottle. The commonly used filling methods in pharmaceutical factories include automatic filling and semi-automatic filling. Automatic filling is suitable for large-scale production.

Sealing

Bottles that have been filled need to be sealed. There are two commonly used sealing methods: sealing machine and sealing pliers. Sealing machines are suitable for large-scale production, while sealing pliers are suitable for small-scale production.

Labeling and packaging

Label qualified drugs and perform external packaging treatment. The label should include necessary information such as the drug name, specifications, production date, expiration date, etc; The outer packaging needs to have certain protective properties to prevent damage to the drug during transportation and storage.

7.What Machines Are Involved in Bottle Packing Line?

Do you know which machines are involved in the entire bottle packing line? You can

Bottle unscrambler

AIPAK Bottle Unscrambler

The bottles are neatly arranged in the bottle unscrambler through a conveyor belt, and the bottles are detected by sensors to ensure that their position and direction are correct.

Then, the bottle will be inverted as a whole. This process usually involves flipping the bottle upside down using a robotic arm or pneumatic device, ensuring that the bottle mouth is facing upwards. In this way, the bottle can continue with the next process operation.

Tablet counting machine

AIPAK Tablet Counting Machine

The fully automatic tablet counting machine is specially designed for fast and accurate counting of small granular objects, such as candies, pills, small hardware, etc. It has advanced photoelectric sensing technology and image processing algorithms.

Its working principle is that the counting mechanism rotates or moves to make a pill move inside the machine and complete the automatic counting function.

Capping machine

AIPAK Capping Machine

Almost all types of bottle caps need bottle capping machines to deal with. The capping machine uses cutting tools to screw aluminum billets onto many different bottles.

The automatic bottle cap conveying system means that the operators of the production line sometimes only need to provide bulk bottle caps for the machines, thereby ensuring efficient and consistent sealing of bottles and other containers throughout the entire production process.

Induction sealing machine

AIPAK Induction Sealing Machine

Adopting the principle of electromagnetic induction, induction sealing machine has the characteristics of high efficiency, energy saving, and environmental protection. Its working principle is to generate induced current through high-frequency electromagnetic field, which causes the aluminum foil cover on the bottle to generate heat, thereby melting it with the plastic film at the bottle mouth to achieve the sealing effect.

Induction sealing machines are widely used in product packaging in industries such as food, medicine, and daily chemical. For different types of products such as liquids, solids, powders, etc., induction sealing machines can be used to complete the sealing operation. The sealed product has good sealing performance and is not easily affected by external factors, thus better protecting the quality and safety of the product.

Labeling machine

AIPAK Labeling Machine

The labeling machine removes labels from the label rack through a conveyor system and transports them to the labeling position. This conveyor system can be a conveyor belt, a pair of wheels, or a suction cup device. During the labeling process, the labeling machine needs to detect the position of the product to be labeled through sensors or visual systems. This ensures that the label is accurately attached to the designated location.

When the product to be labeled passes through the labeling position, the labeling machine will trigger the labeling action. This is usually achieved through pressure, wind pressure, or the action of a robotic arm. Many devices in the bottling line come into direct contact with drugs and other products, and their quality directly affects the stability of product quality.

8.What Quality Standards Should Bottle Packing Line Follow?

Many equipment in the bottle packaging line come into direct contact with drugs and other products, and their quality directly affects the stability of product quality.

GMP standard

GMP Standard - Sourced: BioThrive Sciences

Especially for pharmaceutical equipment, it must comply with the requirements of GMP standards, including design, materials, manufacturing, installation, commissioning, verification, and other aspects. In the use of pharmaceutical equipment, strict management and monitoring are required to ensure the safety and quality of drugs.

CE certification

CE Certification - Sourced: IQS International

To obtain CE certification for pharmaceutical equipment, it must meet the requirements of relevant EU regulations and undergo inspection and review by relevant departments. At the same time, the design, production process, and materials of pharmaceutical equipment also need to comply with CE certification standards.

ISO standard

It mainly covers various aspects such as production management, environmental management, occupational safety and health management, and information security management. For pharmaceutical equipment, ISO standards are a very important requirement that ensures compliance with standards in terms of environmental safety, hygiene conditions, product quality, and other aspects.

FDA standards

FDA Standards - Sourced: Food Safety Magazine

FDA standards refer to the drug safety and quality management practices developed by the US Food and Drug Administration. During the use of pharmaceutical equipment, it is necessary to comply with various regulations and requirements of the FDA, including design and manufacturing standards, environmental and pressure level control, equipment cleaning and disinfection, etc.

9.What Should You Consider When Choosing Bottle Packing Line?

The entire bottling packing line involves many machines, so caution should be exercised when choosing.

Packagingmaterial

Packaging Material - Sourced: iStock

You need to clarify whether the product to be packaged in your bottle is liquid, powder, or granules. The required filling pumps vary for different materials.

In addition, it is necessary to clarify the material of the bottle, such as glass, plastic, etc., as well as the shape and size of the bottle. These are all related to the specifications of the machine, such as sealing and capping.

Production and speed

The output varies depending on the type of machine. You need to determine the daily or hourly production volume in order to choose the appropriate capacity for the bottling line. Production lines of different scales may require different types and scales of equipment.

Supplier’sreputation

Merchant Reputation - Sourced: Assured Solutions

Choosing reputable and experienced suppliers to ensure the quality of equipment and after-sales service. You can investigate the reputation and credibility of the company or brand through Google.

Budget

Budget is an important consideration factor. You should consider the cost of the equipment and the associated operating costs. And you also should ensure that the selected equipment has good cost-effectiveness in long-term operation.

10.What Are the Problems And Solutions of Bottle Packing Line?

The operation of the bottling line cannot be without any problems, and it is normal for some minor issues to occur.

Problem1: The liquid capacity in the bottle is inconsistent, or the number of pills in the bottle is inconsistent.

The Number Of Pills In The Bottle Is Inconsistent - Sourced: Britannica

Solution:

It is necessary to inspect the counter of the filling machine, check whether the circuit and sensor of the counter are normal, and repair or replace them if there are any problems.

Problem2: The cap is not aligned with the bottle mouth.

Solution:

You should calibrate the sensors of the capping machine to ensure that they can detect each bottle and that each bottle is correctly positioned below the capping head.

Problem 3: Inconsistent labeling

Solution:

You need to check the label paper, it may not meet the requirements, such as the size and pattern of the trademark. You also need to check if the gears of the labeling machine are properly aligned and if there are any aging issues.

11.What Bottle Packing Lines Can AIPAK Provide?

AIPAK can provide you with specialized bottling lines, with multiple options for you to choose from.

AIPAK Bottle Packing Line

Low speed bottle packing line

If your budget is limited, you can choose a low speed bottle packing line. Although it can only achieve 50-90 bottles/min, all machines are able to quickly and accurately package drugs according to predetermined doses. It can not only improve production efficiency and reduce costs, but also ensure the quality and stability of drugs.

Medium speed bottle packing line

The speed of AIPAK medium speed bottle packing line is slightly faster than low speed, capable of achieving 90-150 bottles per minute. The entire machine complies with GMP requirements. Medium speed is suitable for production and packaging scientific research institutions, small and medium-sized pharmaceutical factories, and healthcare product factories.

Highspeed bottle packing line

The AIPAK high speed bottle packing line adopts a tooth shaped synchronous bottle moving system, and the entire bottle moving process is smooth without shaking, impact, or bottle tipping. And the tooth shaped synchronous bottle moving system, bottle specifications and sizes, and the number of drugs inside the bottle all have formula storage functions. High speed can achieve 120-2000 bottles/min, with funny speed and large output, suitable for use in large factories.

Conclusion

The bottle packing line can meet your diverse product needs, and the machines of the entire bottling line will vary for different products. The bottle packing line involves numerous machines, such as tablet filling machine, and capping machine, so you should carefully select it. If you want to learn more about bottled lines, you can contact AIPAK at any time.

Don't forget to share this post!

Tablet Counting Machine Related Posts

Tablet Counting Machine Related Products

Tablet Counting Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine