Boba Vs Popping Boba

Do you like boba? If you do, you may have noticed popping boba in current market. Which one is your favorite? The different taste and flavor of boba and popping boba give you different feeling. How much you know about boba and popping boba? Do you want to know the difference of boba and popping boba?

What are the material applied for boba and popping boba manufacturing? What is the manufacturing process of boba and popping boba? What are the machines applied for the manufacturing of boba and popping boba? Why you should apply the production line for the manufacturing of boba and popping boba? Do you want to know more? Come on and have a reading!

1.What Is Boba And Popping Boba?

Boba and popping boba are both the welcomed products which are widely applied for milk tea, dessert and so on.

Boba

Boba-Sourced:mic

Boba has the other name of tapioca boba and it is the traditional drink addition. Boba is the round and chewy ball which is made mainly from tapioca starch. It is usually dark brown or black. The little sweet taste makes great embellishment in your drink and food. The different chewy and gummy texture takes great fun for your drink.

Popping boba

Popping Boba-Sourced:pinterest

Popping boba is the creation which comes from boba. There are flavored fruit juice which is encapsulated in the gel-like shell. Popping boba has different taste for different flavor need. You may have more flavor choice from popping boba here.

2.What Are The Types Of Boba Besides Popping Boba?

Boba has different types. Besides popping boba, here are the common boba types in our market.

Crystal Boba

Crystal Boba-Sourced:honestfoodtalks

Crystal boba has different raw material compared with traditional boba. Without the adopting of tapioca, it applies konjac plant. Crystal boba is vegetarian. It has the different color and you may find the common sign of whitish-clear coloring.

Popping Boba

Popping Boba-Sourced:dasin-tw

Popping boba has the different texture with the film encapsulating the yummy fruit juice. The simple bitten can make the popping balls. It is welcomed by many people for its special texture. But for vegetarian, it may be avoided.

Mini Pearls

Mini Pearls-Sourced:amazon

Mini pearls is the smaller size of tapioca boba. It has little change in the receipt and you may get the similar taste and texture with traditional boba. The big difference lies in their size and the mini size can give you different drinking experience.

3.Boba VSPopping Boba

Boba and popping boba are two different products, and here are the precise comparison between boba and popping boba.

Boba Vs Popping Boba-Sourced:orientalteabox

| Difference | Boba | Popping boba |

| Flavor | Boba has the neutral flavor. It has the mild sweet taste and can make the great corporation with any other drink or desserts. | Popping boba has more flavor. You may have many choice of its flavor from apple, litchi and other fruit. |

| Texture | Boba has the chewy and soft texture. The different experience of chewing and drinking the same time attract people a lot. | Popping boba gives you the releasing fruit drink once you bite them. It is more soft compared with boba. |

| Size | Boba has the larger size compared with popping boba. And the standard size of it is between 1mm to 8mm. | Popping boba has the smaller size compared with boba. The small popping boba has the great transporting of its juice. |

| Shape | There are different shape for your boba. And the most common shape is spherical for your drink or sweet. | Popping boba is usually spherical for the great containing of the different fruit drinks. |

| Origin | Boba is made with plant and tapioca is the common raw material for its chewy and great taste. | Popping boba has the different texture coming from chemical products which makes the thin and gel-like outer later for the stable containing of fruit juice inside. |

| Preparing | You should cook your boba for about an hour for its later further use. Or it will be too hard to chewy. | Popping boba has no cooking need. You may apply them once taken out from container. It saves more time for you. |

| Temperature affect | In hot or iced drink, your boba is soft and chewy. But the smoothies and frozen drink may destroy the taste of boba. | Popping boba can be applied for both hot and iced drink. In warm drink, it may have the weaker taste with time goes on. And in iced drink, it makes the outstanding work. |

4.What Are The Material Applied For Boba And Popping Boba Manufacturing?

The receipt for the manufacturing of boba and popping boba is different. And here are the material applied for boba and popping boba.

Boba

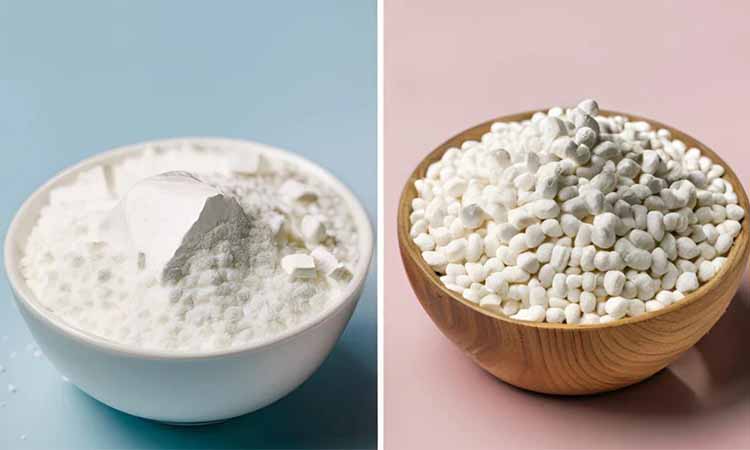

Tapioca starch

Tapioca Starch-Sourced:sirona-naturals

Tapioca starch is the main components of boba. It makes the great job of manufacturing the chewy texture. As the main components of boba manufacturing, the high qualified tapioca is the base of the high qualified boba products.

Water

Water is applied for dough mixing and boba boiling. You may apply water to mix with tapioca and also apply it for the boiling. There are the recommending proportion for the water in your boba products.

Sugar

Sugar-Sourced:marthastewart

There are brown sugar and black sugar for the bubble raw material mixing. The mixing of sugar and honey can make the different flavor for your boba products. Honey improves the sweetness for your boba products. Brown and black sugar can improve the flavor of your boba. You can make your own boba style by adjusting the the proportion of sugar.

Food coloring

Food Coloring-Sourced:chefmaster

The color of your boba is mostly deep brown or black. And you can adjust the color of your food by adding the food coloring. There are artificial color and natural color for you to select.

Popping boba

Sodium alginat

Sodium Alginat-Sourced:neneeysbeauty

Sodium alginat is the material which derived from seaweed. It makes the thickening for the preparing of your popping boba. Usually popping boba makes the sodium alginate for 0.5 to 1% for the total liquid. Sodium alginat is the key for the special taste of your popping boba.

Calcium lactate or calcium chloride

Calcium Lactate Or Calcium Chloride-Sourced:capecrystalbrands

Calcium lactate or calcium chloride is applied for the thin gel making around fruit juice. There are chemical reacts with calcium lactate or calcium chloride with sodium alginat. The proportion of calcium lactate or calcium chloride is also around 0.5-1% of the total weight.

Fruit Juice or Flavored Syrup

Fruit Juice Or Flavored Syrup-Sourced:fridge

Fruit juice or flavored syrup makes the center place for your popping boba products. You have a wide choice for your fruit juice flavor. Besides the common fruit flavor, you may also try yogurt, cola or soya milk for your popping boba.

Water and Sugar

Water and sugar is also the common material applied for the manufacturing of popping boba. It can corporate with sodium alginat and calcium lactate to make the thin film of popping boba.

5.What Are The Manufacturing Process Of Boba And Popping Boba?

The manufacturing process of boba and popping boba isn’t complex. Here come to check the manufacturing process of boba and popping boba.

Manufacturing Process Of Boba And Popping Boba-Sourced:honestfoodtalks

| Manufacturing process | Boba | Popping boba |

| Material preparing | You should prepare the basic material of boba like tarioca starch, sugar, honey, coloring and so on according to the proportion or formulation. | For popping boba, there are two solution you should prepare. One is the fruit juice or syrup and the second is the sodium alginate bath with precise concentration. |

| Products manufacturing | Rounding: Rounding is the step which make the round and spherical boba products. You may make them by hand or apply machine for the cutting and rounding of starch dough in even and uniform shape. | Spherification: You should make the fruit juice drops and drops them in the sodium alginate solution. There will then the the thin film around your drops. This is the miniature of your popping boba. |

| Boiling: Boba requires boiling and cooking. You should make sure the precise temperature maintaining for the total gel and well made of your boba. | Cooking: You should make the precise temperature controlling for your popping boba for the great taste and completeness. | |

| Rinsing: The well cooked popping boba should then be rinsed the remaining calcium solution for the great taste. | ||

| Cooling and rinsing: Cooling for your boba makes your boba with same size and shape. And you should also rinse for the cleaning prove. | ||

| Quality control | Quality control of boba can test the pollution, irregular boba and so on. Your boba products can have nice appearance and shape here. | You should make the strict test about the popping strength, flavor uniformity and size for your high qualified popping boba products. |

| Products packaging | There are the professional sealing and packaging machine for the reliable packaging of your boba products. | You should make the sterile packaging for your popping boba for the freshness and hygiene of your popping boba products. |

6.What Are The Machines Applied For The Manufacturing Of Boba And Popping Boba?

What are the machines applied for the manufacturing of boba and popping boba? Here are the machines which are applied for the manufacturing of boba and popping boba.

Machines applied for manufacturing boba

Dough mixer

Dough Mixer-Sourced:hobartcorp

You should make the comprehensive mixing for your powder material. The even and uniform blending is the base of the boba with great quality and great taste. There are flour powder, sugar and many adding which all need the careful mixing and blending. Dough mixer is the machine which can make the reliable mixing.

Dough Extruder

Dough Extruder-Sourced:axisautomation

Dough extruder is the machine which apply the efficient machinery powder to the manual work for dough mixing. It can handle dough of different type and material. The high qualified and consistent dough it produce makes great work for its later boba manufacturing.

Automatic cutting and rounding machine

Automatic Cutting And Rounding Machine-Sourced:anko

There is the automatic cutting and rounding machine which can make the automatic cutting and rounding of your various dough. You may apply it for your dessert or drink shop or you may apply it for the large scale boba manufacturing process. The high precise of this machine can improve the quality of your boba greatly.

Cooker

Cooker is the machine which can have the temperature adjusted for your material. Here you can have the boiling temperature and time set here for the high qualified boba producing.

Cooling and coating machine

Cooling And Coating Machine-Sourced:en.prosestek

For the well made boba products, you cannot make the packaging instantly. The high temperature and sticky feature make it unsuitable for the further packaging work. You should cool them and make the even and uniform coating with starch for your boba products. Cooling and coating machine is the machine which can make the great job here.

Sachet machine

For the well cooked boba, you can then make the great packaging and sealing of it. Here you may find the sachet as the most common packaging way for boba. Sachet machine makes the efficient and standard packaging for your boba products. Here you may apply the sachet packaging machine for the sachet packaging. Sachet packaging saves space and helps your boba products make great storing.

Machines applied for popping boba

Colloid mill

AIPAK Colloid Mill

Colloid mill can make the precise milling of granules which makes the great dissolving of products. It can make the reducing of droplet size in emulsions. The applying of colloid mill makes the further benefits of the great taste of your popping boba.

Dissolving cooker

AIPAK Dissolving Cooker

Dissolving cooker is the equipment which makes the dissolving for sugar or maltose to the even and uniform solutions. The solution without lumps or uneven mix is the base for the great popping boba. Dissolving cooker can make the high qualified and high efficient manufacturing.

Cooling and storing tank

AIPAK Cooling And Storing Tank

Cooling and storing tank is the machine which store the liquid and lower the temperature. It can connect with blender or cooker and cold water pipe. It makes the temperature cooling and liquid storing for the further applying of your popping boba products.

DepositorMachines

AIPAK Depositor Machine

Depositor machine is equipped with nozzle or dropper which can control the speed and size of your popping boba. The great controlling of time and speed can prove the size uniformity of your popping boba.

Gel-setting tray

While the gel gets set in the water, here may have reaction with solution and have the gel made. Gel-setting tray makes the control of gel appearance. The regular and spherical appearance can take great help for your boba products sale and flavor.

Rotating drum washer

Rotating drum washer is the equipment which is widely used for the popping boba products rinsing. This is the key process which can make sure the great taste of your popping boba. It rinsed the extra calcium and make sure the suitable gel condition.

Packaging machines

There are automatic packaging system which can make the sealing, capping and filming at the same time. The reliable packaging machine can make the efficient and clean pack. You may have the lifespan of your products prolonged here.

7.Why You Should Apply The Production Line For The Manufacturing Of Boba And Popping Boba?

There are production line for the manufacturing of boba and popping boba. Do you know the reason for the production line in manufacturing of boba and popping boba?

High efficiency

High Efficiency-Sourced:motorsatwork

The machinery work of production line makes the high efficient manufacturing of boba and popping boba. It saves your time and energy in employing labor for the slow and uneven boba and popping boba production.

Hygiene prove

Hygiene Prove-Sourced:foodisafourletterword

The less adding of labor or people in the operating of production line for boba and popping boba manufacturing makes the prove of your products hygiene. The stainless steel of the machine can also make the easy and efficient cleaning which can also prove the hygiene.

Quality prove

Quality Prove-Sourced:blackcatsboba

You can also prove the quality of your boba and popping boba by applying the production line which makes the precise dosing, quality and temperature controlling. The standard production line makes sure the high quality of your boba and popping boba products.

Cost saving

It may cost a lot for the purchase of your exquisite and intelligent production line. But it can also make the great saving for your manufacturers. In the long run, it can improve efficiency and quality which means great saving for you and your business.

8.What You Should Pay Attention ToFor The Manufacturing Of Boba And Popping Boba?

To make the high qualified boba and popping boba, you should pay attention to some factors in the manufacturing process.

Packaging

Packaging-Sourced:foodservicedirect

There are different packaging for your boba and popping boba. You should apply vaccum-sealed or nitrogen-flushed methods for the helping of removing oxygen and remaining fresh. You should apply the airtight container and deep your boba in the preservative syrup. You may also apply the nitrogen flushing, air pocket eliminating for the better storing.

Sterilizing

Sterilizing is the prove of your hygienic boba and popping boba products with extended longevity. There are bath pasteurization and retort sterilization for you to choose. Sterilizing reduces the applying of preservative and refrigerating. Sterilizing makes the high request on temperature and time which concerns a lot for your boba and popping boba.

Storing

Storing-Sourced:gummygenix

You should not store your boba and popping boba in room temperature. After opening, the products should be refrigerated at 4°C. The storing of boba and popping boba should avoid the contacting of light or sun for the degrading risk.

9.Are There Difference In Nutrition Between Boba And Popping Boba?

Nutrition Between Boba And Popping Boba-Sourced:healthline

Are there difference in nutrition between boba and popping boba? Of course, there are. Boba and popping boba are two definitely different things and the nutrition is also different. Boba is made of carbohydrates and you may also find calcium and iron of it. For popping boba, there are fruit juice which is rich of vitamin and antioxidants.

Compared with boba and popping boba, your may have more nutrition from popping boba. For the weight lossing people, boba may makes trouble for carbohydrates and popping boba makes trouble for its high sugar content.

10.What Are The Future Trend Of Boba And Popping Boba Market?

Boba and popping boba has great market and in future, there is a little difference for boba and popping boba market.

Intelligent production

Intelligent Production-Sourced:act

With the development of technology, the production of boba and popping boba will be more efficient. The high automation and intelligence makes great benefits for the improving of efficiency and quality of your boba abd popping boba products. The intelligent production can make so many benefits for your business.

More flavor

More Flavor-Sourced:vitalia

There will also exist develop in precise dosage and nozzle work. You may find the easier work in manufacturing the popping boba products of different type and flavor. The creation in flavor will be more according to the trend of world or fashion.

Sustainable and healthy production

The production of your boba and popping boba will be more sustainable and healthy. With more concern on world protection and natural material, the production of boba and popping boba will also change. The production solution will be sustainable and have less affect for environment.

Conclusion

Boba vs popping boba, which one is your favorite? Can you make your own boba and popping boba at home with the according receipt. Besides it, you should also pay attention to the sterilizing, packaging and storing of your boba and popping boba products. If you have any question about it, contact AIPAK right now.

Don't forget to share this post!

Popping Boba Machine Related Products

Popping Boba Machine Related Posts

Popping Boba Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine